Abstract

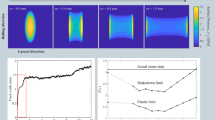

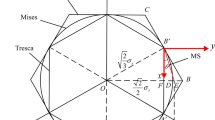

The analytical model for two-dimensional elastoplastic rolling/sliding contact proposed by McDowell is an important tool for predicting residual stress in rolling/sliding processes. In application of the model, a problem of low predicting precision near the surface layer of the component is found. According to the volumeconstancy of plastic deformation, an improved algorithm for McDowell’s model is proposed in order to improve its predicting accuracy of the surface residual stress. In the algorithm, a relationship between three normal stresses perpendicular to each other at any point within the component is derived, and the relationship is applied to McDowell’s model. Meanwhile, an unnecessary hypothesis proposed by McDowell can be eliminated to make the model more reasonable. The simulation results show that the surface residual stress predicted by modified method is much closer to the FEM results than the results predicted by McDowell’s model under the same simulation conditions.

Similar content being viewed by others

References

McDowell D L, Moyar G L, (1991), Wear, 144: 19–37

Sehitoglu H, Jiang R Y. An analytical approach for elastoplastic stress analysis of rolling contact, AAR Report No. 4, November, 1991

McDowell D L, Moyar G J. A more realistic model of nonlinear material respond: application to elastoplastic rolling contact, Proc. 2rid Int. Syrup. On Contact Mechanics and Wear of Rail / Wheel Systems. University of Rhode Island, Kingston, RI, 8–11, July, 1986

McDowell D L. An approximate algorithm for elastoplastic two-dimensional rolling/sliding contact. Wear, 1997, 211(2): 237–246

Ulutan D, Erdem Alaca B, Lazoglu I. Analytical modelling of residual stresses in machining. Journal of Materials Processing Technology, 2007, 183(1): 77–87

Lazoglu I, Ulutan D, Alaca B E, Engin S, Kaftanoglu B. An enhanced analytical model for residual stress prediction in machining. CIRP Annals-Manufacturing Technology, 2008, 57(1): 81–84

Liang S Y, Su J C. Residual Stress Modeling in Orthogonal Machining, Annals of the CIRP, Vol. 56/1/2007

Su J C. Residual Stress Modeling in Machining Processes. Georgia Institute of Technology, 2006

Agrawal S, Joshi S S. Analytical modeling of residual stresses in orthogonal machining of AISI4340 steel. Journal of Manufacturing Processes, 2013, 15(1): 167–179

Starovoito E I. Faig Bakhman Ogli Naghiyev, Foundations of the Theory of Elasticity, Plasticity and Viscoelasticity, Apple Academic Press Inc., 2012

Kumar A M, Hahn G T, Bhargava V, Rubin C. Elasto-plastic finite element analyses of two-dimensional rolling and sliding contact deformation of bearing steel, ASME J Tribol, 1989, 111: 309–314

Bhargava V, Hahn G T, Ham G, Kulkarni S, Rubin C A. Influence of kinematic hardening on rolling contact deformation, in: Gladwell G, Ghonem H, Kalousek J (Eds.). Contact Mechanics and Wear of Rail/Wheel Systems II, University of Waterloo Press, 1987: 33–146

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qi, Z., Li, B. & Xiong, L. An improved algorithm for McDowell’s analytical model of residual stress. Front. Mech. Eng. 9, 150–155 (2014). https://doi.org/10.1007/s11465-014-0295-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-014-0295-9