Abstract

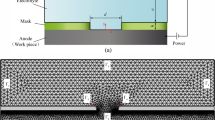

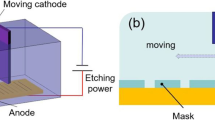

Electrochemical micromachining (EMM) has been gaining popularity as an alternative method to fabricate microstructure. A method of EMM is proposed to produce microhole array or micro-dimple array, in which a patterned inert metal mask (platinum plate) is closely attached to workpiece (anode), not bonded to the anode. When voltage is applied across the anode and the cathode over which electrolyte flows at a high speed, the patterns in the mask are transferred to the anode, and microstructures are produced. A mathematical model to describe the actual machining process is established. By considering the effect of nonlinear electrolyte, the parametric finite element method is adopted to simulate and numerically analyze the erosion process. Some experiments are performed to verify the proposed model.

Similar content being viewed by others

References

Lee ES, Baek SY, Cho CR (2005) A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses. Int J Adv Manuf Technol 31(7–8):762–769

Rajurkar KP, Levy G, Malshe A, Sundaram MM, McGeough J, Hu X, Resnick R, DeSilva A (2006) Micro and nano machining by electro-physical and chemical processes. CIRP Ann-Manuf Technol 55(2):643–666

Lee SJ, Lee CY, Yang KT, Kuan FH, Lai PH (2008) Simulation and fabrication of micro-scaled flow channels for metallic bipolar plates by the electrochemical micro-machining process. J Power Sources 185(2):1115–1121

Jo CH, Kim BH, Chu CN (2009) Micro electrochemical machining for complex internal micro features. CIRP Ann-Manuf Technol 58(1):181–184

Zhu D, Qu NS, Li HS, Zeng YB, Li DL, Qian SQ (2009) Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann-Manuf Technol 58(1):177–180

Qian SQ, Zhu D, Qu NS, Li HS, Yan DS (2010) Generating micro-dimples array on the hard chrome-coated surface by modified through mask electrochemical micromachining. Int J Adv Manuf Technol 47(9–12):1121–1127

Madore C, Piotrowski O, Landolt D (1999) Through-mask electrochemical micromachining of titanium. J Electrochem Soc 146(7):2526–2532

Hardisty H, Mileham AR, Shirvarni H, Bramley AN (1993) A finite element simulation of the electrochemical machining process. CIRP Ann-Manuf Technol 42(1):201–204

Shenoy RV, Datta M, Romankiw LT (1996) Investigation of island formation during through-mask electrochemical micromachining. J Electrochem Soc 143(7):2305–2309

West AC, Madore C, Matlosz M, Landolt D (1992) Shape changes during through-mask electrochemical micromachining of thin metal films. J Electrochem Soc 139(2):499–506

Lee ES, Park JW, Moon YH (2002) A study on electrochemical micromachining for fabrication of microgrooves in an air-lubricated hydrodynamic bearing. Int J Adv Manuf Technol 20(10):720–726

Lohrengel MM, Klüppel I, Rosenkranz C, Bettermann H, Schultze JW (2003) Microscopic investigations of electrochemical machining of Fe in NaNO3. Electrochem Acta 48(20–22):3203–3211

Rajurkar KP, Zhu D, Wei B (1998) Minimzation of machining allowance in electrochemical machining. CIRP Ann-Manuf Technol 47(1):165–168

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, D., Zhu, D. & Li, H. Microstructure of electrochemical micromachining using inert metal mask. Int J Adv Manuf Technol 55, 189–194 (2011). https://doi.org/10.1007/s00170-010-3025-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3025-4