Abstract

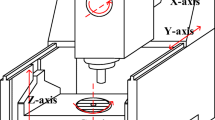

Dicing of semiconductor chips constitutes an important procedure in the processing of integrated circuits, which poses a high-precision and high-speed stability requirements for dicing saw. In this study, the optimization of motion accuracy and position accuracy of dual-axis dicing saw (DDS) is studied and an overall control scheme of the DDS is designed. A programmable multi-axis controller (PMAC) is selected as the main control module and the servo motor is adopted as the linear axis drive element. The positioning algorithm of servo control system is analyzed. The position deviations are studied under different proportional gains, integral time constants, and speed feedforward gains. The high-precision contact and non-contact positioning method of the machine tool is developed. Positioning error of each linear axis is compensated using positioning error compensation module of PMAC. The dicing test results demonstrate that the improved control system could be used for high-precision and high-speed stability dicing of semiconductor chips.

Similar content being viewed by others

References

Kifle E, Loiko P, Griebner U, Petrov V, Camy P, Braud A, Aguilo M, Diaz F, Mateos X (2019) Diamond saw dicing of thulium channel waveguide lasers in monoclinic crystalline films. Opt Lett 44:1596–1599

Loiko P, Soulard R, Brasse G, Doualan JL, Guichardaz B, Braud A, Tyazhev A, Hideur A, Camy P (2018) Watt-level Tm: LiYF4 channel waveguide laser produced by diamond saw dicing. Opt Express 26(19):24653–24662

Wu SJ (2018) A hybrid method of ultrafast laser dicing and high density plasma etching with water soluble mask for thin silicon wafer cutting. Mater Sci Semicond Process 74:64–73

Chen FJ, Ye XQ, Yin SH, Ye QS, Huang S, Tang QC (2019) Automated vision positioning system for dicing semiconductor chips using improved template matching method. Int J Adv Manuf Technol 100(9–12):2669–2678

Araujo LAO, Foschini CR, Jasinevicius RG, Fortulan CA (2016) Precision dicing of hard materials with abrasive blade. Int J Adv Manuf Technol 86(9–12):2885–2894

Kim SC, Lee ES, Kim NH, Jeong HD (2007) Machining characteristics on the ultra-precision dicing of silicon wafer. Int J Adv Manuf Technol 33(7–8):662–667

Lee SM (2015) Effect of sawing velocity variation on the mechanical dicing-induced damage in semiconductor silicon wafer. Korean J Met Mater 53(5):306–311

Chae SH, Zhao JH, Edwards DR, Ho PS (2010) Effect of dicing technique on the fracture strength of Si dies with emphasis on multimodal failure distribution. IEEE T Device Mat Re 10(1):149–156

Von Witzendorff P, Stompe M, Moalem A, Cvetkovic S, Suttmann O, Overmeyer L, Rissing L (2014) Dicing of hard and brittle materials with on-machine laser-dressed metal-bonded diamond blades. Precis Eng 38(1):162–167

Li KN, Wang MZ, Chen F, Yan N, Zou Q, Zhao YC, Li JM, Zhao F (2018) Analysis of the dynamic diameter of superthin diamond blades in the high speed and precision dicing process. Int J Precis Eng Manuf 20:1071–1081

Deng JH, Zhang JQ, Tu YB, Yang PX, An MZ, Wang P (2018) Effect of BEO in the electrodeposition process of Ni/diamond composite coatings for preparation of ultra-thin dicing blades: experiments and theoretical calculations. Ceram Int 44:16828–16836

Zhou HX, Qiu S, Huo YX, Zhang NM (2013) High-speed dicing of silicon wafers conducted using ultrathin blades. Int J Adv Manuf Tech 66(5–8):947–953

Luo SY, Wang ZW (2008) Studies of chipping mechanisms for dicing silicon wafers. Int J Adv Manuf Tech 35:1206–1218

Ang ZZ, Zhang JF, Wang ZK, Liu W, Zhao P (2019) Progress of organic light emitting diodes based on graphene transparent conductive films. Surf Tech 48(6):30–45

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools - a review: part II: thermal errors. Int J Mach Tool Manuf 40(9):1257–1284

Huo F, Poo AN (2013) Precision contouring control of machine tools. Int J Adv Manuf Technol 64(1–4):319–333

Sato R, Hasegawa S, Shirase K, Hasegawa M, Saito A, Iwasaki T (2018) Motion accuracy enhancement of five-axis machine tools by modified CL-data. Int J Automot Technol 12(5):699–706

Sarina ZSY, Xu JH (2013) Transmission system accuracy optimum allocation for multiaxis machine tools' scheme design. P I Mech Eng C-J Mec 227(12):2762–2779

Cheng X, Li L, Huang YM, Zhou SJ, Yang XH, Liu JY (2013) Study on the error distribution and key parameters for a desktop multi-axis micro milling machine tool. Int J Adv Manuf Technol 67(9–12):2521–2527

Fu GQ, Fu JZ, Xu YT, Chen ZC, Lai JT (2015) Accuracy enhancement of five-axis machine tool based on differential motion matrix: geometric error modeling, identification and compensation. Int J Mach Tools Manuf 89:170–181

Hidalgo D, Yeh SS (2018) Development of an analyzing and tuning technology for improving circularity of cone-frustum motions of five-axis CNC machine tools. Int J Adv Manuf Technol 97(9–12):3283–3297

Jiang XG, Wang L, Liu C (2019) Investigation of rotary axes geometric performance of a five-axis machine tool using a double ball bar through dual axes coordinated motion. Int J Adv Manuf Technol 103(9–12):3943–3952

Nojehdeh MV, Arezoo B (2016) Functional accuracy investigation of work-holding rotary axes in five axis CNC machine tools. Int J Mach Tools Manuf 111:17–30

Li XF, Zhao H, Zhao X, Ding H (2017) Contouring compensation control based on high accuracy contour error estimation for multi-axis motion systems. Int J Adv Manuf Technol 93(5–8):2263–2273

Ding S, Huang XD, Yu CJ, Liu XY (2016) Novel method for position-independent geometric error compensation of five-axis orthogonal machine tool based on error motion. Int J Adv Manuf Technol 83(5–8):1069–1078

Wang HQ, Bai W (2019) Finite-time adaptive fault-tolerant control for strict-feedback nonlinear systems. Chin Control Decis Conf 2019:5269–5273

Sun K, Qiu JB, Hamid RK, Yili F (2020) Event-triggered robust fuzzy adaptive finite-time control of nonlinear systems with prescribed performance. IEEE T Fuzzy Syst 99:1–1

Liu Y, Liu XP, Jing YW, Zhang ZY (2019) A novel finite-time adaptive fuzzy tracking control scheme for nonstrict feedback systems. IEEE T Fuzzy Syst 27(4):646–658

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, J., Chen, G. & Chen, F. Positioning accuracy control of dual-axis dicing saw for machining semiconductor chip. Int J Adv Manuf Technol 109, 2299–2310 (2020). https://doi.org/10.1007/s00170-020-05798-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05798-6