Abstract

Salt mist and salt crystallization tests were conducted to determine the resistance of the untreated and water-repellent-treated Döğer tuff samples to salt damage. The Döğer tuffs are of volcanic origin and consist of porous pyroclastic rocks. A series of characterization studies were performed to determine the physicochemical and chemical properties (XRF), mineralogical-petrographic characteristics (polarizing optical microscopy, XRD, and SEM), and pore-size distribution (MIP) of the Döğer tuff prior to the aging tests. Following the aging experiments, the changes in weight, ultrasound pulse velocity, uniaxial compressive strength, and variations in pore size distribution were examined in the tested tuffs. In addition, SEM studies were conducted to analyze the microstructures. The untreated tuff samples were more severely affected by salt crystallization. The increases in dry weight for untreated and water-repellent-treated Döğer tuff samples were 0.27% and 0.13% after 60 cycles of salt mist exposure and 7.2% and 3.76% after salt crystallization cycles using a sodium chloride solution, respectively. Both conditions resulted from the accumulation of NaCl crystals on the tuff surface and within the pores. Salt crystal formation in a sodium sulfate solution led to dry weight change of 2.02% and 0.29% in the untreated and water-repellent-treated samples, respectively. The uniaxial compressive strength of the untreated tuff samples decreased by 36.71% in the presence of sodium chloride solution and by 72.58% in the presence of sodium sulfate solution. The ultrasound pulse velocity values decreased in all tuff samples after the salt crystallization test. However, the Döğer tuff samples were still distinguishable after both tests and their physical integrity remained intact.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

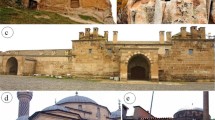

From ancient times to the present, natural building stones have been widely used in construction, for decorative purposes in monumental buildings, and for outdoor and indoor flooring and walls. The Afyonkarahisar region in Turkey is known for its various volcanic rocks that are used as building stones. Döğer tuff quarries, located 51 km from Afyonkarahisar, have been a major source of building stones for centuries. Owing to their workability, availability, and aesthetic appeal, these stones have become the preferred material for numerous historical buildings and monuments. Seljuk and Ottoman civilizations utilized these tuffs to construct many cultural heritage sites in Afyonkarahisar, including fountains, mosques, caravanserais, and bridges. Examples of surviving monumental structures built with these stones include the Imaret Mosque 1472), Mevlevi Tomb Mosque 1905, and Adeyze Mosque 1649 (Fig. 1).

Both artificial materials and natural building stones are subject to external influences such as environmental factors, climate conditions, and pollution effects (Alves et al. 2020; Scrivano and Gaggero 2020). In addition to these external factors, specific characteristics of the internal structure of natural building stones can also contribute to accelerated weathering. For instance, the pore structure plays a crucial role, as it determines the amount of water absorbed by the stone and the movement of water within it (Török and Vásárhelyi 2010; Fan et al. 2020). Tuffs, which are porous stones, can undergo degradation when exposed to water. The weathering of natural building stones owing to salt crystallization is closely linked to the moisture content of the stone (Molina et al. 2011). Water can transport saline solutions, damage stones, and accumulate within their pores. Salty solutions in the pore system can lead to efflorescence and deterioration through salt crystallization over time (Doehne 2002). The deterioration of building stones can range from mild to severe, and can occur continuously or intermittently. To effectively prevent or mitigate the deterioration of natural building stones, it is crucial to understand their underlying processes and then employ techniques and materials to inhibit or slow down their progression. In recent years, there has been an increasing recognition of the significance of historical buildings and monuments as part of our present and future heritage (Charola and Bläuer 2015; Delgado et al. 2016). The crystallization of soluble salts within pores is one of the primary causes of the deterioration of natural buildings (Karoglou et al. 2005; Flatt 2002). Salt crystallization and deposition on the surfaces of natural building stones indicate a salt attack. This phenomenon can expand pores as salt crystals grow when salt solutions penetrate pores (Rodriguez-Navarro and Doehne 1999; Ruiz-Agudo et al. 2006).

The extent of damage to cultural heritage buildings depends on the porosity, saturation of salt solutions, and morphology of salt crystals within natural building stones. Petrological properties also play a role in the degradation of natural building stones during salt crystallization cycles, in addition to porosity and pore size distribution (Angeli et al. 2007). The linear pressure exerted by salt crystals forming in the pores and cracks on the pore walls is inversely proportional to the radius of the pores and is directly related to the salt concentration and crystal size (Benavente et al. 2007). The pore size distribution influences the movement of saline liquids within porous natural building materials, leading to changes in their mechanical and physical behavior and accelerated degradation. Efflorescence or sub-efflorescence is a common consequence of salt crystallization in porous stones during weathering. Efflorescence on the surface of natural stones typically causes minimal or no damage to the stone itself during degradation, while sub-efflorescence can cause significant material damage when it occurs beneath the surface of natural stones (Selwitz and Doehne 2022; Rodriguez-Navarro et al. 2022). During salt crystallization tests, the salt solution first infiltrates the larger pores it encounters, gradually moving into the smaller pores where supersaturation occurs. Consequently, salt crystallization primarily occurs in smaller pores. Because the crystallization stress in smaller pores is higher than that in larger pores, the stone becomes more susceptible to swelling and eventual cracking (Scherer 1999). Thermal and crystallization stresses during salt crystallization can contribute to salt-induced damage in samples. When the pores of the stone are filled with salt crystals and undergo drying, the thermal expansion mismatch between the stone and salt can lead to significant stresses on the tensile strength of the stone, resulting in damage (Scherer et al. 2001).

Salt crystallization is a degradation process caused by soluble salts in natural building materials. Salt spraying is a widely used and standard method for corrosion testing and is employed to assess the corrosion resistance of stone materials and surface coatings. In the case of salt mist degradation, salt solutions are absorbed by the surface of porous natural building stones through a salt spray before penetrating the pores and cracks. On the other hand, during salt crystallization, the salts infiltrate the building stones through capillary absorption (Theoulakis and Moropoula1999). Predicting the susceptibility of building stones to environmental deterioration is crucial to determine the longevity of ancient structures. Various engineering laboratory tests have been used to accurately predict the weathering behavior of construction stones over time and under specific environmental conditions. Under controlled laboratory conditions, these experiments aimed to accelerate the typical physical weathering processes of building stones. Aging tests, such as salt crystallization, thermal shock, and freeze-thaw are some of the tests which are used to investigate the deterioration of construction stones. Standard salt crystallization tests have been specifically designed to accelerate the effects of specific environmental degradation of stones (Ca´rdenes et al. 2014).

The impact of salt mist on the physical characteristics of building stones, such as limestone, marble, and andesite, has been extensively studied (Silva and Simão 2009; Urosevic et al. 2013; Kłopotowska and Łukaszewski 2014; Selim et al. 2019; Karakaş et al. 2021). Some studies have focused on changes in the porosity of natural stones (Fort et al. 2014; Carvalho et al. 2018), whereas others have examined changes in water-repellent-treated and untreated andesite (Çelik et al. 2021). However, no study has explicitly addressed tuffs on this subject.

Researchers have been studying the factors that lead to salt crystallization damage in building stones for many years for various reasons. Salt attack damage to building stones was investigated under different experimental conditions, including the type of salt solution, temperature, sample quantity, and number of cycles. Previous studies have also examined the damage caused by salt solutions, assessing specific petrophysical properties, such as capillarity, porosity, pore size distribution, weight loss, and ultrasound velocity. These studies have shown that salt crystallization significantly reduces the durability of building stones (Alonso et al. 2008; Yu and Oguchi 2010; Di Benedetto et al. 2015; Sun et al. 2019; Çelik and Aygün 2018; Çelik and Sert 2020).

Several scientists have investigated the effects of salt crystallization on the petrophysical characteristics of tuffs used as building stones. In addition to magnesium and sodium sulfate, sodium chloride was used in these studies. They demonstrated that salt crystallization alters various physical and mechanical properties of the tuff (Alves et al. 2011; Jamshidi et al. 2016; Zalooli et al. 2017; Benavente et al. 2018). Sato and Hattanji (2018) examined the changes in the density and porosity of sandstone and tuff after salt crystallization. They observed flaking or swelling on the surfaces of the tuff and sandstone exposed to NaCl. Oguchi and Yuasa (2010) conducted simultaneous salt crystallization, freeze/thaw, and wetting/drying tests on three types of Japanese Oya tuffs. They concluded that the salt-weathered tuff samples suffered the most damage. Özşen et al. (2017) investigated the impact of salt crystallization on the weathering of Cappadocian tuff in Turkey. They found that water absorption and porosity increased for all tested samples, whereas the tensile strength, ultrasonic velocity, and uniaxial compressive strength decreased. Pötzl et al. (2018) studied the degradation of various tuffs used as construction stones in ancient buildings owing to salt crystallization and hydric expansion.

Similarly, Çelik and Aygün 2019examined the effects of salt crystallization on the decay of two different tuffs and one andesite (Turkey), using sodium chloride and sodium sulfate. They found that the Ayazini tuff had a short lifespan and decayed when exposed to sodium sulfate solution. Germinario and Török (2019) investigated the changes in technical properties and durability due to freeze-thaw and salt attacks in tuffs of volcanic origin from the same quarry in Hungary. Çelik and Sert (2020) studied the impact of various salt solutions on the durability of Döğer tuff (Turkey) through salt crystallization experiments. They observed decreased ultrasonic pulse velocity and uniaxial compressive strength values for all the salt solutions.

Protective chemicals and water repellents are commonly used to protect historic buildings and monuments from water damage. Various water-repellent chemicals have been employed in waterproof buildings, including acrylic, silicone, silane, and siloxane. These chemical coatings allow the passage of water vapor while preventing water from penetrating the stone (Cimitàn et al. 1994). Several studies have investigated the use of water-repellents and protective chemicals to safeguard natural stones in historic buildings. La Russa et al. (2017) examined the resistance to salt weathering of untreated and treated samples of Neapolitan yellow tuff (Italy). They found that consolidation improved the resistance of the tuff to salt crystallization. Çelik and Tığlı (2019) investigated the chemical effects of water repellents on salt crystallization in three tuff and andesite samples (Turkey), which are construction stones with high porosity. They concluded that the samples treated with water-repellent chemicals suffered less salt crystallization damage than untreated samples.

Laboratory aging studies were conducted on fresh tuff samples from the Döğer quarry to evaluate potential protective treatments against salt stress. Commercially available solvent-based siloxane was used as the water repellent. The Döğer tuff samples were subjected to artificial aging tests to assess their resistance to salt attack (TS EN 12,370 2020; TS EN 14,147, 2004). Artificial aging processes include salt mist testing to assess salt corrosion on sample surfaces, and salt crystallization cycles to evaluate the resistance to salt damage. Following the aging experiments, changes in the untreated and water-repellent-treated tuff samples were analyzed using the weight change, uniaxial compressive strength, ultrasound pulse velocity, variation in pore size distribution, and SEM analysis to evaluate the microstructure. This study aimed to provide valuable information for those interested in understanding tuff stone preservation.

Materials and methods

Materials

Volcanic tuff can display various properties contingent on its mineral composition, texture, pore structure, and the processes involved in its formation. It is a sedimentary rock formed through consolidation of pyroclasts, categorized by size and shape as ash, lapilli, blocks, and bombs. The pyroclastic deposits may comprise unconsolidated accumulations of pyroclasts or rocks composed of pyroclasts. The common term for unconsolidated pyroclastic deposits is “tephra,” while consolidated pyroclastic rocks primarily made up of ash are termed “tuff.” In contrast, ignimbrite is a pyroclastic rock that contains numerous flattened juvenile fragments, typically from pumice (Fisher and Schmincke 1984; Lowe 2011).

The tuffs under investigation were extensively utilized in monuments during the Seljuk (1075–1308 AD) and Ottoman (1299–1922 AD) periods and are currently quarried primarily for local purposes (Fig. 2). The Döğer tuff is a porous pyroclastic rock with low density. This tuff is typically cream-beige and consists of variously sized phenocrysts and lithic fragments, exhibiting a rough texture on the surface. Apart from the tuff color, the lithic fragments range in dark beige and brown shades. Although it does not possess significant continuous large voids, it contains numerous small discontinuous voids. To obtain low standard deviations of the test results, the Döğer tuff samples used were selected from among homogeneous, crack-free, and solid samples.

Geological settings

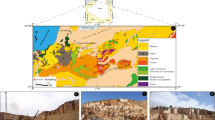

The Afyon Metamorphic rocks of the Paleozoic era formed a basement around Afyonkarahisar. The Afyon Metamorphic rocks consist of alternating layers of marble and schist. The schists are generally coffee, brown, and green, giving the impression of highly metamorphic rocks. They are primarily composed of albite-chlorite-muscovite-biotite-quartz schists. Additionally, these schists are occasional large lenses and bands of meta-conglomerate, metasandstone, marble, and calc-schist. The thickness of the unit is estimated to be approximately 2000 m. A marble unit is a valuable type of white, gray, variegated, and cream-colored marble that can yield large blocks. Numerous marble quarries operate within this unit. The unit is approximately 300 m thick and occurs as a lens within the Afyonkarahisar Metamorphics. Overlying these metamorphic units is the Gebeceler Formation, which exhibits an unconformity. The Gebeceler Formation is comprised of conglomerate, sandstone, agglomerate, tuff, marl, clayey limestone, and silicified limestone. During the Middle Miocene to Late Miocene, intense terrestrial volcanism resulted in the formation of Afyon volcanic units, which consisted of numerous members. The Afyon volcanic units are significant in Inner West Anatolia and extend over a large area between Bayat, İscehisar, Kırka, Sandıklı and Şuhut. Tuffs are extensively exposed in Ayazini, Seydiler, and Döğer (Metin et al. 1987; MTA 2009).

The tuffs are generally milky white and cream colored, exhibiting thick layering. They cover a vast area and are notable for their easily erodible topography. The tuffs, known as the Döğer tuffs, are found within the Gebeceler Formation. The overlying areas were quaternary slope debris and alluvium. The thickness of the alluvial cover varies between 50 and 150 m, comprising fragments of metamorphic basement, Neogene sediments, and volcanic rock materials (Metin et al. 1987; MTA 2009). Figure 3 illustrates the geological map of the Döğer region.

Methods

Resistance to aging by salt mist and salt crystallization tests were conducted in the laboratory to determine the durability of the Döğer tuff. For this purpose, salt crystallization tests were performed using NaCl and Na2SO4 solutions. Mineralogical-petrographic analysis (including polarizing optical microscopy, XRD, and SEM analysis), chemical characterization tests, and Mercury Intrusion Porosimetry (MIP) were conducted to characterize the Döğer tuff samples in this study.

Thin sections were prepared using standard techniques. The petrographic and mineralogical features of the Döğer tuff were examined using a Leica DM 2500P polarizing optical microscope. Chemical analysis was performed using a Rigaku/ZSX Primus II XRF instrument. Microstructural investigations of the tuff samples were performed on carbon-coated samples using an LEO 1430 VP model SEM. The major and minor minerals in the tuff samples were identified using the classical X-ray powder diffraction (XRD) method with a Panalytical X-pert MRD series instrument. The samples for the XRD analysis were crushed, and sub-samples (5 g) were micronized into a fine powder. The pore size distributions of the tuff samples were determined using a Micromeritics Auto Pore IV 9500 instrument. The contact angle of mercury and the surface tension were measured to be 130° and 485 nN/m, respectively. The P-wave velocity measurements on the tuff samples were performed using two transducers at 54 kHz with an ELE series instrument. Some physico-mechanical properties of the Döğer tuff samples were determined both with fresh samples and after the aging tests. Large-sized tuff rocks, approximately 50 × 30 × 30 cm, were extracted from the active tuff quarry. These rocks were then cut to the required dimensions of 50 × 50 × 50 mm for the experiments, and cube-shaped samples were prepared.

Hydrophobic coatings

The penetration of water from exposed surfaces into the interiors of stones used in monuments and structures is one of the leading causes of deterioration and damage (Amoroso and Fassina 1983). Natural stones with high porosities tend to deteriorate more rapidly because of their ability to absorb larger amounts of water. Suitable protective methods are employed to restrict the ingress of water into natural building stones, thereby minimizing decay. Numerous polymer types that impart a hydrophobic character to natural stone surfaces are available for this purpose (Charola 2000; Sadat-Shojai and Ershad-Langroudi 2009). These materials are primarily derived from acrylic-, fluorine-, and silicone-based monomers. Polysiloxanes and their precursors known as silanes are commonly used. Recently, nanocomposites have been produced by incorporating inorganic oxide nanoparticles into hybrid siloxanes or silicone polymers. While some applications of these coatings yield favorable results, others may accelerate the decay or deterioration processes by altering the properties of the stones. Therefore, it is crucial to select the most suitable protective solution for natural stone (Zielecka and Bujnowska 2006; Simionescu et al. 2011; Esposito et al. 2013; Lettieri and Masieri 2016).

In the experiments, commercial solvent-based siloxane was used as a water-repellent material. The surfaces under test were treated by brushing, which ensured the continuous absorption of the water-repellent substance to provide appropriate hydrophobicity. All the surfaces of the samples were coated with a water repellent. Tuff samples were allowed to polymerize for six days before being used in the experiments. This method aimed to create a hydrophobic barrier on the surface of the tuff, thereby reducing saltwater absorption and mitigating potential deterioration due to moisture-related processes.

Petrophysical and durability assessments were conducted according to Technical Specification European Standard (TS EN) standards. The stone properties were determined, including density (TS EN 1936 2010), total and open porosity (TS EN 1936 2010), water absorption (TS EN 13,755 2009), P-wave velocity (TS EN 14,579 2006), uniaxial compressive strength (TS EN 1926 2007), capillary water absorption (TS EN 1925 2000), salt mist (TS EN 14,147, 2004), and salt crystallization (TS EN 12,370 2020). Tuff samples with dimensions of 50 mm ×50 mm ×50 mm (± 1) were used in all experimental studies. Physical, mechanical, and weathering tests were performed with ten samples each, whereas the salt-fog test was conducted with six samples. Before testing, all the samples were dried.

Salt mist test

A salt spray chamber and 10% salt solution (100 g NaCl per liter of water) were used to evaluate the resistance to aging through the salt mist test. The experiment for assessing the resistance to aging by salt mist for untreated and treated tuff samples used in this study was conducted following the TS EN 14,147 standards. For the experiments, tuff samples with dimensions of 50 × 50 × 50 mm (± 1) and a total of 6 + 6 samples were employed, along with the NaCl solution. The tuff samples were washed with deionized water. Subsequently, the edges of the samples were marked with a permanent marker pen to facilitate visual observation of material loss. Subsequently, the samples were dried at 70 ± 5 °C until they reached a constant weight, after which they were cooled to room temperature and weighed. The obtained weight represents the initial value of the dry sample. The stone samples were placed in a special climatic chamber capable of performing alternating cycles of salt mist atmosphere and drying and maintained at 35 ± 5 °C. The tuff samples were subjected to salt fog (5% NaCl) for four hours, the salt spray system was turned off, and the samples were allowed to dry for eight hours, completing one cycle. The test comprised 60 cycles, although it could be concluded earlier if, upon visual inspection, at least two specimens cracked or disintegrated completely. After the test, the tuff samples were carefully removed from the chamber and immersed in deionized water to remove all deposited salts. Hydrophobically treated and untreated Döğer tuff samples were weighed in their dry state after reaching a constant mass by drying and visually inspected. The weight of each tuff sample was measured again following the weathering experiments, and the resulting weight loss, ultrasound pulse velocity (UPV), and uniaxial compressive strength (UCS) values were determined after each cycle.

Salt crystallization test

Tests were conducted following the TS EN 12,370 (2020) standard to assess the resistance of the Döğer tuffs to salt crystallization. Two solutions were used: 14% sodium sulfate decahydrate (Na2SO4·10H2O) and sodium chloride (NaCl). In the aging experiments with saline solutions, the Döğer tuff samples were placed in a specially prepared vessel with a minimum spacing of 10 mm between each sample and at least 20 mm between the samples and the vessel. The samples were soaked in the solution for two hours at a temperature of (20 ± 0.5) °C. After soaking, the samples were removed from the solution and dried in an oven. The oven was initially set to provide high relative humidity during the drying process, gradually increasing the temperature of the samples to (105 ± 5) °C for no less than ten hours and no more than 15 h. The samples were then kept in an oven for at least 16 h, followed by a cooling period of (2.0 ± 0.5) hours to reach room temperature, before being immersed again in the salt solution. This entire sequence of operations constituted one cycle repeated 15 times, excluding cases in which the samples disintegrated or fragmented. The same experiments were conducted on tuff samples treated with surface-protective chemicals. Weight loss, uniaxial compressive strength, and ultrasound pulse velocity measurements were used to evaluate the level of weathering resulting from salt crystallization in both untreated tuff samples, which had undergone aging, and fresh samples that had not been exposed to the aging process. The term “fresh” was used to describe intact samples that had not undergone any aging experiments. In contrast, “untreated” refers to the degraded samples subjected to the aging test.

Results and discussions

Physical and mechanical properties

The physicomechanical characteristics of the Döğer tuff samples were investigated to assess their suitability as building stones (Table 1). The real density is expressed as the ratio of the mass of the ground dry specimen to the volume of the liquid displaced by the mass. The average real density of the Döğer tuff samples was determined to be 2565 kg/m3, whereas the open porosity and total porosity values were 25.74% and 41.9%, respectively. The average water absorption by weight was 17.2%. The average density of 2565 kg/m3 suggests that the Döğer tuff falls within the density range commonly found in volcanic rocks. The apparent density, expressed as the ratio of the dry sample mass to its apparent volume, was determined to be 1474 kg/m3. An open porosity value of 25.7% indicates a relatively high level of interconnected void spaces within the tuff structure. This porous nature is also evident in the total porosity value of 41.9%, which accounts for both the open and closed porosities. Substantial porosity influences the mechanical properties and overall durability of tuff as a construction material. Water absorption by weight is an important parameter for evaluating building stone performance. With an average water absorption of 17.2%, the Döğer tuff demonstrated a moderate capacity to absorb and retain moisture. This characteristic and porous structure can contribute to weathering and deterioration over time.

The density, porosity, water absorption, and uniaxial compressive strength values play a significant role in determining the suitability of the tuff for different applications. The results indicate that the Döğer tuff has a porous structure, which is reflected in its relatively low density. High porosity values adversely affect the tuff’s mechanical properties and categorize it as a lightweight building stone. However, its porous nature also makes it susceptible to deterioration, especially when exposed to water absorption. Therefore, careful consideration should be given to the hydric performance and preservation methods of Döğer tuff when used in construction projects.

The average uniaxial compressive strength of the Döğer tuff is 20.80 MPa. Comparing the uniaxial compressive strength of the Döğer tuff with other volcanic stones, it was observed that it fell on the lower end of the strength spectrum. However, it is important to note that the uniaxial compressive strength of the Döğer tuff was comparable to that of certain tuff varieties. For instance, in a study by Wedekind et al. (2013), 14 volcanic tuffs exhibited uniaxial compressive strength values ranging from 8.21 to 98.04 MPa under dry conditions. Similarly, the average uniaxial compressive strength of Cappadocia (Turkey) tuff ranged between 10.55 and 50.03 MPa (Özşen et al. 2017). Notably, the characteristics of tuff stones vary depending on the welding conditions and preservation methods used. Armenian tuff, for example, demonstrates a compressive resistance ranging from 7.17 to 28.21 MPa (Pötzl et al. 2018).

Chemical analysis

The chemical composition of the Döğer tuff samples used in the experimental study was determined through XRF analysis, and the results for the main elements are presented in Table 2 as weight% oxides. The results revealed a significant amount of SiO2 (70.36%) as the predominant component, which can be attributed to the presence of various silicate minerals, such as quartz, feldspar, pyroxene, hornblende, and mica, as confirmed by XRD analysis. The second most abundant component was Al2O3 (13.53%), likely originating from feldspar minerals (albite and sanidine) and clay minerals (illite) within the tuff samples. Fe2O3 (1.43%) in the tuff samples suggests partial leaching of this element from the surrounding environment. Furthermore, the high K2O content observed can be attributed to the retention of potassium (K) during the transformation of mica minerals (biotite and muscovite) within the tuff samples, consistent with the XRD analysis findings. Loss on Ignition (LOI) refers to the volatile and organic matter contents in the samples. The volatile materials lost during the analysis typically include combined water and CO2. The LOI of the Döğer tuff was 3.18%.

Chemical composition analysis indicates that the Döğer tuff can be classified as a rhyolitic rock in the sub-alkaline field of the silica (SiO2) vs. total alkali (K2O + Na2O) diagram, according to the classification by Le Bas et al. (1986) (Fig. 4). The high SiO2 concentration (70.36%, Table 2) further supports this classification. The classification of the Döğer tuff as rhyolitic rock based on its SiO2 concentration in the sub-alkaline field provides important insights into its geological origin and potential similarities with other volcanic rocks.

The Döğer tuff’s total alkalis versus silica (TAS) rock categorization diagram (after Le Bas et al. (1986). The tested tuff sample is located in the rhyolitic sub-alkaline region

Mineralogical and petrographic studies

Polarizing optical microscope

The Döğer tuff samples were subjected to optical microscopy using three thin sections. Figure 5 presents optical microphotographs showing the characteristics of the Döğer tuff. The presence of volcanic glass, minerals, and rock fragments was evident during the examination. Primary minerals including idiomorphic sanidines, quartz, pyroxene, plagioclase, hornblende, and biotite were identified in the tuff samples. The physical weathering of pyroxene, plagioclase, and K-feldspars manifested through the intense fractures observed in these minerals. The fractures observed in pyroxene, plagioclase, and K-feldspars highlight the impact of physical weathering on the mineralogical stability of the tuff. Slight discoloration and the formation of Fe oxide staining were observed in hornblende and biotite. The slight discoloration and Fe oxide staining surrounding hornblende and biotite suggest possible alteration processes affecting these minerals. Plagioclase and K-feldspar were the most abundant microcrystals present in the tuff. The predominance of plagioclase and K-feldspars as microcrystals in the tuff aligns with their common occurrence in the volcanic rocks.

Under plane-polarized light, the glass components appeared thin and elongated, exhibiting colors from colorless to light brown. The tuff matrix primarily consists of fine volcanic glass, occasionally including lithic fragments. The presence of volcanic glass suggests rapid cooling during tuff formation. These lithic fragments displayed dark, beige, and brownish colors. Optical microscopy analysis confirmed that the Döğer tuff exhibited a vitro-porphyritic texture and could be classified as crystal vitric tuff. The vitro-porphyritic texture observed in the Döğer tuff indicates the presence of larger crystals (sanidines) embedded in a fine-grained volcanic glass matrix.

SEM–EDX analysis

Scanning electron microscopy (SEM) was employed to investigate the crystal shapes and micro-morphological properties of the sub-microscopic minerals and those not readily observable in thin sections (Fig. 6). The results revealed the presence of critical components such as quartz, feldspar minerals, volcanic glass, and micropores. One significant finding was the widespread occurrence of micropores throughout the Döğer tuff, with sizes typically ranging from 1 μm to 10 μm. These micropores contribute to the overall porosity and may affect the various physical and mechanical properties of the tuff. The characteristics of micropores are of particular interest. They exhibited a predominantly elongated tube-like or tubular morphology, consistent with previous observations. However, spherical formations were occasionally observed, suggesting the presence of diverse pore structures within the tuff. SEM observations confirmed quartz and feldspar minerals, which were also identified using energy-dispersive X-ray spectroscopy (EDX) analysis. Additionally, as previously observed in the optical microscope examinations, volcanic glass was once again detected in abundance during the SEM studies. The SEM analysis reinforced the findings from the optical microscope examinations and provided additional details about the micromorphology and composition of the Döğer tuff. Identifying quartz, feldspar minerals, volcanic glass, and micropores contributes to our understanding of the geological and petrological features of the tuff.

XRD analysis

Two significant peaks corresponding to quartz and albite were identified in the X-ray diffraction analysis of Döğer tuff. The presence of additional minerals is indicated by peaks of varying intensities, as depicted in Fig. 7. The identification of quartz and albite as predominant peaks confirmed their prominent role in the composition of the tuff. Additionally, peaks of varying intensities indicated the presence of other minerals, such as feldspar (sanidine, anorthite), pyroxene, hornblende, mica (biotite and muscovite), and illite. The presence of illite minerals suggests the occurrence of weathering processes, indicating that the tuff samples underwent alteration over time. Weathering processes have affected the volcanic glass components and feldspars, leading to their relative alteration and weathered appearance.

X-ray diffraction (XRD) analysis revealed the presence of illite. Identifying illite minerals signifies the presence of clay minerals and suggests that the tuff samples have undergone weathering processes, with volcanic glass components and feldspars being relatively weathered. Furthermore, insights into weathering processes can contribute to studies on tuff stability, durability, and suitability for different engineering and construction purposes. Furthermore, the XRD graph displays a rising baseline from 2θ = 18°, indicating the presence of volcanic glass, which was also visually confirmed in the thin sections. The findings from the XRD analysis were consistent with the observations made in the thin sections, where the presence of volcanic glass was visually confirmed.

Pore structure

Porosity and pore size distribution play a crucial role in the physical characteristics of natural building stones, as they directly influence their water and salt solution absorption properties. To determine these characteristics, data from a mercury porosimeter were used to calculate the pore size distribution, mean pore size, and total pore area. Several recommendations have been made in the literature for classifying pore sizes in natural building stones. Classifying the pore size distribution consistently is difficult because of the different definitions of the macro-, meso-, and micropore intervals. For instance, IUPAC (1976) defined micropores as those with diameters less than 2 nm, mesopores with diameters ranging between 2 and 50 nm, and macropores larger than 50 nm in diameter. On the other hand, Klopfer (1985) and Graue et al. (2011) classified micropores as those with a diameter less than 0.1 μm, mesopores between 0.1 μm and 1 mm, and macropores as larger than 1 mm.

Table 3 summarizes the mercury porosimetry data for the fresh Döğer tuff samples. The average pore diameter of the Döğer tuff sample was 0.27 μm. The median pore diameter (volume) and median pore diameter (area) obtained from the MIP results were 0.95 μm and 0.03 μm, respectively. Figure 8 shows the pore-size distribution curves of the tested tuff. The total porosity of the tuff was 38.89%, with pore sizes ranging from 0.01 to 8 μm. The pore-size distribution curve displayed a unimodal pattern, with a prominent peak observed at a pore radius of 1 μm. Further analysis of the pore size distribution in Döğer tuff indicated that pores larger than 1 μm accounted for 57.62% of the total, while pores between 0.1 μm and 1 μm accounted for 36.42%. Pores smaller than 0.1 μm constituted 5.96% of the total.

Based on the classifications proposed by Klopfer (1985) and Graue et al. (2011), the Döğer tuffs can be categorized as mesoporous natural stones, falling within the range of 0.1 μm to 1 mm. The presence of pores ranging from 0.01 to 1 μm in the Döğer tuff significantly determines its capillary water absorption capacity. Capillary pores are vital for regulating water movement within building stones, and the results of porosimetry studies indicate that the Döğer tuff possesses a substantial number of capillary pores. This suggests that the tuff exhibits favorable characteristics for capillary water absorption, which is an essential consideration in applications where moisture management is crucial.

Capillary water absorption

Six standards and six water repellent-treated samples were used to assess the capillary water absorption characteristics of the Döğer tuff samples. The capillary water absorption behavior of the tuff samples based on the water absorption times during the experiments is illustrated in Fig. 9. The capillary water absorption coefficient (C) of the Döğer tuff samples was determined to be 14.70 kg/m2s0.5 after 4320 min, indicating a high-water absorption rate. This can be attributed to the capillary pore size distribution of the tuff, which ranges from 0.01 μm to 8 μm and exhibits a unimodal distribution with a single peak. The water-repellent-treated samples, however, displayed limited water absorption due to the protective effect of the resin, resulting in a significantly lower water absorption coefficient of 0.36 kg/m2s0.5. This demonstrates the effectiveness of the water-repellent treatment in reducing water absorption. The rapid saturation of untreated tuff samples highlights their vulnerability to water ingress.

The capillary pore structure, which is characterized by a wide range of pore sizes, contributes to the high absorption rate. This poses a potential risk of damage, particularly when the tuff is exposed to high humidity. Therefore, caution should be exercised when considering Döğer tuff for construction in highly humid environments. In contrast, the water-repellent treatment effectively mitigated water absorption in the tuff samples. The protective resin creates a barrier that limits the water penetration and reduces the absorption coefficient. This indicates that water-repellent treatment can be a valuable solution for enhancing the durability and performance of Döğer tuffs in applications where moisture-related issues are a concern. To ensure the optimal use of the Döğer tuff, employing material above the capillary level in construction projects is recommended. Avoiding direct exposure to capillary action can minimize the potential risks of high water absorption.

Aging tests

Experiments involving salt mist and crystallization tests were conducted to assess the durability of the untreated and water-repellent-treated Döğer tuff samples. The purpose of this study was to evaluate the performance and effectiveness of water-repellent treatment in enhancing the tuff samples’ resistance to environmental deterioration, particularly with regard to salt-induced degradation. By comparing the performance of untreated and water-repellent-treated samples, the effectiveness of the treatment in enhancing the tuff’s resistance to salt-related damage was determined. This information is crucial for understanding the potential benefits of water-repellent treatments in preserving tuff-based structures, particularly those in salt-laden environments.

Salt mist test

Visual examination of salt mist-exposed tuff samples

Visual observations were conducted after the salt mist tests to identify any deterioration in the tested samples (Fig. 10). The results demonstrate the effectiveness of the water-repellent treatment in enhancing the durability of the Döğer tuff samples against the detrimental effects of salt mist. Applying water-repellent procedures significantly mitigated the destructive impacts of salt mist on the treated Döğer tuff samples. The delay in degradation observed in the water-repellent-treated samples indicated the ability of the treatment to act as a protective barrier, reducing the penetration of moisture and salts into the tuff samples. This, in turn, minimized the surface damage, erosion, and material loss that occurred owing to salt mist exposure. Moreover, noticeable disparities in the surface appearance were observed, with the water-repellent-treated samples exhibiting smoother and generally cleaner surfaces. The improved surface appearance of the water-repellent-treated samples was also noteworthy. The smoother and cleaner surfaces suggest that the treatment not only enhances the durability of the tuff, but also contributes to the aesthetic preservation of the structures.

The change in dry weight caused by salt mist

Figure 11 illustrates the variations in dry weight resulting from the salt mist test conducted on both untreated and treated Döğer tuff samples. After 60 cycles of salt mist exposure, the net average weight increase for the untreated and treated Döğer tuff samples was 0.27% and 0.13% of the original stone weight, respectively. According to Angeli et al. (2007), the weight evolution due to salt crystallization can be divided into three stages. In the first stage, the weight increased owing to salt absorption. The second stage involved competition between mass loss and salt absorption, resulting in potential weight fluctuations. Finally, in the third stage, weight reduction occurs as salt absorption becomes negligible compared with stone damage. In this study, the absence of significant mass changes in the samples after the salt mist test suggests that weight evolution did not progress beyond the first stage, indicating that salt intake was limited. The dry weight changes observed in the Döğer tuff samples were attributed to the accumulation of NaCl salt. Notably, the water-repellent treatment resulted in less salt deposition in the treated samples than in the untreated samples. Additionally, microstructural analysis using SEM confirmed the presence of NaCl accumulation, contributing to the observed increase in mass of the Döğer tuff samples.

Previous studies have investigated the weight changes resulting from salt-vapor testing on various building stones. Leal et al. (2011) reported weight loss values ranging from 0.7 to 1% for limestones and less than 0.6% for igneous rocks. Fort et al. (2014) observed a weight loss of 1.0% in a salt mist test conducted on Colmenar limestone. Simão et al. (2015) examined three polished Portuguese limestones and found minimal weight loss, less than 1% after washing, following exposure to 60 salt spray cycles. Carvalho et al. (2018) reported weight decreases between 0.12% and 0.38% after 60 salt mist cycles for six limestone samples. Çelik et al. (2021) noted a weight change of 0.49% for untreated andesites and 0.29% for treated andesites. Similarly, Karakaş et al. (2021) and Selim et al. (2019) observed average mass changes of 0.08% and 0.05%, respectively, following the salt mist test conducted on the Kandıra and Lefke stones.

Moreover, noticeable disparities in surface appearance were observed, with the water-repellent treated samples exhibiting smoother and generally cleaner surfaces. The improved surface appearance of the water-repellent treated samples is also noteworthy. The findings of this study indicate that water repellent treatment effectively limits salt intake and subsequent weight changes in Döğer tuff samples subjected to salt mist. The results align with those of previous research on weight changes in various building stones, highlighting the importance of understanding and mitigating salt-induced deterioration. Additionally, the observed improvements in surface appearance underscore the benefits of water-repellent treatments for both the structural and aesthetic preservation of tuff-based structures.

The effect of salt mist on ultrasonic pulse velocity (UPV) values

The results of the salt mist test conducted on both untreated and water-repellent-treated Döğer tuff samples demonstrated a significant decrease in the ultrasonic pulse velocity (UPV) values compared to the pre-experimental data, as depicted in Fig. 12. The average UPV of the untreated tuff samples decreased from 2.44 km/s to 2.19 km/s after the test, representing an average decrease of 11.39%. Similarly, the average UPV of the water-repellent treated tuff samples decreased from 2.44 km/s to 2.27 km/s, indicating a reduction of approximately 7.32%. The observed decrease in UPV can be attributed to the formation and propagation of new cracks and expansion of existing microcracks and pores, as explained by Simão (2015). These cracks and the increase in porosity occurred because of the tensile stress exerted on the pore surfaces and microcracks within the tuff samples. The reduction in UPV reflects the degradation of the internal structure of the tuff, indicating the presence of cracks and an increased level of porosity.

The formation of cracks and increase in porosity can compromise the mechanical integrity and durability of the tuff, making it more susceptible to further deterioration over time. These findings are consistent with those of previous research, where a reduction in the UPV was observed for various building materials subjected to salt fog testing. Kłopotowska and Łukaszewski (2014) reported an 8% decrease in UPV for limestones during cyclic experiments. Additionally, Çelik et al. (2021) found that untreated andesite samples exhibited a UPV reduction of 1.34%, whereas treated andesite samples showed a decrease of 0.67% in the salt fog test.

The effect of salt mist on uniaxial compression strength (UCS) values

The average UCS value of 25.88 MPa recorded before the test decreased to 24.20 MPa for the untreated samples, representing a 5.70% decrease. In contrast, the water-repellent-treated tuff samples exhibited an increase in UCS, with the average value reaching 27.80 MPa, indicating an increase of 7.97% (Fig. 13). The observed decrease in the UCS for the untreated tuff samples can be attributed to the development of stress pressures resulting from the growth of salt crystals within microcracks and voids. As the UCS decreases, a higher formation of micro-fissures within these samples may occur. This deterioration process indicates the vulnerability of untreated tuff to salt exposure, leading to a reduction in its mechanical strength.

Conversely, the water-repellent-treated tuff samples demonstrated improved performance and resistance to the detrimental effects of the salt mist. Applying a water-repellent material to the tuff surfaces played a crucial role in maintaining the integrity of the samples. The flexible nature of the water-repellent coating provided better protection against the ingress of salt and prevented the formation of micro-fissures. As a result, the UCS values increased, indicating an enhanced mechanical strength and durability. The findings of this study align with previous research that reported a decrease in the UCS for various types of building stones following salt mist testing. Kłopotowska and Łukaszewski (2014) documented a significant UCS reduction exceeding 30% for Śmiłów sandstones and Józefów limestones after a salt mist test. Similarly, Çelik et al. (2021) observed a decrease in the UCS of 1.45% for an andesite sample subjected to the salt mist test.

The effect of salt mist on the pore size distribution (PSD)

The porosity and pore size distribution (PSD) of the Döğer tuff were examined using a mercury intrusion porosimeter after the salt mist test (Table 3). The results indicated a decrease in the average pore diameter of the tuff from 0.27 μm to 0.22 μm following the salt mist test. The results revealed a decrease in the average pore diameter of the tuff from 0.27 μm to 0.22 μm after exposure to the salt mist. Similarly, the total porosity decreased from 38.89 to 37.30%. This reduction in the pore ratio can be attributed to the accumulation of salt crystals within the pores ranging from 0.1 –1 μm, as shown in Fig. 14. The PSD measurements further indicated an increase in the volume percentage of pores within the 0.1–1 μm range, suggesting the formation of new pores with an approximate size of 1 μm. Furthermore, the untreated samples demonstrated an average weight gain of 0.27% of the original stone weight after 60 salt-mist cycles.

A comprehensive comparison of the PSD classifications before and after the salt mist test for the Döğer tuff is presented in Table 4. The analysis revealed an increase in the PSD of pores smaller than 0.1 μm, with values escalating from 5.96 μm to 7.12 μm. Additionally, the PSD between 0.1 μm and 1 μm exhibited an increased from 36.42 μm to 45.16 μm on average. These increments corresponded to growth rates of 19.53% and 23.99%, respectively. In contrast, pore ratios larger than 1 μm experienced a reduction of 17.19%, leading to a decrease in the average size from 57.62 μm to 47.72 μm. The decrease observed in pores larger than 1 μm after the salt mist test suggested that these pores were filled with salt. Furthermore, the increase in pore sizes smaller than 1 μm can be attributed to the transformation of larger pores into smaller sizes due to partial filling with salt.

The porosity behavior under salt mist conditions has been explored in various studies involving different types of building stones. For instance, Fort et al. (2014) reported no change in the porosity of Colmenar limestone after 120 salt mist cycles. Similarly, Pires et al. (2014) observed an increase in the average pore diameter from 0.14 μm to 0.17 μm after 45 salt mist cycles in biomicrite limestone. These findings provide insights into the response of porosity and pore size distribution in tuff stone materials subjected to salt mist conditions.

Microstructural analysis by SEM after the salt mist test

SEM micrographs of both treated and untreated Döğer tuff samples subjected to the salt mist test are presented in Fig. 15. As a result of salt mist exposure, a thin layer of NaCl salt formed on the sample surfaces, as depicted in Fig. 15a. The solvent-based siloxane layer exhibited a more continuous appearance on the surface, acting as an effective passivating layer against salt attacks. However, some microcracks were observed in the silane layer, indicating susceptibility to segregation and the inability to provide a protective barrier against salt attack. SEM analysis of the untreated Döğer tuff sample after the salt mist test revealed the presence of weathered mica, volcanic glass, and a significant number of sodium chloride crystals, as shown in Fig. 15b and c. In addition, numerous microcracks with an approximate width of 1 μm were observed, as shown in Fig. 15d.

The MIP data provided valuable insights into the effects of the salt mist test on Döğer tuff samples. The results showed a decrease in the mean pore diameter from 0.27 μm to 0.22 μm and a reduction in total porosity from 38.89 to 37.30% following the salt mist test. The SEM observations revealed the presence of visible microcracks. These microcracks were filled with sodium chloride crystals, indicating subflorescence. Fortunately, owing to insufficient crystallization pressure, most examined tuff surfaces did not experience significant material loss or damage.

In conclusion, the SEM micrographs provide visual evidence of the effects of the salt mist test on the Döğer tuff samples. The formation of a NaCl salt layer, the presence of microcracks in the silane layer, and the discovery of weathered mica, volcanic glass, and sodium chloride crystals highlight the challenges faced by stone materials when exposed to salt mist conditions. The reduction in the pore diameter and total porosity, along with the observation of microcracks filled with sodium chloride crystals, emphasizes the impact of the salt mist test on the structural integrity of the tuff. Notably, insufficient crystallization pressure prevents significant material deterioration in most cases. These findings contribute to our understanding of the performance and durability of Döğer tuff in salt-laden environments.

Salt crystallization experiment

Salt crystallization is a significant deterioration that affects porous building stones. Among the salts commonly found in building stones, sodium chloride and sulfate are the most prevalent. In particular, sodium sulfate poses a significant threat to porous building blocks because of its theoretical 4.15 times molar volume expansion during the transition from the anhydrous phase Na2SO4 (tenardite) to the decahydrate phase Na2SO4 10H2O (mirabilite). This transition occurs in response to changes in the temperature or relative humidity (Winkler 1975; Goudie 1993).

Not all pores are filled with liquid when a wetted surface undergoes capillary rise. The capillary rise of a liquid containing water-soluble salts differed from that of pure water. Salts can precipitate and alter the characteristics of liquid and pore systems during the capillary rise. Depending on the type of salt and the environmental conditions, a coating of salt crystals may form on the surface or within the pores of the material. Most salts typically require complete supersaturation to generate sufficient pressure to fracture building stones. In porous materials with low saturation rates, the salt crystallization pressure is also low, potentially preventing significant deterioration of the stone (Nielsen 1991). Salts, particularly sodium chloride and sulfate, pose a significant threat to porous building stones because of the expansion and pressure generated during crystallization. The capillary rise of salt-laden liquids further contributes to the alteration of the pore system and formation of salt crystal coatings. Understanding the mechanisms and conditions leading to salt-induced deterioration is crucial for developing effective preservation and mitigation strategies for porous building materials.

Visual examination of tuff samples subjected to salt crystallization

Visual inspection is crucial for selecting natural building stones that satisfy the required grade and possess adequate durability for construction purposes. Therefore, it is paramount to examine natural building stone samples following aging tests. During the salt crystallization tests, namely the sodium sulfate test (Fig. 16) and sodium chloride test (Fig. 17), both untreated and treated tuff samples underwent regular visual inspections.

Visual inspection of untreated tuff samples subjected to salt crystallization tests revealed various signs of deterioration, including roughening, rounding, partial disintegration, fracturing, peeling, and scaling. These visual observations indicate that the untreated tuff specimens experienced partial damage and visible effects, such as rounding edges, which became evident after the 10th cycle. However, complete disintegration did not occur during the testing. Additionally, the formation of a whitish efflorescence on the untreated tuff samples was observed from the initial cycles, followed by pronounced rounding of edges and partial fractures in subsequent cycles. However, applying water-repellent chemicals to the tuff samples demonstrated their effectiveness in mitigating the destructive effects of salt crystallization.

The treated Döğer tuff samples exhibited smoother and cleaner surfaces overall, showing noticeable differences in surface appearance compared with the untreated samples. The significant reduction in visible deterioration demonstrated the protective value of water-repellent treatments. Photographic assessments further revealed that the tuff samples exposed to sodium sulfate solution experienced more severe damage than those exposed to sodium chloride solution. This suggests that sodium sulfate has a greater detrimental impact on tuff samples, highlighting the importance of considering the specific salt composition when assessing the potential damage to building materials.

The change in dry weight caused by salt crystallization

The extent of salt crystallization damage in porous stones is influenced by the pore size, porosity, salt type, evaporation, and movement of saline solutions. Porosity and salt damage are directly related, with higher porosity in natural building stones resulting in greater salt crystallization damage (Benavente et al. 2007). Salt damage to building stones is commonly expressed in terms of the dry weight change. In addition, the dry weight change, pore size range where salt precipitation occurs, crystallization pressure, and rock strength are significant factors in the deterioration caused by salt crystallization.

Figure 18 illustrates the variation in dry weight change (mean of ten samples) values in the untreated and water-repellent-treated Döğer tuff samples during the salt crystallization experiments. The results of the salt crystallization tests using sodium sulfate and sodium chloride solutions indicated minimal differences in the weight loss between the treated and untreated tuff samples. Specifically, in the sodium sulfate test, the untreated tuff samples exhibited a higher weight loss rate than the water-repellent-treated samples, which occurred primarily during the last two cycles. As the test cycles progressed, weight gain was observed in the untreated tuff samples exposed to salt solutions. Interestingly, the untreated tuff samples demonstrated a consistent increase in weight until the sixth cycle, followed by a gradual decrease starting from the ninth cycle and resulting in weight reduction from the 14th cycle onwards. The untreated tuff samples lost 2.02% of their weight in the sodium sulfate test, whereas the water-repellent-treated samples experienced a lower weight loss of 0.29%.

These findings align with the damage formation mechanism in the salt crystallization test proposed by Angeli et al. (2007). According to the experimental results, the untreated tuff samples exhibited a weight increase owing to salt intake during the first six cycles, representing the first stage of damage formation. This first stage continued until the ninth cycle, after which a second stage was observed, characterized by weight reduction from the ninth to the 13th cycle. After the 13th cycle, the third stage occurred, indicating a stable condition. In the sodium chloride solution, weight gain was observed until the fourth cycle, and subsequent weight changes fluctuated without significant variation until the 15th cycle. In the sodium chloride test, the accumulated salt in the untreated tuff samples compensated for weight loss, indicating a stable state after the 15th cycle. The untreated and water-repellent-treated tuff samples experienced a weight increase of 7.21% and 3.76%, respectively, in the sodium chloride test (Fig. 19). This weight increase was attributed to salt crystallization in the pore network of the Döğer tuff, resulting from the infiltration of the sodium chloride solution. Notably, the application of water-repellent chemicals provided significant protection and effectively reduced salt damage. Spry (1989) proposed a classification linking the weight loss observed after a sodium sulfate test with the durability of building stones. According to this classification, the tested Döğer tuff falls into the B-class, indicating “increased susceptibility to salt attack,” with a weight loss of 1–5%.

As reported in previous studies, damage was observed in untreated samples after completing the required cycles in the salt crystallization test using both salt solutions. Jamshidi et al. (2013) reported dry weight changes of 8.8% for ignimbrite and 20.1% for vitric tuff after 20 cycles of salt crystallization. Özşen et al. (2017) conducted a study on the weathering of pyroclastic rocks in Cappadocia, Turkey, and observed mass losses ranging from 5.29 to 86.21% due to salt crystallization. In the case of Oya tuff samples from Japan, Sato and Hattanji (2018) found that after 13 cycles with Na2SO4 solution, the samples disintegrated rapidly, resulting in a final weight of 43.8% of the original weight. Germinario and Török (2019) examined four Hungarian tuffs and found that the Sirok tuff experienced a mass reduction of 3–18% after up to 30 cycles.

The effect of salt crystallization on ultrasonic pulse velocity (UPV) values

The results of the salt crystallization test revealed a decrease in the ultrasonic pulse velocity (UPV) of all tuff samples (Fig. 20). The untreated tuff samples exhibited a substantial loss of approximately 125.92% in the UPV values after the Na2SO4 tests, indicating significant deterioration. In contrast, the water-repellent-treated tuff samples exhibited a much lower decrease of 9.32% after the Na2SO4 tests. This significant disparity in the UPV values between the untreated and treated samples can be attributed to the protective effect of the water-repellent material, which effectively sealed the pores of the tuff stones. Consequently, the treated tuff samples exhibited better resistance to the destructive effects of salt crystallization. The observed reduction in the UPV values of the untreated tuff samples can be attributed to the formation of microcracks induced by salt crystallization and subsequent weathering processes. The strain resulting from salt crystallization generates tensile stress within the pores and microcracks, forming new cracks or expanding existing ones, as described by Simão et al. (2015). These microcracks significantly contributed to the deterioration of the tuff samples and were reflected in the decreased UPV values.

The initial mean UPV of the untreated tuff samples was 2.36 km/s, which decreased to 1.44 km/s after the salt crystallization test, representing an average decrease of 64.24%. In contrast, the treated tuff samples exhibited a mean velocity of 2.36 km/s before the salt crystallization experiments using the NaCl solution. Following the test, the mean UPV decreased to 2.22 km/s, indicating a decrease of approximately 6.17%. The relatively smaller reduction in the UPV values for the treated samples indicates the effectiveness of the water-repellent treatment in mitigating salt solution absorption and limiting the deterioration caused by salt crystallization.

The effect of salt crystallization on uniaxial compression strength (UCS) values

The results of the UCS tests on the untreated and water-repellent-treated Döğer tuff samples revealed significant differences in the mean UCS loss values, depending on the type of salt used (Fig. 21). The untreated tuff samples exhibited a mean UCS loss of 72.58% when exposed to the sodium sulfate solution, whereas the loss was 36.71% when exposed to the NaCl solution. The variation in the UCS of the untreated tuff samples was attributed to the different degrees of damage caused by the type of salt. Weathering processes contribute to the deterioration of rock materials. In the tuff samples, weathering leads to increased porosity, resulting in higher absorption and decreased strength. Therefore, it is expected that untreated tuff samples would exhibit lower durability than treated tuff samples.

In contrast, the processed tuff samples treated with the water repellent showed relatively low UCS loss values after the salt crystallization test. The UCS value of the processed tuff samples decreased by only 5.61% in the sodium sulfate solution. In comparison, it increased by 1.79% in the Na2SO4 solution because of the protective effect of the water-repellent treatment. This suggests that the water-repellent treatment enhances the resistance of the tuff samples to salt crystallization and helps mitigate the detrimental effects on their uniaxial compression strength.

Comparing the change in the UCS of the Döğer tuff with other tuff specimens mentioned in the literature provided valuable insights into the degradation rates of different tuff types. Previous studies on volcanic tuff rocks have reported similar UCS values, indicating a certain level of consistency. For instance, Akin et al. (2017) noted that the tested tuff samples experienced a maximum decrease in strength of approximately 80% after the salt crystallization test, signifying a specific loss of integrity. Comparisons with other tuff specimens mentioned in literature support the notion that the degradation rates of different tuff types can vary.

The effect of salt crystallization on the pore size distribution (PSD)

Table 3 presents the mercury intrusion porosimetry (MIP) analysis results for the tested Döğer tuff samples, both under their initial conditions and following salt crystallization. The results obtained from the mercury intrusion porosimetry (MIP) analysis provided valuable insights into the behavior of Döğer tuff stones with respect to salt crystallization. According to the MIP data, the average pore diameter showed a reduction from 0.27 μm to 0.17 μm and 0.13 μm after subjecting the samples to Na2SO4 and NaCl tests, respectively. This decline in the mean pore diameter can be attributed to the infiltration of salt crystals into the micropores during the salt crystallization process, as observed by scanning electron microscopy (SEM). As a consequence of salt crystallization, the total porosity was reduced in weathered samples subjected to Na2SO4 and NaCl solutions. The total porosity of the weathered tuff samples decreased from 38.89% in the fresh sample to 36.68% in Na2SO4 solution and 33.01% in NaCl solution. Figure 22 shows that this decrease is primarily due to the filling of pores between 1 μm and 3 μm with salt crystals. Notably, the total pore area exhibited the most significant increase, with a porosity of 4.02%, which increased to 5.85% and 6.44% after sodium sulfate and chloride tests, respectively. This increase in the pore area can be attributed to the formation of new pores and microcracks induced by the crystallization process. As shown in Fig. 22, the pore size smaller than 0.1 μm increased from 5.96 to 9.22% and 12.97% owing to the formation of new pores during the sodium sulfate and salt chloride tests, respectively. According to Gómez-Heras et al. (2006), these newly formed micropores and microcracks are more susceptible to wetting-drying cycles and create favorable conditions for water condensation, thus promoting water-related degradation processes in the stone.

Table 4 displays the variation in particle size distribution (PSD) classification after the salt crystallization experiment on the Döğer tuff samples. The sodium sulfate test increased the PSD below 0.1 μm, while the PSD between 0.1 μm and 1 μm also exhibited growth. The PSD below 0.1 μm increased from 5.96 μm to 9.22 μm following the sodium sulfate test, while the PSD between 0.1 μm and 1 μm increased on average from 36.42 μm to 47.47 μm (Table 4). These pores exhibited growth rates of 54.73% and 30.34%, respectively. Pores larger than 1 μm decreased from 57.62 to 43.31%. The average pore ratio greater than 1 μm decreased by 24.84%, declining from 57.62 μm to 43.31 μm. The decrease in “pores larger than 1 µm” during the salt crystallization test indicated that these pores were filled with salt. The increase in pore sizes smaller than 1 μm can be attributed to transforming “pores larger than 1 µm” into smaller sizes due to partial salt filling. Likewise, the sodium chloride test exhibited comparable patterns, with an increase in pore sizes smaller than 1 μm and a decrease in sizes larger than 1 μm. In the sodium chloride test, the pore size rate smaller than 1 μm increased by 117.63%, the pore size rate between 0.1 μm and 1 μm increased by 20.62%, and the pore size rate larger than 1 μm decreased by 25.20%. Similar trends were observed in the sodium chloride test, with the pore size rate smaller than 1 μm increasing by 117.63%, the pore size rate between 0.1 μm and 1 μm increasing by 20.62%, and the pore size rate larger than 1 μm decreasing by 25.20%.

The vulnerability of building stones to salt crystallization attacks depends on the size of the micropores. Our findings agree with those of Yu and Oguchi (2010), suggesting that building stones with micropores larger than 1 μm are more susceptible to such attacks than those with micropores smaller than 0.1 μm. Smaller micropores play a critical role in increasing the crystallization pressure, while larger micropores ranging from 0.1 μm to 5 μm are more prone to salt absorption. The changes in porosity observed in this study are consistent with the findings reported by other researchers investigating the effects of salt crystallization on various building stones. López-Arce et al. (2010) studied the porosity and pore size distribution of Spanish granites exposed to salt crystallization. They reported a significant decrease in the proportion of pores with diameters ranging from 1 to 3 μm, accompanied by an increase in the proportion of pores with diameters between 3 and 10 μm. A new group of pores with sizes ranging from 5 to 10 μm appeared. These findings support the notion that salt crystallization induces changes in the pore structure of the building stones. Similarly, Torrero et al. (2014) examined the pore characteristics of limestone in Cuenca. Their results revealed a total porosity of 10 μm–20% and pore size intervals ranging from 0.1 μm to 10 μm. These studies provide additional evidence of the influence of salt crystallization on the porosity and pore size distribution of different types of stones.

Microstructural analysis by SEM after the salt crystallization test

SEM images of the surface of the Döğer tuff samples after 15 exposures to sodium sulfate are shown in Fig. 23. Microphotographs of the silane-treated tuff surface demonstrated a consistent and uniform coating of a water-repellent substance. This coating acted as a barrier, effectively impeding the further penetration of sodium sulfate solutions into the pores of the tuff material (Fig. 23c, d). However, it is worth noting that the solvent-based siloxane layer exhibited visible pores and microcracks, which ultimately reduced the overall effectiveness of the barrier. Despite the coating hindering the entry of salt solutions into the tuff pores, the surface textures of the volcanic glass fragments within the samples remained identifiable. Upon closer examination at a higher magnification, it became apparent that the gel layer enveloped the water-repellent agent and crystalline grains.

The SEM images in Fig. 24 illustrate the surface features of the Döğer tuff samples after exposure to NaCl for 15 cycles. The solvent evaporation process forms a film composed of polymerized water repellents on the tuff samples. This silane film is shown in Fig. 24c and d. The tuff samples were covered to prevent the infiltration of salt solutions into the tuff pores. However, it is important to note that the surface textures and volcanic glass fragments of the tuff remained discernible, despite the protective coating.

Comparison of salt mist and salt crystallization findings

The results of the untreated and water-repellent-treated samples aged with salt mist in this study were compared with those obtained from samples aged with salt crystallization. The impact and damage caused by different salt solutions and tests were evaluated by analyzing the obtained results.

The aging tests showed two distinct effects on the variation in dry weight change. On the one hand, the crystallization and accumulation of salts increased the weight of the samples. On the other hand, salt crystallization near the sample surface led to the detachment of small chips or flakes, decreasing the weight. Among the tested salts, sodium sulfate was highly damaging, causing the most significant deterioration in the salt crystallization test. Consequently, mass reductions of 2.02% and 0.29% were observed for untreated and treated tuff samples, respectively. Conversely, mass increases were observed in the salt mist and NaCl crystallization tests, with the salt crystallization test showing a greater mass increase than the salt mist test.

Furthermore, the comparison of both tests revealed similar reductions in ultrasonic pulse velocity (UPV) for the water-repellent-treated samples, as indicated by the findings from the salt mist and salt crystallization tests. Specifically, the UPV values decreased by 6.97%, 8.90%, and 5.93% in the salt mist, Na2SO4 crystallization, and NaCl crystallization tests, respectively. The average UPV value for fresh Döğer tuff samples in the salt mist test was measured at 2.44 km/h, whereas it decreased to 2.19 km/h for untreated samples after the test. The corresponding values for the sodium sulfate and chloride solutions were 1.04 km/h and 1.44 km/h, respectively. Consequently, the ultrasonic pulse velocity (UPV) values decreased by 10.25% in the salt mist test, 55.93% for sodium sulfate, and 38.98% for sodium chloride in the salt crystallization test. These results highlight that salt crystallization has a more detrimental effect on the UPV values than salt mist, with sodium sulfate being identified as the most damaging salt.

Moreover, the tuff samples’ uniaxial compressive strength (UCS) values of the tuff samples decreased following the salt mist and crystallization tests. The accumulation of salt crystals in the pores over time generated internal stress against the pore walls, resulting in the expansion of existing pores and formation of new microcracks, as observed in the SEM studies. The uniaxial compressive strength of the Döğer tuff samples, with an average value of 25.58 MPa, was determined to be 24.2 MPa for the untreated samples and 27.8 MPa for the treated samples after the salt mist test. In the untreated samples, the corresponding values for sodium sulfate and sodium chloride solutions decreased by 42.07% and 26.88%, respectively. These results support the widely accepted notion of the significant impact of sodium sulfate solution. In conclusion, this study provides valuable insights into the comparative effects of salt mist and salt crystallization aging on the deterioration of tuff samples. These results underscored the damaging influence of sodium sulfate and emphasized the importance of water-repellent treatments in mitigating the adverse effects of salt exposure.

In conclusion, while both salt mist and salt crystallization tests induce deterioration, salt crystallization, especially with sodium sulfate, has emerged as a more damaging process. This emphasizes the importance of considering specific salt types and testing conditions when assessing the effectiveness of protective measures against salt-induced deterioration of tuff samples.

Conclusions

The findings of this study can be summarized as follows. Investigating salt mist exposure and salt crystallization effects on Döğer tuff samples provides essential insights into porous building materials’ durability and preservation strategies in salt-laden environments. This study demonstrated the efficacy of water-repellent treatments in mitigating the detrimental effects of salt exposure, as evidenced by various analytical methods and visual inspection.

Visual examination following salt mist exposure revealed degradation and improved surface appearance in water-repellent-treated samples compared with untreated samples. The protective barrier created by the treatment minimized moisture and salt penetration, thereby reducing surface damage, erosion, and material loss. Moreover, the smoother and cleaner surfaces of the treated samples suggest the aesthetic preservation benefits associated with the treatment.

The change in dry weight due to salt mist exposure further supported the effectiveness of water-repellent treatments by reducing salt deposition and absorption in the treated samples. Microstructural analysis using SEM confirmed the presence of NaCl accumulation, with treated samples exhibiting less deposition than untreated samples.

Significant reductions in ultrasonic pulse velocity (UPV) and uniaxial compression strength (UCS) values following salt mist exposure highlighted structural degradation in the tuff samples. The observed decrease in the UPV and UCS values was attributed to the formation and propagation of cracks induced by salt exposure, emphasizing the vulnerability of untreated tuff to salt-induced deterioration.

Analysis of the pore size distribution (PSD) indicated that salt mist exposure decreased the pore diameter and total porosity, suggesting infiltration of salt crystals into the pores. Despite the water-repellent treatments, some microcracks were still present, indicating the need to further enhance the treatment effectiveness.

The salt crystallization experiments yielded similar results, with sodium sulfate causing more severe damage than sodium chloride. Visual inspection, changes in dry weight, reductions in UPV and UCS values, and alterations in PSD highlighted the negative impact of salt crystallization on the tuff samples.

In summary, the importance of water-repellent treatments for safeguarding porous building materials against salt exposure is underscored. The comparative analysis emphasized the damaging effects of sodium sulfate and the necessity for customized preservation approaches tailored to specific salt compositions encountered in various environments. These findings enhance our understanding of salt-induced deterioration mechanisms and aid in the development of preservation strategies for porous building materials, such as Döğer tuff.

References

Akin M, Özvan A, Dinçer İ, Topal T (2017) Evaluation of the physico-mechanical parameters affecting the deterioration rate of Ahlat ignimbrites (Bitlis, Turkey). Environ Earth Sci 76:827. https://doi.org/10.1007/s12665-017-7175-7

Alonso FJ, Vázquez P, Esbert RM, Ordaz J (2008) Ornamental granite durability: evaluation of damage caused by salt crystallization test. Mater Constr 58:191–202. https://doi.org/10.3989/mc.2008.v58.i289-290.78