Abstract

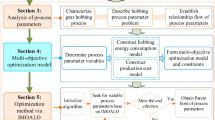

In modern machine tool design, precision is an important index to characterize machine tool performance and precision allocation has become a key task. Since the middle of the twentieth century, precision allocation methods using optimization technology to balance manufacturing cost and precision level have gradually developed, but most methods mainly take the cost minimization as the goal to optimize the precision allocation. As the precision and manufacturing costs are a pair of factors to be comprehensively considered, balance between them is needed to meet different design requirements. This paper proposes a comprehensive optimization method to trade-off between precision and cost. A multi-object precision allocation optimization model aiming at minimizing fuzzy manufacturing cost and comprehensive precision of machine tool is constructed. A multi-object optimization algorithm to solve the model is designed, combining the multi-objective gray wolf optimization algorithm with multi-objective decision analysis method Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS). A case study based on a large-scale hobbing machine shows that the comprehensive optimization of manufacturing cost and machining precision is realized by using the proposed multi-object precision allocation optimization method.

Similar content being viewed by others

Abbreviations

- \({S}_{x},{S}_{y},{S}_{z}\) :

-

Displacements of linear motion axes X, Y, and Z

- \({\theta }_{A},{\theta }_{C},{\theta }_{M}\) :

-

Rotation angles of rotating motion axes A, C, and M

- \({}_{X}\delta {}_{x}\left({S}_{x}\right),{}_{X}\delta {}_{y}\left({S}_{x}\right),{}_{X}\delta {}_{z}\left({S}_{x}\right)\) :

-

Position errors of axis X at \({S}_{x}\)

- \({}_{X}\varepsilon {}_{x}\left({S}_{x}\right),{}_{X}\varepsilon {}_{y}\left({S}_{x}\right),{}_{X}\varepsilon {}_{z}\left({S}_{x}\right)\) :

-

Angle errors of axis X at \({S}_{x}\)

- \({}_{Y}\delta {}_{x}\left({S}_{y}\right),{}_{Y}\delta {}_{y}\left({S}_{y}\right),{}_{Y}\delta {}_{z}\left({S}_{y}\right)\) :

-

Position errors of axis Y at \({S}_{y}\)

- \({}_{Y}\varepsilon {}_{x}\left({S}_{y}\right),{}_{Y}\varepsilon {}_{y}\left({S}_{y}\right),{}_{Y}\varepsilon {}_{z}\left({S}_{y}\right)\) :

-

Angle errors of axis Y at \({S}_{y}\)

- \({}_{Z}\delta {}_{x}\left({S}_{z}\right),{}_{Z}\delta {}_{y}\left({S}_{z}\right),{}_{Z}\delta {}_{z}\left({S}_{z}\right)\) :

-

Position errors of axis Z at \({S}_{z}\)

- \({}_{Z}\varepsilon {}_{x}\left({S}_{z}\right),{}_{Z}\varepsilon {}_{y}\left({S}_{z}\right),{}_{Z}\varepsilon {}_{z}\left({S}_{z}\right)\) :

-

Angle errors of axis Z at \({S}_{z}\)

- \({}_{A}\delta {}_{x}\left({\theta }_{A}\right),{}_{A}\delta {}_{y}\left({\theta }_{A}\right),{}_{A}\delta {}_{z}\left({\theta }_{A}\right)\) :

-

Position errors of axis A at \({\theta }_{A}\)

- \({}_{A}\varepsilon {}_{x}\left({\theta }_{A}\right),{}_{A}\varepsilon {}_{y}\left({\theta }_{A}\right),{}_{A}\varepsilon {}_{z}\left({\theta }_{A}\right)\) :

-

Angle errors of axis A at \({\theta }_{A}\)

- \({}_{C}\delta {}_{x}\left({\theta }_{C}\right),{}_{C}\delta {}_{y}\left({\theta }_{C}\right),{}_{C}\delta {}_{z}\left({\theta }_{C}\right)\) :

-

Position errors of axis C at \({\theta }_{C}\)

- \({}_{C}\varepsilon {}_{x}\left({\theta }_{C}\right),{}_{C}\varepsilon {}_{y}\left({\theta }_{C}\right),{}_{C}\varepsilon {}_{z}\left({\theta }_{C}\right)\) :

-

Angle errors of axis C at \({\theta }_{C}\)

- \({}_{M}\delta {}_{x}\left({\theta }_{M}\right),{}_{M}\delta {}_{y}\left({\theta }_{M}\right),{}_{M}\delta {}_{z}\left({\theta }_{M}\right)\) :

-

Position errors of axis M at \({\theta }_{M}\)

- \({}_{M}\varepsilon {}_{x}\left({\theta }_{M}\right),{}_{M}\varepsilon {}_{y}\left({\theta }_{M}\right),{}_{M}\varepsilon {}_{z}\left({\theta }_{M}\right)\) :

-

Angle errors of axis M at \({\theta }_{M}\)

- \({}_{X}{}^{C}\delta {}_{x},{}_{X}{}^{C}\delta {}_{y},{}_{X}{}^{C}\delta {}_{z}\) :

-

Position errors between X and C axes

- \({}_{X}{}^{C}\varepsilon {}_{x},{}_{X}{}^{C}\varepsilon {}_{y},{}_{X}{}^{C}\varepsilon {}_{z}\) :

-

Angle errors between X and C axes

- \({}_{Z}{}^{X}\delta {}_{x},{}_{Z}{}^{X}\delta {}_{y},{}_{Z}{}^{X}\delta {}_{z}\) :

-

Position errors between Z and X axes

- \({}_{Z}{}^{X}\varepsilon {}_{x},{}_{Z}{}^{X}\varepsilon {}_{y},{}_{Z}{}^{X}\varepsilon {}_{z}\) :

-

Angle errors between Z and X axes

- \({}_{A}{}^{Z}\delta {}_{x},{}_{A}{}^{Z}\delta {}_{y},{}_{A}{}^{Z}\delta {}_{z}\) :

-

Position errors between A and Z axes

- \({}_{A}{}^{Z}\varepsilon {}_{x},{}_{A}{}^{Z}\varepsilon {}_{y},{}_{A}{}^{Z}\varepsilon {}_{z}\) :

-

Angle errors between A and Z axes

- \({}_{Y}{}^{A}\delta {}_{x},{}_{Y}{}^{A}\delta {}_{y},{}_{Y}{}^{A}\delta {}_{z}\) :

-

Position errors between Y and A axes

- \({}_{Y}{}^{A}\varepsilon {}_{x},{}_{Y}{}^{A}\varepsilon {}_{y},{}_{Y}{}^{A}\varepsilon {}_{z}\) :

-

Angle errors between Y and A axes

- \({}_{M}{}^{Y}\delta {}_{x},{}_{M}{}^{Y}\delta {}_{y},{}_{M}{}^{Y}\delta {}_{z}\) :

-

Position errors between M and Y axes

- \({}_{M}{}^{Y}\varepsilon {}_{x},{}_{M}{}^{Y}\varepsilon {}_{y},{}_{M}{}^{Y}\varepsilon {}_{z}\) :

-

Angle errors between M and Y axes

- \({M}_{\mathrm{1,2}},{M}_{\mathrm{2,3}},{M}_{\mathrm{3,4}},{M}_{\mathrm{4,5}},{M}_{\mathrm{5,6}},{M}_{\mathrm{6,7}}\) :

-

Motion transformation matrices

- \({E}_{\mathrm{1,2}}^{m},{E}_{\mathrm{2,3}}^{m},{E}_{\mathrm{3,4}}^{m},{E}_{\mathrm{4,5}}^{m},{E}_{\mathrm{5,6}}^{m},{E}_{\mathrm{6,7}}^{m}\) :

-

Motion axis error transformation matrices

- \({E}_{C,X}^{P},{E}_{X,Z}^{P},{E}_{Z,A}^{P},{E}_{A,Y}^{P},{E}_{Y,M}^{P}\) :

-

Inter axis error transformation matrices

- \({M}_{\mathrm{1,7}}\) :

-

Ideal motion transformation matrix of hobbing

- \({M}_{\mathrm{1,7}}^{e}\) :

-

Motion transformation matrix of hobbing considering errors

- \(E\) :

-

Total error matrix of hobbing machine

- \(\delta x,\delta y,\delta z,\varepsilon x,\varepsilon y,\varepsilon z\) :

-

Total errors of hobbing machine

- \({\sigma }_{\delta x},{\sigma }_{\delta y},{\sigma }_{\delta z},{\sigma }_{\varepsilon x},{\sigma }_{\varepsilon y},{\sigma }_{\varepsilon z}\) :

-

Error distribution variances

- \({I}_{\delta x},{I}_{\delta y},{I}_{\delta z},{I}_{\varepsilon x},{I}_{\varepsilon y},{I}_{\varepsilon z}\) :

-

Precisions at \(3\sigma\)

- \({F}_{X},{F}_{Y},{F}_{Z},{F}_{A},{F}_{C},{F}_{M},F{A}_{ij}\) :

-

Fuzzy manufacturing costs of moving axes

- \(a,b,c,d,{m}_{ij}\) :

-

Precision-cost function coefficients

- \(F\left(Error\right)\) :

-

Fuzzy cost optimization objective

- \(Ip\left(Error\right),Ia\left(Error\right)\) :

-

Precision optimization objectives

- \({W}_{Ip},{W}_{Ia},{W}_{F}\) :

-

Optimize decision weights

References

Hongliang S, Wenyun Y (1990) Development direction and key of precision distribution theory for modern mechanism. Optical technology 5:33–36

Hallmann M, Schleich B, Wartzack S (2020) From tolerance allocation to tolerance-cost optimization: a comprehensive literature review. Int J Adv Manuf Technol 107(1):1–54. https://doi.org/10.1007/s00170-020-05254-5

Hongliang S, Wenyun Y (1991) Value analysis method of mechanism precision distribution. Optical technology 05:3–6

Dong Z, Hu W, Xue D (1994) New production cost-tolerance models for tolerance synthesis. Asme J Eng Industry 116(2):199–206. https://doi.org/10.1115/1.2901931

Feng CX, Robust KA (1997) Tolerance design with the integer programming approach. J Manuf Sci Eng 119(4A):603. https://doi.org/10.1115/1.2831193

Diplaris SC, Sfantsikopoulos MM (2000) Cost-tolerance function. A new approach for cost optimum machining accuracy. Int J Adv Manuf Technol 16(1):32–38

Rao S, Wu W (2005) Optimum tolerance allocation in mechanical assemblies using an interval method. Eng Optim 37(3):237–257. https://doi.org/10.1080/0305215512331328240

Krishna AG, Rao KM (2006) Simultaneous optimal selection of design and manufacturing tolerances with different stack-up conditions using scatter search. Int J Adv Manuf Technol 30(3–4):328–333. https://doi.org/10.1007/s00170-005-0059-0

Huang X , Ding W , Hong R . (2006) Research on accuracy design for remanufactured machine tools International Technology & Innovation Conference., Hangzhou

Fang K, fan Jinwei. (2008) Optimal allocation method for manufacturing precision of CNC machine tools. Mech Sci Technol 27(5):588–591

Muthu P, Dhanalakshmi V, Sankaranarayanasamy K (2009) Optimal tolerance design of assembly for minimum quality loss and manufacturing cost using metaheuristic algorithms. Int J Adv Manuf Technol 44(11–12):1154–1164. https://doi.org/10.1007/s00170-009-1930-1

Sanz-Lobera A, Sebastián MA, Pérez JM (2010) New cost-tolerance model for mechanical part design. Int J Adv Manuf Technol 51(5–8):421–430. https://doi.org/10.1007/s00170-010-2661-z

Sarina ZS, Xu J (2013) Transmission system accuracy optimum allocation for multiaxis machine tools’ scheme design. Proc Ins Mech Eng, Part C: J Mech Eng Sc 227(12):2762–2779. https://doi.org/10.1177/0954406213479723

Yu Z, Liu Z, AI Y et al (2013) Geometric error modeling and precision allocation based on reliability theory for large CNC gantry guide rail grinder. J Mech Eng 49(17):142–151. https://doi.org/10.3901/JME.2013.17.142

Yuan X, Lianhong Z, Baiyan HE et al (2014) Precision inverse design method for CNC machine tools based on multi-body theory. J Agric Mach 45(3):282–287

Cai L, Zhang Z, Cheng Q et al (2015) A geometric accuracy design method of multi-axis NC machine tool for improving machining accuracy reliability. Eksploatacja i Niezawodnosc - Maint Reliab 17(1):143–155

Cheng Q, Zhang Z, Zhang G et al (2015) Geometric accuracy allocation for multi-axis CNC machine tools based on sensitivity analysis and reliability theory. Proc Inst Mech Eng C J Mech Eng Sci. https://doi.org/10.1177/0954406214542491

Guo J, Liu Z, Li B et al (2015) Optimal tolerance allocation for precision machine tools in consideration of measurement and adjustment processes in assembly. Int J Adv Manuf Technol 80(9–12):1625–1640. https://doi.org/10.1007/s00170-015-7122-2

Yang Z, Zhu Y, Ren H et al (2015) Comprehensive reliability allocation method for CNC lathes based on cubic transformed functions of failure mode and effects analysis. Chinese J Mech Eng 28:315–324. https://doi.org/10.3901/CJME.2015.0105.004

Zhao YM, Liu DS, Wen ZJ (2016) (2016) Optimal tolerance design of product based on service quality loss. Int J Adv Manuf Technol 82(9–12):1715–1724. https://doi.org/10.1007/s00170-015-7480-9

Zhang Y, Ji S, Zhao J et al (2016) Tolerance analysis and allocation of special machine tool for manufacturing globoidal cams. Int J Adv Manuf Technol 87:1597–1607. https://doi.org/10.1007/s00170-016-8558-8

Zhang Z, Liu Z, Cai L et al (2017) An accuracy design approach for a multi-axis NC machine tool based on reliability theory. Int J Adv Manuf Technol 91:1547–1566. https://doi.org/10.1007/s00170-016-9824-5

Peng L, Jun H, Zhigang L et al (2016) Research on machine tool tolerance allocation using adaptive genetic algorithm. J Xi’an Jiaotong Univ 50(1):115–123. https://doi.org/10.1007/s00170-016-8981-x

Cai L, Zhang Z, Qiang C et al (2016) An approach to optimize the machining accuracy retainability of multi-axis NC machine tool based on robust design. Precis Eng 43:370–386. https://doi.org/10.1016/j.precisioneng.2015.09.001

Zhang Z, Cai L, Cheng Q et al (2016) A geometric error budget method to improve machining accuracy reliability of multi-axis machine tools. J Intell Manuf 30:495–519. https://doi.org/10.1007/s10845-016-1260-8

Balamurugan C, Saravanan A, Babu PD et al (2016) Concurrent optimal allocation of geometric and process tolerances based on the present worth of quality loss using evolutionary optimisation techniques. Res Eng Design 28(2):1–18. https://doi.org/10.1007/s00163-016-0230-7

Bin CB, Huang Mei FA, Yue WZ et al (2016) Optimal allocation of assembly tolerance based on actual working conditions. Mech Des Res 32(2):123–126

Zhang Z, Liu Z, Cheng Q et al (2017) An approach of comprehensive error modeling and accuracy allocation for the improvement of reliability and optimization of cost of a multi-axis NC machine tool. Int J Adv Manuf Technol 89:561–579. https://doi.org/10.1007/s00170-016-8981-x

Tlija M, Ghali M, Aifaoui N (2019) Integrated CAD tolerancing model based on difficulty coefficient evaluation and Lagrange multiplier. Int J Adv Manuf Technol 101:2519–2532. https://doi.org/10.1007/s00170-018-3140-1

Wang H, Li T-J, Ding X-H (2021) Tolerance analysis of the volumetric error of heavy-duty machine tool based on interval uncertainty. Int J Adv Manuf Technol 114:2185–2199. https://doi.org/10.1007/s00170-021-06941-7

He C, Zhang S, Qiu L et al (2020) Statistical tolerance allocation design considering form errors based on rigid assembly simulation and deep Q-network. Int J Adv Manuf Technol 111(11–12):1–17. https://doi.org/10.1007/s00170-020-06283-w

Fan J, Tao H, Pan R et al (2020) (2020) Optimal tolerance allocation for five-axis machine tools in consideration of deformation caused by gravity. Int J Adv Manuf Technol 111(1–2):1–12. https://doi.org/10.1007/s00170-020-06096-x

Hocken RJ, Simpson JA, Borchardt B, Lazar J, Reeve C, Stein P (1977) Three dimensional metrology. Journal of Ann CIRP 26(2):403–408

Dufour P, Groppetti R (2006) Computer aided precision improvement in large NC machine-tools. Proc 2006 Int Conference MTDR 22:611–618

Portman VT (1982) A universal method for calculating the precision of mechanical devices. J Sov Eng Res 1(7):11–15

Kiridena V, Ferreira PM (1993) Mapping the effects of positioning errors on the volumetric precision of five-axis CNC machine tools. Int J Mach Tools Manuf 33(3):417–437

Guoqiang Fu (2016) Research on geometric error modeling and compensation of CNC machine tools based on the product-of-exponential theory and transforming differential changes between coordinate frames. Zhenjiang University, Hangjou

Jianxiong C, Shuwen L (2014) Geometric error decoupling for multi-axis CNC machines based on differential transformation. China Mech Eng 25(17):2290–2294

Wang SX, Yun JT, Zhang ZF (2003) Modeling and compensation technique for the geometric errors of five-axis CNC machine tools. Chin J Mech Eng 16:197–201

Shi XL, Liu HL, Li H, Liu C, Tan GY (2016) Comprehensive error measurement and compensation method for equivalent cutting forces. Int J Adv Manuf Technol 85(1–4):149–156. https://doi.org/10.1007/s00170-015-7789-4

Shi YG, Zhao XY, Zhang HJ, Nie YX, Zhang DW (2016) A new top-down design method for the stiffness of precision machine tools. Int J Adv Manuf Technol 83(9–12):1887–1904. https://doi.org/10.1007/s00170-015-7705-y

Sun S, Wang S, Wang Y, Lim TC, Yang Y (2018) Prediction and optimization of hobbing gear geometric deviations. Mech Mach Theory 120:288–301. https://doi.org/10.1016/j.mechmachtheory.2017.09.002

Qiang, C., Wu, C., Gu, P., Chang, W., & Xuan, D. (2013) An analysis methodology for stochastic characteristic of volumetric error in multiaxis cnc machine tool. Math Problems Eng,2013,(2013–10–21), 2013(pt.11), -. https://doi.org/10.1155/2013/863283

Cheng Q, Zhao HW, Zhang GJ, Gu PH, Cai LG (2014) An analytical approach for crucial geometric errors identification of multiaxis machine tool based on global sensitivity analysis. Int J Adv Manuf Technol 75(1):107–121. https://doi.org/10.1007/s00170-014-6133-8

Guo S, Jiang G, Me X (2017) Investigation of sensitivity analysis and compensation parameter optimization of geometric error for five-axis machine tool. Int J Adv Manuf Technol 93:3229–3243. https://doi.org/10.1007/s00170-017-0755-6

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer. Adv Eng Softw 69:46–61

Mirjalili S, Saremi S, Mirjalilic SM et al (2015) Multi-objective grey wolf optimizer: a novel algorithm for multi-criterion optimization. Expert Syst Appl 47:106–119. https://doi.org/10.1016/j.eswa.2015.10.039

Funding

This work was supported by the Key Project of National Natural Science Foundation of China (Grant No. 51635003).

Author information

Authors and Affiliations

Contributions

Zongyan Hu contributed to the conception of the study and wrote the manuscript. Shilong Wang contributed to the conception of the study, funding acquisition, and supervision. Chi Ma contributed to analysis and manuscript review.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, Z., Wang, S. & Ma, C. Precision allocation method of large-scale CNC hobbing machine based on precision-cost comprehensive optimization. Int J Adv Manuf Technol 126, 3453–3474 (2023). https://doi.org/10.1007/s00170-023-11303-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11303-6