Abstract

For decades, attentions have been paid to metal cutting processes, especially for the critical components in aerospace, marine, medical industries, etc. Scholars investigated the influence of cutting parameters, tool geometry, lubricant, pursuing a deeper understanding of process signatures, better tool performance, and more superior surface integrity. Edge microgeometry is proved to be an essential factor that significantly influences the tool-workpiece-chip contact, plastic deformation, and heat generation, which in turn affects the cutting phenomena.

This paper aims to provide an insight and scientific overview of the role of edge microgeometries in metal cutting, with special attention on material flow state, cutting mechanics, tool performance, as well as the surface integrity. The characterization of edge microgeometries includes edge types (honed, chamfered, mixed), size parameters (edge radius, form-factor K, chamfer angle, chamfer length), and edge preparation techniques (grinding, drag finishing, brushing, micro-blasting, etc.). The researches on the influence of edge microgeometries on material flow state and cutting mechanics are reviewed, mainly focusing on analytical modeling and finite element method to explain how the edge microgeometries affect cutting processes. Then, the researches on the influence of edge microgeometries on tool performance and surface integrity are well organized to present the various findings in these topics. From the current perspective, many scholars have noticed the importance of edge microgeometries in metal cutting and have done numerous researches on this topic. Summary and future suggestions are given based on their state-of-the-art contributions in the last section.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

Bobzin K (2017) High-performance coatings for cutting tools. CIRP J Manuf Sci Technol 18:1–9

Brinksmeier AE, Meyer AD, Heinzel AC, Lübben T, Slter AJ, Langenhorst AL, Frerichs AF, Kmmler AJ, Kohls AE, Kuschel AS (2018) Process signatures—the missing link to predict surface integrity in machining. Procedia CIRP 71:3–10

Brinksmeier E, Gläbe R, Klocke F, Lucca DA (2011) Process signatures—an alternative approach to predicting functional workpiece properties. Procedia Eng 19:44–52

Thakur A, Gangopadhyay S (2016) State-of-the-art in surface integrity in machining of nickel-based super alloys. Int J Mach Tools Manuf 100:25–54

Junge T, Liborius H, Mehner T, Nestler A, Schubert A, Lampke T (2020) Method for process monitoring of surface layer changes in turning of aluminium alloys using tools with a flank face chamfer. Procedia CIRP 87:432–437

Magalhães F, Ventura C, Abrão A, Denkena B (2020) Experimental and numerical analysis of hard turning with multi-chamfered cutting edges. J Manuf Process 49:126–134

Karpuschewski B, Schmidt K, Beňo J, Maňková I, Prilukova J (2014) Measuring procedures of cutting edge preparation when hard turning with coated ceramics tool inserts. Measurement 55:627–640

Zhao T, Zhou JM, Bushlya V, Ståhl JE (2017) Effect of cutting edge radius on surface roughness and tool wear in hard turning of AISI 52100 steel. Int J Adv Manuf Technol 91(9):3611–3618

Hu C, Zhuang KJ, Weng J, Zhang XM (2019) Thermal-mechanical model for cutting with negative rake angle based on a modified slip-line field approach. Int J Mech Sci 164:105167

Yussefian NZ, Koshy P (2013) Parametric characterization of the geometry of honed cutting edges. Precis Eng 37(3):746–752

Benjamin B, Thilo G (2018) Basic principles for the design of cutting edge roundings. CIRP Ann Manuf Technol 67(1):73–78

Wan L, Wang D, Gao Y (2015) Investigations on the effects of different tool edge geometries in the finite element simulation of machining. Stroj Vestn-J Mech Eng 61(3):157–166

Mayer P, Kirsch B, Müller R, Becker S, Ev H, Aurich JC (2016) Influence of cutting edge geometry on deformation induced hardening when cryogenic turning of metastable austenitic stainless steel AISI 347. Procedia CIRP 45:59–62

Varela PI, Rakurty CS, Balaji AK (2014) Surface integrity in hard machining of 300M steel: effect of cutting-edge geometry on machining induced residual stresses. Procedia CIRP 13:288–293

Denkena B, Köhler J, Ventura CEH (2013) Customized cutting edge preparation by means of grinding. Precis Eng 37(3):590–598

Reilly GA, McCormack BAO, Taylor D (2004) Cutting sharpness measurement: a critical review. J Mater Process Technol 153-154:261–267

Karpat Y, Özel T (2008) Mechanics of high speed cutting with curvilinear edge tools. Int J Mach Tool Manu 48(2):195–208

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Ann Manuf Technol 63(2):631–653

He GH, Liu XL, Wu CH, Zhang SQ, Zou LL, Li DJ (2016) Study on the negative chamfered edge and its influence on the indexable cutting insert ' s lifetime and its strengthening mechanism. Int J Adv Manuf Technol 84(5-8):1229–1237

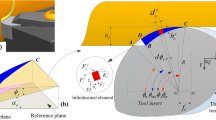

Weng J, Zhuang KJ, Chen D, Guo SS, Ding H (2017) An analytical force prediction model for turning operation by round insert considering edge effect. Int J Mech Sci 128-129:168–180

Weng J, Zhuang KJ, Hu C, Ding H (2019) A PSO-based semi-analytical force prediction model for chamfered carbide tools considering different material flow state caused by edge geometry. Int J Mech Sci 169:105329

Ventura CEH, Koehler J, Denkena B (2015) Influence of cutting edge geometry on tool wear performance in interrupted hard turning. J Manuf Process 19:129–134

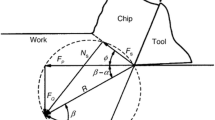

Merchant ME (1945) Mechanics of the metal cutting process I. orthogonal cutting and a type 2 chip. J Appl Phys 16(5):267–275

Lee E (1951) The theory of plasticity applied to a problem of machining. J Appl Phys 18:405

Shaw MC, Cook NH, Finnie I (1953) The shear angle relationship in metal cutting. Trans ASME 75:273–288

Oxley PLB, Welsh MJM (1967) An explanation of the apparent bridgman effect in Merchant ' s orthogonal cutting results. J Eng Ind 89(3):549–555

Zorev N (1958) Results of work in the field of the mechanics of the metal cutting process. In: Proceedings of Conference on Technology of Engineering Manufacture, pp 255–268

Toropov A, Ko S-L (2003) Prediction of tool-chip contact length using a new slip-line solution for orthogonal cutting. Int J Mach Tool Manu 43(12):1209–1215

Kudo H (1965) Some new slip-line solutions for two-dimensional steady-state machining. Int J Mech Sci 7(1):43–55

Dewhurst P (1978) Eigen-vector slip-line field solutions. In: Applications of Numerical Methods to Forming Processes, pp 121–127

Usui E (1981) Simulation analysis of built-up edge formation in machining of low carbon steel. Bull Jpn Soc Precis Eng 15:237–242

Fang N, Dewhurst P (2005) Slip-line modeling of built-up edge formation in machining. Int J Mech Sci 47(7):1079–1098

Ozturk S (2012) Slip-line modeling of machining and determine the influence of rake angle on the cutting force. Trans Can Soc Mech Eng 36(1):23–35

Basuray P, Misra B, Lal G (1977) Transition from ploughing to cutting during machining with blunt tools. Wear 43(3):341–349

Yuan Z, Zhou M, Dong S (1996) Effect of diamond tool sharpness on minimum cutting thickness and cutting surface integrity in ultraprecision machining. J Mater Process Technol 62(4):327–330

Kim C-J, Bono M, Ni J (2002) Experimental analysis of chip formation in micro-milling. Trans NAMRI/SME 30:247–254

Zhou TF, Wang Y, Ruan BS, Liang ZQ, Wang XB (2020) Modeling of the minimum cutting thickness in micro cutting with consideration of the friction around the cutting zone. Front Mech Eng-PRC 15(1):81–88

Abdelmoneim ME, Scrutton R (1974) Tool edge roundness and stable build-up formation in finish machining. J Eng Ind 96(4):1258–1267

Wan M, Wen DY, Ma YC, Zhang WH (2019) On material separation and cutting force prediction in micro milling through involving the effect of dead metal zone. Int J Mach Tool Manu 146:103452

Waldorf DJ, DeVor RE, Kapoor SG (1998) A slip-line field for ploughing during orthogonal cutting. J Manuf Sci E T ASME 120(4):693–699

Fang N, Jawahir I (2003) Analytical prediction of the chip back-flow angle in machining with restricted contact grooved tools. J Manuf Sci E T ASME 125(2):210–219

Jin X, Altintas Y (2011) Slip-line field model of micro-cutting process with round tool edge effect. J Mater Process Technol 211(3):339–355

Ozturk S, Altan E (2012) A slip-line approach to the machining with rounded-edge tool. Int J Adv Manuf Technol 63(5-8):513–522

Zhang T, Liu Z, Shi Z, Xu C (2017) Investigation on size effect of specific cutting energy in mechanical micro-cutting. Int J Adv Manuf Technol 91(5-8):2621–2633

Zhang H, Liu P, Hu R (1991) A three-zone model and solution of shear angle in orthogonal machining. Wear 143(1):29–43

Ren H, Altintas Y (2000) Mechanics of machining with chamfered tools. J Manuf Sci E T ASME 122(4):650–659

Fang N, Wu Q (2005) The effects of chamfered and honed tool edge geometry in machining of three aluminum alloys. Int J Mach Tool Manu 45(10):1178–1187

Karpat Y, Özel T (2006) An integrated analytical thermal model for orthogonal cutting with chamfered tools. Transactions of the North American Manufacturing Research Institution of SME (Society of Manufacturing Engineers) 34:9–16

Kiyota H, Itoigawa F, Endo S, Nakamura T (2013) Analytical approach for optimization of chamfered cutting tool preparation considering built-up edge extrusion behavior. Int J Autom Technol 7(3):329–336

Hu C, Zhuang KJ, Weng J, Zhang XM, Ding H (2020) Cutting temperature prediction in negative-rake-angle machining with chamfered insert based on a modified slip-line field model. Int J Mech Sci 167:105273

Dai X, Zhuang KJ, Ding H (2019) A systemic investigation of tool edge geometries and cutting parameters on cutting forces in turning of Inconel 718. Int J Adv Manuf Technol 105(1-4):531–543

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design. Cambridge university press

Albrecht P (1960) New developments in the theory of the metal-cutting process: part I—the ploughing process in metal cutting. J Eng Ind 82(4):348–357

Moufki A, Dudzinski D, Le Coz G (2015) Prediction of cutting forces from an analytical model of oblique cutting, application to peripheral milling of Ti-6Al-4V alloy. Int J Adv Manuf Technol 81(1-4):615–626

Gao P, Liang Z, Wang X, Li S, Zhou T (2018) Effects of different chamfered cutting edges of micro end mill on cutting performance. Int J Adv Manuf Technol 96(1-4):1215–1224

Liang SY, Su JC (2007) Residual stress modeling in orthogonal machining. CIRP Ann Manuf Technol 56(1):65–68

Zhang WQ, Wang XL, Hu YJ, Wang SY (2018) Predictive modelling of microstructure changes, micro-hardness and residual stress in machining of 304 austenitic stainless steel. Int J Mach Tool Manu 130-131:36–48

Wan M, Ye XY, Yang Y, Zhang WH (2017) Theoretical prediction of machining-induced residual stresses in three-dimensional oblique milling processes. Int J Mech Sci 133:426–437

Srinivasa YV, Shunmugam MS (2013) Mechanistic model for prediction of cutting forces in micro end-milling and experimental comparison. Int J Mach Tool Manu 67:18–27

Yuan YJ, Jing XB, Ehmann KF, Cao J, Li HZ, Zhang DW (2018) Modeling of cutting forces in micro end-milling. J Manuf Process 31(JAN):844–858

Weng J, Zhuang KJ, Zhu DH, Guo SS, Ding H (2018) An analytical model for the prediction of force distribution of round insert considering edge effect and size effect. Int J Mech Sci 138-139:86–98

Wyen CF, Wegener K (2010) Influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann Manuf Technol 59(1):93–96

Ventura CEH, Breidenstein B, Denkena B (2018) Influence of customized cutting edge geometries on the workpiece residual stress in hard turning. Proc Inst Mech Eng B J Eng 232(12):2132–2139

Ranganath S, Campbell AB, Gorkiewicz DW (2007) A model to calibrate and predict forces in machining with honed cutting tools or inserts. Int J Mach Tool Manu 47(5):820–840

Kalyan C, Samuel GL (2015) Cutting mode analysis in high speed finish turning of AlMgSi alloy using edge chamfered PCD tools. J Mater Process Technol 216:146–159

Zhou L, Peng FY, Yan R, Yao PF, Yang CC, Li B (2015) Analytical modeling and experimental validation of micro end-milling cutting forces considering edge radius and material strengthening effects. Int J Mach Tool Manu 97:29–41

Li B, Zhang S, Yan Z, Jiang D (2018) Influence of edge hone radius on cutting forces, surface integrity, and surface oxidation in hard milling of AISI H13 steel. Int J Adv Manuf Technol 95(1-4):1153–1164

Padmakumar M (2020) Effect of cutting edge form factor (K-factor) on the performance of a face milling tool. CIRP J Manuf Sci Technol 31:305–313

Bassett E, KöHler J, Denkena B (2012) On the honed cutting edge and its side effects during orthogonal turning operations of AISI1045 with coated WC-Co inserts. CIRP J Manuf Sci Technol 5(2):108–126

Denkena B, Köhler J, Breidenstein B, Abrão AM, Ventura CEH (2014) Influence of the cutting edge preparation method on characteristics and performance of PVD coated carbide inserts in hard turning. Surf Coat Technol 254:447–454

Tomoiagă V-B, Popa MS, Sattel S, Conţiu G, Vereş OV, Bozga M, Slătineanu L, Merticaru V, Mihalache AM, Dodun O (2018) Influence of the cutting edge microgeometry in drilling operation of 42CrMo4 and X5CrNi18-10. MATEC Web of Conferences 178:01011

Gutnichenko O, Bushlya V, Zhou JM, Ståhl JE (2017) Tool wear and machining dynamics when turning high chromium white cast iron with pcBN tools. Wear 390:258–269

Zhuang KJ, Weng J, Zhu DH, Ding H (2018) Analytical modeling and experimental validation of cutting forces considering edge effects and size effects with round chamfered ceramic tools. J Manuf Sci E T ASME 140(8):081012

Weng J, Zhuang KJ, Zhou JM, Ding H (2020) A hybrid model for force prediction in orthogonal cutting with chamfered tools considering size and edge effect. Int J Adv Manuf Technol 110(11):1367–1384

Liu Y, Xu DD, Agmell M, Saoubi RM, Zhou JM (2021) Numerical and experimental investigation of tool geometry effect on residual stresses in orthogonal machining of Inconel 718. Simul Model Pract Theory 106:102187

Yang Y, Zhu WW (2014) Study on cutting temperature during milling of titanium alloy based on FEM and experiment. Int J Adv Manuf Technol 73(9):1511–1521

He HB, Li HY, Yang J, Zhang XY, Yue QB, Jiang X, Lyu SK (2017) A study on major factors influencing dry cutting temperature of AISI 304 stainless steel. Int J Precis Eng Manuf 18(10):1387–1392

Liu GL, Huang CZ, Su R, Özel T, Liu Y, Xu LH (2019) 3D FEM simulation of the turning process of stainless steel 17-4PH with differently texturized cutting tools. Int J Mech Sci 155:417–429

Qi ZX, Li B, Xiong LS (2014) An improved algorithm for McDowell ' s analytical model of residual stress. Front Mech Eng-PRC 9(2):150–155

Grzesik W (2006) Determination of temperature distribution in the cutting zone using hybrid analytical-FEM technique. Int J Mach Tool Manu 46(6):651–658

Fuat K, Kubilay A, Adem Ç (2016) Prediction of cutting temperature in orthogonal machining of AISI 316L using artificial neural network. Appl Soft Comput 38:64–74

Özel T (2009) Computational modelling of 3D turning: influence of edge micro-geometry on forces, stresses, friction and tool wear in PcBN tooling. J Mater Process Technol 209(11):5167–5177

Segebade E, Kümmel D, Zanger F, Schneider J, Schulze V (2018) Influence of cutting edge asymmetry on grain refinement of Ti6Al4V. Procedia CIRP 71:232–237

Komanduri R, Hou ZB (2000) Thermal modeling of the metal cutting process: Part I—Temperature rise distribution due to shear plane heat source. Int J Mech Sci 42(9):1715–1752

Komanduri R, Hou ZB (2001) Thermal modeling of the metal cutting process—Part II: temperature rise distribution due to frictional heat source at the tool–chip interface. Int J Mech Sci 43(1):57–88

Huang Y, Liang SY (2003) Modelling of the cutting temperature distribution under the tool flank wear effect. Proc Inst Mech Eng C J Mech Eng Sci 217(11):1195–1208

Huang XD, Zhang XM, Ding H (2016) A novel relaxation-free analytical method for prediction of residual stress induced by mechanical load during orthogonal machining. Int J Mech Sci 115-116:299–309

Yi K, Tr Ö (2008) Analytical and thermal modeling of high-speed machining with chamfered tools. J Manuf Sci E T ASME 130(1):119–129

Karpat Y, Özel T (2008) Analytical and thermal modeling of high-speed machining with chamfered tools. J Manuf Sci Eng 130(1):011001

Hua J, Shivpuri R, Cheng X, Bedekar V, Matsumoto Y, Hashimoto F, Watkins TR (2005) Effect of feed rate, workpiece hardness and cutting edge on subsurface residual stress in the hard turning of bearing steel using chamfer+hone cutting edge geometry. Mater Sci Eng A MAT SCI ENG A-STRUC 394(1-2):238–248

Klocke F, Brinksmeier E, Weinert K (2005) Capability profile of hard cutting and grinding processes. CIRP Ann 54(2):22–45

Tiffe M, Aßmuth R, Saelzer J, Biermann D (2019) Investigation on cutting edge preparation and FEM assisted optimization of the cutting edge micro shape for machining of nickel-base alloy. Prod Eng 13(3):459–467

Bassett E (2013) Belastungsspezifische auslegung und herstellung von schneidkanten für drehwerkzeuge. (PhD-Thesis) Leibniz Universita¨ t, Hannover

Fu XS, Zou B, Liu YN, Huang CZ, Yao P (2019) Edge micro-creation of Ti(C, N) cermet inserts by micro-abrasive blasting process and its tool performance. Mach Sci Technol 23(6):951–970

Zhou JM, Walter H, Andersson M, Stahl JE (2003) Effect of chamfer angle on wear of PCBN cutting tool. Int J Mach Tool Manu 43(3):301–305

Chen T, Song LX, Li SY, Liu XL (2019) Experimental study on wear characteristics of PCBN tool with variable chamfered edge. Chin J Mech Eng-EN 32(1):37

Wang W, Saifullah MK, Aßmuth R, Biermann D, Arif A, Veldhuis S (2020) Effect of edge preparation technologies on cutting edge properties and tool performance. Int J Adv Manuf Technol 106(5-6):1823–1838

Bouzakis KD, Michailidis N, Skordaris G, Kombogiannis S, Hadjiyiannis S, Efstathiou K, Erkens G, Rambadt S, Wirth I (2002) Effect of the cutting edge radius and its manufacturing procedure, on the milling performance of PVD coated cemented carbide inserts. CIRP Ann Manuf Technol 51(1):61–64

Zhang S, Zou B, Liu Y, Wang Y, Huang C, Liu Z (2018) Edge passivation and quality of carbide cutting inserts treated by wet micro-abrasive blasting. Int J Adv Manuf Technol 96(5-8):2307–2318

Chen T, Li SY, Han BX, Liu GJ (2014) Study on cutting force and surface micro-topography of hard turning of GCr15 steel. Int J Adv Manuf Technol 72(9-12):1639–1645

Davoudinejad A, Noordin MY (2014) Effect of cutting edge preparation on tool performance in hard-turning of DF-3 tool steel with ceramic tools. J Mech Sci Technol 28(11):4727–4736

Denkena B, Lucas A, Bassett E (2011) Effects of the cutting edge microgeometry on tool wear and its thermo-mechanical load. CIRP Ann Manuf Technol 60(1):73–76

Özel T, Karpat Y, Srivastava A (2008) Hard turning with variable micro-geometry PcBN tools. CIRP Ann Manuf Technol 57(1):73–76

Varghese A, Maurya PK, Kulkarni V, Joshi SS (2018) Experimental investigation of the correlation between surface roughness and tool-life in micromilling. Adv Mater Process Technol 5(1):67–77

Gao P, Wang XB, Liang ZQ, Xiang JF, Xie JQ (2019) Effects of WC grain size and Co content on microscale wear behavior of micro end mills in aluminum alloy 7075 machining. Int J Adv Manuf Technol 104(11-12):2401–2413

Bozga MB, Popa MS, Sattel S, Tomoiag VB (2017) Influence of the cutting edge microgeometry on the tool life in austenitic stainless steel machining with carbide end mill. MATEC Web Conf 112:01016

Fulemová J, Řehoř J (2015) Influence of form factor of the cutting edge on tool life during finishing milling. Procedia Eng 100:682–688

Zetek M, Lvana E, Vojtěch V (2014) Increasing cutting tool life when machining Inconel 718. Procedia Eng 69:1115–1124

Denkena B, Koehler J, Rehe M (2012) Influence of the honed cutting edge on tool wear and surface integrity in slot milling of 42CrMo4 steel. Procedia CIRP 1:190–195

Cheung FY, Zhou ZF, Geddam A, Li KY (2008) Cutting edge preparation using magnetic polishing and its influence on the performance of high-speed steel drills. J Mater Process Technol 208(1-3):196–204

Liang XL, Liu ZQ, Wang B (2019) State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: a review. Measurement 132:150–181

Ventura CE, Chaves HS, Rubio JCC, Abrão AM, Denkena B, Breidenstein B (2017) The influence of the cutting tool microgeometry on the machinability of hardened AISI 4140 steel. Int J Adv Manuf Technol 90(9):2557–2565

Özel T, Hsu TK, Zeren E (2005) Effects of cutting edge geometry, workpiece hardness, feed rate and cutting speed on surface roughness and forces in finish turning of hardened AISI H13 steel. Int J Adv Manuf Technol 25(3-4):262–269

Burhanuddin Y, Che Haron CH, Ghani JA (2011) The effect of tool edge geometry on tool performance and surface integrity in turning Ti-6Al-4V alloys. Adv Mater Res 264-265:1211–1221

Thiele JD, Melkote SN (1999) Effect of cutting edge geometry and workpiece hardness on surface generation in the finish hard turning of AISI 52100 steel. J Mater Process Technol 94(2–3):216–226

Zhao T, Agmell M, Persson J, Bushlya V, Ståhl JE, Zhou JM (2017) Correlation between edge radius of the cBN cutting tool and surface quality in hard turning. J Superhard Mater 39(4):251–258

Maiss O, Grove T, Denkena B (2017) Influence of asymmetric cutting edge roundings on surface topography. Prod Eng 11(4-5):383–388

Denkena B, Grove T, Maiss O (2015) Influence of the cutting edge radius on surface integrity in hard turning of roller bearing inner rings. Prod Eng 9(3):299–305

Karpat Y (2019) Influence of diamond tool chamfer angle on surface integrity in ultra-precision turning of singe crystal silicon. Int J Adv Manuf Technol 101(5):1565–1572

Khan SA, Umar M, Saleem MQ, Mufti NA, Raza SF (2018) Experimental investigations on wiper inserts’ edge preparation, workpiece hardness and operating parameters in hard turning of AISI D2 steel. J Manuf Process 34:187–196

Coelho R, Silva L, Braghini A, Bezerra A (2004) Some effects of cutting edge preparation and geometric modifications when turning Inconel 718™ at high cutting speeds. J Mater Process Technol 148(1):147–153

Han J, Hao X, Li L, Wu Q, He N (2017) Milling of high volume fraction SiCp/Al composites using PCD tools with different structures of tool edges and grain sizes. Int J Adv Manuf Technol 92(5-8):1875–1882

Zhou JM, Bushlya V, Peng RL, Johansson S, Avdovic P, Stahl JE (2011) Effects of tool wear on subsurface deformation of nickel-based superalloy. Procedia Eng 19:407–413

Bushlya V, Zhou JM, Ståhl JE (2012) Effect of cutting conditions on machinability of superalloy Inconel 718 during high speed turning with coated and uncoated PCBN tools. Procedia CIRP 3:370–375

Thiele JD, Melkote SN (2000) Effect of tool edge geometry on workpiece subsurface deformation and through-thickness residual stresses for hard turning of AISI 52100 steel. J Manuf Process 2(4):270–276

Li BX, Zhang S, Fang YJ (2019) Effect of edge hone radius on plowing-induced plastic deformation in hard milling: analytical modeling and experimental validation. Int J Adv Manuf Technol 105(7-8):3017–3029

Wyen C-F, Jaeger D, Wegener K (2012) Influence of cutting edge radius on surface integrity and burr formation in milling titanium. Int J Adv Manuf Technol 67(1-4):589–599

Bordin FM, Zeilmann RP (2014) Effect of the cutting edge preparation on the surface integrity after dry drilling. Procedia CIRP 13:103–107

Zeilmann RP, Ost CA, Fontanive F (2018) Characterization of edge preparation processes and the impact on surface integrity after milling of AISI P20 steel. J Braz Soc Mech Sci 40(9):421

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: A review. Int J Mach Tool Manu 51(3):250–280

Yin QG, Liu ZQ, Wang B, Song QH, Cai YK (2020) Recent progress of machinability and surface integrity for mechanical machining Inconel 718: a review. Int J Adv Manuf Technol 109(1-2):215–245

Zhang XM, Chen L, Ding H (2016) Effects of process parameters on white layer formation and morphology in hard turning of AISI 52100 steel. J Manuf Sci E T ASME 138(7):074502

Zhang XM, Huang XD, Chen L, Leopold J, Ding H (2017) Effects of sequential cuts on white layer formation and retained austenite content in hard turning of AISI 52100 steel. J Manuf Sci E T ASME 139(6):064502

Thiele JD, Melkote SN, Peascoe RA, Watkins TR (2000) Effect of cutting-edge geometry and workpiece hardness on surface residual stresses in finish hard turning of AISI 52100 steel. J Manuf Sci E T ASME 122(4):642–649

Bashir K, Alkali AU, Elmunafi MHS, Yusof NM (2018) Experimental investigation into effect of cutting parameters on surface integrity of hardened tool steel. IOP Conf Ser: Mater Sci Eng 344:012020

Zhang WW, Zhuang KJ (2020) Effect of cutting edge microgeometry on surface roughness and white layer in turning AISI 52100 steel. Procedia CIRP 87:53–58

Ren XP, Liu ZQ (2018) Microstructure refinement and work hardening in a machined surface layer induced by turning Inconel 718 super alloy. Int J Miner Metall Mater 25(8):937–949

Thakur DG, Ramamoorthy B, Vijayaraghavan L (2009) Study on the machinability characteristics of superalloy Inconel 718 during high speed turning. Mater Des 30(5):1718–1725

Umbrello D (2013) Investigation of surface integrity in dry machining of Inconel 718. Int J Adv Manuf Technol 69(9-12):2183–2190

Xu X, Zhang J, Outeiro J, Xu BB, Zhao WH (2020) Multiscale simulation of grain refinement induced by dynamic recrystallization of Ti6Al4V alloy during high speed machining. J Mater Process Technol 286:116834

Zheng GM, Cheng X, Dong YJ, Liu HB, Yu YZ (2020) Surface integrity evaluation of high-strength steel with a TiCN-NbC composite coated tool by dry milling. Measurement 166:108204

Hughes JI, Sharman ARC, Ridgway K (2006) The effect of cutting tool material and edge geometry on tool life and workpiece surface integrity. Proc Inst Mech Eng B J Eng 220(2):93–107

Rotella G, Dillon OW, Umbrello D, Settineri L, Jawahir IS (2013) The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int J Adv Manuf Technol 71(1-4):47–55

Wang B, Liu ZQ (2018) Influences of tool structure, tool material and tool wear on machined surface integrity during turning and milling of titanium and nickel alloys: a review. Int J Adv Manuf Technol 98(5-8):1925–1975

Arisoy YM, Özel T (2015) Prediction of machining induced microstructure in Ti–6Al–4V alloy using 3-D FE-based simulations: effects of tool micro-geometry, coating and cutting conditions. J Mater Process Technol 220:1–26

Jafarian F, Umbrello D, Jabbaripour B (2016) Identification of new material model for machining simulation of Inconel 718 alloy and the effect of tool edge geometry on microstructure changes. Simul Model Pract Theory 66:273–284

Gerstenmeyer M, Ort B-L, Zanger F, Schulze V (2017) Influence of the cutting edge microgeometry on the surface integrity during mechanical surface modification by complementary machining. Procedia CIRP 58:55–60

Segebade E, Zanger F, Schulze V (2016) Influence of different asymmetrical cutting edge microgeometries on surface integrity. Procedia CIRP 45:11–14

Dai X, Zhuang KJ, Pu DL, Zhang WW, Ding H (2020) An investigation of the work hardening behavior in interrupted cutting Inconel 718 under cryogenic conditions. Materials 13(9):2202

Hua Y, Liu ZQ (2018) Effects of cutting parameters and tool nose radius on surface roughness and work hardening during dry turning Inconel 718. Int J Adv Manuf Technol 96(5-8):2421–2430

Khan SA, Ahmad MA, Saleem MQ, Ghulam Z, Qureshi MAM (2016) High-feed turning of AISI D2 tool steel using multi-radii tool inserts: Tool life, material removed, and workpiece surface integrity evaluation. Mater Manuf Process 32(6):670–677

Montazeri S, Aramesh M, Veldhuis SC (2018) An investigation of the effect of a new tool treatment technique on the machinability of Inconel 718 during the turning process. Int J Adv Manuf Technol 100(1-4):37–54

Arısoy YM, Guo C, Kaftanoğlu B, Özel T (2016) Investigations on microstructural changes in machining of Inconel 100 alloy using face turning experiments and 3D finite element simulations. Int J Mech Sci 107:80–92

Zhang PR, Liu ZQ (2015) Effect of sequential turning and burnishing on the surface integrity of Cr–Ni-based stainless steel formed by laser cladding process. Surf Coat Technol 276:327–335

Hotz H, Kirsch B (2020) Influence of tool properties on thermomechanical load and surface morphology when cryogenically turning metastable austenitic steel AISI 347. J Manuf Process 52:120–131

Zhuang KJ, Hu C, Zhou JM, Peng RL (2020) Investigation on work hardening phenomenon in turning Inconel 718 with chamfered inserts considering thermal-mechanical loads. Procedia CIRP 87:47–52

Pawade RS, Joshi SS, Brahmankar PK (2008) Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int J Mach Tool Manu 48(1):15–28

Kundrak J, Mamalis AG, Gyani K, Bana V (2010) Surface layer microhardness changes with high-speed turning of hardened steels. Int J Adv Manuf Technol 53(1-4):105–112

Sarnobat SS, Raval HK (2019) Experimental investigation and analysis of the influence of tool edge geometry and work piece hardness on surface residual stresses, surface roughness and work-hardening in hard turning of AISI D2 steel. Measurement 131:235–260

Kurniawan D, Yusof NM, Sharif S (2010) Hard machining of stainless steel using wiper coated carbide: tool life and surface integrity. Mater Manuf Process 25(6):370–377

Bai W, Bisht A, Roy A, Suwas S, Sun R, Silberschmidt VV (2018) Improvements of machinability of aerospace-grade Inconel alloys with ultrasonically assisted hybrid machining. Int J Adv Manuf Technol 101(5-8):1143–1156

Agic A, Eynian M, Ståhl JE, Beno T (2018) Dynamic effects on cutting forces with highly positive versus highly negative cutting edge geometries. Int J Interact Des Manuf 13(2):557–565

Chen L, El-Wardany TI, Harris WC (2004) Modelling the effects of flank wear land and chip formation on residual stresses. CIRP Ann Manuf Technol 53(1):95–98

Huang ZY, He SJ, Zhuang KJ, Zhang XM, Ding H (2016) An analysis of cutting parameters, coated materials and nose radii on residual stresses when turning Inconel 718. Procedia CIRP 46:368–371

Arunachalam RM, Mannan MA, Spowage AC (2004) Surface integrity when machining age hardened Inconel 718 with coated carbide cutting tools. Int J Mach Tool Manu 44(14):1481–1491

Yang D, Xiao X, Liang XL (2019) Analytical modeling of residual stress in orthogonal cutting considering tool edge radius effect. Int J Adv Manuf Technol 103(5-8):2965–2976

Schoop J, Ambrosy F, Zanger F, Schulze V, Jawahir IS, Balk TJ (2015) Increased surface integrity in porous tungsten from cryogenic machining with cermet cutting tool. Mater Manuf Process 31(7):823–831

Nespor D, Denkena B, Grove T, Böß V (2015) Differences and similarities between the induced residual stresses after ball end milling and orthogonal cutting of Ti–6Al–4V. J Mater Process Technol 226:15–24

Özel T, Ulutan D (2012) Prediction of machining induced residual stresses in turning of titanium and nickel based alloys with experiments and finite element simulations. CIRP Ann Manuf Technol 61(1):547–550

Guddat J, M ' Saoubi R, Alm P, Meyer D (2011) Hard turning of AISI 52100 using PCBN wiper geometry inserts and the resulting surface integrity. Procedia Eng 19:118–124

Paschoalinoto NW, Bordinassi EC, Bortolussi R, Leonardi F, Delijaicov S (2020) The effect of process parameters and cutting tool shape on residual stress of SAE 52100 hard turned steel by high speed machining. Proc Inst Mech Eng B J Eng 235(1-2):290–300

Hua J, Umbrello D, Shivpuri R (2006) Investigation of cutting conditions and cutting edge preparations for enhanced compressive subsurface residual stress in the hard turning of bearing steel. J Mater Process Technol 171(2):180–187

Shen Q, Liu ZQ, Hua Y, Zhao JF, Lv WY, Mohsan A (2018) Effects of cutting edge microgeometry on residual stress in orthogonal cutting of Inconel 718 by FEM. Materials 11(6):1015

Funding

This work is partially supported by the National Natural Science Foundation of China (51705385, 51975237), and State Key Laboratory of Digital Manufacturing Equipment and Technology (DMETKF2020009, DMETKF2021005).

Author information

Authors and Affiliations

Contributions

KZ: supervision, original idea, manuscript writing. CF: manuscript writing, data collection. JW: reviewing and editing. CH: manuscript writing, data collection.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All the authors involved have agreed to participate in this submitted article.

Consent for publication

All the authors involved in this manuscript give full consent for publication of this submitted article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhuang, K., Fu, C., Weng, J. et al. Cutting edge microgeometries in metal cutting: a review. Int J Adv Manuf Technol 116, 2045–2092 (2021). https://doi.org/10.1007/s00170-021-07558-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07558-6