Abstract

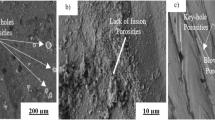

Commercial powders of magnesium were processed by high-energy ball milling (HEBM) using a two-stage composite process. The microstructural and morphological evolution of the powders was studied using scanning electron microscopy (SEM), energy-dispersive spectrometry (EDX), and X-ray diffraction (XRD). From the results obtained, it was determined that the energy transferred by means of the control of balls size and high milling speeds allowed the particles of Mg powder to deform and fracture, achieving grain refinement and particle size reduction in a relatively short time. Likewise, milling energy calculations were made to determine the effect of the milling parameters. Subsequently, milled powders were compacted and HIPed reaching a densification of 95%. Finally, mechanical tests showed that the developed process increased the hardness and compressive strength of Mg compared to the material obtained by casting.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

Change history

18 May 2022

A Correction to this paper has been published: https://doi.org/10.1007/s00170-022-09358-y

References

Phasha MJ, Bolokang AS, Ngoepe PE (2010) Solid-state transformation in nanocrystalline Ti induced by ball milling. Mater Lett 64:1215–1218. https://doi.org/10.1016/j.matlet.2010.02.054

Chaubey AK, Scudino S, Khoshkhoo MS et al (2013) Synthesis and characterization of nanocrystalline Mg-7.4%Al powders produced by mechanical alloying. Metals (Basel) 3:58–68. https://doi.org/10.3390/met3010058

Liao H, Chen J, Peng L et al (2017) Fabrication and characterization of magnesium matrix composite processed by combination of friction stir processing and high-energy ball milling. Mater Sci Eng A 683:207–214. https://doi.org/10.1016/j.msea.2016.11.104

Ghayour H, Abdellahi M, Bahmanpour M (2016) Optimization of the high energy ball-milling: modeling and parametric study. Powder Technol 291:7–13. https://doi.org/10.1016/j.powtec.2015.12.004

Khan MUF, Mirza F, Gupta RK (2018) High hardness and thermal stability of nanocrystalline Mg–Al alloys synthesized by the high-energy ball milling. Materialia 4:406–416. https://doi.org/10.1016/j.mtla.2018.10.004

Mojarrad NR, Kheirifard R, Mousavian RT et al (2016) Filling ratio of vial: an important parameter for ball milling. J Therm Anal Calorim 126:1097–1103. https://doi.org/10.1007/s10973-016-5635-z

Kho HX, Bae S, Bae S et al (2014) Planetary ball mill process in aspect of milling energy. J Korean Powder Metall Inst 21:155–164. https://doi.org/10.4150/kpmi.2014.21.2.155

Phasha M, Maweja K, Babst C (2010) Mechanical alloying by ball milling of Ti and Mg elemental powders: operation condition considerations. J Alloys Compd 492:201–207. https://doi.org/10.1016/j.jallcom.2009.11.184

Kamrani S, Penther D, Ghasemi A et al (2018) Microstructural characterization of Mg-SiC nanocomposite synthesized by high energy ball milling. Adv Powder Technol 29:1742–1748. https://doi.org/10.1016/j.apt.2018.04.009

Yu H, Zhou H, Sun Y et al (2017) Microstructure thermal stability of nanocrystalline AZ31 magnesium alloy with titanium addition by mechanical milling. J Alloys Compd 722:39–47. https://doi.org/10.1016/j.jallcom.2017.06.098

Sankaranarayanan S, Sabat RK, Jayalakshmi S et al (2013) Effect of hybridizing micron-sized Ti with nano-sized SiC on the microstructural evolution and mechanical response of Mg-5.6Ti composite. J Alloys Compd 575:207–217. https://doi.org/10.1016/j.jallcom.2013.04.095

Bemanifar S, Rajabi M, Hosseinipour SJ (2017) Microstructural characterization of Mg-SiC nanocomposite powders fabricated by high energy mechanical milling. SILICON 9:823–827. https://doi.org/10.1007/s12633-017-9570-9

Chaubey AK, Scudino S, Samadi Khoshkhoo M et al (2014) High-strength ultrafine grain Mg-7.4%Al alloy synthesized by consolidation of mechanically alloyed powders. J Alloys Compd 610:456–461. https://doi.org/10.1016/j.jallcom.2014.05.029

Mondet M, Barraud E, Lemonnier S et al (2016) Microstructure and mechanical properties of AZ91 magnesium alloy developed by spark plasma sintering. Acta Mater 119:55–67. https://doi.org/10.1016/j.actamat.2016.08.006

Chaudry UM, Hamad K, Kim JG (2019) On the ductility of magnesium based materials: a mini review. J Alloys Compd 792:652–664. https://doi.org/10.1016/j.jallcom.2019.04.031

Yu H, Sun Y, Hu L et al (2017) The effect of Ti addition on microstructure evolution of AZ61 Mg alloy during mechanical milling. J Alloys Compd 704:537–544. https://doi.org/10.1016/j.jallcom.2017.02.029

Yu H, Sun Y, Wan Z et al (2018) Nanocrystalline Ti/AZ61 magnesium matrix composite: evolution of microstructure and mechanical property during annealing treatment. J Alloys Compd 741:231–239. https://doi.org/10.1016/j.jallcom.2018.01.136

Jabbari-Taleghani MA, Torralba JM (2014) Hot workability of nanocrystalline AZ91 magnesium alloy. J Alloys Compd 595:1–7. https://doi.org/10.1016/j.jallcom.2014.01.091

Vahid A, Hodgson P, Li Y (2018) Effect of high-energy ball milling on mechanical properties of the Mg–Nb composites fabricated through powder metallurgy process. Adv Eng Mater 20:1700759. https://doi.org/10.1002/adem.201700759

Khan MUF, Patil A, Christudasjustus J et al (2020) Spark plasma sintering of a high-energy ball milled Mg-10 wt% Al alloy. J Magnes Alloy 8:319–328. https://doi.org/10.1016/j.jma.2020.02.006

Hübler D, Ghasemi A, Riedel R et al (2020) Effect of hot isostatic pressing on densification, microstructure and nanoindentation behaviour of Mg–SiC nanocomposites. J Mater Sci 55:10582–10592. https://doi.org/10.1007/s10853-020-04758-5

Indrakanti SS, Nesterenko VF, Maple MB et al (2001) Hot isostatic pressing of bulk magnesium diboride: mechanical and superconducting properties. Philos Mag Lett 81:849–857. https://doi.org/10.1080/09500830110093236

Atkinson HV, Davies S (2000) Fundamental aspects of hot isostatic pressing: an overview. Metall Mater Trans A Phys Metall Mater Sci 31:2981–3000. https://doi.org/10.1007/s11661-000-0078-2

Galindez Y, Correa E, Zuleta AA et al (2019) Improved Mg–Al–Zn magnesium alloys produced by high energy milling and hot sintering. Met Mater Int. https://doi.org/10.1007/s12540-019-00490-1

Avar B, Ozcan S (2014) Structural evolutions in Ti and TiO2 powders by ball milling and subsequent heat-treatments. Ceram Int 40:11123–11130. https://doi.org/10.1016/j.ceramint.2014.03.137

Ghasemi A, Penther D, Kamrani S (2018) Microstructure and nanoindentation analysis of Mg-SiC nanocomposite powders synthesized by mechanical milling. Mater Charact 142:137–143. https://doi.org/10.1016/j.matchar.2018.05.023

Hosseini-Gourajoubi F, Pourabdoli M, Uner D, Raygan S (2015) Effect of process control agents on synthesizing nano-structured 2Mg–9Ni–Y catalyst by mechanical milling and its catalytic effect on desorption capacity of MgH2. Adv Powder Technol 26:448–453. https://doi.org/10.1016/j.apt.2014.11.017

Sakher E, Loudjani N, Benchiheub M, Bououdina M (2018) Influence of milling time on structural and microstructural parameters of Ni50Ti50 prepared by mechanical alloying using Rietveld analysis. J Nanomater 2018:1–11. https://doi.org/10.1155/2018/2560641

Kurama H, Erkuş Ş, Gaşan H (2017) The effect of process control agent usage on the structural properties of MgB2 synthesized by high energy ball mill. Ceram Int 43:S391–S396. https://doi.org/10.1016/j.ceramint.2017.05.274

Zhou H, Hu L, Sun H, Chen X (2015) Synthesis of nanocrystalline Mg-based Mg-Ti composite powders by mechanical milling. Mater Charact 106:44–51. https://doi.org/10.1016/j.matchar.2015.05.021

Yazdani A, Hadianfard MJ, Salahinejad E (2013) A system dynamics model to estimate energy, temperature, and particle size in planetary ball milling. J Alloys Compd 555:108–111. https://doi.org/10.1016/j.jallcom.2012.12.035

Magini M, Iasonna A, Padella F (1996) Ball milling: an experimental support to the energy transfer evaluated by the collision model. Scr Mater 34:13–19. https://doi.org/10.1016/1359-6462(95)00465-3

Sivakumar M, Dasgupta A, Ghosh C et al (2019) Optimisation of high energy ball milling parameters to synthesize oxide dispersion strengthened alloy 617 powder and its characterization. Adv Powder Technol 30:2320–2329. https://doi.org/10.1016/j.apt.2019.07.014

Magini M, Iasonna A (1995) Energy transfer in mechanical alloying (overview). Mater Trans JIM 36:123–133. https://doi.org/10.2320/matertrans1989.36.123

Zou C, Long Y, Zheng X et al (2017) Effect of ball sizes on synthesis of OsB2 powders by mechanical alloying. Ceram Int 43:17111–17115. https://doi.org/10.1016/j.ceramint.2017.09.128

Hong S-M, Park J-J, Park E-K et al (2015) Fabrication of titanium carbide nano-powders by a very high speed planetary ball milling with a help of process control agents. Powder Technol 274:393–401. https://doi.org/10.1016/j.powtec.2015.01.047

Rios J, Restrepo A, Zuleta A et al (2021) Effect of ball size on the microstructure and morphology of Mg powders processed by high-energy ball milling. 1–10. https://doi.org/10.3390/met11101621

Fahimpour V, Sadrnezhaad SK (2017) Breakage mechanism of Mg during ball milling with NaCl, KCl and urea for nanopowder production. Trans Indian Inst Met 70:1783–1793. https://doi.org/10.1007/s12666-016-0979-4

Çakmak G, Öztürk T (2013) Milling of magnesium powders without additives. Powder Technol 237:484–488. https://doi.org/10.1016/j.powtec.2012.12.026

Liu Y, Li K, Luo T et al (2015) Powder metallurgical low-modulus Ti-Mg alloys for biomedical applications. Mater Sci Eng C 56:241–250. https://doi.org/10.1016/j.msec.2015.06.010

Park K, Park J, Kwon H (2018) Effect of intermetallic compound on the Al-Mg composite materials fabricated by mechanical ball milling and spark plasma sintering. J Alloys Compd 739:311–318. https://doi.org/10.1016/j.jallcom.2017.12.054

Zhang DL (2004) Processing of advanced materials using high-energy mechanical milling. Prog Mater Sci 49:537–560. https://doi.org/10.1016/S0079-6425(03)00034-3

Shashanka R, Chaira D (2015) Optimization of milling parameters for the synthesis of nano-structured duplex and ferritic stainless steel powders by high energy planetary milling. Powder Technol 278:35–45. https://doi.org/10.1016/j.powtec.2015.03.007

Wu ZM, Liang YX, Fan Y et al (2018) The ball to powder ratio (BPR) dependent morphology and microstructure of tungsten powder refined by ball milling. Powder Technol 339:256–263. https://doi.org/10.1016/j.powtec.2018.07.094

Maweja K, Phasha M, van der Berg N (2010) Microstructure and crystal structure of an equimolar Mg-Ti alloy processed by Simoloyer high-energy ball mill. Powder Technol 199:256–263. https://doi.org/10.1016/j.powtec.2010.01.014

Wang HW, Der CS, Wang SH et al (2010) Hydrogen absorption properties of Mg2Ni alloy with excess Mg synthesized by wet milling in toluene without annealing. J Alloys Compd 491:623–626. https://doi.org/10.1016/j.jallcom.2009.11.025

Wang HW, Der CS, Wang SH et al (2009) Amorphous phase formation in intermetallic Mg2Ni alloy synthesized by ethanol wet milling. J Alloys Compd 479:330–333. https://doi.org/10.1016/j.jallcom.2008.12.077

Asano K, Enoki H, Akiba E (2009) Synthesis of HCP, FCC and BCC structure alloys in the Mg-Ti binary system by means of ball milling. J Alloys Compd 480:558–563. https://doi.org/10.1016/j.jallcom.2009.01.086

Chen H, Xiao H, Wang Y et al (2020) Insight into the energy conversion and structural evolution of magnesium hydride during high-energy ball milling for its controllable synthesis. J Alloys Compd 836:155312. https://doi.org/10.1016/j.jallcom.2020.155312

Alaneme KK, Okotete EA (2017) Enhancing plastic deformability of Mg and its alloys—a review of traditional and nascent developments. J Magnes Alloy 5:460–475. https://doi.org/10.1016/j.jma.2017.11.001

Kim KR, Ahn JW, Kim GH et al (2014) Corrosion behavior of magnesium powder fabricated by high-energy ball milling and spark plasma sintering. Met Mater Int 20:1095–1101. https://doi.org/10.1007/s12540-014-6023-5

Fecht HJ, Hellstern E, Fu Z, Johnson WL (1990) Nanocrystalline metals prepared by high-energy ball milling. Metall Trans A 21:2333–2337. https://doi.org/10.1007/BF02646980

Ruiz-Navas EM, Edil da Costa C, Velasco López F, Torralba Castelló JM (2000) Aleación mecánica: Método de obtención de polvos metálicos y de materiales compuestos. Rev Metal 36:279–286. https://doi.org/10.3989/revmetalm.2000.v36.i4.578

Cao P, Lu L, Lai MO (2001) Grain growth and kinetics for nanocrystalline magnesium alloy produced by mechanical alloying. Mater Res Bull 36:981–988. https://doi.org/10.1016/S0025-5408(01)00578-5

Rousselot S, Bichat MP, Guay D, Roué L (2008) Structure and electrochemical behaviour of metastable Mg50Ti50 alloy prepared by ball milling. J Power Sources 175:621–624. https://doi.org/10.1016/j.jpowsour.2007.09.022

Ponhan K, Tassenberg K, Weston D et al (2020) Effect of SiC nanoparticle content and milling time on the microstructural characteristics and properties of Mg-SiC nanocomposites synthesized with powder metallurgy incorporating high-energy ball milling. Ceram Int 46:26956–26969. https://doi.org/10.1016/j.ceramint.2020.07.173

Suryanarayana C (2019) Mechanical Alloying: A Novel Technique to Synthesize Advanced Materials. Research 2019:1–17. https://doi.org/10.34133/2019/4219812

Hwang S, Nishimura C, McCormick P (2001) Mechanical milling of magnesium powder. Mater Sci Eng A 318:22–33. https://doi.org/10.1016/S0921-5093(01)01767-1

Seth PP, Singh N, Singh M et al (2020) Formation of fine Mg2Si phase in Mg–Si alloy via solid-state sintering using high energy ball milling. J Alloys Compd 821:153205. https://doi.org/10.1016/j.jallcom.2019.153205

Kumar A, Pandey PM (2020) Development of Mg based biomaterial with improved mechanical and degradation properties using powder metallurgy. J Magnes Alloy 8:883–898. https://doi.org/10.1016/j.jma.2020.02.011

German RM (2010) Thermodynamics of sintering. In: Sintering of advanced materials. Elsevier, pp 3–32

Cheng Y, Cui Z, Cheng L et al (2017) Effect of particle size on densification of pure magnesium during spark plasma sintering. Adv Powder Technol 28:1129–1135. https://doi.org/10.1016/j.apt.2017.01.017

Burke P, Kipouros GJ, Fancelli D, Laverdiere V (2009) Sintering fundamentals of magnesium powders. Can Metall Q 48:123–132. https://doi.org/10.1179/cmq.2009.48.2.123

Funding

The authors received funding from the Departamento Administrativo de Ciencia, Tecnología e Innovación—COLCIENCIAS (Project 111580862830, contract 183–2019), Universidad de Antioquia, Centro de Investigación para el Desarrollo y la Innovación (CIDI) of the Universidad Pontificia Bolivariana (Rad:482C-05/19–35), and Universidad de Medellín.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Affiliations 2 and 3 were interchanged.

Rights and permissions

About this article

Cite this article

Rios, J.M., Restrepo, A.H., Zuleta, A.A. et al. Effects of two-step high-energy ball milling process and hot isostatic pressing on the mechanical properties of PM magnesium. Int J Adv Manuf Technol 121, 187–196 (2022). https://doi.org/10.1007/s00170-022-09299-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09299-6