Abstract

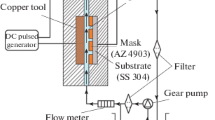

Micro-dimples are among the basic microfeatures that have been applied to different products in various fields. The product performance and service life of textured surfaces are directly affected by size, location, and density. A modified microscale pattern transfer process without photolithography of substrates, through the use of movable dry-film mask electrochemical micromachining, has been proposed for the production of micro-dimples. This paper investigates the influence of electrochemical micromachining parameters, namely, applied voltage and machining time on the machining accuracy of micro-dimples produced using this technique. Experimental results indicate that the machining accuracy deteriorates with prolonged machining time and increasing applied voltage. It is found that to obtain high machining accuracy when machining micro-dimples of similar depth, a combination of higher current density with reduced machining time is recommended.

Similar content being viewed by others

References

Ancona A, Carbone G, Scaraggi M et al (2014) Laser surface micro-texturing to enhance the frictional behavior of lubricated steel. Proc SPIE 8968:896806

Menezes PL, Kishore KSV (2010) Influence of die surface textures during metal forming—a study using experiments and simulation. Mater Manuf Process 25(9):1030–1039

Burzynski T, Papini M (2010) Level set methods for the modelling of surface evolution in the abrasive jet micromachining of features used in MEMS and microfluidic devices. J Micromech Microeng 20(8):085004

Syahputra HP, Ko TJ (2013) Application of image processing to micro-milling process for surface texturing. Int J Precis Eng Manuf 14(9):1507–1512

Hyde JM, Cadet L, Montgomery J et al (2014) Multi-scale areal topographic analysis of surfaces created by micro-EDM and functional correlations with discharge energy. Surf Topogr Metrol Prop 2(4):045001

Fan H, Hu T, Zhang Y et al (2014) Tribological properties of micro-textured surfaces of ZTA ceramic nanocomposites under the combined effect of test conditions and environments. Tribol Int 78:134–141

Zhu D, Qu NS, Li HS, Zeng YB, Li DL, Qian SQ (2009) Electrochemical micromachining of microstructures of micro hole and dimple array. CIRP Ann Manuf Technol 58:177–180

Rajurkar KP, Sundaram MM, Malshe AP (2013) Review of electrochemical and electrodischarge machining. Proc CIRP 6:13–26

Malapati M, Bhattacharyya B (2011) Investigation into electrochemical micromachining process during micro-channel generation. Mater Manuf Process 26(8):1019–1027

Hao X, Wang L, Wang Q et al (2011) Surface micro-texturing of metallic cylindrical surface with proximity rolling-exposure lithography and electrochemical micromachining. Appl Surf Sci 257(21):8906–8911

Chen X, Qu N, Li H et al (2014) The fabrication and application of a PDMS micro through-holes mask in electrochemical micromanufacturing. Adv Mech Eng 2014:943092

Qian S, Zhu D, Qu N et al (2010) Generating micro-dimples array on the hard chrome-coated surface by modified through mask electrochemical micromachining. Int J Adv Manuf Technol 47(9–12):1121–1127

Wang X, Kato K, Adachi K et al (2003) Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol Int 36(3):189–197

Roy T, Choudhury D, Bin Mamat A et al (2014) Fabrication and characterization of micro-dimple array on Al2O3 surfaces by using a micro-tooling. Ceram Int 40(1):2381–2388

Thanigaivelan R, Arunachalam RM (2010) Experimental study of overcut in electrochemical micromachining for 304 stainless steel. Trans NAMRI/SME 38:253–260

Rathod V, Doloi B, Bhattacharyya B (2014) Experimental investigations into machining accuracy and surface roughness of microgrooves fabricated by electrochemical micromachining. Proc Inst Mech Eng B J Eng Manuf. doi:10.1177/0954405414539486

Parreira JG, Gallo CA, Costa HL (2012) New advances on maskless electrochemical texturing (MECT) for tribological purposes. Surf Coat Technol 212:1–13

Qu NS, Chen XL, Li HS, Zeng YB (2014) Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist. Chin J Aeronaut 27:612–618

Qian S, Ji F, Qu N et al (2014) Improving the localization of surface texture by electrochemical machining with auxiliary anode. Mater Manuf Process 29(11–12):1488–1493

Qu NS, Zhang XF, Chen XL et al (2015) Modified microscale pattern transfer without photolithography of substrates. J Mater Process Technol 218:71–79

Hackert-Oschätzchen M, Kowalick M, Meichsner G, Schubert A (2012) Multiphysics simulation of the electrochemical finishing of micro bores. In Proceedings of the European COMSOL Conference

Hackert-Oschätzchen M, Kowalick M, Meichsner G, et al (2013) 2D Axisymmetric simulation of the electrochemical finishing of micro bores by inverse jet electrochemical machining. In Proceedings of the European COMSOL Conference

Nouraei S, Roy S (2008) Electrochemical process for micropattern transfer without photolithography: a modeling analysis. J Electrochem Soc 155:D97–D103

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, X., Qu, N., Li, H. et al. Investigation of machining accuracy of micro-dimples fabricated by modified microscale pattern transfer without photolithography of substrates. Int J Adv Manuf Technol 81, 1475–1485 (2015). https://doi.org/10.1007/s00170-015-7283-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7283-z