Abstract

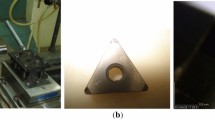

Tool life is a significant issue for the application of micro mills. Optimizing cutting edge geometries of micro mill is an effective way to improve tool life. This paper investigates the effects of different chamfered cutting edges of micro mill on the tool cutting performance. A series of slot milling experiments are conducted on aluminum alloy 7075 by using micro mills with various cutting edge chamfer lengths, and the tool wear and surface roughness are measured. The results show that the cutting edge chamfer of micro mill can improve the tool life. For the micro mill fabricated with sharp cutting edge, the fracture of cutting edge easily occurs resulting in the tool early broken. As the cutting edge chamfer length is bigger, the tool life becomes longer, but the tool flank wear width increases due to the higher stress in cutting region. However, the effects of various cutting edge chamfer lengths on surface roughness are not obviously found.

Similar content being viewed by others

References

Cheng X, Wang Z, Nakamoto K, Yamazaki K (2010) Design and development of PCD micro straight edge end mills for micro/nano machining of hard and brittle materials. J Mech Sci Technol 24(11):2261–2268. https://doi.org/10.1007/s12206-010-0804-7

Cheng X, Wang Z, Nakamoto K, Yamazaki K (2011) A study on the micro tooling for micro/nano milling. Int J Adv Manuf Technol 53(5-8):523–533. https://doi.org/10.1007/s00170-010-2856-3

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Ann 63(2):631–653. https://doi.org/10.1016/j.cirp.2014.05.009

Denkena B, Köhler J, Bergmann B (2015) Development of cutting edge geometries for hard milling operations. CIRP J Manuf Sci Technol 8:43–52

Wan L, Wang D, Gao Y (2015) Investigations on the effects of different tool edge geometries in the finite element simulation of machining. Stroj Vestn-J Mech E 61(3):157–166. https://doi.org/10.5545/sv-jme.2014.2051

Fang N, Wu Q (2005) The effects of chamfered and honed tool edge geometry in machining of three aluminum alloys. Int J Mach Tools Manuf 45(10):1178–1187. https://doi.org/10.1016/j.ijmachtools.2004.12.003

Karpat Y, Özel T (2008) Mechanics of high speed cutting with curvilinear edge tools. Int J Mach Tools Manuf 48(2):195–208. https://doi.org/10.1016/j.ijmachtools.2007.08.015

Özel T (2009) Computational modelling of 3D turning: influence of edge micro-geometry on forces, stresses, friction and tool wear in PcBN tooling. J Mater Process Technol 209(11):5167–5177. https://doi.org/10.1016/j.jmatprotec.2009.03.002

Varela PI, Rakurty CS, Balaji AK (2014) Surface integrity in hard machining of 300 M steel: effect of cutting-edge geometry on machining induced residual stresses. Procedia Cirp 13:288–293. https://doi.org/10.1016/j.procir.2014.04.049

Almeida FA, Oliveira FJ, Sousa M, Frenandes AJS, Sacrameto J, Silva RF (2005) Machining hardmetal with CVD diamond direct coated ceramic tools: effect of tool edge geometry. Diam Relat Mater 14(3-7):651–656. https://doi.org/10.1016/j.diamond.2004.09.002

He G, Liu X, Wu C, Zhang S, Zou L, Li D (2016) Study on the negative chamfered edge and its influence on the indexable cutting insert’s lifetime and its strengthening mechanism. Int J Adv Manuf Technol 84(5–8):1229–1237

Gilbin A, Fontaine M, Michel G, Thibaud S, Picard P (2013) Capability of tungsten carbide micro-mills to machine hardened tool steel. Int J Precis Eng Manuf 14(1):23–28. https://doi.org/10.1007/s12541-013-0004-3

Jafarian F, Umbrello D, Jabbaripour B (2016) Identification of new material model for machining simulation of Inconel 718 alloy and the effect of tool edge geometry on microstructure changes. Simul Model Pract Theory 66:273–284. https://doi.org/10.1016/j.simpat.2016.05.001

Wang MY, Chang HY (2004) Experimental study of surface roughness in slot end milling AL2014-T6. Int J Mach Tools Manuf 44(1):51–57. https://doi.org/10.1016/j.ijmachtools.2003.08.011

Kountanya R, Al-Zkeri I, Altan T (2009) Effect of tool edge geometry and cutting conditions on experimental and simulated chip morphology in orthogonal hard turning of 100Cr6 steel. J Mater Process Technol 209(11):5068–5076

Kang IS, Kim JS, Kim JH, Kang MC, Seo YW (2007) A mechanistic model of cutting force in the micro end milling process. J Mater Process Technol 187–188(3):250–255

Woon KS, Rahman M, Fang FZ, Neo KS, Liu K (2008) Investigations of tool edge radius effect in micromachining: a fem simulation approach. J Mater Process Technol 195(1–3):204–211. https://doi.org/10.1016/j.jmatprotec.2007.04.137

Bassett E (2014) Belastungsspezifische Auslegung und Herstellung von Schneidkanten für Drehwerkzeuge (PhD-Thesis) Leibniz Universität, Hannover.

Torres CD (2009) Analyzing the performance of diamond-coated micro end mills. Int J Mach Tools Manuf 49(7):599–612. https://doi.org/10.1016/j.ijmachtools.2009.02.001

Funding

This work was supported by the National Basic Research Program of China (No. 2015CB059900), National Natural Science Foundation of China (No. 51575049), and Beijing Institute of Technology (BIT) Foundation for Fundamental Research (No. 20150342013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, P., Liang, Z., Wang, X. et al. Effects of different chamfered cutting edges of micro end mill on cutting performance. Int J Adv Manuf Technol 96, 1215–1224 (2018). https://doi.org/10.1007/s00170-018-1640-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1640-7