Abstract

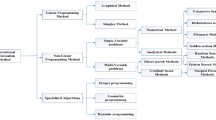

Non-traditional algorithms are the realistic models that are used for solving many complex engineering optimization problems. Machining is one of the most important and widely used manufacturing processes which rely on optimization. Optimization problems may be either constrained or unconstrained in nature. The complication factor with constrained optimization is that there is a possible existence of one or more complex constraints. These constraints must be incorporated into the problem otherwise solution is unacceptable from a practical standpoint. Non-traditional algorithms are the best way for solving the constrained optimization problems. The advantages of non-traditional techniques are its tolerant of imprecision, uncertainty, and meta-heuristics. In this work, three different non-traditional algorithms such as genetic algorithm (GA), simulated annealing (SA), and particle swarm optimization (PSO) are used in multi-pass turning machining operation to identify the set of optimal parameter values for minimizing unit production cost. The mathematical model is taken from the literature (Chen and Tsai, Int J Prod Res 34:2803–2825, 1996 and it is used for the evaluation of algorithmic parameters. The main aim of this work is to analyze the effect of algorithmic parameters of non-traditional technique in turning operation. The analyses performed are (i) sensitivity analysis in GA, PSO, and SA, (ii) analysis to find the best reproduction method in GA (iii) analysis to analyze the performance of GA, PSO, and SA by varying algorithmic parameters, and (iv) analysis to compare the results of the algorithms with the literature, and the best one is proposed.

Similar content being viewed by others

References

Chen MC, Sai DMT (1996) A Simulated Annealing approach for optimization of multi-pass turning operations. Int J Prod Res 34:2803–2825

Chandrasekar M, Muralidhar M, Murali Krishnan C, Dixit US (2010) Application of soft computing techniques in machining performance prediction and optimization: a literature review. Int J Adv Manuf Technol 46:445–464

Mukherjee I, Ray PK (2006) A review of optimization techniques in metal cutting processes. Comput Ind Eng 50:15–34

Aggarwal A, Singh H (2005) Optimization of machining techniques—a retrospective and literature review. Sadhana 30:699–711

Hui YV, Leung LC, Linn R (2001) Optimal machining conditions with costs of quality and tool maintenance for turning. Int J PROD RES 39:4647–665

Shin YC, Joo YS (1992) Optimization of machining conditions with practical constraints. Int J Prod Res 30(12):2907–2919

Onwubolu GC, Kumalo T (2001) Multi-pass turning operations optimization based on genetic algorithms. IMechE 215:117–123

Balic J, Kovacic M, Vaupotic B (2006) Intelligent programming of CNC turning operations using genetic algorithm. J Intell Manuf 17:331–340

Saravanan R, Sivakumar R, Asokan P, Vijayakumar R, Prabaharan G (2005) Optimization of cutting conditions during continuous finished profile machining using non-traditional techniques. Int J Adv Manuf Technol 26:30–40

Saravan R, Asokan P, Vijayakumar K (2003) Machining parameters optimization for turning cylindrical stock into a continuous finished profile using genetic algorithm (GA) and simulated annealing (SA). Int J Manuf Technol 21:1–9

Sathishkumar S, Asokan P, Kumanan S (2006) Optimization of depth of cut in multi-pass turning using non-traditional optimization techniques. Int J Adv Manuf Technol 29:230–238

Satishkumar S, Asokan P (2008) Selection of optimal cutting conditions for CNC multitool drilling system using non-traditional techniques. Int J Mach Mach Mater 3:190–207

Yildz AR (2009) A novel particle swarm optimization approach for product design and manufacturing. Int J Adv Manuf Technol 40:617–628

Deep K, Bansal JC (2008) Peformance analysis of turning process via particle swarm optimization. Stud Comput Intell (SCI) 129:453–460

Muthu P, Dhanalaskshmi V, Sankaranarayanaswamy K (2009) Optimal tolerance design of assembly for minimum quality loss and manufacturing cost using metaheuristic algorithms. Int J Adv Manuf Technol 44:1154–1164

Bharathi Raja S, Baskar N (2010) Optimization techniques for machining operations: a retrospective research based on various mathematical models. Int J Adv Manuf Technol 48:1075–1090

Bharathi Raja S, Baskar N (2011) Particle swarm optimization technique for determining optimal machining parameters of different work piece materials in turning operation. Int J Adv Manuf Technol 54:445–463

Venkata Rao P, Pawar PJ (2010) Parameter optimization of a multi-passing milling process using non-raditional optimization algorithms. Applied soft computing 10:445–456

Cus F, Balic J, Zuperl U (2009) Hybrid ANFIS-ants system based optimization of turning parameters. J Achiev Mater Manuf Eng 36:79–86

Vijayakumar K, Prabhaharan G, Asokan P, Saravana R (2003) Optimization of multi-pass turning operations using ant colony system. Int J Machine Tools Manu 43:1663–1639

Grosan C, Abhraham A (2007) Hybrid evolutionary algorithms: methodologies, architectures, and reviews. Stud Comput Intell 75:1–17

Wang X, Jawahir IS (2001) Optimization of multi-pass turning operation using genetic algorithms for the selection of cutting conditions and cutting tools and cutting tools with tool-wear effect. IEEE 0-7803-7078-3/01:3093–3100

Wang ZG, Wong YS, Rahman M (2004) Optimisation of multi-pass milling using genetic algorithm and genetic simulated annealing. Int J Adv Manuf Technol 34:727–732

Siva Sankar R, Asokan P, Saravanan R, Kumanan S, Prabhaharan G (2007) Selection of machining parameters for constrained machining problem using evolutionary computation. J Adv Manuf Technol 32:892–901

Shutong XIE, Yinbiao GUO (2011) Intelligent selection of machining parameters in multi-pass turnings using GA-based approach. J Comput Inf Syst 7(5):1714–1721

Venkatesan D, Kannan K, Saravanan R (2009) A genetic algorithm-based artificial neural network model for the optimization of machining processes. Neural Comput Appli 18:135–140

Zhang JY, Liang SY, Yao J, Chen JM, Huang JL (2006) Evolutionary optimization of machining processes. J Intell Manuf 17:203–215

Royachka K, Karova M (2006) High performance optimization of genetic algorithms. IEEE 1-4244-0551-3

Zaharie D (2009) Influence of crossover on the behavior of differential evolution algorithms. Applied Soft Computing 9:1126–1138

Sardinas RQ, Santana MR, Brindis EA (2006) Genetic algorithm-based multi-objective optimization of cutting parameters in turning process. Eng Appl Artif Intell 19:127–133

Abburi NR, Dixit US (2007) Multi-objective optimization of multipass turning process. Int J Adv Manuf Technol 32:902–930

Datta R, Majumder A (2010) Optimization of turning process parameters using multi-objective evolutionary algorithm. IEEE 978-1-4244-8126-2/10

Datta R, Deb K (2009) A classical-cum-evolutionary multi-objective optimization for optimal machining parameters. IEEE 978-1-4244-5612-3

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gayatri, R., Baskar, N. Performance analysis of non-traditional algorithmic parameters in machining operation. Int J Adv Manuf Technol 77, 443–460 (2015). https://doi.org/10.1007/s00170-014-6452-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6452-9