Abstract

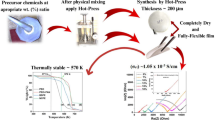

The composite solid polymer electrolytes based on Polymethyl methacrylate–Lithium triflate with nanochitosan as inert nanofiller were prepared by membrane hot-press method. Nanochitosan was synthesized from shrimp shell. The obtained polymer membrane was subjected to X-ray diffraction and Fourier transform infrared spectroscopy to study the structural behavior. X-ray diffraction studies revealed that the incorporation of nanochitosan in the prepared polymer matrix enhanced the amorphous phase. The complexation behavior of the prepared electrolytes was analyzed by Fourier transform infrared spectroscopy. Thermogravimetric and differential scanning calorimetric studies were carried out to understand the thermal stability of the prepared polymer composite electrode. The incorporation of nanochitosan in the polymer matrix significantly reduces the crystalline temperature of polymethyl methacrylate which was confirmed by differential scanning calorimetric study. Universal testing studies were carried to know the mechanical stability of the prepared solid polymer electrolytes. The ionic conductivity of the prepared composite polymer electrolyte was carried out using electrochemical impedance spectroscopy from ambient to 120 °C.

Similar content being viewed by others

Introduction

Polymethyl methacrylate (PMMA) is a transparent polymeric material and has many desirable properties such as light weight, high light transmittance, chemical resistance, uncolored, corrosion resistance, and good insulating properties [1]. Also, it has been used as a polymer host due to its high stability at the lithium-electrolyte surface since it is less reactive towards the lithium electrode. In this polymer, a monomer methyl methacrylate (MMA) has a polar functional group in the main polymer chain and has high affinity to lithium ions which are transported. The oxygen atoms in these monomers will form a coordinate bond with the lithium ion which is from the doping salts. Thus, due to the presence of polar functional group in PMMA, the increase in effective ionic transport of PMMA based polymer electrolytes might be achieved. Among various lithium salts, lithium triflate (LiTf, LiCF3SO3) is an interesting salt since it decreases the polymer host’s crystallinity and is more thermally and chemically stable than other traditional lithium salts [2].

In addition, the developing of new composite polymer electrolyte by dispersing with inorganic or organic filler is to improve the ionic conductivity and mechanical stability in the polymer electrolyte system. Chitosan is a cationic polymer obtained from chitin through alkaline deacetylation process. It finds many applications in field of medical and engineering based on the inherent properties such as antibacterial, antifungal, antiviral, antacid, nontoxic, and total biodegradable as well as film formation, fiber formation, and hydrogel formation properties [3,4,5]. Due to its functional groups, it can be easily tailored with other molecules in order to improve the properties. Several research works was carried out to enhance the properties of the materials by adding nanochitosan to the various fields and reported in the literature [6,7,8]. In the present work, PMMA-LiTf solid polymer electrolytes were prepared and the nanochitosan was employed as nanofiller. The structural properties of the prepared samples were analyzed by employing the X-ray diffraction and Fourier transform infrared spectroscopy. The thermal and mechanical studies of the prepared polymer electrolytes were studied. Also, the ionic conductivity of the prepared composite polymers was carried out.

Methods

Materials

Poly (methyl methacrylate) (Mw = 35,0000, Sigma-Aldrich), Lithium triflate (LiCF3SO3, Merck), and Tetrahydrofuran (C4H8O, Merck) were used to the preparation of composite polymer electrolytes. Nanochitosan (Mw = 3923, 85% DD) was synthesized from shrimp cell as the method reported earlier [9].

Preparation of polymer composite membrane

The solution was prepared by dissolving the required amount of PMMA, Nanochitosan (NC) and Lithium triflate (LiTf) in tetrahydrofuran (THF). The homogeneous solution was prepared by stirring constantly until the mixture took a viscous appearance. Thus, the obtained solution was poured on to a Teflon push and allows the THF to evaporate in air at room temperature. The samples were collected and hot pressed as film specimens at high temperature using membrane hot press. The thickness of the prepared film was measured using screw gauge. Different composite membranes were prepared by repeating the process through varying the amount of polymer (PMMA) and filler (NC). The various compositions of filler, lithium salt and polymer used for the preparation of composite polymer electrolyte were tabulated in Table 1. The obtained homogeneous, self-standing polymer electrolyte were stored in vacuum desiccators and then subjected to further characterizations.

Characterization techniques

X-ray diffraction measurements were carried out from Panalytical make, MODEL X’per PRO with Cu-Kα1 radiation. Fourier transform infrared spectroscopy of all the prepared were measured from JASCO-FTIR4100/Japan. Thermogravimetric analysis (TGA) and differential scanning calorimetric (DSC) analysis of all the prepared polymer electrolytes was carried out from Perkin Elmer STA 600 and Netzsch DSC 204 F1 in the temperature range 30–500 °C at a heating rate of 10 °C/min in nitrogen atmosphere. The samples were investigated with a universal material-testing machine equipped with a 10-ton load cell using Dak System Inc. (Model No. UTB 9103), in room temperature. The ionic conductivity of the prepared composite polymer electrolyte was studied using ZAHNER, IM6 Electrochemical workstation in the temperature range from 303 K to 393 K over a wide frequency range from 1 Hz to 100 kHz.

Results and discussion

XRD analysis

Figure 1a–f shows the X-ray diffraction pattern of the polymer electrolytes prepared in the present study.

In Fig. 1 b, we noticed that there was no change in the X-ray diffraction pattern due to the addition of lithium triflate salt. This X-ray diffraction pattern is similar to the x-ray pattern of PMMA; the crystalline peak corresponding to LiTf were not observed in Fig. 1b. This indicates that the added lithium salt is completely dissolved in the polymer matrix and thereby confirming the complex formation of PMMA and LiTf [10].

On incorporating nanochitosan to the polymer electrolyte system, the diffraction peaks corresponding to PMMA become less intense and broadened (Fig. 1 c–f). Thus, the addition of nanochitosan may induce a significant increase in the amorphicity of the polymer matrix. The reflections at 2θ values of 15.2° correspond to the crystal planes, viz., (1 2 0) yielding the strongest lines of nanochitosan as evidenced by the JCPDS file. The intensity of PMMA peak were decreased and broadened as the filler concentration increases in the ratio of 5–20 wt% in the polymer matrix. This is shown in Fig. 1 c–f. This result clearly suggested that the amorphous nature of PMMA increases with increasing nanochitosan concentration.

The filler nanochitosan supports higher dissociation of lithium triflate salt which leads to higher mobility and increase in conductivity. These results are in accordance with the result reported earlier using TiO2 as nanofiller in PMMA matrix [11].

Fourier transform infrared (FTIR) analysis

The FTIR spectra of PMMA, nanochitosan, and polymer electrolytes are shown in Fig. 2a–g). The vibrational peaks and corresponding band assignments are tabulated in Table 2. From the figure, it is understood that the characteristic frequencies of LiCF3SO3 at 3481 cm−1, 1641 cm−1, and 1182 cm−1 are shifted to 3585 cm−1, 1718 cm−1, and 1145 cm−1 in the polymer complex. This can be attributed to the change in environment for the CF3SO3− ions in the complex. The observed peaks at 1145 and 979 cm−1 confirmed the presence of lithium ions in the prepared PMMA-based polymer electrolyte [12].

In Fig. 2d–g, the incorporation of nanochitosan to the polymer electrolytes has shifted the band at 1646 cm−1 (Fig. 2d), 1644 cm−1(Fig. 2e), 1642 cm−1(Fig. 2f), and 1631 cm−1 (Fig. 2g). This result is due to the complexation of the PMMA, LiTf, and nanochitosan. The peaks at 3484 cm−1 (Fig. 2d), 3440 cm−1(Fig. 2e), 3423 cm−1(Fig. 2f), and 3415 cm−1 (Fig. 2g) are attributed to the hydrogen bonding with SO3− anions of the salt and OH group of chitosan. This result is in agreement with the earlier reports [13,14,15].

Further, it is informed that the addition of nanochitosan creates an insulating layer and reduces the number of surface layer which is formed between PMMA and NC. Therefore, this impedes the mobility of charge carriers in the PMMA polymer matrix and it helps the transportation of Li+ ions in the polymer network by creating voids or vacancy and improves ionic conductivity.

Differential scanning calorimetry (DSC) analysis

Figure 3a–e shows the melting temperature (Tm) of TF-NC0, TF-NC5, TF-NC10, TF-NC15, and TF-NC20. On incorporation of nanochitosan in the polymer matrix was found to decrease the melting temperature of PMMA as shown in Fig. 3b–d.

Addition of nanochitosan in the prepared PMMA based polymer electrolyte results in the broadening of the melting endotherm with an apparent decrease in the heat of fusion (ΔHf) [16,17,18,19]. The values of ΔHf and Tm of all prepared PMMA based polymer electrolytes were observed from the DSC curve and are summarized in Table 3. The value of ΔHf was found to decrease significantly in the presence of nanochitosan filler in the prepared PMMA based polymer matrix which is inferred from Table 3.

The melting temperature (Tm) of the prepared polymer composite electrolyte is decreasing while increasing the concentration of nanofiller and this reduction is suggested that the interaction between the polymer PMMA and NC upset the polymer chain dynamics. This is because of the coordination bonds between the transient cross-linkage bonds of –O– and carbonyl group. At the same time, the glass transition temperature (Tg) of the prepared composite polymer is increasing with increasing of nanofiller. This shift towards higher temperature is due to the Li+ preferring to cooperate with the cross-linkage bonds, that is Li+–O– binding which obstruct the rotation of polymer segments and decreases the flexibility of polymer backbone. These may be due to the agglomeration of nanofillers in the polymer chain that creates blocking effects for ion conduction. As a consequence, the polymer chain elasticity decreases which leads to a decrease in ionic conductivity [20, 21].

Thermogravimetry analysis (TGA)

Figure 4a–d shows the thermogravimetric scans of TF-NC0, TF-NC5, TF-NC10, TF-NC15, and TF-NC20 respectively.

It is observed from the thermograms that the initial weight loss of the samples noted that 4 to 7% around 130 °C is due to the evaporation of residual solvent, moisture and impurities (Fig. 4a–e). Fluorine is also the contributor for the initial weight loss, as the polymer tends to absorb moisture from its surroundings [22]. The thermal stability of the prepared polymer electrolytes systematically increases with the incorporation of nanochitosan filler which is evident from Fig. 4b–e. Table 4 summarizes the decomposition stages and the corresponding weight loss for TF-NC0, TF-NC5, TF-NC10, TF-NC15, and TF-NC20.

From the results obtained, we inferred that the incorporation of nanochitosan has enhanced the thermal stability of the polymer electrolytes significantly. The reason is due to the formation of hard filler-polymer interaction which makes the polymer electrolytes more thermally and mechanically stable. These results are in agreement with the results obtained by ionic conductivity and mechanical properties of the prepared polymer electrolytes [23, 24].

Mechanical studies

The mechanical behavior of the prepared PMMA based polymer electrolytes prepared in the present study is displayed in Fig. 5a–e. The tensile strength and Young’s modulus values of the prepared PMMA based polymer electrolytes were calculated and are tabulated in Table 5.

As we increase the filler concentration, it is noticed that the tensile strength and flexibility have increased. This is more preferred when the flexibility of the polymer electrolyte has improved the practical application of the lithium rechargeable battery.

The addition of LiTf into the rigid PMMA basically improves the flexibility of the polymer electrolyte. However, the mechanical strength is reduced. The addition of nanochitosan in the polymer matrix was found to increase in tensile strength of the polymer electrolytes and it is found to increase further with filler concentration (Fig. 6). With the dispersing of the filler, into the polymer electrolyte, both mechanical strength and flexibility have increased. Additionally, the increase in mechanical stability with respect to nanochitosan concentration may be due to the fact of appropriate dispersion of filler, sufficient load transfer, good interfacial action of nanochitosan on the polymer host surface, and less number of cavities. Figure 7 shows the variation of Young’s modulus with the different concentration of nanochitosan in the polymer electrolytes. Young’s modulus of the polymer electrolyte increases with increase of filler content [25,26,27].

Ionic conductivity

The prepared composite polymer electrolytes were sandwiched between two stainless steel blocking electrodes and the ionic conductivity was determined by measuring the bulk resistance for the temperature range with signal amplitude of 1 V and frequency range of 1 Hz to 100 kHz using the formula σ = t/RbA, where t is the thickness (in cm); Rb is the bulk resistance (in Ω) and A is the known area in contact with the electrodes (in cm2). The variation of logarithm of ionic conductivity as a function of inversion temperature for different wt% of nanochitosan based polymer electrolytes are depicted in Fig. 8. As it is evident from Fig. 8, the ionic conductivity of polymer electrolytes obeys Vogel-Tamman-Fulcher relation [VTF], i.e., the conductivity increases with increase in temperature. This implies that as the temperature increases, the polymer can expand easily and produce free volume. This leads to the increase of ion mobility and segmental mobility that will assist ion transport and practically compensate for the retarding effect of the ion clouds [28,29,30,31].

It is also noticed from Fig. 8 that the conductivity increases with increase in nanochitosan content up to 10 wt% (Fig. 8b, c). This is due to the fact that the nanochitosan increases the polymer chain segmental motion as well as amorphous region. This amorphous region favors the migration of lithium ion in the free volume of polymer matrix.

In the meantime, if the concentration of NC was increased beyond 10 wt%, the conductivity decreases rapidly as shown in Fig. 8. This is due to phase discontinuities; dilution effect predominates in the polymer matrix, viscosity of polymer matrix increases by the way of inter-chain self cross-linking and results in decrease the polymer segmental motion (Fig. 8 d, e). Further increasing of NC content hinders the migration of Li+ along the polymer chain. Hence, the termination of conducting pathway occurs results in decreasing the conductivity drastically.

The ionic conductivity for TF-NC10 is greater than TF-NC15; this may be concluded that the smaller particle size of filler might have a better dispersion phase and provides a better Lewis acid-base interaction with lithium triflate in the polymer electrolyte. The maximum ionic conductivity is found to be in the order of 10−5.4 S/cm corresponding to the sample with 10 weight ratio of NC to PMMA-LiTf-NC polymer complex. Similar observations are reported for other polymer electrolytes such as PVA, PVC, PMMA, and its blend with different fillers [32,33,34].

Conclusions

Nanocomposite solid polymer electrolyte consisting of PMMA-LiTf-nanochitosan was synthesized and their films were prepared by hot-press method. The structural, thermal, mechanical and conductivity characterization of the prepared samples were studied. The enhancement of amorphous phases in the prepared composite polymer electrolytes was observed while increasing the nanofillers in the polymer matrix as evidenced by reduction in the intensity of X-ray diffraction characteristic peaks. The Fourier transform infrared studies confirmed that the complexation of the electrolyte systems in the prepared composite polymer electrolyte. Thermal studies of the prepared composite polymer electrolyte indicated that the melting temperature was reduced upon incorporation of nanofillers and glass transition temperature was increased with increase of nanofillers. Mechanical stability of the prepared composite polymer was found to increase with increases the filler concentration in the polymer matrix. The ionic conductivity of the prepared composite polymer increases with increase in temperature and reaches maximum at10 wt% nanochitosan content in the polymer matrix.

Availability of data and materials

The datasets used and/or analyzed during the current study are available from the corresponding author/First author on reasonable request.

Abbreviations

- DSC:

-

Differential scanning calorimetry

- FTIR:

-

Fourier transform infrared

- JCPDS:

-

Joint Committee on Powder Diffraction Standards

- LiTf:

-

Lithium triflate

- MMA:

-

Methyl methacrylate

- Mw:

-

Molecular weight

- NC:

-

Nanochitosan

- PMMA:

-

Polymethyl methacrylate

- TF-NC:

-

Triflate-Nanochitosan

- TGA:

-

Thermogravimetry analysis

- THF:

-

Tetrahydrofuran

- XRD:

-

X-ray diffraction

References

Ramesh S, Wen LC (2010) Investigation on the effects of addition of SiO2 nanoparticles on ionic conductivity, FTIR, and thermal properties of nanocomposite PMMA–LiCF3SO3–SiO2. Ionics 16:255–262

Visakh PM, Thomas S (2010) Preparation of bionanomaterials and their polymer nanocomposites from waste and biomass. Waste Biomass Valor 1:121–134

Muzzarelli RAA (1996) Chitin chemistry in the polymeric materials. CRC Press, Florida

Harish Prashanth KV, Tharanathan RN (2007) Chitin/chitosan: modifications and their unlimited application potential—an overview. Trends Food Sci Technol 18(3):117–131

Dutta PK, Duta J, Tripathi VS (2004) Chitin and chitosan: chemistry, properties and applications. J Sci Ind Res 63(1):20–31

Bano I, Arshad M, Yasin T, Ghauri MA (2019) Preparation, characterization and evaluation of glycerol plasticized chitosan/PVA blends for burn wounds. Int J Biol Macromol 124(1):155–162

Muzaffar S, Abbas M, Siddiqua UH, Arshad M, Tufail A, Ahsan M, Alissa SA, Abubshait SA, Abubshait HA, Iqbal M (2021) Enhanced mechanical, UV protection and antimicrobial properties of cotton fabric employing nanochitosan and polyurethane based finishing. J Mat Res Technol 11(1):946–956

Abbas M, Hussain T, Arshad M, Ansari AR, Irshad A, Nisar J, Hussain F, Masood N, Nazir A, Iqbal M (2019) Wound healing potential of curcumin cross-linked chitosan/polyvinyl alcohol. Int J Biol Macromol 140(1):871–876

Ali M, Aboelfadl M, Seliem A, Khalil H, Elkady G (2018) Chitosan nanoparticles extracted from shrimp shells, application for removal of Fe(II) and Mn(II) from aqueous phases. Sep Sci Technol 53. https://doi.org/10.1080/01496395.2018.1489845

Jung HR, Lee WJ (2011) Electrochemical characteristics of electrospunpoly(methyl methacrylate)/polyvinyl chloride as gel polymer electrolytes for lithium ion battery. ElectrochimicaActa 58:674–680

Kumar D, Hashmi SA (2010) Ion transport and ion–filler-polymer interaction in poly(methyl methacrylate)-based, sodium ion conducting, gel polymer electrolytes dispersed with silica nanoparticles. JPower Sources 195(15):5101–5108

Tretinnikov ON, Nakao K, Ohta K, Iwarnoto R (1996) Surface studies of stereoregularpoly(methyl methacrylate)s: Effect of interface on near-surface composition and crystallinity. Macromol Chem Phys 197:753–765

Costa MM, Terezo AJ, Matos AL, Moura WA, Jose AG, Sombra ASB (2010) Impedance spectroscopy study of dehydrated chitosan and chitosan containing LiClO4. Physica B 405(21):4439–4444

Suait MS, Ahmad A, Hamzah H, Rahman MYA (2011) Effect of lithium salt concentrations on blended 49% poly(methyl methacrylate) grafted natural rubber and poly(methyl methacrylate) based solid polymer electrolyte. Electrochim Acta 57:123–131

Sumithraj Premkumar P (2019) Preparation and electrical studies on pure and oxygen plasma treated polyvinyl alcohol films. J Mater Res Technol 8(2):2232–2237

Vickraman P, Ramamoorthy S (2006) A study on the blending effect of PVDF in the ionic transport mechanism of plasticized PVC–LiBF4 polymer electrolyte. Mater.Lett 60(28):3431–3436

Rajendran S, Uma T, Mahalingam T (2000) Conductivity studies on PVC–PMMA–LiAsF6–DBP polymer blend electrolyte. Eur Polym J 36(12):2617–2620

Saikia D, Kumar A (2005) Ionic transport in P(VDF-HFP)–PMMA–LiCF3SO3–(PC + DEC)–SiO2 composite gel polymer electrolyte. Eur Polym J 41(3):563–568

Ramesh S, Yuen TF, Shen CJ (2008) Conductivity and FTIR studies on PEO–LiX [X: CF3SO3−, SO42−] polymer electrolytes. Spectrochim Acta Part A 69(2):670–675

Ramesh S, Lu SC (2008) Effect of nanosized silica in poly(methyl methacrylate)–lithium bis(trifluoromethanesulfonyl)imide based polymer electrolytes. J Power Sources 185:1439–1443

Rajendran S, Sivakumar M, Subadevi R (2004) Investigations on the effect of various plasticizers in PVA–PMMA solid polymer blend electrolytes. Mater Lett 58:641–649

Rajendran S, Mahendran O, Kannan R (2002) Ionic conductivity studies in composite solid polymer electrolytes based on methylmethacrylate. J Phys Chem Solids 63:303–307

Ramesh S, Shanthi R, Durairaj R (2011) Effect of ethylene carbonate in poly (methyl methacrylate)-lithium tetraborate based polymer electrolytes. J Non-Cryst Solids 357:1357–1363

Salehan SS, Nadirah BN, Saheed MSM et al (2021) Conductivity, structural and thermal properties of corn starch-lithium iodide nanocomposite polymer electrolyte incorporated with Al2O3. J Polym Res 28:222. https://doi.org/10.1007/s10965-021-02586-y

Wang YJ, Kim D (2007) Crystallinity, morphology, mechanical properties and conductivity study of in situ formed PVdF/LiClO4/TiO2 nanocomposite polymer electrolytes. Electrochim Acta 52:3181–3189

Chen C, Li D, Deng Q, Zheng B (2012) Optically Transparent Biocomposites: Polymethylmethacrylate Reinforced with High-Performance Chitin Nanofibers. Bio Resources 7:5960–5971

Regu T, Ambika C, Karuppasamy K et al (2019) Al2O3-incorporated proton-conducting solid polymer electrolytes for electrochemical devices: a proficient method to achieve high electrochemical performance. Ionics 25:5117–5129

Rajendran S, Uma T (2000) Lithium ion conduction in PVC-LiBF4 electrolytes gelled with PMMA. J Power Sources 88:282–285

Karuppasamy K, Thanikaikarasan S, Antony R et al (2012) Effect of nanochitosan on electrochemical, interfacial and thermal properties of composite solid polymer electrolytes. Ionics 18:737–745

Manuel Stephan A, Nahm KS, Anbu Kulandainathan M et al (2006) Electrochemical studies on nanofiller incorporated poly(vinylidene fluoride–hexafluoropropylene) (PVdF–HFP) composite electrolytes for lithium batteries. J Appl Electrochem 36:1091–1097

Angulakshmi NP, Kumar T, Thomas S, Manuel Stephan A (2010) Ionic conductivity and interfacial properties of nanochitin-incorporated polyethylene oxide–LiN(C2F5SO2)2 polymer electrolytes. Electrochim Acta 55(4):1401–1406

Johan MR, Fen LB (2010) Combined effect of CuO nanofillers and DBP plasticizer on ionic conductivity enhancement in the solid polymer electrolyte PEO–LiCF3SO3. Ionics 16:335–338

Rajendran S, Mahendran O, Mahalingam T (2002) Thermal and ionic conductivity studies of plasticized PMMA/PVdF blend polymer electrolytes. Eur Polym J 38(1):49–55

Stephan AM, Renganathan NG, Kumar TP et al (2000) Ionic conductivity studies on plasticized PVC/PMMA blend polymer electrolyte containing LiBF4 and LiCF3SO3. Solid State Ionics 130(1–2):123–132

Acknowledgements

The authors thank Prof. X. Sahaya Shajan, Director (Research), Centre for Scientific and Applied Research, PSN College of Engineering and Technology, Melathediyoor, Tirunelveli, Tamilnadu, India, for his permission to use the facility and discussion.

Funding

No funding was received from any sources to carry out this research work.

Author information

Authors and Affiliations

Contributions

The experiment and analysis of the present study was carried out by the first author. The second author was involving to do the mechanical studies of the prepared samples. Third author gave the ideology to carry out the research work and helped the entire analysis of the submitted article. All authors read and approved the final manuscuript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

About this article

Cite this article

Shyly, P.M., Ammakutti Sridevi, N. & Sumithraj Premkumar, P. Thermal and mechanical studies of nanochitosan incorporated polymethyl methacrylate-based composite electrolytes. J. Eng. Appl. Sci. 69, 26 (2022). https://doi.org/10.1186/s44147-022-00077-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s44147-022-00077-5