Abstract

Structural optimization within concrete construction has been increasingly taken up in research within the last two decades. Possible drivers are the need for material-reduced and thus resource-efficient structures as well as recent advancements in automated concrete construction. However, structural concrete is characterized by nonlinear material behavior. Consequently, the merge of structural concrete design and topology optimization is not trivial. This paper reviews and assesses the topic of topology optimization within concrete construction, carrying out an extensive quantitative as well as qualitative review on practical and numerical applications. The following research areas are identified: Multimaterial modeling, stress constraints, concrete damage modeling, strut and tie modeling, combined truss-continuum topology optimization, the consideration of multiple load cases, a focus on construction techniques and alternative approaches. Although the number of research papers dealing with the topic of topology optimization in concrete construction is numerous, there are only few that actually realized topology optimized concrete structures. In addition, only a little number of experiments was performed for an objective evaluation of the found geometries so far. Concluding this review, a list of future challenges, like the incorporation of sustainability measurements within the optimization process, is given and thus serves as a guidance for subsequent research.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction: motivation and objectives

The global cement industry represents the third-largest source of anthropogenic carbon dioxide (CO2) emissions worldwide (Andrew 2018) and is responsible, according to latest estimations (Crave and Bischoff 2019), for 8 % of global greenhouse gas emissions. Apart from the required fuel to run the cement production, its inherent chemical process within the production phase accounts for a significant portion of the overall generated emissions: The combustion of cement’s raw material limestone results in a chemical reduction from calcium carbonate to calcium oxide, during which CO2 is released. According to the report of Mauschitz (2018)) commissioned by the Association of the Austrian Cement Industry VÖZ, these so-called process emissions account for approximately two thirds of the total CO2 emissions in Austria.

To meet the goals set by the Paris Agreement, limiting the increase of temperature to \(1.5^{\circ }\text {C}\) above pre-industrial levels, actions have to be taken to lower the environmental impact of the cement and concrete industry (United Nations 2015). For this purpose, two main ecological optimization strategies, as defined by Kromoser (2021), can be pursued: The optimization of the material and the optimization of the structure. Regarding concrete structures, the first approach comprises of an optimization of concrete binder material and reinforcement. One way to decrease Portland cement clinker demand, for example, is by optimizing the cement composition, provided that the concrete’s performance regarding durability and mechanical properties is not impaired. On a different note, the study of Bolte et al. (2019) can be mentioned, where an optimization tool for the composition of cement with a comparatively low environmental footprint and blast-furnace slag as supplementary cementitious material is presented. A further example of material optimization is described in the work of Kromoser et al. (2018), who pursued the application of high-performance materials such as carbon fiber-reinforced polymers and ultra-high performance concrete to create lightweight, resource-efficient structures. Within their research study, the choice of materials with a favorable ratio between specific weight and required material properties is targeted. In this context, the research study of Stoiber et al. (2021) shows the environmentally favorable behavior of a carbon concrete pedestrian bridge in comparison to a conventionally reinforced concrete as well as a mild steel pedestrian bridge. The study assessed the production phase of the bridges’ superstructures.

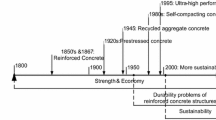

In addition to the optimization of the material, Kromoser (2021) identifies the optimization of the structure as a promising lever within the cementitious construction value chain to decrease CO2 emissions and further differentiates between the optimization of the inner and of the outer structure. The inner structure refers to a gradation of e.g. concrete density or concrete quality, whereas the outer structure refers to the optimization of the structure’s topology. The idea of mass-optimized structures is not new to the field of civil engineering: In 1866, Culmann stated in his work on graphical statics that the overlaying target of efforts regarding the evaluation of loads on a building structure is the minimization of the amount of required material. At the beginning of the 20th century, the initial considerations in regard to structural optimization in the sense of finding a mathematical optimum were made by Michell (1904) during his investigations on the limits of economy of frame-structures. The structures were characterized by curves of orthogonal systems, which were subject to maximum compression and tension forces under minimum compliance. The principles of Michell (1904) were extended by grillages by Prager and Rozvany (1972).

The research field of structural optimization experienced a significant updraft especially within the last four decades, as computerization enabled an efficient conduction of finite element analysis of building structures. Research disciplines within structural optimization were progressively extended, e.g. from linear to nonlinear material behavior as well as from consideration of single to multiple load cases. Methods of optimization were continuously elaborated and implemented in practice, putting increasingly more attention on their application within the field of concrete construction. Optimization tools were developed by research institutions and made available to the public, at which the frequently addressed compact matlab code by Sigmund (2001) must be mentioned.

As a result of the unstoppable advancement in technology structural engineers see themselves increasingly confronted with demands on enhancing structural optimization within concrete construction. Simultaneously the topic of resource friendly design is omnipresent, as a consequence of climate change. More and more claims are made to incorporate sustainability criteria, e.g. within construction law or the award of public work contracts (Crave and Bischoff 2019). As a first guiding sustainability indicator for structural engineers, Favier et al. (2018) proposed to design and build a structure with less than 250 kg CO2/m2 of building.

This paper dedicates itself to enhancing the resource- efficiency of concrete structures via an extensive review, analysis and display of the hitherto achievements in structural, more precisely, in topology optimization (TO) of concrete structures. TO characterizes the optimization of material distribution within a two or three-dimensional design space (Kromoser 2021). TO represents one of several disciplines of structural optimization and is characterized by a high degree of design freedom. It is commonly applied within an early stage of the design process. An identified frequent approach within TO is the consideration of structures made from materials showing a linear material behavior. As an example, steel can be mentioned, which is characterized by a distinctive linear material behavior in compression as well as in tension. As the general material behavior of concrete is profoundly nonlinear, including effects like cracking, creep and shrinkage, the close-to-reality optimization of this material becomes especially challenging. Furthermore, as stated by Smarslik et al. (2016), the potential of TO in civil engineering has not yet been fully realized with being mostly limited to areas of discontinuity of structural concrete. Hence, this review paper aims at contributing to this topic by reviewing, analyzing and categorizing literature and research about TO in concrete construction, where both numerical and experimental applications are incorporated. It intends to serve as an orientation guideline within the field as well as a spur for future research. Following research questions are addressed:

-

Which TO methods or concepts have been incorporated within the field of concrete construction so far? What were the findings?

-

How can the findings be qualitatively as well as quantitatively categorized?

-

Which and how many numerical and experimental investigations have been made in this context?

-

To what extent have specifics of concrete’s inherent nonlinear material behavior been considered within the context of TO so far?

-

Which future research gaps can be identified and which suggestions can be deduced from the findings?

The present systematic literature review paper is structured as follows: Sect. 2 outlines the relevant theoretical framework, with an elaboration of the general information about TO methods and specifics in regard to concrete structures. The section aims at giving a compact overview of TO in general, especially for structural engineers new to the field. Sect. 3 clarifies the methods and materials used within this research study. Subsequently, in Sects. 4 and 5, a qualitative as well as a quantitative analysis and an identification of research gaps are carried out. Section 6 summarizes the findings of this literature review.

2 Theoretical framework: topology optimization

2.1 Concept of optimization

An optimization aims at reaching the best possible state of a defined problem. A clarification of this rather vague term ”best” is necessary and commonly takes place on an individual level. In civil engineering, one of the primary claims for a structure is the ability to transfer loads. Mathematically optimizable mechanical measures of a structural performance in civil engineering might range from stiffness, weight and instabilities like buckling to displacement restrictions. Further parameters include economy, environment, functionality, durability and aesthetics, with the latter being comparatively more difficult to measure. The inherent functioning of a structure is typically comprised within a constraint formulation, e.g. via predetermined supports or fixed dimensions as for example the width of a bridge structure due to a set number of road lanes.

In the first instance, a general mathematical form of a structural optimization problem is depicted in order to make the topic tangible to the reader: A structural mathematical optimization problem commonly consists of an objective function f, a design variable x and a state variable y within a structural search space \(\Omega \) (Christensen and Klarbring 2009). The objective function f(x, y) represents a maximization or rather a minimization problem of a measurable parameter. According to Schumacher (2013), commonly the compliance of a structure or its weight is intended to be minimized. For a vivid explanation of the objective function the reader is referred to Konečný et al. (2017). The design variable x defines the structural design (e.g. geometry or material), which is subjected to change within the optimization process. The state variable y constitutes the structural response (e.g. displacement or stresses). Besides the generally set constraint of structural equilibrium, the design and state variables encounter limitations due to defined constraints. Several solution strategies exist to solve the optimization problem and determine the optimum value of the above outlined mathematical construct, which are addressed in Sect. 2.4.

2.2 Design parameterization

According to the characteristic of the design variable x, one can divide structural optimization into size (also: parameter, dimension), shape and topology optimization. Shape optimization aims at optimizing the contours of a structure, e.g. with the intention of reducing notch stresses. In case of the comparably more restricted size optimization, design variables usually represent specific geometrical parameters such as a drill diameter or a cross section. The third and most general form of structural optimization is the already mentioned topology optimization.

The term ”topology” per se defines, according to Sauer et al. (2018), the arrangement of geometrical entities within a design space. Thus, TO distinguishes itself by the ability to permanently remove material. Due to their load-adaptive character, bones are a popular example of topology-optimized bionic structures. As the topology of a building component or rather the position and arrangement of structural elements within a design space can show significant influence on the overall structural behavior, TO is typically applied within an early stage of the design process (Schumacher 2013). For more detailed information on the three structural optimization types the reader is referred to Christensen and Klarbring (2009), Baier et al. (1994), Sauer et al. (2018), Schumacher (2013), Harzheim (2019), Bendsøe and Sigmund (2004) or Querin et al. (2017). A consecutive or rather connected application of the three design parameterization approaches is also frequently addressed within academic literature. Further information can be found in Hassani et al. (2013), Smarslik et al. (2016), Querin et al. (2017), Sauer et al. (2018) amongst others.

2.3 Topology optimization methodologies

According to Querin et al. (2017), TO methods can be divided into optimality criteria (OC) methods and heuristic-intuitive methods based on, e.g., evolutionary or genetic algorithms. The first group includes the Ground Structure Method (GSM), the Homogenization Method (HM), Solid Isotropic Material with Penalization (SIMP), whereas the second group includes Evolutionary Structural Optimization (ESO) and Bi-directional Evolutionary Structural Optimization (BESO) amongst others. The OC methods are more generally referred to by Harzheim (2019) as mathematical respectively gradient-based TO methods, which are suitable for a relatively large number of design variables and only a limited number of constraints. On the other hand, according to Querin et al. (2017), heuristic-intuitive methods cannot always guarantee optimality, but can provide viable efficient solutions. Xia et al. follows a rougher classification and differentiates between GSM, ESO TO methods and density-based TO methods. Regarding evolutionary approaches, a separation between genetic algorithms representing zero-order methods and TO methods such as ESO and BESO should be made. It has to be kept in mind that transitions between the above-mentioned categorizations are fluid and dependent on the considered aspects, e.g. continuous versus discrete variables amongst others. Subsequently, the basic principles of frequently consulted TO methods, which serve for the understanding of this literature review, are briefly outlined.

2.3.1 Ground structure method

The Ground Structure Method (GSM), firstly proposed by Dorn et al. (1964), refers to the layout optimization of truss structures. This method is characterized by a design space built of discrete structural elements. A fixed grid of joints is initialized, between which bars with fixed or variable cross-sectional dimensions are added, resulting in a growing ground structure. This method is commonly seen as size optimization. Through the fact that the bars can also be removed, characteristics of TO are included (Querin et al. 2017).

2.3.2 Homogenization method

The Homogenization Method (HM) aims at solving a problem made up of an infinite number of microscale voids in finite elements, resulting in a porous structure with cavity areas and solid material areas. A connection between material density and Young’s modulus can be derived from a homogenization of this microscale structure. Via HM, TO is extended from discrete structures to continua. The numerical implementation of the concept of material distribution using HM was first proposed by Bendsøe and Kikuchi (1988). Bendsøe and Sigmund (2004) further state that many TO developments are based on HM.

2.3.3 Solid isotropic material with penalization

A subsequent development of HM is the Solid Isotropic Material with Penalization (SIMP) method, which is well-established within the field of TO (Bendsøe and Sigmund 2004). As primal work, the research study by Bendsøe (1989) is mentioned. Within the SIMP approach, the considered structural design domain commonly consists of homogeneous and isotropic elements. The design variable x represents an artificial element density \(\rho \), ranging from 0 or rather \(\rho _{\text{min}}\) to 1. The stiffness matrix depends on the density of the material. A penalty p is put on intermediate values of the Young’s modulus of a structure, commonly resulting in either the initial value or a new artificial Young’s modulus of a value preferably close to 0. That way, with increasing penalization, the continuous problem of HM shifts into a discrete valued problem. Throughout literature, it is commonly seen as modifying the ”grey” optimization problem into a ”black-white” optimization. SIMP is often the preferred choice within TO, as a macroscopic 0 – 1 solution can be manufactured more easily than a graded geometric layout, which results from HM (Sigmund and Petersson 1998). As the SIMP approach is well established within the field, the power-law approach is outlined in Equation 1 below, where c represents compliance, e represents the element index, N is the total number of elements, p the penalization factor, K the stiffness matrix, F the load vector, f the volume fraction, U the displacement vector, V the volume and x the density as design variable:

2.3.4 (Bi-directional) evolutionary structural optimization

The heuristic-intuitive Evolutionary Structural Optimization (ESO) method proposed by Xie and Steven (1993) follows the principle of removing inefficient material from a design domain. After the conduction of an FEA, elements not satisfying the defined rejection ratio RR applied to the maximum design variable (e.g. von-Mises stress or displacement) or showing a low sensitivity value (e.g. low stress or strain energy) are removed from the structural domain space \(\Omega \). As the elements can be either removed or left in place, the ESO approach is seen as a discrete valued problem (Edwards et al. 2007). As a further development, the Bidirectional Evolutionary Structural Optimization (BESO) method by Young et al. (1999) reintroduces elements around highly stressed areas.

2.4 Solution strategies

According to Sauer et al. (2018), solution strategies for structural optimization problems can be divided into pure mathematical techniques, stochastic methods (e.g. Monte-Carlo-Method), evolutionary algorithms, pure heuristic methods and OC methods. The latter method is further divided into a heuristic as well as a mathematical approach or being based on the Karush–Kuhn–Tucker condition. The classification is built on the pursued strategy of optimization variable variation throughout the optimization process.

An OC method consists of a mathematically formulated optimality criterion as well as a heuristic update scheme for the design variable. According to Baier et al. (1994), a mathematical programming technique is dependent on local conditions, while an OC method is one step ahead consisting of a locally independent orientation of the solution and being more capable of passing over local extreme values. Consequently, OC methods are seen as more specific, less costly, yet less universally valid solution methods. They represent first-order methods based on sensitivity analysis, where gradients of objective functions and constraints are determined and represent the changes of mechanical behavior. Comparatively, mathematical programming converges slower, while being capable of solving more complex problems. As an example, the Method of Moving Asymptotes (MMA), as introduced by Svanberg (1987), is mentioned as an approximation methods. An extension of this method is given by Svanberg (2007), additionally allowing for a consideration of non-structural or bigger number of constraints. Other examples of mathematical approximation techniques include Sequential Linear Programming and Sequential Quadratic Programming.

In this context, the publicly available TO 99-line code for matlab, as elaborated by Sigmund (2001), is mentioned. An analysis of a rectangular design domain consisting of square bilinear quadrilateral finite elements with constant densities is conducted. The code enables the implementation of a TO for minimum compliance of statically loaded structures. More recent developments of open-source and educational codes are referenced at this point, such as the 88-line code by Andreassen et al. (2011) as a further development of the 99-line code by Sigmund (2001). On a different note, a new generation of the 99-line code with an extension to 3D optimization problems is presented by Ferrari and Sigmund (2020). Aage et al. (2015), e.g., propose an easily applicable TO framework using the Portable and Extendable Toolkit for Scientific Computing (PETSc). Additionally, topology optimization codes written in Python are freely available online (Aage 2019).

Regarding evolutionary algorithms, Sauer et al. (2018) states that these strategies are based on the principles of evolution in solving a technical problem, which is often referred to as ”survival of the fittest”. The fitness of the different variations of the development steps is assessed according to experiments, subjective assessment, given objective functions or simulations. In this context, a random component enables the algorithm to pass local extreme values, however, this solution strategy converges comparatively slower. Evolutionary algorithms comprise evolutionary strategies and programming as well as genetic algorithms (zero order methods).

2.5 Numerical instabilities

In this section, selected numerical instabilities associated with TO methods are briefly addressed, including the checkerboard problem and mesh dependency. The goal of this chapter is to raise the reader’s awareness for numerical instabilites, if new to the field. As an illustrative example, the numerical instabilities in regard to compliance minimization of statically loaded structures are displayed in Fig. 1. The benchmark case is outlined at the very top in Fig. 1. Checkerboard patterns (Fig. 1, lower center) display adjoining finite elements attributed with alternating solid and void characteristics, representing an example for non-convergence. One reason for this phenomenon, as described by Harzheim (2019), is that linear finite elements cannot depict stiffness properties in a numerically correct manner. Furthermore, mesh dependency (Fig. 1, bottom) refers to qualitatively different solutions when choosing different mesh sizes.

Considering the variety of uncertainties and numerical instabilities that go along with mathematical optimization, Christensen and Klarbring (2009) indicate engineering intuition as the final guide, when accepting or rejecting an optimized geometry layout.

2.6 Specifics of concrete construction

2.6.1 Nonlinear material behavior

TO software is often geared to mechanical engineering, consequently primarily focusing on the optimization of metals, which are characterized by linear material behavior under both compression and tension. However, plain concrete, as a two-phase system of cement stone and aggregate, is inherently characterized by high-grade nonlinear material behavior, a high compression and comparatively low tensile strength. The latter is commonly compensated within structural concrete via the use of steel reinforcement. Typical nonlinear effects of concrete due to tension include tension softening, shrinkage and macrocracking. Tension softening refers to the decrease in bridging stresses across a crack width with models based on fracture energy being frequently consulted to quantify this effect. Furthermore, compression softening and confinement in compression have to be considered amongst others, as listed within the fib Practitioner’s guide to finite element modeling of reinforced concrete structures (Maekawa et al. 2008). Regarding reinforcement, strain hardening, yielding or rupture as well as buckling can be mentioned as nonlinear effects. Considering the combination of concrete and steel reinforcement in reinforced concrete, nonlinear effects like aggregate interlock, tension stiffening and bond behavior become relevant. It is important to note that the effect of tension softening is not to be confused with tension stiffening.

Commonly, within structural concrete design, the structure is calculated based on a linear-elastic approach with the subsequent cross-sectional design conducted according to Eurocode 2, which takes the material nonlinearity of concrete into account. Additionally, the influence of the nonlinear material behavior on the whole structure could be considered, for example, via the redistribution of moments of a continuous beam as outlined within Eurocode 2 (Mehlhorn and Kollegger 1996). To get a more accurate image of the reality in the course of a detailed analysis, sophisticated material models can be incorporated. A variety of constitutive models, describing the material-specific relationship between stresses and strains in concrete, exist, with three major constitutive frameworks, as listed by Maekawa et al. (2008), being:

-

Nonlinear elasticity

-

Theory of plasticity

-

Damage mechanics

The first approach comprises of the definition of isotropic or rather orthotropic linear material behavior before as well as after cracking. By formulating offset strains, effects like shrinkage, thermal strains and dilatation can be considered. The flow theory of plasticity, being the second listed approach, is typically characterized by the accumulation of irrecoverable strains. It includes the formulation of a yield condition, a flow rule, a hardening law and the fact that the total strain can be decomposed into elastic and plastic strain. Several failure envelopes can be consulted to define the yield surface according to plasticity theory, at which the von Mises, Tresca, Mohr-Coulomb and Drucker-Prager failure criteria are mentioned. The continuum damage mechanics theory is defined within the strain space and comparable to the plasticity theory, as a loading function specifies the elastic domain and, in this case, the state of growing damage. Damage mechanics is characterized by recoverable strains and the degradation to absorb elastic energy, thus allowing the elastic stiffness of the material to be reduced for example as a result of damage caused by repeated loading. Damage models can be favored in regard to their explicit stress evaluation algorithm, which shows no need for iterations during solving.

Commonly, TO tools do not comprise nonlinear material behavior by default. As depicted by Kromoser (2021), the input of the respective relevant nonlinear material parameters demands well-developed understanding of material science from the civil engineer. Therefore, a popular approach within concrete construction research is to only consider linear material behavior within the optimization process. This assumption is only valid within the linear-elastic ascent of the load-deformation curve in compression, meaning that the tensile strength must not be reached and cracks must not appear. First ideas for ideal reinforcement arrangements, the determination of structural strength demands, rough dimensioning of the structure or an approximation of the material optimized geometry can be concluded from this approach, as stated by Maekawa et al. (2008). Calculated forces often give reasonably close results for ultimate state verification in comparison to the results of a nonlinear analysis. Nevertheless, the material strength in conventionally designed concrete structures is often underutilized. As an example, Kromoser (2021) mentions a conventional concrete slab in high-rise buildings under bending stress, of which only around 20% of the concrete material is well exploited, thus showing the optimization potential of the structure.

This literature review assesses to which extent concrete’s inherent material behavior is already incorporated within TO. It has to be mentioned that the term ”nonlinear” used within this study refers to material nonlinearity. Further nonlinear effects, like geometrical nonlinearity or nonlinear support conditions, are not discussed within this paper.

2.6.2 Finite element analysis

During and/or after the optimization process the geometry obtained from a TO typically undergoes a finite element analysis (FEA). According to Mehlhorn and Kollegger (1996), the approximation of concrete structures modeled within FEA is dependent on several aspects: Material behavior via the chosen material model, the behavior of the finite element in dependence on the interpolation functions and the behavior of the whole structure, expressed via the chosen element type and discretization aspects. Thus, accuracy requirements of the material model highly depend on the investigated structural problem.

According to Maekawa et al. (2008), several levels of analysis complexity are given depending on the scale of the considered structural concrete problem (small, medium, large), defining the respective nonlinear material effects such as strain localization and size effect that should be considered for each case. Strain localization is especially relevant in the case of FEA of plain concrete. It occurs when an increasing strain shows a decreasing stress, e.g. as it is the case for concrete in tension or in compression after reaching peak stresses. The strains localize in small bands, whose widths can be determined by numerical parameters such as mesh density. Thus, this effect is highly dependent on the chosen mesh settings like mesh size, mesh type and element order (number of integration points), as discrete cracks form between the elements. Furthermore, the strain localization effect is often coupled to the size effect, which is responsible that larger specimens fail at comparably lower stresses than smaller specimens. As mentioned within the fib Model Code for Concrete Structures 2010 (International Federation for Structural Concrete 2013), the defined finite elements should be sufficiently small. An inappropriately chosen mesh is often accompanied by an over- or underestimation regarding the structure’s capacity or post-peak behavior. Common solution methods of nonlinear problems within FEA include step-wise incremental analysis such as the (modified) Newton-Raphson method or the Arc-Length method. When it comes to computational costs within optimization, FEA is seen as main driver besides sensitivity analysis (Harzheim 2019).

Validation methods of numerical results from nonlinear analysis comprise basic material tests, structural tests or benchmark tests as well as mesh sensitivity tests (International Federation for Structural Concrete 2013). The concept of safety is not considered within this publication and deliberations are limited to mean values of material properties. However, it is stated within Eurocode 2 (ÖNORM EN 1992-1-1 2015) that, regarding nonlinear analyses, material properties that represent the behavior in a realistic manner and take failure uncertainties into account should be used. The fib Model Code for Concrete Structures 2010 (International Federation for Structural Concrete 2013) outlines safety formats for nonlinear analysis, specifying that the global resistance format is favorable in that context. The concept of partial safety factors would not be applicable in the case of nonlinear FEA, as stated by Maekawa et al. (2008).

3 Methodology and material: systematic review

A comprehensive retrieval and analysis of literature is conducted in the course of this systematic literature review. The whole process is outlined in Fig. 2 with following research areas being identified:

-

Multimaterial modeling (MM)

-

Stress constraints (SC)

-

Concrete damage (CD)

-

Strut and tie modeling (STM)

-

Combined truss-continuum optimization (CO)

-

Multiple load cases (MLC)

-

Construction techniques (CT)

-

Alternative approaches (AA)

The above-mentioned research areas are further elaborated in the context of the qualitative analysis, e.g. MM in Sect. 5.1.1. It has to be noted that many terms used within this section are characteristic to the field of scientific literature reviewing. Consulted digital scientific literature databases comprise ScienceDirect, Scopus, Web of Science and Wiley Online Library amongst others. Publications of all types were considered, with the majority representing original peer-reviewed papers. As keyword formulations, combinations of plural and singular forms of the following terms in English as well as in German were used (the list is not exhaustive): Additive, anisotropy, behavior, concrete, constraints, construction, continuum, damage, manufacturing, material, modeling, nonlinear, optimization, orthotropy, printing, stress, structural, structure, strut and tie, topology, truss, 3D. More than 200 research pieces were extracted and subsequently narrowed down to a number of 60+ relevant to the topic of TO in concrete construction. These research pieces were divided according to a numerical and/or practical nature and subjected to a quantitative or so-called meta analysis as well as a qualitative analysis. A further categorization according to selected research aspects was made resulting in the evolution of a taxonomy of research areas as listed above. Further 29 research pieces were identified as supplementary significant for the main analysis, accordingly fulfilling either relevant concrete specific aspects or covering strongly related TO aspects. The total list of publications, including all subdivisions and allocations, is provided by the authors for further use.

At an advanced stage of the literature review process and in the interest of data quality assessment, lists of sources of selected, already reviewed papers were consulted as a basis to assess whether a sufficient penetration level of the scholarly literature was reached. Lastly, the research pieces were subjected to a final reappraisal round in order to verify the already made research area allocations.

4 Quantitative results

60+ research pieces fulfilling concrete specific aspects as well as the use of TO, compare with Fig. 2, serve as a basis for the quantitative analysis. The goal of this meta analysis is to offer a broader picture of the temporal, regional and thematic research distribution. An emphasis is put on a tangible visualization of the extracted data.

4.1 Hard facts: publishing date, origin and literature type

Figure 3 illustrates the publishing timeline of the research pieces between the years 2001 and 2020, distinguished between numerical and/or experimental studies. A significant increase in research activity over the last few years can be recorded. This upward trend is identified amongst all research categories. The stacked area graph further shows that the first experimental application of TO within concrete construction is recorded in 2014. It has to be noted that double counting on a small scale is included, because four research pieces comprised numerical as well as experimental investigations. The authors believe that the reasons for this specific upward trend are numerous, at which the increasing provision of open-source optimization codes (compare with Sect. 2.4) as well as recent advancements in manufacturing of complex structures can be mentioned as exemplary drivers.

Furthermore, the extracted literature is categorized according to the institution’s origin of the first stated author, as displayed in Fig. 4. A separate country category was made, if at least 3 allocations were present. No specific local limitations, but a general global distribution of research pieces is discernible. The pie chart shows that a pioneering role within the field could be attributed to Germany, as it accounts for around one quarter of the analyzed research pieces. It has to be noted, though, that the authors’ origin of this literature review paper is Austria, a German-speaking country. Hence, a certain degree of data bias is assumed to be present.

Figure 5 subdivides the analyzed research pieces in accordance with the literature type with a special focus set on journal publications. The distinction ”Other literature pieces” includes conference proceedings, a commemorative publication and one master thesis. A separate journal category is presented, if at least three literature pieces were identified up to this point. Considering all collected data and with reference to the pie chart presented in Fig. 5 an identification of the journal Structural and Multidisciplinary Optimization as most frequent platform of published research pieces within the field of TO in concrete construction can be made. To do justice to scientific integrity, the authors intention of submitting the paper to the journal Structural and Multidisciplinary Optimization, even before the data was evaluated, has to be noted. As the topic of TO within concrete construction emerged especially within the last few years (as pictured in Fig. 3), about one quarter of total analyzed research pieces are conference proceedings.

4.2 In focus: research areas

Figure 6 visualizes the general distribution and overlapping of the identified research areas as listed in Sect. 3. The area sizes of the ellipses and circles and the overlapping represent the shares of the total extracted and determined publication number. The orientation of the shapes, more precisely the x- and y-location, has no meaning. It has to be noted, for the sake of clarity, that the areas within this Venn diagram are approximate without any loss of informative value. A clear emphasis on STM as well as MM as research areas can be recognized. No overlapping of CT or AA (comprising multi-physics optimization, prestressing and aesthetics) with other research areas was identified. Furthermore, combined truss-continuum TO can be identified as going hand in hand with MM and/or STM.

Quantitative visualization of identified (as presented in Sect. 3) research areas and their overlapping areas

The shares of numerical and experimental studies per research area are illustrated in Fig. 7. Apart from the research area of CT, experimental studies represent often only a small proportion of the total extracted publication number. Double counting is a possibility.

Subsequently the authors’ aim is to reach a deeper level of the quantitative analysis by determining the TO methods used amongst the research publications as illustrated in the stacked bar chart of Fig. 8. The TO methods are divided into SIMP, GSM, (B)ESO, HM and other TO methods comprising Isolines Topology Design, Genetic Programming, Thermodynamic TO, Performance-Based Optimization or the Material-Replacement Method. Multiple allocations are possible. SIMP can be stated as being a popular TO method within the scientific community, as a predominant use of it can be recognized. The provision of programming codes, compare with Sigmund and Petersson (1998), presumably contribute to this fact. The GSM, which is especially suitable in the case of reinforcement design, is also frequently consulted. STM shows the most diverse and distributed use of TO methods.

The investigated structural examples are displayed in Fig. 9, where each subfigure represents a different research area. Each grid line represents a number of two investigated examples. The work of Schlaich et al. (1987) served as a basis for the determination of investigated structural examples (deep beam, deep beam with opening, beam structure, corbel and bridge-like structures). In comparison to a classic beam, a deep beam is characterized by span widths less than four times the structure’s depth. A beam structure includes single span girders as well as continuous beams. Investigated loads comprise single point as well as distributed loads. A structural component is determined as being ”bridge-like”, if the term or a context to bridge construction was mentioned within the text. The net charts in Fig. 9 show deep beams with or without opening as well as beam structures as frequent examples of investigations. The charts might serve as a guidance for future researchers to find appropriate structural examples amongst scientific literature for comparison with their own work.

5 Qualitative results

60+ research pieces, distinguished by the use of TO in the context of concrete construction, compare with in Fig. 2, serve as a basis for the qualitative analysis. The publications are profoundly reviewed and opposed, with significant findings being extracted and highlighted. Note that multiple research area allocations are possible and a sharp differentiation between these is not always possible. Details are outlined below.

5.1 Review on numerical investigations

5.1.1 Multimaterial modeling

As outlined in Sect. 2.6.1, concrete is characterized by a high compressive and comparatively low tensile strength. Thus, a frequently addressed topic within structural concrete optimization is multimaterial modeling (MM): Studies within this research area aspire a differentiation between a compression and tension material during the optimization process. Consequently, a separate consideration of steel reinforcement and concrete material is facilitated and frequently pursued. However, also anisotropic respectively orhotropic strength characteristics of plain concrete can be considered or controlled by the user via this approach. The term ”multimaterial modeling” was taken up by the authors according to the reviewed literature. Often, an extension of the SIMP approach, a so-called multiphase SIMP method is applied in this context. Instead of the classical SIMP approach, where only one solid material and void is present, another solid instead of the void material or even three different solid phases can be considered within the extended approach. Kato et al. (2008), for example, applies multiphase SIMP to investigate the use of fibers in concrete. Note that the interpretation of the term ”multimaterial” is seen as rather broad. The following three publications are especially representative for the identified research area of MM.

Smarslik et al. (2019) present a TO approach for tension- or compression-biased structural concrete design. They investigate a truss-, a continuum- as well as a combined truss-continuum model, introducing a stress-ratio dependent weighting factor \(\psi \). With this factor being assigned to the tensile or compressive material, pushing the design ”more or less aggressively” towards a stress-neutral, a tension- or a compression-dominant result becomes possible. Further aspects about their combined truss-continuum TO approach are discussed in Sect. 5.1.5. Through their research, Smarslik et al. (2019) highlight the suitability of stress-weighting to design structures affine to occurrent force distributions.

Another showcase study investigating tension and compression anisotropy enhanced topology design is the work of Gaganelis et al. (2019). The applied concept includes a modification of concrete’s material stiffness via a weight function, consulting the signs of principal stresses to differ between tension and compression. The presented procedure is based on the material replacement method (MRM) (Cai 2011) and thermodynamic TO (TDO) (Junker and Hackl 2015). In MRM, material separation is conducted via element stiffness modification, whereas in TDO via energetic penalization. The final analysis of both approaches shows similar results for tension-compression sensitive structural elements such as an L-shaped cantilevers. Continuative experimental applications are outlined in Sect. 5.2.

Within another publication, a Heaviside step function to formulate the relationship of multiple material moduli is consulted (Liu and Qiao 2011).

5.1.2 Stress constraints

The inclusion of stress constraints (SC) within the optimization process, as a further identified research area, is outlined in this section. As identified within the reviewed research literature, the consulted optimization algorithm within the context of SC often shifts from a volume-constrained maximum stiffness to a stress-constrained minimum volume problem. The Drucker–Prager criterion (Drucker and Prager 1952) is mostly consulted in this context, as it allows for a consideration of different strength levels in comparison to, e.g., the Von Mises criterion. Research pieces dealing in general with stress-constrained TO include (Yang and Chen 1996; Duysinx and Bendsøe 1998; París et al. 2009; Le et al. 2010) and Holmberg et al. (2013). The latter authors claim that SC should already be considered within the first optimization steps and not afterwards, for example, in the course of shape optimization, which is commonly done to avoid notch stresses.

In 2012, Luo and Kang pursue the goal of minimizing material volume under local SC, making use of the Drucker-Prager yield criterion. They show that pressure-constrained material models have a significant effect on the material distribution of continuum structures. Subsequently, Luo et al. (2012) present a three-phase TO procedure to generate optimal material distribution for steel-concrete composites under strength constraints, again based on the Drucker–Prager criterion. They consult a minimum material cost formulation in accordance with Bruggi and Duysinx (2012). Furthermore, the incorporation of strength constraints, but in a two-phase material optimization scheme, is investigated (Luo and Kang 2013). They find their approach leading to favorable designs in regard to material strength utilization and highly applicable for structural components with high crack control requirements, like nuclear reactor vessels. In a continuative work, Luo et al. (2015) extend their approach by including shrinkage-effect consideration through the introduction of an additional design-dependent force component.

The Drucker–Prager criterion is further also consulted by Bruggi and Duysinx (2013), providing smooth approximations of unilateral stress fields instead of symmetric material modeling and coupled with a conventional volume-constrained minimization of compliance. Another time a TO aiming at fiber-reinforced retrofitted structures, searching for regions in need for strengthening, is conducted (Bruggi and Taliercio 2013). They aim at minimizing the highest occurring equivalent stress, striving for a non-compression state of the reinforcement via a SC formulation. Bruggi and Duysinx (2012) inspired Jewett and Carstensen, who investigate the optimization of plain concrete structures through the use of density-based TO under SC in (2019). They minimize compliance under restricted material use, impose stress limits (Drucker-Prager) and compare their results with a common minimum compliance problem. The stress-constrained optimization designs assign more concrete mass to high-tension areas of the investigated beam. The respective experimental investigations are outlined in Sect. 5.2.5.

A computational procedure to find concrete-steel layouts using elasto-plastic modeling, once again based on the Drucker–Prager yield criterion, is proposed later on (Bogomolny and Amir 2012). They highlight the general importance of mesh refinement when optimizing reinforced concrete structures, as steel volume often accounts for only approx. 1% of the total volume in practice.

Via the use of a classic rate-independent elasto-plastic material model, an implicit approach to stress-constrained TO is pursued by Amir (2017). He proposes an additional single global constraint on the total sum of plastic strains, enabling control over local stress violations. It is noted that such a sophisticated material behavior consideration is accompanied by high computational costs.

Pastore et al. (2019) followed a different path and developed a TO approach including risk factors, favoring a minimization of the beam’s density. These factors quantify the distance of the principal stresses to the determined maximum or minimum stresses. The comparison of anisotropic with Von Mises stresses shows that the latter solutions lack physical feasibility, as the occurring tensile stresses significantly exceed the maximum tensile stress. Furthermore, they included project-specific displacement restrictions, with their findings indicating a nonlinear relationship between load and density. A consideration of such design requirements might yield varying solutions. Therefore, Pastore et al. (2019) highlight the importance of including manufacturing constraints directly within the optimization process, since subsequent consideration may invalidate the earlier obtained optimized designs. As a further extension of their publication, Pastore et al. (2020) investigate multiple load actions on cantilevers.

5.1.3 Concrete damage

Another approach enabling a more realistic modeling modeling of concrete is by concrete damage (CD) considerations. For these cases, the isotropic damage model with a single scalar parameter, illustrated in Eq. 2 and subsequently briefly outlined, is often consulted.

Within the calculation of the stresses using the isotropic damage model C represents the elastic constitutive tensor, \(\sigma \) the stress tensor, \(\epsilon \) the strain tensor and \(\omega \) the damage parameter. At the beginning of loading, the damage parameter \(\omega \) is equal to zero and the response of the material is linear elastic. Isotropic stiffness moduli decrease proportionally, regardless of the direction of loading. The incorporation of the damage considerations within the optimization process amongst scientific literature is subsequently discussed.

Kato and Ramm propose an optimization strategy for fiber-reinforced concrete in (2010), which does not count to topology but rather shape optimization, but is nevertheless briefly discussed within the context of concrete damage modeling. An isotropic, gradient-enhanced continuum damage model for the nonlinear behavior of concrete (Peerlings et al. 1996) is consulted, resulting in higher optimization degrees, especially when an improvement of ductility is aspired, than when only linear material behavior is considered. The research of Kato and Ramm (2010) further inspired Amir and Sigmund (2013) to combine truss TO according to the GSM with a continuum damage model to investigate reinforcement layout design in concrete structures. The objective of this approach is to reach the possibly stiffest structure by redistributing the given volume of reinforcement within a concrete domain. Reinforcement elements are considered as elastic bars via an embedded formulation within the concrete domain. Plain concrete elements are represented using an isotropic exponential damage law with strain softening (Peerlings et al. 1996). It has to be noted that, in this case, optimization per se only takes place on the reinforcement level. Amir (2013) continues the work of Amir and Sigmund (2013) proposing a TO procedure to simultaneously optimize concrete and reinforcement while maintaining the damage modeling approach. The density-based approach is combined with the GSM minimizing concrete volume subjected to constraints based on the load-bearing capacity as well as on steel volume. In contrast to common linear optimization processes, a compliance instead of a volume restriction is set to avoid numerical difficulties when linking the numerical optimization process to the damage modeling approach. Results, based on a load-bearing capacity per unit weight evaluation, show that optimized designs outperform initial layouts. The optimized structures bear 80 % of the total load carried by full, non-optimized pendants.

5.1.4 Strut and tie modeling

A well-established approach within structural concrete design is strut and tie modeling (STM), rooting back to Schlaich et al. (1987) and is often taken up in TO. Within STM, a structural geometry can be divided into regions of geometrical or static discontinuities characterized by nonlinear strain distributions (so-called D-regions) as well as regions of linear strain distribution designed via the use of the Bernoulli theory (so-called B-regions). Typical examples of D-regions include load introduction areas, supports, openings, corners or corbels. In D-regions, a truss of struts and ties combined by nodes can be designed. To find such trusses, Schlaich et al. (1987) propose the consideration of an elastic material behavior, e.g. consulting linear elastic stress trajectory layout from FEA as a template for drawing an appropriate truss model. Liang et al. (2000) argue that the latter method is complicated in the case of sophisticated loading mechanisms or geometry conditions. It is further noted that layouts from nonlinear results can be helpful in assessing D-regions in more detail (Maekawa et al. 2008). Nevertheless, the accuracy is questionable, as nonlinear stress distributions highly depend on the interaction between cracked concrete and reinforcement. It is required that a strut and tie (ST) model, as a statically admissible field, reaches external as well as internal equilibrium at each node. Nevertheless, strain compatibility does not have to be satisfied, leading to a non-unique character. The field of STM is already well-established and incorporated within standardization, e.g. chapter 6.5 of ÖNORM EN 1992-1-1 (2015). A variety of publications exists to compare found ST models against each other, e.g. Kumar (1978). The potential suitability of TO to identify ST model is frequently investigated within academic literature, at which commonly TO is consulted as an alternative approach to manual methods in identifying a ST model.

In regard to investigations based on evolutionary procedures, the research of Liang et al. (2000) is started with. Within his literature piece the performance-based ESO method to automatically create ST models in reinforced concrete based on weight minimization criteria and displacement constraints is presented. Their findings indicate the method to be appropriate for finding truss models in continuum-like, non-flexural concrete members. Kwak and Noh also proposed ESO to determine ST models (2006), but instead of using the classical in-plane element a basic brick unit element consisting of six truss elements is designed. Unlike the classical ESO method this approach results in minimized strain energy for linear elastic material behavior. A further investigation specializes on an application to three-dimensional reinforced concrete structure (Leu et al. 2006). Lanes et al. (2019) used the ESO method by Liang et al. (1999) to create ST models based on linear as well as nonlinear material behavior of concrete, consulting the Concrete Damage Plasticity model provided by Abaqus (version 6.10). After considering the results of both material modeling approaches, a suggestion is made that the resulting topology with maximum stiffness is to be adapted for the subsequent truss layout. A more profound analysis of the differences between these two material modeling approaches is not given.

The BESO method, a further extension of ESO, was taken up by Mezzina et al. (2012) to compare ST models for the design of concrete bridge decks subjected to seismic in-plane actions with models found by the use of the load path method by Schlaich et al. (1987). Hardjasaputra (2015) and Palmisano et al. (2014) also investigate the finding of ST models for reinforced concrete structures, consulting the software BESO2D or rather BESO3D by RMIT University, Australia (no further details which version) by Huang and Xie (2010), with the second publication investigating several nonlinear constitutive laws.

The research of Schnellenbach-Held and Habersaat (2014) can also be mentioned at this point, although the term STM does not explicitly occur. Via genetic programming, a reinforcement configuration for biaxial concrete slabs inspired by spider webs is presented. The process allows for a modification of the bar angles and amount. The results show less deformation in comparison to conventionally designed slabs, with an almost identical amount of total steel length.

When shifting from the evolutionary algorithms to other TO methods, the investigations of Bruggi (2009) come to light. A classical volume-constrained minimum compliance SIMP formulation for automatic truss-like layout generation and ST model extraction, embedded within a commercial FE modeling environment is used. Within the subsequent publication in (2010), Bruggi furthermore considers the effect of horizontal forces by investigating multiple load cases in seismic concrete structure design. A method to generate optimal load paths in plain and reinforced concrete structures with regions of prescribed reinforcement is also presented (Bruggi 2016). For further information on this energy-based approach, the reader is referred to Bruggi (2014).

The general suitability of TO for reinforced concrete truss design via the use of the GSM is investigated by Guest and Moen (2010). They highlight the importance of constructability of optimized solutions, especially when it comes to curved concrete struts. The GSM is further consulted by Achtziger (1996), who considers bar properties different for tension and compression.

Another research regards the Isolines Topology Design method, based on the work of Querin et al. (2010), with the goal of finding ST models within reinforced concrete (Victoria et al. 2011). The method considers the boundary of a structure as a design variable. Victoria et al. (2011) introduce a fixed stress ratio for concrete and steel leading to a constant strain energy by unit weight. To facilitate such an optimality criteria method, a Fully Stressed Design solution is pursued. Furthermore, effects of creep are considered via introducing a creep factor \(\phi \), reducing the Young’s module over time. When using the same material levels for tension and compression, the results were well aligned with the findings of Schlaich et al. (1987).

Putke and Mark compare optimized STM results from literature with own calculations using the software Ansys (release 12.1) and the SIMP method in (2014), highlighting the dependency of the TO quality on mesh settings, stop criteria and material reduction requirements. A structural area reduction of 60% to 90 % in the context of STM is suggested to be achieved. Putke and Mark (2014) further outline the necessity of refining the final layout, as the initial TO-based design often does not meet the required limitations due to reinforcement configuration.

Very recently, a fully automatic evaluation procedure of ST models defined through TO is elaborated (Xia et al. 2020a). This research is characterized particularly by an objective character. In a first step, an automated conversion of TO results to truss-like 2D structures is proposed via an automatic extraction process, consisting of binary image transformation, thinning through skeletonization methods, node detection, redundant node reduction and connection determination. The results are measured using indices as for example the Tensile Region Similarity index. Their findings show that the obtained TO results lead to better results in representing the tensile regions of the original structure and in lower steel consumption in comparison to optimized designs using conventional ST models. On a more negative note the less favorable results regarding the amount of shear forces within the system, which often entail subsequent manual adjustment of the obtained TO results, have to be mentioned. Overall, the ST models found through varying TO methods as investigated by Xia et al. (2020a) show similar performance to the ones presented by Schlaich et al. (1987). The work of Xia et al. (2020a) highlight better results for linear elastic, isotropic models than orthotropic models. Xia et al. (2020b) continued the research, incorporating 3D calculations, by maximizing stiffness via a linear-elastic TO method, an extraction of the found topology and subsequent shape optimization. The nonlinear FEA that follow results show that TO extracted outcomes are more economical in comparison to manually generated ST models.

5.1.5 Combined truss-continuum topology optimization

Combined or rather simultaneous truss-continuum optimization (CO) is identified as further research area. As structural concrete commonly represents a combination of steel reinforcement and plain concrete, this approach is especially relevant to the field of TO within concrete construction.

Smarslik et al. (2019) compared the results of a sole truss, a sole continuum and a combined truss-continuum optimization approach, whose findings are subsequently outlined into more detail. The respective continuum TO approach is based on the matlab code of Sigmund (2001) and for the combined optimization approach the publications of Amir (2013) (further outlined in section 5.1.3) and Gaynor Andrew et al. (2013) are consulted. The truss-continuum hybrid model of the latter work is taken up, generalized even extended for concrete material constitutive equations by Smarslik et al. (2019). The major advantage of combining truss with continuum optimization is the ability to capture lateral tension forces in areas of concentrated forces, so-called spreading forces, see Fig. 10. In general, Smarslik et al. (2019) suggest continuum TO to be applied on a global scale within an early design stage. Truss TO is suggested to be used when searching for an appropriate ST model in local cross sections. The more computationally intense approach of combining both optimization approaches is suggested to be applied on a local as well as on a global scale. Furthermore, the general suitability to apply TO within all stages of structural concrete design is shown.

Truss-continuum optimization concept (left) by Smarslik and Mark (2019) with illustrated bar forces representing lateral tension forces (right) (Credits: Mario Smarslik, Institute of Concrete Structures, Ruhr University Bochum)

5.1.6 Multiple load cases

Smarslik et al. (2016) outline that an optimization process is normally conducted for one specific load case. Within concrete construction design, the consideration of multiple load cases is however indispensable. Consequently, the superposition of several single load cases is outlined by Smarslik et al. (2016), based on Harzheim (2019). A plural number of weighted objective functions can be solved as follows (Kämper et al. 2017):

The equation above represents a global objective function as a sum of weighted single functions. In the course of this so-called multi-objective approach, the objective function is modified by weighting the compliances with factors \(w_k\). These weighting factors \(w_k\) mirror the share of single functions on the global result, allowing for the consideration of multiple load cases n. Konečný et al. (2017) see a great time-saving potential in applying TO to concrete reinforcement design, when multiple load cases are considered.

Regarding the consideration of multiple load cases within the form finding processes, the work of Kämper et al. (2017) on parabolic concrete collectors is discussed. The load-bearing structure as well as the orientation and curvature of the reflector area, considering self-weight, torsional and wind loads, are optimized. Based on the high requirements regarding low deformations due to optical reasons linear elastic material behavior of concrete up to tensile strength is considered. The findings prove the overall numerical feasibility of the pursued TO approach with multiple load cases. The work of Kämper et al. (2017) is continued to multi-level optimization, meaning that both topology and shape optimization techniques are used for one specific optimization problem. The optimization methods are combined to determine the position as well as shape of outer stiffeners for parabolic shells (Forman et al. 2018).

5.1.7 Construction techniques

Current production trends or construction techniques (CT), like additive manufacturing, promise a more viable realization of organic, topology optimized geometries. This section outlines numerical advances towards this topic, e.g. incorporating manufacturability considerations within the optimization process. It has to be noted that some of the presented research is not explicitly concrete specific and is thus not included within the quantitative analysis. The studies are discussed according to their relevance for the identified research area.

ST models defined by TO are often characterized by an organic layout, impeding a final layout design as well as manufacturing. The following investigations, mostly based on the GSM, contribute in overcoming this challenge: Zhu et al. summarized advancements of including constructability objectives and constraints into TO procedures with an emphasis on economic design efficiency (2014). Respective concepts include the standardization of patterns, member orientations and discrete member sizes. A method to rationalize trusses obtained from layout optimization by introducing fixed joint lengths and geometry optimization during post-processing is proposed (He and Gilbert 2015). Torii et al. (2016) also investigate the topic of reducing design truss complexity by manipulating the number of bars. Interestingly, the work of Asadpoure et al. (2015) investigates the incorporation of fabrication costs by assigning a cost unit to each truss element.

Kontovourkis et al. investigate an entire digital design and fabrication methodology for a concrete building wall element in (2020). The BESO-based plugin Ameba of Grasshopper for Rhinoceros (no further details which version) is used for toolpath planning in the context of robotic additive clay manufacturing. Søndergaard et al. (2013), on the other hand, propose a combined integrated design, optimization and fabrication method for space-frame truss structures in the course of an autonomous digital process.

A focus is now set on 3D concrete printing in the context of TO within concrete construction. A TO approach for staged construction segmental bridges constructed as balanced cantilevers as well as additive manufacturing as a field of application (Amir and Mass 2018). The compliance of each construction stage is tainted with a relative weight and supporting structures are penalized via the addition of gravity-based load cases. Low-penalty material interpolation models are used to exploit usually unfavored ”grey” material regions, interpreting these as temporary supporting structures. Many other studies address the topic of support structures within additive manufacturing, at which the publications of Langelaar (2017) or Gaynor and Guest (2016) can be mentioned. Allaire et al. (2017) and Mass and Amir (2017) considered overhang constraints, which are typical within the field of additive manufacturing. The latter work presents a virtual skeleton to reduce supporting material amount. Manufacturing as well as material specific constraints of 3D-printed concrete structures within TO with incorporated maximum overhang limitations can be considered. Also orthotropic properties of printed concrete as well as the manufacturing constraint have been taken into account (Martens et al. 2018). In their recent study, Wang et al. (2020) think the issue of constructing optimal geometries even further and propose a space-time TO algorithm that allows for concurrent optimization of the structure as well as fabrication sequences for additive manufacturing.

5.1.8 Alternative approaches

A small number of publications was identified for following other research directions. These alternative approaches (AA) which are subsequently summarized within this section.

Aesthetics

Beghini et al. (2014) highlight the potential of TO to benefit a collaboration of structural engineers and architects, enhancing aspects of aesthetics.The development of structural systems formed by optimally distributed prefabricated structural shapes that can be predefined by e.g. the architect are discussed by Sotiropoulos et al. (2020). That way, principles of aesthetics, manufacturability and architectural design can be incorporated within one mathematical optimization formulation. Dombernowsky and Søndergaard investigate topology optimized, prestressed concrete and its realization via CNC milling in 2009. The conclusion is presented that even though aesthetic considerations are difficult to be included within the computational optimization process, aesthetic reflections can be indirectly included via output evaluation. By consulting the software OptiStruct by Altair Engineering (no further details which version), a simply supported concrete slab under post-tension was designed. They describe the organic shape of the found geometries is described as ”characterized by sinuous curves that meander in contracting and diverging sequences”, stating that such geometries on the one hand impede production, while on the other hand enhancing aesthetic quality. A brief outlook on 1:1 CNC milling of the found geometries out of polystyrene blocks is given. On a different note, Dapogny et al. (2017) propose an optimization framework for conceptual architectural design, combining shape as well as topology optimization. Via their set geometrical constraints they allow for a resulting design driven by a predefined shape and geometrical pattern in accordance with the user’s preferences.

Prestressing

Amir and Shakour (2018) propose an approach to optimize prestressed concrete structures. The concrete domain is modeled as a linear elastic, uncracked and optimized continuum, whereas the linear tendon segments are shape-optimized. A filter ensures appropriate embedding of the tendons within the concrete domain. Tendon forces are transferred to the concrete in dependence on their angle, at which the tendon is seen as an accumulation of equivalent loads. The design variables comprise concrete density as well as the y-coordinates of the tendons. The final problem formulation combines topology as well as shape optimization of the tendon layout. The application on beams with concentrated or uniform loads shows that the desired fully compressed design with deformations close to zero can be achieved. The requirements on appropriate coupling of the tendons with the surrounding concrete domain are highlighted to receive physically feasible results. Amir and Shakour (2018) conclude with the suggestion of using tendon curvature constraints in future work.

Multi-physics optimization

In their research paper, Vantyghem et al. (2018) combine structural as well as thermal performance requirements via a weighted sum objective under volume constraints. Three optimum variables are included, representing void with low structural and good thermal performance, a variable with favorable structural but less favorable thermal properties and an improvement of the structure’s thermal conductivity under a certain degree of structural integrity. Similar to the interpolation of the Young’s module within SIMP, the thermal conductivity is penalized by Vantyghem et al. (2018). The research is continued through an investigation of a density based multi-physics optimization strategy for 3D printed buildings by Vantyghem et al. (2019). Within this process, the density variables are linked to varying 3D printed infill patterns, thus incorporating manufacturability aspects.

5.2 Review on experimental applications

Recently, as illustrated in Fig. 3, experimental applications, e.g. laboratory experiments of concrete structures designed via the use of TO, have gained in popularity. Showcase studies are discussed in the following section.

5.2.1 Multimaterial modeling

Gaganelis and Mark, continuing the work of Gaganelis et al. (2019), tested an optimized reinforced concrete beam loaded in a four-point bending setup in 2019. A reinforced concrete truss as well as a hybrid concrete-steel truss structure with ulta-high performance fiber-reinforced concrete (UHPFRC) were developed. The results indicate significant weight savings (approximately 50% and 80% for the reinforced concrete truss and hybrid beam version, respectively). The similar or even higher stiffness compared to the conventionally cast reference beam is analytically elaborated: The optimized structure’s height is increased while keeping the load-bearing capacity similar. The optimized systems are characterized by dominating axial forces instead of bending and shear, leading to reduced crack initiation. As a consequence of the optimized, organic structure, additional effort in design know-how and fabrication (e.g. formwork preparation) was required. The fabrication of the complex node types of merging compression and tension struts is outlined in detail within the publication. The hybrid beam version’s formwork and final shape is pictured in Fig. 11. Furthermore, nodal design is mentioned a one of the key factors to realize slender, light concrete structures with minimized environmental impact.

Formwork and assembly of a hybrid concrete-steel truss structure by Gaganelis and Mark (2019) (Credits: Georgios Gaganelis, Institute of Concrete Structures, Ruhr University Bochum)

5.2.2 Stress constraints

Jewett and Carstensen (2019) performed a density-based optimization with stress constraints followed by an investigation of manufacturing as well as experimental testing of such plain concrete beams. The numerical background is outlined in section 5.1.2. The resulting designs were cast in CNC-cut expanded polystyrene molds and tested in a deflection-controlled manner with four loaded points and one central support. The results show that minimum compliance design is characterized by stiff behavior up to design load and low ductility prior to failure, whereas low tension designs show a similar behavior up to design load but a significantly softer behavior after design load and before failure. High tension designs behave even more ductile. According to the interpretation of Jewett and Carstensen (2019), the compliance designs failed due to failure of the tension chord, the high tension designs due to shear failure and the low tension designs showed a combination of failure modes. Furthermore, the need for implementing optimization within manufacturing in post-processing of optimized as well as rounded geometries in Abaqus (2017), was highlighted, as a change of stress patterns can be detected between the numerically optimized and practically rounded geometries.

5.2.3 Strut and tie modeling

Putke and Mark use TO to identify truss models for tubbing segments under shear force and a neglect of axial force in (2014). The experimental elaboration of the results is outlined by Putke et al. (2015). The resulting ST model has a simple layout and serves as a basis for reinforcement concepts, including micro-reinforcement, anchored steel fibers and rebars welded to anchor plates. Topological results show that bearing materials such as steel elements are necessary in certain areas of the geometry.

In 2015, Schnellenbach-Held and Habersaat investigate a bionic inspired reinforcement layout for optimized concrete slabs, with the numeric background outlined within their publication in (2014) Schnellenbach-Held and Habersaat. A 130 mm thick concrete slab with a square side length of 4 m was built and tested. The optimization of the reinforcement configuration resulted in a more ductile structural behavior. As a further example, a ribbed slab inspired by water lilies was compared to reference slabs with a solid cross section and an orthogonal rib structures, all with identical material usage. The load-bearing behavior of the optimized slab is shown to be higher by approximately 10 %.

On a different note, tests on conventional and optimized ST models of dapped beams have been performed (Oviedo et al. 2016). The results show a more favorable crack growth propagation for the optimized specimens as well as slightly higher load bearing capacities. The optimized specimens’ geometry even facilitates assembly, resulting in non-congested reinforcement cages. Their presented findings indicate that the reinforcement should be orientated parallel to ties of the optimized layout and that the simplified orthogonal cages should be avoided.

Another practical example within the context of STM is outlined by Schmidt-Thrö et al. (2019), who investigate concrete elements under partial strip loading. The layout of the splitting reinforcement is based on previous results of hybrid TO, referring to Putke and Mark (2014) and Putke et al. (2015). The optimization-based reinforcement regions show little improvement in load-bearing properties while other reinforced regions have more dominant effects on the load-bearing behavior.

5.2.4 Combined truss-continuum topology optimization

Smarslik and Mark (2019) follow a method based on Amir (2013) and Gaynor Andrew et al. (2013), combining truss and continuum optimization. Partial area loading for centric or eccentric load cases on segmental lining longitudinal joints, considering multiple load combinations, are investigated. The optimized results suggest the use of hybrid reinforcement concepts, thus combining steel fibers to cover small, distributed tensile stresses and rebars for high, concentrated forces. Two experimental series with varying load and reinforcement types were performed. Their results indicate the potential of TO to enhance the structural performance of segmental lining longitudinal joints, promoting hybrid reinforcement concepts. An optimization based cage design in practical execution is shown in Fig. 12.

Optimization based reinforcement cage practically executed by Smarslik and Mark (2019) (Credits: Mario Smarslik, Institute of Concrete Structures, Ruhr University Bochum)

5.2.5 Construction techniques

This subsection gives practical advances in the field of construction techniques regarding optimized concrete structures. Construction workflows and realized examples are outlined and discussed.