Abstract

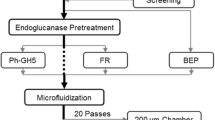

A GH5 hyperthermostable endoglucanase from the archaeon Pyrococcus horikoshii (Ph-GH5) and a commercial endoglucanase FR were used to treat bleached eucalyptus pulp (BEP) fibers to produce cellulose nanofibrils (CNFs) through subsequent microfluidization. Enzymatic treatments facilitated CNF production due to the reduced degree of polymerization (DP) of the fibers. SEM imaging indicated that FR reduced fiber DP drastically and resulted in much shorter fibers than with Ph-GH5, even at very low dosages (1 mg protein/g fiber) of FR treatment compared with a high dosage (10 mg protein/g fiber) of Ph-GH5. The fibers treated with FR were much more uniform in length perhaps due to the presence of exoglucanase and beta-glucosidase saccharifying short microfibers into glucose. TEM imaging indicated that Ph-GH5 produced longer and entangled CNFs than FR with the same number of microfluidization passes. However, the CNF diameters were approximately the same for all CNFs from enzyme-treated fibers using both endoglucanases at two dosages (1 or 10 mg protein/g fiber). CNFs produced from BEP fibers without enzymatic treatment showed larger diameters than those with enzymatic treatment.

Similar content being viewed by others

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87(2):963–979

Abdul Khalil HPS, Davoudpour Y, Islam MN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohydr Polym 99:649–665

Ando S, Ishida H, Kosugi Y, Ishikawa K (2002) Hyperthermostable endoglucanase from Pyrococcus horikoshii. Appl Environ Microbiol 68(1):430–433

Belbekhouche S, Bras J, Siqueira G, Chappey C, Lebrun L, Khelifi B, Marais S, Dufresne A (2011) Water sorption behavior and gas barrier properties of cellulose whiskers and microfibrils films. Carbohydr Polym 83(4):1740–1748

Bradford M (1976) A rapid and sensitive for the quantitation of microgram quantitites of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

de Souza Lima MM, Borsali R (2004) Rodlike cellulose microcrystals: structure, properties, and applications. Macromol Rapid Commun 25:771–787

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33

Fukuzumi H, Saito T, Wata T, Kumamoto Y, Isogai A (2009) Transparent and high gas barrier films of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 10:162–165

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Henriksson M, Berglund LA, Isaksson P, Lindström T, Nishino TD (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Kang HJ, Ishikawa K (2007) Analysis of active center in hyperthermophilic cellulase from Pyrococcus horikoshii. J Microbiol Biotechnol 17(8):1249–1253

Kang HJ, Uegaki K, Fukada H, Ishikawa K (2007) Improvement of the enzymatic activity of the hyperthermophilic cellulase from Pyrococcus horikoshii. Extremophiles 11(2):251–256

Kashima Y, Mori K, Fukada H, Ishikawa K (2005) Analysis of the function of a hyperthermophilic endoglucanase from Pyrococcus horikoshii that hydrolyzes crystalline cellulose. Extremophiles 9(1):37–43

Kim H-W, Mino K, Ishikawa K (2008) Crystallization and preliminary X-ray analysis of endoglucanase from Pyrococcus horikoshii. Acta Crystallogr Sect F 64(12):1169–1171

López-Rubio A, Lagaron JM, Ankerfors M, Lindström T, Nordqvist D, Mattozzi A, Hedenqvist MS (2007) Enhanced film forming and film properties of amylopectin using micro-fibrillated cellulose. Carbohydr Polym 68(4):718–727

Mazumder BB, Ohtani Y, Cheng Z, Sameshima K (2000) Combination treatment of kenaf bast fiber for high viscosity pulp. J Wood Sci 46:364–370

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Nogi M, Iwamoto S, Nakagaito AN, Yano H (2009) Optically Transparent Nanofiber Paper. Adv Mater 21(16):1595–1598

Pääkko M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Qing Y, Sabo R, Zhu JY, Agarwal U, Cai Z, Wu Y (2013) A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr Polym 97(1):226–234

Siddiqui N, Mills RH, Gardner DJ, Bousfield D (2010) Production and characterization of cellulose nanofibers from wood pulp. J Adhes Sci Technol 25(6–7):709–721

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2011) Determination of structural carbohydrates and Lignin in Biomass Laboratory Analytical Procedure (LAP). NREL Technical Report NREL/TP-510-42618 (Version 07-08-2011)

Studier FW (2005) Protein production by auto-induction in high-density shaking cultures. Protein Expr Purif 41(1):207–234

Svagan AJ, Azizi Samir MAS, Berglund LA (2007) Biomimetic polysaccharide nanocomposites of high cellulose content and high toughness. Biomacromolecules 8(8):2556–2563

Tanpichai S, Quero F, Nogi M, Yano H, Young RJ, Lindström T, Sampson WW, Eichhorn SJ (2012) Effective young’s modulus of bacterial and microfibrillated cellulose fibrils in fibrous networks. Biomacromolecules 13(5):1340–1349

TAPPI Standard Test Method (1999) T230 om-99, Viscosity of pulp (capillary viscometer method)

Teugjas H, Väljamäe P (2013) Selecting β-glucosidases to support cellulases in cellulose saccharification. Biotechnol Biofuels 6:105

Wang QQ, Zhu JY, Reiner RS, Verrill SP, Baxa U, McNeil SE (2012) Approaching zero cellulose loss in cellulose nanocrystal (CNC) production: recovery and characterization of cellulosic solid residues (CSR) and CNC. Cellulose 19(6):2033–2047

Zhu JY, Sabo R, Luo X (2011) Integrated production of nano-fibrillated cellulose and cellulosic biofuel (ethanol) by enzymatic fractionation of wood fibers. Green Chem 13(5):1339–1344

Acknowledgments

We acknowledge the financial supports by a USDA Agriculture and Food Research Initiative (AFRI) Competitive Grant (No. 2011-67009-20056), Chinese Scholarship Council (CSC), National Natural Science Foundation of China (Grant Nos. 31070512 and 31370571). The funding from these programs made the visiting appointment of Wang at the USDA Forest Products Laboratory (FPL) possible. We also acknowledge Thomas Kuster of the Analytical Chemistry and Microscopy Lab of FPL for SEM imaging and Debra Sherman of DS imaging LLC, West Lafayette, IN, for TEM imaging.

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was conducted on official government time of Zhu, Kersten, Mozuch, and Sabo while Wang was a visiting student at the US Forest Service, Forest Products Lab.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, W., Mozuch, M.D., Sabo, R.C. et al. Production of cellulose nanofibrils from bleached eucalyptus fibers by hyperthermostable endoglucanase treatment and subsequent microfluidization. Cellulose 22, 351–361 (2015). https://doi.org/10.1007/s10570-014-0465-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0465-2