Abstract

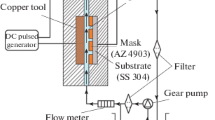

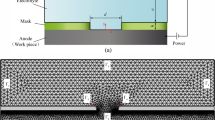

Surface texturing with micro-dimples has been proved to be an effective approach in many fields to improve the functionalities and performances of some mechanical components. Through-mask electrochemical micromachining (TMEMM) is a popular technique to create textures on metallic surface, but it is still very challenging to be used to texture curved surface. In this paper, a novel TMEMM process was proposed to generate micro-dimple array on the cylindrical surface. In this TMEMM process, a foamed metal film with a good pliancy performance and a huge number of interconnected micropores is introduced to serve as the cathode, which is further integrated with the reusable through-mask and workpiece to form a sandwich-like assembly. The current distribution within each region being machined and its correlation with the geometric dimensions of through-hole, as well as with the relative location of the through-hole in the mask, are analyzed numerically. With this TMEMM process, a great number of micro-dimples with a good uniformity in their geometric dimensions can be produced both on the planar and the entire 360° cylindrical workpiece surfaces in only one operation, showing the minimum coefficient of variation of the dimple’s depth and diameter being 5.6 and 2.4%, respectively. The reasons for such a favorable result are interpreted theoretically. The proposed TMEMM process here could have a great potential in generating geometrically consistent surface textures on the curved surface efficiently and low-costly.

Similar content being viewed by others

References

Evans CJ, Bryan JB (1999) Structured, textured or engineered surfaces. CIRP Ann Manuf Technol 48(2):541–556

Bruzzone AAG, Costa HL, Lonardo PM, Lucca DA (2008) Advances in engineered surfaces for functional performance. CIRP Ann Manuf Technol 57(2):750–769

Li XM, Reinhoudt D, Crego-Calama M (2007) What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces. Chem Soc Rev 36(8):1350–1368

Wakuda M, Yamauchi Y, Kanzaki S, Yasuda Y (2003) Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254(3):356–363

Demir AG, Previtali B, Lecis N (2013) Development of laser dimpling strategies on TiN coatings for tribological applications with a highly energetic Q-switched fibre laser. Opt Laser Technol 54:53–61

Burzynski T, Papini M (2010) Level set methods for the modelling of surface evolution in the abrasive jet micromachining of features used in MEMS and microfluidic devices. J Micromech Microeng 20(8):085004

Amanov A, Pyoun YS, Cho IS, Lee CS, Park IG (2012) Micro-dimpled surface by ultrasonic nanocrystal surface modification and its tribological effects. Wear 286:136–144

Zhang J, Meng Y (2012) A study of surface texturing of carbon steel by photochemical machining. J Mater Process Technol 212(10):2133–2140

Datta M, Landolt D (1981) Electrochemical machining under pulsed current conditions. Electrochi Acta 26(7):899–907

Rajurkar KP, Zhu D, McGeough JA, Kozak J, De Silva A (1999) New developments in electro-chemical machining. CIRP Ann Manuf Technol 48(2):567–579

Costa HL, Hutchings IM (2007) Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol Int 40(8):1227–1238

Costa HL, Hutchings IM (2009) Effects of die surface patterning on lubrication in strip drawing. J Mater Process Technol 209(3):1175–1180

Datta M, Harris D (1997) Electrochemical micromachining: an environmentally friendly, high speed processing technology. Electrochim Acta 42(20–22):3007–3013

Chauvy PF, Hoffmann P, Landolt D (2003) Applications of laser lithography on oxide film to titanium micromachining. Appl Surf Sci 208:165–170

Landolt D, Chauvy PF, Zinger O (2003) Electrochemical micromachining, polishing and surface structuring of metals: fundamental aspects and new developments. Electrochi Acta 48(20):3185–3201

Asoh H, Oide A, Ono S (2006) Formation of microstructured silicon surfaces by electrochemical etching using colloidal crystal as mask. Electrochem Communi 8(12):1817–1820

Schönenberger I, Roy S (2005) Microscale pattern transfer without photolithography of substrates. Electrochi Acta 51(5):809–819

Costa HL, Hutchings IM (2009) Development of a maskless electrochemical texturing method. J Mater Process Technol 209(8):3869–3878

Parreira JG, Gallo CA, Costa HL (2012) New advances on maskless electrochemical texturing (MECT) for tribological purposes. Surf Coat Technol 212:1–13

Qu NS, Chen XL, Li HS, Zeng YB (2014) Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist. Chin J Aeronaut 27:1030–1036

Qu NS, Zhang XF, Chen XL, Li HS, Zhu D (2015) Modified microscale pattern transfer without photolithography of substrates. J Mater Process Technol 218:71–79

Zhang XF, Qu NS, Chen XL (2016) Sandwich-like electrochemical micromachining of micro-dimples. Surf Coat Technol 302:438–447

Zhu D, Qu NS, Li HS, Zeng YB, Li DL, Qian SQ (2009) Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann Manuf Technol 58(1):177–180

Qian SQ, Zhu D, Qu NS, Li HS, Yan DS (2010) Generating micro-dimples array on the hard chrome-coated surface by modified through mask electrochemical micromachining. Int J Adv Manuf Technol 47(9–12):1121–1127

Li DL, Zhu D, Li HS, Liu JG (2011) Effects of mask wall angle on matrix-hole shape changes during electrochemical machining by mask. J Cent S Univ Technol 18(4):1115–1120

Li DL, Zhu D, Li HS (2011) Microstructure of electrochemical micromachining using inert metal mask. Int J Adv Manuf Technol 55(1–4):189–194

Chen XL, Qu NS, Li HS, Zhu D (2014) The fabrication and application of a PDMS micro through-holes mask in electrochemical micromanufacturing. Adv Mech Eng 6:943092

Qu NS, Chen XL, Li HS, Zhu D (2014) Fabrication of PDMS micro through-holes for electrochemical micromachining. Int J Adv Manuf Technol 72:487–494

Chen XL, Qu NS, Li HS, Guo Z (2015) Removal of islands from micro-dimple arrays prepared by through-mask electrochemical micromachining. Precis Eng 39:204–211

Chen XL, Qu NS, Li HS, Xu ZY (2016) Electrochemical micromachining of micro-dimple arrays using a polydimethylsiloxane (PDMS) mask. J Mater Process Technol 229:102–110

Ming PM, Zhou WH, Zhao CH, Zhou HM, Qin G, Zhang XM (2016) Active through-mask electrochemical machining with its interelectrode gap filled with flexible porous material (in Chinese). Sci Sin Tech 46(10):1005–1015

West AC, Matlosz M, Landolt D (1991) Normalized and average current distributions on unevenly spaced patterns. J Electrochem Soc 138(3):728–735

Sautebin R, Froidevaux H, Landolt D (1980) Theoretical and experimental modeling of surface leveling in ECM under primary current distribution conditions. J Electrochem Soc 127(5):1096–1100

Shenoy RV, Datta M (1996) Effect of mask wall angle on shape evolution during through-mask electrochemical micromachining. J Electrochem Soc 143(2):544–549

Shenoy RV, Datta M, Romankiw LT (1996) Investigation of island formation during through-mask electrochemical micromachining. J Electrochem Soc 143(7):2305–2309

West AC, Madore C, Matlosz M, Landolt D (1992) Shape changes during through-mask electrochemical micromachining of thin metal films. J Electrochem Soc 139(2):499–506

Datta M, Landolt D (2000) Fundamental aspects and applications of electrochemical microfabrication. Electrochi Acta 45(5):2535–2558

Madore C, Piotrowski O, Landolt D (1999) Through-mask electrochemical micromachining of titanium. J Electrochem Soc 146(7):2526–2532

Vuik C, Cuvelier C (1985) Numerical solution of an etching problem. J Comp Phys 59(2):247–263

Chen XL, Qu NS, Li HS (2015) Improvement of dimensional uniformity on micro-dimple arrays generated by electrochemical micro-machining with an auxiliary electrode. Int J Adv Manuf Technol 81:1577–1585

Zhang XF, Qu NS, Li HS, Xu ZY (2015) Investigation of machining accuracy of micro-dimples fabricated by modified microscale pattern transfer without photolithography of substrates. Int J Adv Manuf Technol 81(9–12):1475–1485

Zhang XF, Qu NS, Fang XL (2017) Sandwich-like electrochemical micromachining of micro-dimples using a porous metal cathode. Surf Coat Technol 311:357–364

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51475149), Plan for Scientific Innovation Talent of Henan Province (No. 154100510008), and the Program for Science & Technology Innovation Team in Henan Polytechnic University (No. T2014-1).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ming, P., Zhao, C., Zhang, X. et al. Investigation of foamed cathode through-mask electrochemical micromachining developed for uniform texturing on metallic cylindrical surface. Int J Adv Manuf Technol 96, 3043–3056 (2018). https://doi.org/10.1007/s00170-018-1755-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1755-x