Abstract

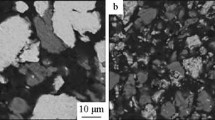

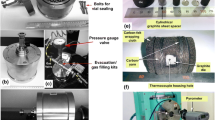

The effect of speed and milling time on the morphology, crystallite size, and phase composition of Ti Cp powders processed in n-hexane by high-energy ball milling (HEBM) using a E-max Retsch equipment was studied by scanning electron microscopy (SEM), X-ray diffraction (XRD), and transmission electron microscopy (TEM). Lattice parameters, mean crystallite size, lattice strain, and dislocation density were obtained from Rietveld analysis. The XRD and TEM results show that the HEBM process of the Ti Cp promotes the transition from HCP to FCC after 6 h of milling at 1400 rpm. The transformation process could be attributed to the energy generated in the milling process which induces high deformation and presence of high-density dislocations in the powder.

Graphical Abstract

Similar content being viewed by others

References

Fang ZZ, Paramore JD, Sun P, Ravi Chandran KS, Zhang Y, Xia Y, Cao F, Koopman M, Free M (2018) Powder metallurgy of titanium–past, present, and future. Int Mater Rev 63(7):407–459. https://doi.org/10.1080/09506608.2017.1366003

Wang M, Zhou J, Yin Y, Nan H, Xue P, Tu Z (2017) Hot deformation behavior of the Ti6Al4V alloy prepared by powder hot isostatic pressing. J Alloys Compd 721:320–332. https://doi.org/10.1016/j.jallcom.2017.06.003

Romero C, Yang F, Bolzoni L (2018) Fatigue and fracture properties of Ti alloys from powder-based processes – a review. Int J Fatigue 117:407–419. https://doi.org/10.1016/j.ijfatigue.2018.08.029

Duan W, Yin Y, Zhou J, Wang M, Nan H, Zhang P (2019) Dynamic research on Ti6Al4V powder HIP densification process based on intermittent experiments. J Alloys Compd 771:489–497. https://doi.org/10.1016/j.jallcom.2018.08.261

Whittaker D, Froes FH (Sam) (2015) Future prospects for titanium powder metallurgy markets. Titanium Powder Metallurgy 579–600. https://doi.org/10.1016/B978-0-12-800054-0.00030-7

Duda T, Raghavan LV (2016) 3D metal printing technology. Int Fed Autom Control (IFAC) :49(29):103–110. https://doi.org/10.1016/j.ifacol.2016.11.111

Bolzoni L (2011) Diseño y Procesado de Aleaciones de Titanio mediante Técnicas Pulvimetalúrgicas Avanzadas. Tesis Doctoral, Universidad Carlos III de Madrid.

Esteban PG, Bolzoni L, Ruiz-Navas EM, Gordo E (2011) Introducción al procesado pulvimetalúrgico del titanio. Rev Metal 47(2):169–187. https://doi.org/10.3989/revmetalmadrid.0943

Nouri A, Sola A (2018) Metal particle shape: a practical perspective. Met Powder Rep 73(5):276–282. https://doi.org/10.1016/j.mprp.2018.04.001

Phasha M, Maweja K, Babst C (2010) Mechanical alloying by ball milling of Ti and Mg elemental powders: operation condition considerations. J Alloys Compd 492(1–2):201–207. https://doi.org/10.1016/j.jallcom.2009.11.184

Dabhade VV, Rama Mohan TR, Ramakrishnan P (2001) Synthesis of nanosized titanium powder by high energy milling. Appl Surf Sci 182(3–4):390–393. https://doi.org/10.1016/S0169-4332(01)00456-1

Galindez Y, Correa E, Zuleta AA, Valencia-Escobar A, Calderon D, Toro L, Chacon P, Echeverría F (2019) Improved Mg–Al–Zn magnesium alloys produced by high energy milling and hot sintering. Met Mater Int. https://doi.org/10.1007/s12540-019-00490-1

Yang L (2015) Nanotechnology-enhanced metals and alloys for orthopedic implants, Nanotechnology-Enhanced Orthopedic Materials. Elsevier Ltd, Amsterdam

Phasha MJ, Bolokang AS, Ngoepe PE (2010) Solid-state transformation in nanocrystalline Ti induced by ball milling. Mater Lett 64(10):1215–1218. https://doi.org/10.1016/j.matlet.2010.02.054

Dorofeev GA, Lubnin AN, Lad Yanov VI, Mukhgalin VV, Puskkarev BE (2014) Structural and phase transformations during ball milling of titanium in medium of liquid hydrocarbons. Phys Met Metallogr 115(2):157–168. https://doi.org/10.1134/S0031918X14020057

Suryanarayana C (2004) Mechanical alloying and milling. Marcel Dekker, New York

Suryanarayana C, Froes FHS (1990) Nanocrystalline titanium-magnesium alloys through mechanical alloying. J Mater Res 5(9):1880–1886. https://doi.org/10.1557/JMR.1990.1880

Suzuki T, Nagumo N (1995) Metastable intermediate phase formation at reaction milling of titanium and n-heptane. Scr Metall Mater 32(8):1215–1220. https://doi.org/10.1016/0956-716X(95)00128-I

Bolokang AS, Motaung DE, Arendse CJ, Muller TFG (2015) Formation of the metastable FCC phase by ball milling and annealing of titanium-stearic acid powder. Adv Powder Technol 26(2):632–639. https://doi.org/10.1016/j.apt.2015.01.013

Avar B, Ozcan S (2014) Structural evolutions in Ti and TiO2 powders by ball milling and subsequent heat-treatments. Ceram Int 40(7 PART B):11123–11130. https://doi.org/10.1016/j.ceramint.2014.03.137

Manna I, Chattopadhyay PP, Nandi P, Banhart F, Fecht HJ (2003) Formation of face-centered-cubic titanium by mechanical attrition. J Appl Phys 93(3):1520–1524. https://doi.org/10.1063/1.1530718

Wawner FE, Lawless KR (1969) Epitaxial growth of titanium thin films. J Vac Sci Technol 6(4):588–590. https://doi.org/10.1116/1.1315691

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9(7):671–675. https://doi.org/10.1038/nmeth.2089

Waseda Y, Matsubara E, Shinoda K (2001) X ray diffraction crystallography. Springer, Berlin

Hajalilou A, Hashim M, Ebrahimi-Kahizsangi R, Ismail I, Sarami N (2014) Synthesis of titanium carbide and TiC-SiO2 nanocomposite powder using rutile and Si by mechanically activated sintering. Adv Powder Technol 25(3):1094–1102. https://doi.org/10.1016/j.apt.2014.02.008

Ali S, Karunanithi R, Prashanth M, Rahman MA (2019) X-ray peak broadening on microstructure, and structural properties of titanium and Ti-6Al-4V alloys. Mater Today Proc 27:2390–2393. https://doi.org/10.1016/j.matpr.2019.09.137

Sakher E, Loudjani N, Benchiheub M, Bououdina M (2018) Influence of milling time on structural and microstructural parameters of Ni50Ti50 prepared by mechanical alloying using rietveld analysis. J Nanomater 2018:1–11. https://doi.org/10.1155/2018/2560641

Singh P, Abhash A, Yadav N, Shafeeq M, Singh IB, Mondal DP (2018) Effect of milling time on powder characteristics and mechanical performance of Ti4wt%Al alloy. Powder Technol 342:275–287. https://doi.org/10.1016/j.powtec.2018.09.075

Asano K, Enoki H, Akiba E (2009) Synthesis process of Mg–Ti BCC alloys by means of ball milling. J Alloys Compd 486(1–2):115–123. https://doi.org/10.1016/j.jallcom.2009.06.140

Ghosh B, Pradhan SK (2010) Microstructure characterization of nanocrystalline TiC synthesized by mechanical alloying. Mater Chem Phys 120(2–3):537–545. https://doi.org/10.1016/j.matchemphys.2009.11.048

Shial SR, Masanta M, Chaira D (2018) Recycling of waste Ti machining chips by planetary milling: generation of Ti powder and development of in situ TiC reinforced Ti-TiC composite powder mixture. Powder Technol 329:232–240. https://doi.org/10.1016/j.powtec.2018.01.080

Hosseini-Gourajoubi F, Pourabdoli M, Uner D, Raygan S (2015) Effect of process control agents on synthesizing nano-structured 2Mg-9Ni-Y catalyst by mechanical milling and its catalytic effect on desorption capacity of MgH2. Adv Powder Technol 26:448–453. https://doi.org/10.1016/j.apt.2014.11.017

Ma Q, Froes FHS (2015) Titanium Powder Metallurgy. Elsevier Inc., Amsterdam

Xu W, Xiao S, Lu X, Chen G, Liu C, Qu X (2019) Fabrication of commercial pure Ti by selective laser melting using hydride-dehydride titanium powders treated by ball milling. J Mater Sci Technol 35(2):322–327. https://doi.org/10.1016/j.jmst.2018.09.058

Zhou H, Hu L, Sun Y, Zhang H, Duan C, Yu H (2016) Synthesis of nanocrystalline AZ31 magnesium alloy with titanium addition by mechanical milling. Mater Charact 113:108–116. https://doi.org/10.1016/j.matchar.2016.01.014

Kurama H, Erkuş Ş, Gaşan H (2017) The effect of process control agent usage on the structural properties of MgB2 synthesized by high energy ball mill. Ceram Int 43:S391–S396. https://doi.org/10.1016/j.ceramint.2017.05.274

Zou C, Long Y, Zheng X, Lin H, Zhang F (2017) Effect of ball sizes on synthesis of OsB2 powders by mechanical alloying. Ceram Int 43(18):17111–17115. https://doi.org/10.1016/j.ceramint.2017.09.128

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46(1–2):1–184. https://doi.org/10.1016/S0079-6425(99)00010-9

Keskinen J, Pogany A, Rubin J, Ruuskanen P (1995) Carbide and hydride formation during mechanical alloying of titanium and aluminium with hexane. Mater Sci Eng A 196:205–211. https://doi.org/10.1016/0921-5093(94)09701-1

Lohse BH, Calka A, Wexler D (2005) Raman spectroscopy as a tool to study TiC formation during controlled ball milling. J Appl Phys 97(11):1–7. https://doi.org/10.1063/1.1927282

Delogu F, Takacs L (2014) Mechanochemistry of Ti-C powder mixtures. Acta Mater 80:435–444. https://doi.org/10.1016/j.actamat.2014.08.036

Chen C, Qian S, Wang S, Niu L, Liu R, Liao B, Zhong Z, Lu P, Li P, Cao L, Wu Y (2018) The microstructure and formation mechanism of face-centered cubic Ti in commercial pure Ti foils during tensile deformation at room temperature. Mater Charact 136:257–263. https://doi.org/10.1016/j.matchar.2017.12.031

Edalati K, Emami H, Staykov A, Smith DJ, Akiba E, Horita Z (2015) Formation of metastable phases in magnesium–titanium system by high-pressure torsion and their hydrogen storage performance. Acta Mater 99:150–156. https://doi.org/10.1016/j.actamat.2015.07.060

Zhang DL, Ying DY (2002) Formation of fcc titanium during heating high energy ball milled Al-Ti powders. Mater Lett 52(4–5):329–333. https://doi.org/10.1016/S0167-577X(01)00417-7

Han G, Lu X, Xia Q, Lei B, Yan Y, Shang CJ (2018) Face-centered-cubic titanium - a new crystal structure of Ti in a Ti-8Mo-6Fe alloy. J Alloys Compd 748:943–952. https://doi.org/10.1016/j.jallcom.2018.03.218

Lu CJ, Zhang J, Li ZQ (2004) Structural evolution of titanium powder during ball milling in different atmospheres. J Alloys Compd 381(1–2):278–283. https://doi.org/10.1016/j.jallcom.2004.03.130

Chatterjee P, Sen Gupta SP (2001) An X-ray diffraction study of nanocrystalline titanium prepared by high-energy vibrational ball milling. Appl Surf Sci 182(3–4):372–376. https://doi.org/10.1016/S0169-4332(01)00451-2

Chatterjee P, Sen Gupta SP (2001) An X-ray diffraction study of strain localization and anisotropic dislocation contrast in nanocrystalline titanium. Philos Mag A 81(1):49–60. https://doi.org/10.1080/01418610108216617

Funding

This study is supported by the ‘Departamento Administrativo de Ciencia, Tecnología e Innovación– COLCIENCIAS (Project 111580862830, contract 183-2019), Universidad de Antioquia, Centro de Investigación para el Desarrollo y la Innovación (CIDI) from the Universidad Pontificia Bolivariana (Rad:482C-05/19-35), and Universidad de Medellín.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Restrepo, A.H., Ríos, J.M., Arango, F. et al. Characterization of titanium powders processed in n-hexane by high-energy ball milling. Int J Adv Manuf Technol 110, 1681–1690 (2020). https://doi.org/10.1007/s00170-020-05991-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05991-7