Abstract

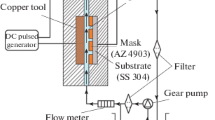

It has been recently identified that micro-dimples can act as fluid reservoirs and promote the retention of a lubricating film to reduce friction between mechanical components. Various techniques are employed to produce micro-dimples on the surface of friction pair. In this study, a modified through mask electrochemical micromachining (TMEMM), in which the insulation layer was directly attached to the cathode, was developed to produce micro-dimples on the hard chrome-coated surface. By controlling machining parameters, micro-dimples array, with hundreds of micrometers in diameter and several micrometers in depth, were produced. Compared with the traditional TMEMM, the modified method can both reduce cost and improve machining efficiency. Friction experiments show that the friction coefficient of the surface with appropriate micro-dimples array is obviously lower than that with nondimples.

Similar content being viewed by others

References

Wakuda M, Yamauchi Y, Kanzaki S, Yasuda Y (2003) Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254:356–363

Blatter A, Maillat M, Pimenov SM, Shafeev GA, Simakin AV, Loubnin EN (1999) Lubricated sliding performance of laser-patterned sapphire. Wear 232:226–230

Ryk G, Kligerman Y, Etsion I (2002) Experimental investigation of laser surface texturing for reciprocating automotive components. Tribol Trans 45:444–449

Herbert D (1999) Blast finishing. Metal Finish 97(1):93

Wakuda M, Yamauchi Y, Kanzaki S (2003) Material response to particle impact during abrasive jet machining of alumina ceramics. J Mater Process Technol 132:177–183

Wang X, Kato K, Adachi K, Aizawa K (2001) The effect of laser texturing of Sic surface on the critical load for the transition of water lubrication mode from hydrodynamic to mixed. Tribol Int 34:703–711

Munda J, Bhattacharyya B (2008) Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int J Adv Manuf Technol 35:821–832

Bhattacharyya B, Doloi B, Sridhar PS (2001) Electrochemical micro-machining: new possibilities for micro-manufacturing. J Mater Process Technol 113:301–305

Kozak J, Rajurkar KP, Makkar Y (2004) Selected problems of micro-electrochemical machining. J Mater Process Technol 149:426–431

Madore C, Piotrowski O, Landolt D (1999) Through-mask electrochemical micromachining of titanium. J Electrochem Soc 146:2526–2532

Lu X, Leng Y (2005) Electrochemical micromachining of titanium surfaces for biomedical applications. J Mater Process Technol 169:173–178

Williams JD, Wang WJ (2004) Study on the postbaking process and the effects on UV lithography of high aspect ratio SU-8. J Microlithogr Microfabrication Microsyst 3:563–568

Mardare AI, Wieck AD, Hassel AW (2007) Microelectrochemical lithography: a method for direct writing of surface oxides. Electrochimica Acta 52:7865–7869

JainVK PPC (1981) Tooling design for ECM: a finite element approach. J Eng Ind Trans ASME 103:183–191

Zhu D, Wang K, Yang J (2003) Design of electrode profile in electrochemical manufacturing process. Ann CIRP 52(1):169–172

Hocheng H, Sun YH, Lin SC, Kao PS (2003) A material removal analysis of electrochemical machining using flat-end cathode. J Mater Process Technol 140:264–268

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qian, S., Zhu, D., Qu, N. et al. Generating micro-dimples array on the hard chrome-coated surface by modified through mask electrochemical micromachining. Int J Adv Manuf Technol 47, 1121–1127 (2010). https://doi.org/10.1007/s00170-009-2246-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2246-x