Abstract

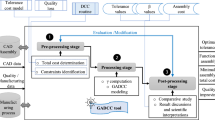

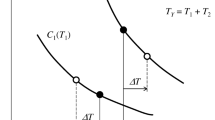

Tolerance allocation is a design tool for reducing overall cost of manufacturing while meeting target levels for quality. An important consideration in product design is the assignment of design and manufacturing tolerances to individual component dimensions so that the product can be produced economically and functions properly. The allocation of tolerances among the components of a mechanical assembly can significantly affect the resulting manufacturing costs. In this work, the tolerance allocation problem is formulated as a non-linear integer model by considering both the manufacturing cost of each component by alternate processes and the quality loss of assemblies so as to minimise the manufacturing cost. Metaheuristics techniques such as genetic algorithm and particle swarm optimisation are used to solve the model and obtain the global optimal solution for tolerance design. An example for illustrating the optimisation model and the solution procedure is provided. Results are compared with conventional technique and the performances are analysed.

Similar content being viewed by others

References

Hong YS, Chang TC (2002) A comprehensive review of tolerancing research. Int J Prod Res 40(11):2425–2459

Sfantsikopoulos MM (1990) A cost-tolerance analytical approach for design and manufacturing. Int J Adv Manuf Technol 5:126–134. doi:10.1007/BF02601602

Choi R, Park M-H, Salisbury E (2000) Optimal tolerance allocation with loss functions. J Manuf Sci Eng 22(3):529–535. doi:10.1115/1.1285918

Smathers W, Ostwald PF (1972) Optimization of component functional dimensions and tolerances. ASME, 72 -DE-18

Dresner TL (1993) Optimal tolerance allocation for tolerance stack-ups. Adv Des Autom 2:167–174

Wilde D (1975) Simplifying discrete tolerance assignment. ASME, 75-DET-106

Ostwald PF, Huang J (1977) A method for optimal tolerance selection. J Eng Ind Trans ASME 99(2):558–565

Ngoi KA, Teck OC (1997) A tolerancing optimization method for product design. Int J Adv Manuf Technol 13(4):290–299

Ye B, Salustri FA (2003) Simultaneous tolerance synthesis for manufacturing and quality. Res Eng Des 14(2):98–106

Krishna G, Mallikarjuna Rao K (2006) Simultaneous optimal selection of design and manufacturing tolerances with different stack-up conditions using scatter search. Int J Adv Manuf Technol 30(3–4):328–333. doi:10.1007/s00170-005-0059-0

Lee WJ, Woo TC (1989) Optimal selection of discrete tolerance. J Mech. Transm Auto Des Trans ASME. 111(2):243–251

Chase KW, Greenwood WH, Loosli B, Hauglund LF (1990) Least cost tolerance allocation for Mechanical assemblies with automated process selection. Manuf Rev 3(1):49–59

Chen B, Maghsoodloo S (1995) optimization of mechanical assembly tolerances by incorporating Taguchi’s quality loss function. J Manuf Syst 14(4):264–276

Ji S, Li X, Ma Y, Cai H (2000) Optimal tolerance allocation based on fuzzy comprehensive evaluation and genetic algorithm. Int J Adv Manuf Technol 16:461–468. doi:10.1007/s001700070053

Nassef AO, Elmaraghy HA (1997) Allocation of geometric tolerances: New criterion and methodology. Ann CIRP 46:101–106

Chen TC, Fischer W (2000) A GA-based search method for the tolerance allocation problem. Artif Intell Eng 14(2):133–141. doi:10.1016/S0954-1810(00)00006-6

Singh PK, Jain SC, Jain PK (2003) Tolerance allocation with alternative manufacturing processes-suitability of genetic algorithm. Int J Simul Model 2(1–2):22–34

Zhang C, Wang HP (1993) Integrated Tolerance Optimization with Simulated Annealing. Int J Adv Manuf Technol 8(3):167–174. doi:10.1007/BF01749907

Dupinet E, Balazinski M, Czogala E (1996) Tolerance allocation based on fuzzy logic and simulated annealing. J Intell Manuf 7(6):487–497. doi:10.1007/BF00122838

Kopardekar P, Anand S (1995) Tolerance allocation using neural networks. Int J Adv Manuf Technol 8(3):269–276

Chen MC (2001) Tolerance synthesis by neural learning and nonlinear programming. Int J Prod Econ 70(1):55–65. doi:10.1016/S0925-5273(00)00044-X

Wu Z, Elmaraghy WH, Elmaraghy HA (1988) Evaluation of cost-tolerance algorithms for design tolerance analysis and synthesis. Manuf Rev 1(3):168–179

Taguchi G, Elsayed EA, Hsiang TC (1989) Quality engineering in production systems. McGraw-Hill, New York

Goldberg DD (1989) Genetic algorithm search. Optimization and machine learning. Reading. MA: Addison-Wesly

Kennedy J, Eberhart R (1995) Particle swarm optimization. Proc IEEE Int Conf Neural Netw, Perth, Australia, pp 1942–1945

Kennedy J, Eberhart R (2001) Swarm intelligence, 1st edn. Academic Press, San Diego, CA

Fortini ET (1967) Dimensioning for interchangeable manufacturing. Industrial Press, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muthu, P., Dhanalakshmi, V. & Sankaranarayanasamy, K. Optimal tolerance design of assembly for minimum quality loss and manufacturing cost using metaheuristic algorithms. Int J Adv Manuf Technol 44, 1154–1164 (2009). https://doi.org/10.1007/s00170-009-1930-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-1930-1