Abstract

About 85 years have passed since the shaking culture was devised. Since then, various monitoring devices have been developed to measure culture parameters. O2 consumed and CO2 produced by the respiration of cells in shaking cultures are of paramount importance due to their presence in both the culture broth and headspace of shake flask. Monitoring in situ conditions during shake-flask culture is useful for analysing the behaviour of O2 and CO2, which interact according to Henry’s law, and is more convenient than conventional sampling that requires interruption of shaking. In situ monitoring devices for shake-flask cultures are classified as direct or the recently developed bypass type. It is important to understand the characteristics of each type along with their unintended effect on shake-flask cultures, in order to improve the existing devices and culture conditions. Technical developments in the bypass monitoring devices are strongly desired in the future. It is also necessary to understand the mechanism underlying conventional shake-flask culture. The existing shaking culture methodology can be expanded into next-generation shake-flask cultures constituting a novel culture environment through a judicious selection of monitoring devices depending on the intended purpose of shake-flask culture. Construction and sharing the databases compatible with the various types of the monitoring devices and measurement instruments adapted for shaking culture can provide a valuable resource for broadening the application of cells with shake-flask culture.

Similar content being viewed by others

References

Ahn WS, Jeon JJ, Jeong YR, Lee SJ, Yoon SK (2008) Effect of culture temperature on erythropoietin production and glycosylation in a perfusion culture of recombinant CHO cells. Biotechnol Bioeng 101:1234–1244

Amoabediny G, Büchs J (2010) Determination of CO2 sensitivity of micro-organisms in shaken bioreactors. I. Novel method based on the resistance of sterile closure. Biotechnol Appl Biochem 57:157–166

Amoabediny G, Abbas MP, Büchs J (2010) Determination of CO2 sensitivity of micro-organisms in shaken bioreactors. II. Novel online monitoring method. Biotechnol Appl Biochem 57:167–175

Anderlei T, Büchs J (2001) Device for sterile online measurement of the oxygen transfer rate in shaking flasks. Biochem Eng J 7:157–162

Anderlei T, Zang W, Papaspyrou M, Büchs J (2004) Online respiration activity measurement (OTR, CTR, RQ) in shake flasks. Biochem Eng J 17:187–194

Beutel S, Henkel S (2011) In situ sensor techniques in modern bioprocess monitoring. Appl Microbiol Biotechnol 91:1493–1505

Blombach B, Takors R (2015) CO2—intrinsic product, essential substrate, and regulatory trigger of microbial and mammalian production processes. Front Bioeng Biotechnol 3:108

Büchs J (2001) Introduction to advantages and problems of shaken cultures. Biochem Eng J 7:91–98

Büchs J, Maier U, Lotter S, Peter CP (2007) Calculating liquid distribution in shake flasks on rotary shakers at waterlike viscosities. Biochem Eng J 34:200–208

Burkholder PR, Sinnott EW (1945) Morphogenesis of fungus colonies in submerged shaken cultures. Am J Bot 32:424–431

Corman J, Tsuchiya HM, Koepsell HJ, Benedict RG, Kelley SE, Feger VH, Dworschack RG, Jackson RW (1957) Oxygen absorption rates in laboratory and pilot plant equipment. Appl Microbiol 5:313–318

Danielson PB, Büchs J, Stöckmann C, Fogleman JC (2004) Maximizing cell densities in miniprep-scale cultures with H15 medium and improved oxygen transfer. Biochem Eng J 17:175–180

Dixon NM, Kell DB (1989) The inhibition by CO2 of the growth and metabolism of microorganisms. J Appl Bacteriol 67:109–136

Eibes GM, Lú-Chau TA, Ruiz-Dueñas FJ, Feijoo G, Martínez MJ, Martínez AT, Lema JM (2009) Effect of culture temperature on the heterologous expression of Pleurotus eryngii versatile peroxidase in Aspergillus hosts. Bioprocess Biosyst Eng 32:129–134

Eibl R, Kaiser S, Lombriser R, Eibl D (2010) Disposable bioreactors: the current state-of-the-art and recommended applications in biotechnology. Appl Microbiol Biotechnol 86:41–49

Falch EA, Heden CG (1963) Disposable shaker flasks. Biotechnol Bioeng 5:211–220

Farmer IS, Jones CW (1976) The effect of temperature on the molar growth yield and maintenance requirement of Escherichia coli W during aerobic growth in continuous culture. FEBS Lett 67:359–363

Finn RK (1954) Agitation-aeration in the laboratory and in industry. Bacteriol Rev 18:254–274

Flitsch D, Ladner T, Lukacs M, Büchs J (2016) Easy to use and reliable technique for online dissolved oxygen tension measurement in shake flasks using infrared fluorescent oxygen-sensitive nanoparticles. Microb Cell Factories 15:45

Freedman D (1970) Chapter VI the shaker in bioengineering. In: Norris JR, Ribbons DW (eds) Methods in microbiology. Academic, pp 175–185

Fujita M, Iwahori K, Tatsuta S, Yamakawa K (1994) Analysis of pellet formation of Aspergillus niger based on shear stress. J Ferment Bioeng 78:368–373

Gaden EL (1962) Improved shaken flask performance. Biotechnol Bioeng 4:99–103

Garcia-Ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27:153–176

Ge X, Rao G (2012) Real-time monitoring of shake flask fermentation and off gas using triple disposable noninvasive optical sensors. Biotechnol Prog 28:872–877

Gerhardt P, Gee LL (1946) Brucella suis in aerated broth culture I. Preliminary studies on growth assays, inoculum, and growth characteristics in an improved medium. J Bacteriol 52:261–269

Gupta A, Rao G (2003) A study of oxygen transfer in shake flasks using a non-invasive oxygen sensor. Biotechnol Bioeng 84:351–358

Hansen S, Kensy F, Käser A, Büchs J (2011) Potential errors in conventional DOT measurement techniques in shake flasks and verification using a rotating flexitube optical sensor. BMC Biotechnol 11:49

Henzler HJ, Schedel M (1991) Suitability of the shaking flask for oxygen supply to microbiological cultures. Bioprocess Eng 7:123–131

Hirata M, Ikeda M, Fukuda F, Abe M, Sawada H, Hashimoto S (2017) Effect of temperature on the production rates of methyl halides in cultures of marine proteobacteria. Mar Chem 196:126–134

Ikeno Y, Ozaki A (1967) Factors affecting oxygen transfer into shaken flask. Agric Biol Chem 32:912–915

Jensen AL, Schultz JS (1966) Apparatus for monitoring the oxygen uptake and carbon dioxide production of fermentations. Biotechnol Bioeng 8:539–548

Jones RP, Greenfield PF (1982) Effect of carbon dioxide on yeast growth and fermentation. Enzym Microb Technol 4:210–222

Junne S, Solymosi T, Oosterhuis N, Neubauer P (2013) Cultivation of cells and microorganisms in wave-mixed disposable bag bioreactors at different scales. Chem Ing Tech 85:57–66

Kantorowicz O (1951) Shaking apparatus for the aeration of bacterial cultures. J Gen Microbiol 5:276–278

Kanzaki H, Imura D, Sashida R, Kobayashi A, Kawazu K (1999) Effective production of dehydro cyclic dipeptide albonours in exhibiting pronuclear fusion inhibitory activity I. Taxonomy and fermentation. J Antibiot 52:1017–1022

Kato I (1998) Problems of shaking culture from the viewpoint of aeration effect and development of a novel shake flask [in Japanese]. University of Tsukuba, Dissertation

Kato I, Tanaka H (1998a) Development of a novel box-shaped shake flask with efficient gas exchange capacity. J Ferment Bioeng 85:404–409

Kato I, Tanaka H (1998b) Influence of CO2 ventilation on microbial cultivation in shake-flasks. Biotechnol Tech 12:325–328

Kato Y, Tada Y, Watanabe S, Nagatsu Y, Iwata S, Lee YS, Koh ST (2005) Mixing condition and solid-liquid and gas-liquid mass transfer in a shaking vessel with figure-eight motion [in Japanese]. Kagaku Kogaku Ronbunshu 31:394–398

Klöckner W, Büchs J (2012) Advances in shaking technologies. Trends Biotechnol 30:307–314

Kluyver AJ, Perquin LHC (1932) Methodology in the research of mold metabolism [in German]. Biochem Z 266:68–81

Kunerth W (1922) Solubility of CO2 and N2O in certain solvents. Phys Rev 19:512–524

Kybal J, Sikyta B (1985) A device for cultivation of plant and animal cells. Biotechnol Lett 7:467–470

Lattermann C, Büchs J (2015) Microscale and miniscale fermentation and screening. Curr Opin Biotechnol 35:1–6

Li C, Xia JY, Chu J, Wang YH, Zhuang YP, Zhang SL (2013) CFD analysis of the turbulent flow in baffled shake flasks. Biochem Eng J 70:140–150

Liu Y, Wang ZJ, Zhang JW, Xia JY, Chu J, Zhang SL, Zhuang YP (2016) Quantitative evaluation of the shear threshold on Carthamus tinctorius L. cell growth with computational fluid dynamics in shaken flask bioreactors. Biochem Eng J 113:66–76

Maier U, Büchs J (2001) Characterisation of the gas-liquid mass transfer in shaking bioreactors. Biochem Eng J 7:99–106

Marose S, Lindemann C, Ulber R, Scheper T (1999) Optical sensor systems for bioprocess monitoring. Trends Biotechnol 17:30–34

Mcdaniel LE, Bailey EG, Zimmerli A (1965) Effect of oxygen-supply rates on growth of Escherichia coli I. Studies in unbaffled and baffled shake flasks. Appl Microbiol 13:109–114

Mrotzek C, Anderlei T, Henzler H, Büchs J (2001) Mass transfer resistance of sterile plugs in shaking bioreactors. Biochem Eng J 7:107–112

Nickerson CA, Ott CM, Wilson JW, Ramamurthy R, Pierson DL (2004) Microbial responses to microgravity and other low-shear environments. Microbiol Mol Biol Rev 68:345–361

Osorio JG, Muzzio FJ (2015) Evaluation of resonant acoustic mixing performance. Powder Technol 278:46–56

Peter CP, Suzuki Y, Büchs J (2006) Volumetric power consumption in baffled shake flasks. Chem Eng Sci 61:3771–3779

Philip P, Meier K, Kern D, Goldmanns J, Stockmeier F, Bähr C, Büchs J (2017) Systematic evaluation of characteristics of the membrane-based fed-batch shake flask. Microb Cell Factories 16:122

Postigo MA, Katz M (1987) Solubility and thermodynamics of carbon dioxide in aqueous ethanol solutions. J Solut Chem 16:1015–1024

Reynoso-Cereceda GI, Garcia-Cabrera RI, Valdez-Cruz NA, Trujillo-Roldán MA (2016) Shaken flasks by resonant acoustic mixing versus orbital mixing: mass transfer coefficient k La characterization and Escherichia coli cultures comparison. Biochem Eng J 105:379–390

Running JA, Bansal K (2016) Oxygen transfer rates in shaken culture vessels from Fernbach flasks to microtiter plates. Biotechnol Bioeng 113:1729–1735

Ruottinen M, Bollok M, Kögler M, Neubauer A, Krause M, Hämäläinen ER, Myllyharju J, Vasala A, Neubauer P (2008) Improved production of human type II procollagen in the yeast Pichia pastoris in shake flasks by a wireless-controlled fed-batch system. BMC Biotechnol 8:33

Scheidle M, Klinger J, Büchs J (2007) Combination of on-line pH and oxygen transfer rate measurement in shake flasks by fiber optical technique and respiration activity monitoring system (RAMOS). Sensors 7:3472–3480

Schneider K, Schütz V, John GT, Heinzle E (2010) Optical device for parallel online measurement of dissolved oxygen and pH in shake flask cultures. Bioprocess Biosyst Eng 33:541–547

Schultz JS (1964) Cotton closure as an aeration barrier in shaken flask fermentations. Appl Microbiol 12:305–310

Shiota H, Sakaguchi KI (1950) Studies on the production of mold protease in the submerged culture part I [in Japanese]. Nippon Nogeikagaku Kaishi 23:426–429

Singh V (1999) Disposable bioreactor for cell culture using wave-induced agitation. Cytotechnology 30:149–158

Sumino Y, Sonoi K, Doi M (1993) Scale-up of purine nucleoside fermentation from a shaking flask to a stirred-tank fermentor. Appl Microbiol Biotechnol 38:581–585

Suresh S, Srivastava VC, Mishra IM (2009a) Critical analysis of engineering aspects of shaken flask bioreactors. Crit Rev Biotechnol 29:255–278

Suresh S, Srivastava VC, Mishra IM (2009b) Techniques for oxygen transfer measurement in bioreactors: a review. J Chem Technol Biotechnol 84:1091–1103

Takahashi M, Aoyagi H (2018) Effect of intermittent opening of breathable culture plugs and aeration of headspace on the structure of microbial communities in shake-flask culture. J Biosci Bioeng. https://doi.org/10.1016/j.jbiosc.2018.01.009

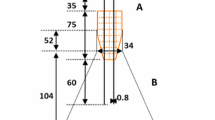

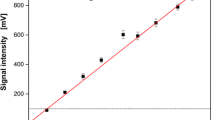

Takahashi M, Sawada Y, Aoyagi H (2017) Development of a circulation direct sampling and monitoring system for O2 and CO2 concentrations in the gas-liquid phases of shake-flask systems during microbial cell culture. AMB Express 7:163

Tanaka H, Ishikawa H, Nobayashi H, Takagi Y (1991) A new scale-up method based on the effect of ventilation on aerated fermentation systems. J Ferment Bioeng 72:204–209

Tolosa L, Kostov Y, Harms P, Rao G (2002) Noninvasive measurement of dissolved oxygen in shake flasks. Biotechnol Bioeng 80:594–597

Truesdale GA, Downing AL (1954) Solubility of oxygen in water. Nature 173:1236–1236

Tunac JB (1989) High-aeration capacity shake-flask system. J Ferment Bioeng 68:157–159

Ude C, Hentrop T, Lindner P, Lücking TH, Scheper T, Beutel S (2015) New perspectives in shake flask pH control using a 3D-printed control unit based on pH online measurement. Sensors Actuators B Chem 221:1035–1043

Ulber R, Frerichs JG, Beutel S (2003) Optical sensor systems for bioprocess monitoring. Anal Bioanal Chem 376:342–348

van Rensburg E, du Preez JC (2007) Effect of pH, temperature and nutrient limitations on growth and leukotoxin production by Mannheimia haemolytica in batch and continuous culture. J Appl Microbiol 102:1273–1282

Vansuijdam JC, Kossen NWF, Joha AC (1978) Model for oxygen transfer in a shake flask. Biotechnol Bioeng 20:1695–1709

Vasala A, Panula J, Bollók M, Illmann L, Hälsig C, Neubauer P (2006) A new wireless system for decentralised measurement of physiological parameters from shake flasks. Microb Cell Factories 5:8

Vergara M, Becerra S, Berrios J, Osses N, Reyes J, Rodríguez-Moyá M, Gonzalez R, Altamirano C (2014) Differential effect of culture temperature and specific growth rate on CHO cell behavior in chemostat culture. PLoS One 9:e93865

Vojinović V, Cabral JMS, Fonseca LP (2006) Real-time bioprocess monitoring Part I: In situ sensors. Sensors Actuators B Chem 114:1083–1091

Watanabe I, Okada S (1967) Effects of temperature on growth rate of cultured mammalian cells (L5178Y). J Cell Biol 32:309–323

Wittmann C, Kim HM, John G, Heinzle E (2003) Characterization and application of an optical sensor for quantification of dissolved O2 in shake-flasks. Biotechnol Lett 25:377–380

Yang T, Huang Y, Han Z, Liu H, Zhang R, Xu Y (2013) Novel disposable flexible bioreactor for Escherichia coli culture in orbital shaking incubator. J Biosci Bioeng 116:452–459

Yeh SY, Peterson RE (1964) Solubility of carbon dioxide, krypton, and xenon in aqueous solution. J Pharm Sci 53:822–824

Yoon SK, Kim SH, Lee GM (2003) Effect of low culture temperature on specific productivity and transcription level of anti-4-1BB antibody in recombinant Chinese hamster ovary cells. Biotechnol Prog 19:1383–1386

Zhang H, Williams-Dalson W, Keshavarz-Moore E, Shamlou PA (2005) Computational-fluid-dynamics (CFD) analysis of mixing and gas-liquid mass transfer in shake flasks. Biotechnol Appl Biochem 41:1–8

Acknowledgements

The manuscript has been edited by native English-speaking professional editors from Editage, a division of Cactus Communications.

Authors’ information

Masato Takahashi (postdoctoral researcher; research fellow of the Japan Society for the Promotion of Science). Faculty of Life and Environmental Sciences, University of Tsukuba, Tsukuba, Ibaraki 305-8572, Japan

Hideki Aoyagi (professor and principal investigator). Division of Life Sciences and Bioengineering, Graduate School of Life and Environmental Sciences and Faculty of Life and Environmental Sciences, University of Tsukuba, Tsukuba, Ibaraki 305-8572, Japan

Funding

This work was supported by a grant-in-aid for Japan Society for the Promotion of Science (JSPS) fellows (grant number 16J00800). This work was a funded by a JSPS KAKENHI (grant number 15H04569), JSPS KAKENHI Challenging Research [Exploratory] (grant number 17K19218), and the Sumitomo Electric Industries Group Corporate Social Responsibility Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

About this article

Cite this article

Takahashi, M., Aoyagi, H. Practices of shake-flask culture and advances in monitoring CO2 and O2. Appl Microbiol Biotechnol 102, 4279–4289 (2018). https://doi.org/10.1007/s00253-018-8922-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-018-8922-8