Abstract

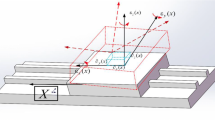

To improve the accuracy of five-axis machine tool with a swiveling head, an approach for optimizing compensation values taking into account the sensitivity of position-independent geometric error is proposed in this paper. At first, the synthetic volumetric error model of five-axis machine tool has been established with homogeneous transformation method and multibody system theory, which describes the effect of geometric error components on position and orientation error vector intuitively. Second, the probability distributions of geometric errors in workspace of machine tool are sufficiently taken into account in order to overcome the defects of the analysis at certain locations, and then, global quantitative sensitivity analysis is introduced for determining the effect of each geometric error on precision of machine tool. Next, the optimum values are obtained by multiobjective quality loss and precision robustness trade-offs based on archive-based microgenetic algorithm (AMGA) for geometric error compensation. Finally, the geometric error compensation experiments were carried out, and the results show that the accuracy of measuring trajectories are improved significantly, which reaches 73.7% after error compensation with optimum values based on sensitivity analysis. Hence, the proposed methodology of analysis and compensation are effective for analyzing the effect of geometric errors and improving the precision of machine tool.

Similar content being viewed by others

References

Ni J (1997) CNC machine accuracy enhancement through real-time error compensation. ASME J Manuf Sci Eng 119:717–725

Li T, Li F, Jiang Y, Wang H (2017) Thermal error modeling and compensation of a heavy gantry-type machine tool and its verification in machining. Int J Adv Manuf Technol. doi:10.1007/s00170-017-0353-7

Lee HH, Son JG, Yang SH (2017) Techniques for measuring and compensating for servo mismatch in machine tools using a laser tracker. Int J Adv Manuf Technol. doi:10.1007/s00170-017-0382-2

Wang JD, Guo JJ (2013) Algorithm for detecting volumetric geometric accuracy of NC machine tool by laser tracker. Chin J Mec Eng 26(1):166–175

Shen HY, Fu JZ, He ZY, Yao XY (2012) On-line asynchronous compensation methods for static/quasi-static error implemented on CNC machine tools. Int J Mach Tools Manuf 60:14–26

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann-Manuf Technol 57(2):660–675

ISO 230–7 (2015) Test code for machine tool-part 7: geometric accuracy of axes of rotation, ISO

Lee KI, Yang SH (2013) Robust measurement method and uncertainty analysis for position-independent geometric errors of a rotary axis using a double ball-bar. Int J Precis Eng Manuf 14(2):231–239

Zargarbashi SHH, Mayer JRR (2009) Single setup estimation of a five-axis machine tool eight link errors by programmed end point constraint and on the fly measurement with Capball sensor. Int J Mach Tools Manuf 49(10):759–766

Tsutsumi M, Saito A (2003) Identification and compensation of systematic deviations particular to 5-axis machining centers. Int J Mach Tools Manuf 43(8):771–780

Lasemi A, Xue DY, Gu PH (2016) Accurate identification and compensation of geometric errors of 5-axis CNC machine tools using double ball bar. Meas Sci Technol 27(5):055004

Andolfatto L, Lavernhe S, Mayer JRR (2011) Evaluation of servo, geometric and dynamic error sources on five axis high-speed machine tool. Int J Mach Tools Manuf 51(10):787–796

Ramesh R, Mannan M, Poo A (2000) Error compensation in machine tools—a review: part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Uddin MS, Ibaraki S, Matsubara A, Matsushita T (2009) Prediction and compensation of machining geometric errors of five-axis machining centers with kinematic errors. Precis Eng 33(2):194–201

Schultschik R (1977) The components of the volumetric accuracy. CIRP Ann 25(1):223–228

Lin Y, Shen Y (2003) Modelling of five-axis machine tool metrology models using the matrix summation approach. Int J Adv Manuf Technol 21(4):243–248

Lee KI, Lee DM, Yang S-H (2012) Parametric modeling and estimation of geometric errors for a rotary axis using double ball-bar. Int J Adv Manuf Technol 62(5–8):741–750

Mir YA, Mayer JRR, Fortin C (2002) Tool path error prediction of a five-axis machine tool with geometric errors. Proc Inst Mech Eng B J Eng Manuf 216(5):697–712

Fu GQ, Fu JZ, Xu YT, Chen ZC, Lai JT (2015) Accuracy enhancement of five-axis machine tool based on differential motion matrix: geometric error modeling, identification and compensation. Int J Mach Tools Manuf 89:170–181

Xiang ST, Altintas Y (2015) Modeling and compensation of volumetric errors for five-axis machine tools. Int J Mach Tools Manuf 101:65–78

Moon SK, Moon YM, Kota S, Landers RG (2001) Screw theory based metrology for design and error compensation of machine tools. In Proceedings of the ASME 2001 Design Engineering Technical Conferences (DETC 2001), Pittsburgh, Pennsylvania, September 2001

Fu GQ, Fu JZ, Shen HY, Xu YT, Jin YA (2015) Product-of-exponential formulas for precision enhancement of five-axis machine tools via geometric error modeling and compensation. Int J Adv Manuf Technol 81(1):289–305

Cheng Q, Wu C, Gu PH, Chang WF, Xuan DS (2013) An analysis methodology for stochastic characteristic of volumetric error in multiaxis CNC machine tool. Math Probl Eng 2013:863283

Cheng Q, Sun BW, Liu ZF, Li JY, Dong XM, Gu PH (2017) Key geometric error extraction of machine tool based on extended Fourier amplitude sensitivity test method. Int J Adv Manuf Technol 90(9):3369–3385

Saltelli A, Tarantola S, Campolongo F, Ratto M (2004) Sensitivity analysis in practice: a guide to assessing scientific models. John Wiley and Sons, New York

Kato N, Sato R, Tsutsumi M (2013) Analysis of circular trajectory equivalent to cone-frustum milling in five-axis machining centers using motion simulator. Int J Mach Tools Manuf 64(4):1–11

Lei WT, Wang WC, Fang TC (2014) Ballbar dynamic tests for rotary axes of five-axis CNC machine tools. Int J Mach Tools Manuf 82:29–41

Zargarbashi SHH, Mayer JRR (2006) Assessment of machine tool trunnion axis motion error, using magnetic double ball bar. Int J Mach Tools Manuf 46(14):1823–1834

Lee RS, Lin YH (2012) Applying bidirectional kinematics to assembly error analysis for five-axis machine tools with general orthogonal configuration. Int J Adv Manuf Technol 62(9–12):1261–1272

Yao HH, Li ZQ, Zhao XS, Sun T, Dobrovolskyi G, Li G (2016) Modeling of kinematics errors and alignment method of a swing arm ultra-precision diamond turning machine. Int J Adv Manuf Technol 87(1):165–176

Cheng Q, Zhao HW, Zhang GJ, Gu PH, Cai LG (2014) An analytical approach for crucial geometric errors identification of multi-axis machine tool based on global sensitivity analysis. Int J Adv Manuf Technol 75(1):107–121

Chen GD, Liang YC, Sun YZ, Chen WQ, Wang B (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68(9):2525–2534

Zhang XF, Zhang YM, Pandey MD (2015) Global sensitivity analysis of a CNC machine tool: application of MDRM. Int J Adv Manuf Technol 81(1):159–169

Peng FY, Ma JY, Wang W, Duan XY, Sun PP, Yan R (2013) Total differential methods based universal post processing algorithm considering geometric error for multi-axis NC machine tool. Int J Mach Tools Manuf 70:53–62

Nojedeh MV, Habibi M, Arezoo B (2011) Tool path accuracy enhancement through geometrical error compensation. Int J Mach Tools Manuf 51(6):471–482

Lei WT, Sung MP (2008) NURBS-based fast geometric error compensation for CNC machine tools. Int J Mach Tools Manuf 48(3):307–319

Tsutsumi M, Tone S, Kato N, Sato R (2013) Enhancement of geometric accuracy of five-axis machining centers based on identification and compensation of geometric deviations. Int J Mach Tools Manuf 68:11–20

Bi QZ, Huang ND, Sun C, Wang YH, Zhu LM, Ding H (2015) Identification and compensation of geometric errors of rotary axes on five-axis machine by on-machine measurement. Int J Mach Tools Manuf 89:182–191

Givi M, Mayer JRR (2016) Optimized volumetric error compensation for five-axis machine tools considering relevance and compensability. CIRP J Manuf Sci Technol 12:44–55

Fu GQ, Fu JZ, Shen HY, Yao XH, Chen ZC (2015) NC codes optimization for geometric error compensation of five-axis machine tools with one novel mathematical model. Int J Adv Manuf Technol 80(9):1879–1894

Chen JX, Lin SW (2017) An error compensation scheme for multi-axis machine tool using machining method template. Int J Adv Manuf Technol 90(9):3013–3023

Ding S, Huang XD, Yu CJ, Liu XY (2016) Novel method for position-independent geometric error compensation of five-axis orthogonal machine tool based on error motion. Int J Adv Manuf Technol 83(5–8):1069–1078

Ibaraki S, Iritani T, Matsushita T (2012) Calibration of location errors of rotary axes on five-axis machine tools by on-the-machine measurement using a touch-trigger probe. Int J Mach Tools Manuf 58:44–53

ISO 230-1 (2012) Test code for machine tools-part 1: geometric accuracy of machines operating under no-load or quastic-static conditions. ISO

Houston R, Liu YW (1991) Multi-body system dynamics. Tianjin University Press, Tianjin

ISO 10791-6 (2014) Test conditions for machining centres. Part 6 Accuracy of speeds and interpolation. ISO

Pianosi F, Sarrazin F, Wagener T (2015) A matlab toolbox for global sensitivity analysis. Environ Model Softw 70:80–85

Saltelli A, Tarantola S, Chan KS (1999) A quantitative model-independent method for global sensitivity analysis of model output. Technometrics 41(1):39–56

Kalpakjian S (2009) Manufacturing engineering and technology. Prentice Hall, New Jersey

Jiang ZX, Tang XQ, Zhou XD, Zheng SQ (2015) Machining tests for identification of location errors on five-axis machine tools with a tilting head. Int J Adv Manuf Technol 79(1–4):245–254

Ibaraki S, Sawada M, Matsubara A, Matsushita T (2010) Machining tests to identify kinematic errors on five-axis machine tools. Precis Eng 34(3):387–398

Chen LZ (2000) Robust design. China Machine Press, Bei Jing

Taguchi G (1986) Introduction to quality engineering. Asian Productivity Organization, Tokyo

Tian MS, Gong XY, Yin L, Li HZ, Ming WY, Zhang Z, Chen JH (2016) Multi-objective optimization of injection molding process parameters in two stages for multiple quality characteristics and energy efficiency using Taguchi method and NSGA-II. Int J Adv Manuf Technol 89(1):241–254

Tiwari S, Koch P, Fadel G, Deb K (2008) AMGA: an archive-based micro genetic algorithm for multi-objective optimization. In Proceedings of the 10th annual conference on genetic and evolutionary computation, (GECCO 2008), Atlanta, July 2008

China S. A 10791-2 (2007) The 5-axes simultaneous vertical machining centers-part 1: testing of the accuracy, in Chinese

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Guo, S., Jiang, G. & Mei, X. Investigation of sensitivity analysis and compensation parameter optimization of geometric error for five-axis machine tool. Int J Adv Manuf Technol 93, 3229–3243 (2017). https://doi.org/10.1007/s00170-017-0755-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0755-6