Abstract

Background

Despite its popularity, acceptability, and convenience, the oral route is not the classical route for the administration of all critical bioactives including lipophilic drugs, proteins, and peptides. Recent advances in drug delivery have identified the transdermal route as a compelling alternative channel for improved delivery of essential biomolecules due to the illuminating advantages derived from this route. In order to circumvent the poor permeation of the stratum corneum by transdermal patches, microneedles (MNs) technology, which combine the advantages of parenteral delivery using hypodermic needles and transdermal delivery, has been unveiled as a novel biomimetic technology for efficient and effective transport of payloads across the stratum corneum.

Main body of abstract

The concept of MNs was first documented by Chambers in 1921 when he reported some problems encountered during experimentation using Echinoderm eggs. Since the first patent recorded in 1976, there has been consistent interest and funding in development of MNs for various biomedical applications. MNs have been developed and classified based on their physical attributes and functional profiles into solid, coated, hollow, dissolvable, and swellable or hydrogel-based MNs. These devices are fabricated using advanced techniques like 3D bioprinting, laser methods, photolithography, and molding, and applying materials such as carbohydrates, silica, ceramics, metals, glass and polymers. MNs could be characterized based on their morphological, geometrical, surface, mechanical properties, biocompatibility, and permeability profiles. Evidences have shown that MNs could be commercialized for various clinical adaptations. The numerous biomedical applications of microneedles in drug, peptide, and protein delivery attest to the versatility and dynamic nature of the fabrication techniques, and the pliability of the formulation materials. In spite of the enormous potentials of MNs, extant literature has shown that MNs also have their own share of limitations like every novel technology designed for theranostic purposes.

Short conclusion

In this review, we have escalated discussions on the progress and advances made in the development and use of MNs by summarizing the benefits, limitations, fabrication techniques, fabrication materials, characterization methods, therapeutic applications, sterilization and stability considerations, safety and toxicological concerns, regulatory guidelines, and tips for successful commercialization of MNs.

Similar content being viewed by others

Background

As the most acceptable, prominent, and convenient route for administration of bioactives, oral drug delivery enjoys wide acceptance across all groups of patients (pediatrics, adults, and geriatrics), despite its known disadvantages like first-pass metabolism of drugs, low bioavailability for lipophilic drugs, poor compliance in severe illness. e.g., vomiting, coma, unconsciousness, etc. Parenteral injections, which provide rapid onset of activity of therapeutics with high bioavailability, is limited by low patient adherence, excessive anxiety, pain at injection site as well as rapid manifestation of adverse effects. Over the years, several researchers and formulators have made pivotal attempts at developing advanced and newer strategies and techniques for seamless targeted delivery of drugs and other biomolecules with low side effects. A few of these strategies have progressed from the laboratory scale to the industrial batches for final use in the clinics, while some interventions are still undergoing clinical trials. Of these attempts, the transdermal route has been favored as a vital pathway for enhanced delivery of biomolecules due to its illuminating advantages including absence of pain at administration site, increased patient compliance and decreased anxiety, excellent ease of administration, impressive flexibility of formulation design, use of simple operations to develop systems with sophisticated clinical performance, and possibility of accomplishing improved therapeutic outcomes with low cargo load, and provision of sustained drug release [1, 2]. However, it is difficult for transdermal patches to permeate the stratum corneum barrier for deep drug deposition. This challenge has been confronted by formulating transdermal drug delivery systems incorporating chemical penetrating materials (CPM) like esters and fatty alcohols or through the application of physical methods including electroporation, laser microporation, and iontophoresis. Skin allergies, inflammation, and irritation resulting in decreased product acceptability and patient adherence are possible drawbacks of the incorporation of CPM in transdermal drug delivery systems in addition to adverse and destructive interaction between the active pharmaceutical principles due to molecular incompatibility. The physical methods of improving transdermal drug delivery are expensive and do not guarantee reproducible delivery of encapsulated payload. Further, these methods are sophisticated because they require state-of-the-art equipment and high technical skills, which might not be readily and easily available in the industry [3]. Considering these challenges, it is very imperative to explore other options provided by nanotechnology like microneedle-based drug delivery, which might not require high sophistry to attain efficient and effective transdermal drug delivery. Therefore, this work is aimed at evaluating the recent and emerging perspectives in the application of MN technology as precision tool for drug, peptide, and protein delivery by summarizing its benefits and limitations, and discussing the fabrication techniques and materials for fabricating MN. In addition, characterization methods and biomedical applications of MN will be addressed. Likewise, sterilization and stability, safety and toxicological concerns, and regulatory guidelines and tips for successful commercialization of MN will be covered. The limitations of transdermal drug delivery system are illustrated in Fig. 1.

Main text

Drug disposition using microneedles

Since the innovative concept of microneedles (MNs), a smart delivery device, was first patented in 1976 to its initial public description as an essential tool for transdermal delivery of therapeutics, it has attracted increasing interests and researches from various laboratories as well as funding from grant awarding bodies and companies. This is because MNs can be developed as an easily adaptable, affordable, biocompatible, and flexible device for non-invasive and throughput distribution of biomacromolecules, drugs, vaccines, and micromolecules [4]. The skin is an important beneficiary of this technology because it circumvents physiological stresses on the skin like inflammation, pain, discomfort, and irritability, to enhance transdermal delivery of biomolecules. MNs are described as polymeric devices showing smooth, needle-shaped projections measured in micrometers (up to 2500 µm) and supported by a flexible base impregnated with biomolecules for therapeutic and diagnostic (theranostic) purposes. Essentially, it is a hybrid device that embodies the functional advantages of transdermal patches and hypodermic needles [5,6,7]. It has been used to facilitate, consolidate, and accomplish transdermal delivery of therapeutics across the stratum corneum and into the viable epidermal structures of the skin maintaining the desired local therapeutic concentration for a prolonged period of time, while evading any intimacy with the nervous and venous structures of the dermis, which could trigger inflammatory or immunological damages. Therapeutic agents encapsulated in MNs include drug compounds, peptides, micromolecules, hormones, vaccines, genes, and proteins, for use in chronic wound healing, inflammatory skin conditions, tissue regeneration, tissue printing, cellular therapy, and diabetes mellitus. In addition, several MNs patents have been obtained, some devices are undergoing clinical trials, and scholarly publications on MNs have been documented which present cocktails of information on MNs including fabrication techniques, advantages and disadvantages, characterization methods, and biomedical applications [5, 8, 9]. In spite of its numerous advantages including production of excellent reproducible drug bioavailability devoid of inter-patient variability, MNs possess certain limitations like irritability due to sensitive skin especially if the hair-thick tips of the needles are broken under the epidermis. However, this is a rare occurrence and could be completely avoided by designing and carefully implementing a systematic quality systems during MNs development and complying with instructions during use. Various types of MNs have been fabricated and described including hydrogel-based, hollow, solid, and dissolving MNs, which were formulated using polymers, silica, glass, and sugars through technologies like lithography, thin-film deposition, micromolding, etc. [10, 11]. Biomedical dispositions of microneedles are illustrated in Fig. 2.

Types of microneedles

Microneedles are fabricated and classified according to their physical attributes and functional techniques as discussed in this section.

Solid microneedles (poke and patch-type)

Solid microneedles puncture the skin layer and deliver payloads to the desired site [12]. Initially, solid MNs were utilized for skin preparation before administering APIs from an external reservoir through the poke-and-patch technique [10]. It is possible to employ solid MNs both with and without engineered drug molecules [13]. Integrating these MNs into a smart patch system helps to achieve controlled drug delivery [14]. These systems enhanced the detection of biomarkers that are most commonly used in clinical laboratories and hospitals with the help of lab-on-a-chip technology [15]. According to a report, it was claimed that using solid MNs enhanced ex vivo transdermal absorption [16]. Compared to conventional approaches used for vaccine delivery, delivering vaccines with a solid MN is advantageous since it lasts much longer and strengthens the immune system [14]. Interstitial fluid (ISF) can also be extracted easily using solid MNs [17]. Solid MNs have some drawbacks, including patient inconvenience, prolonged occlusion time, and increased risk of microbial infection [18]. The stratum corneum is intended to be penetrated by the microneedle structure to optimize drug administration by forming microchannels throughout the layer to the dermis and increased bioavailability and distribution throughout the skin [19]. Silicon, metals, and polymers can be used to manufacture solid microneedles [10]. Solid MNs enhance the penetration of substances through the skin making it possible to administer macromolecules transdermally [20]. Some MNs rollers like Dermaroller®, Medik8®, and other commercially available MNs devices initially created for cosmetics applications have been modified for drug delivery [16].

Coated microneedles (coat and poke-type)

Coated microneedle is prepared by coating solid MNs with the drug solution [21]. Drug loading could be calculated based on the thickness of the coat, and it usually contains a low amount of the drug [22]. Following the insertion of the coated MNs into the skin, the entrapped molecules dissolve and permeate into the skin (coat-and-poke approach) [23]. This is a one-step application process that is simple and convenient for use [24]. Drug-coated microneedles have the benefit of staying active for a long time. Hence, their usage is restricted to potent biomolecules with dosing usually confined to microgram levels [25]. Current developments in coated MNs enable various applications, including the transport and detection of biomolecules, and provide a transdermal delivery system that is more regulated and effective in distribution than the skin pre-treatment method [21]. A functional coating layer can change the biocompatibility and mechanical robustness of coated MNs [23, 24]. PVP and other biocompatible materials are used to coat the probe layer [16]. To avoid using silicon and metal, which are less biocompatible materials, coated polymeric MNs have also been studied in recent years [26]. Agents like peptide stabilizers, viscosity enhancers, and surfactants are used to achieve coating homogeneity, thickness, and active stability [27]. According to an in vivo experiment, coated MNs produce longer-lasting drug levels in the sub-epidermal layer than those produced by subcutaneous injection delivering a reproducible blood concentration [18]. It was also shown that MN patches caused rapid peak plasma levels three times quicker than what was observed following the administration of the subcutaneous comparator, which was likewise independent of the target site [28].

Hollow microneedles (poke and flow-type)

The hollow microneedle has a vacant, hollow core or compartment, which retains drug solutions [10]. This technique helps in the administration of larger amounts of encapsulated drugs than solid and coated MNs, which can only deliver small amounts of payloads [16]. Hollow MNs consist either a solitary needle or an array of numerous needles with different bore diameters (5–70 m wide), which can be fabricated using silicon, metals, or glass [27]. The microneedle bore permits drug administration either passively by diffusion or under pressure from a syringe, pump, or gas [21]. Hollow MNs facilitate flow of the drug solution at 10–100 L/min and continuously deliver its content into specific skin layers (poke and flow). This system is commonly used to administer vaccines and insulin followed by collection of blood and ISF samples for prompt evaluation to quantify and distinguish the analytes present in the body fluids [7, 16]. In accordance with this methodology, analytes (e.g., protein, ions, or glucose in body fluid) would be identified through hollow MN-based sensing systems [29]. Hollow MNs are simple to manufacture, inexpensive, and accurate in controlling drug release from the liquid mixture [30]. An array of MNs also can incorporate a microfluidic chip or micropump to achieve regulated API delivery [31]. Delivering dry formulations, typically utilized to enhance medication stability and simplicity of patch-based delivery, is difficult when reconstituted [29]. The main disadvantages of hollow MNs are technical problems including drug leakage and blockage during administration. To circumvent this drawback, a side opening with off-centered perforations is created [10]. In contrast to solid MNs, hollow MNs are significantly weaker and deserve special attention with regard to needle design and insertion technique [12].

Dissolvable microneedles (poke and release-type)

Considering their attributes, dissolvable microneedle is a promising drug delivery device [10]. Two essential qualities of dissolvable MNs include one-step drug delivery, which facilitates simple medication administration, and the quick release of therapies and biotherapeutics [32]. Besides APIs, soluble matrix including biocompatible polymers or sugars makes up dissolvable MNs [21]. When it contacts the interstitial fluid, MN tips disintegrate releasing the API (poke-and-release approach) [33]. This method is considered superior to others because of the improvement in applying MNs that dissolve after poke and release [34]. When the skin is pierced by the MNs, they dissolve and the breakdown of the needle tip causes the entrapped bioactive to release and distribute [30]. Because of the fact that the rate at which the constituent polymers disintegrate affects how fast the active component is released, drug distribution can be regulated by varying the polymer composition and its use concentration or production process [35]. This class of MNs have good patient compliance and biocompatibility because they are often made with hydrophilic biodegradable polymers or sugars [4]. The micromold fabrication approach is best-suited for manufacturing dissolvable MNs [10]. A sound technical skill is necessary to develop and manufacture dissolvable MNs. Since safe polymers can be employed as raw materials, dissolvable MNs offer a high biocompatibility and loading capacity [25]. However, the major drawback in the clinical application of dissolvable MN is polymer accumulation within the skin, and this is not safe for prolonged use [18]. Since this allows API delivery without generating sharp, non-biodegradable, and bio-contaminated waste materials, dissolvable MNs are becoming increasingly popular and recommended [34]. In addition, it significantly reduces the price of synthesizing MNs due to use of artificial and semisynthetic polymers and polysaccharides. The patient benefits greatly from polymeric MNs that dissolve into the skin after insertion. A one-step medication delivery method provides a user-friendly interface because the medication is kept inside the needles [36]. Due to the total dissolution of the MNs upon application, making it impossible to re-insert the needles into another patient, the chance of infection transmission or needle stick injury is diminished. In comparison to solid and hollow MNs, dissolvable MNs are considerably safer [10].

Hydrogel MNs (swelling microneedles-type)

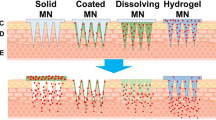

Hydrogel MNs, originally introduced in 2010, swell and increase in size after API is loaded, and through enlarged MNs, it is delivered from the patch [13]. Compared to biodegradable or dissolvable MNs, hydrogel MNs work by inserting a needle into the skin, releasing the payload, and dispensing the needle [37, 38]. Since the hydrogel is hydrophilic, the microneedles will absorb interstitial fluid and swell when it is introduced into the skin. Thus, materials with good swelling characteristics and biocompatibility are usually applied to create hydrogel-based microneedles [39]. This innovative method uses integrated systems which project cross-linked polymeric particles from the solid substrate containing the API. After injection, the interstitial fluid in the tissue is swiftly absorbed by the needles causing the API to diffuse through swollen MNs [40]. Amylopectin and ultra-low viscous carboxymethylcellulose (CMC) have been used to fabricate hydrogel MNs. They were effectively dissolved in the skin after combination with sulforhodamine, bovine serum albumin, or lysozyme, enabling bolus or sustained release administration. Noticeably, the skin was undamaged and free of any polymer remnants after removing the hydrogel MNs [17]. Hydrogel MNs lower the danger of infection transmission as they are sufficiently soft to prevent reapplication. They maintain good mechanical strength, although slightly deformed and can load higher amount of drugs than dissolvable MNs [37]. The different types of microneedles are illustrated in Fig. 3.

Schematic illustration of the different types of microneedles showing A solid B hollow C coated D dissolving, and E hydrogel-forming microneedles. Reprinted from [158]. S. Sharma, K. Hatware, P. Bhadane, S. Sindhikar, D.K. Mishra, Recent advances in microneedle composites for biomedical applications: Advanced drug delivery technologies, Mater. Sci. Eng: C. 103 (2019) 109717. https://doi.org/10.1016/j.msec.2019.05.002, Copyright (2023) with permission from Elsevier

Benefits of microneedles array

Drug delivery

Microneedles (MNs) are effective in delivering molecules of various sizes, including small molecules and biomolecules such as proteins, peptides, genes, and vaccines for viruses like SARS, MERS, and COVID-19. In the cosmetic industry, MN patches incorporating hyaluronic acid (HA) have been applied directly to the skin to improve skin health due to the moisturizing effect of HA. Transdermal delivery using MNs also bypasses first-pass metabolism and enzymatic degradation, thereby improving the efficacy of administered drug over conventional methods like the oral route. Fractional dosing or dose-sparing effect of drugs within microneedles allows enhanced vaccine efficacy when resources are limited and regulated like in the case of pandemics. Temporary and reversible disruption of the skin during MNs insertion reduces skin irritation and the risk of infection. As microneedles can be fabricated using biocompatible materials, they eliminate any cases of inflammation or toxic reactions in the body. Trained personnel is not required for administration as MNs are easy to use but self-administration by the patient improves compliance. MNs design can be modified to meet delivery requirements such as sustained or burst release or combination drug delivery for a specific patient population, and length of microneedles can be modified for targeted drug delivery to precise layers of the skin [41].

Flexibility of microneedles

Microneedles need to be flexible enough to reshape themselves to the surface it is being applied, especially in wound healing applications. Using lithographic techniques, it is possible to fabricate microneedles flexible enough to treat difficult-to-reach areas in cases like chronic wounds where there is a disruption of the skin structure and interference to conventional therapies caused by biofilms generated by the bacteria present. According to a report, MNs were fabricated using a polyethylene terephthalate substrate and loaded with polyvinylpyrrolidone-calcium peroxide to combat tissue hypoxia and antibiotic resistance in wounds. The MNs showed sustained release of oxygen for 6 h leading to better antibacterial activity in both gram-positive and gram-negative (Staphylococcus aureus and Pseudomonas aeruginosa) bacteria and improved oxygen delivery from 8 to 12 ppm to hypoxic wounds over 2 h resulting in better wound healing [42].

Cost of fabrication

To enable seamless translation of microneedles to clinical settings, affordability must be considered. Despite the potential benefits of this relatively new technology, there is still a need for a proper economic evaluation of microneedles, as their fabrication process is complex, their storage requirements are demanding, and the approval process can be time-consuming [5]. A cost-effective method for developing master templates for microneedle patches involves modifying commercially available stainless-steel templates used for tattoo needle cartridges. Polydimethylsiloxane (PDMS), a commercial solution with high flexibility and low adhesive properties, was used to modify the templates. This method supported the removal of polymeric microneedles from the mold and is stable at high temperatures [43]. Fabricating microneedles using microfabrication technique and natural polysaccharides such as chitosan, alginate, and xyloglucan could reduce the cost of production. Particularly, polymeric microneedles made from chitosan-PVA have shown a cumulative release of 20.18% of diclofenac in vitro in 30 h, indicating their potential use as a drug delivery system. This approach is far more economical compared to the use of metals or silicones to make microneedles, which could result in increased cost of production [44].

Safety of microneedles

Various clinical researches confirm that microneedles are safe and effective and do not cause systemic infections, though they are applied to the skin and penetrate the stratum corneum [45]. Skin permeation studies indicated that after microneedle insertion, the skin layer remained intact with no visible injury and microchannels formed precluded S. aureus bacteria transfer across the skin [46]. Studies on microbe permeation did not show signs of E. coli infection when microneedles were delivered to the anal sphincter muscle [47]. However, skin infection owing to skin puncture during microneedle application is always a possibility. In this scenario, MNs have a quick skin-sealing function that prevents microbiological infiltration. Dissolvable MNs are potentially used as they minimize skin punctures, thus reducing the chances of infections [20].

Limitations of microneedles delivery technology

Microneedles have limited drug-carrying capacity prompting difficulties in incorporating drugs with large doses. Polymeric MNs have low mechanical strength and break easily. In some cases, polylactic acid has been used to impart mechanical strength to MNs. The elastic nature of the skin prevents penetration of microneedles and delivery of entrapped drug to the target sight. Accurate dosing with MNs requires factors such as thickness, elasticity, and hydration of the skin to remain constant. Manufacturing microneedles with high-temperature conditions would create challenges in the delivery of thermolabile drugs, scarcity of materials viable for microneedle fabrication, and obstruction of microneedle bore, resulting in low penetration and efficacy. Lack of regulatory guidelines in manufacturing protocols, and poor quality control standards for large-scale manufacturing also hinder development of microneedles [41].

For MNs to show good activity and patient compliance, it depends on factors like the geometry of the MNs, more specifically the shape of the MNs, the diameter of the tip and base as well as the interspacing between microneedles. Delivery of drug and penetration of the MNs at the target site also depends on the health status of the skin, management of the MNs applied on the skin, and material used for the fabrication of the MNs. Depending on the drug of interest and application, certain parameters of MNs such as geometry and composition can be modified for accuracy in drug delivery.

Shape of the microneedles

In a recent study, simulations were performed using computer tomography (CT) scans to determine the mechanical strength, integrity, and penetration of microneedles. It was found that the buckling force of MNs increased as the number of vertices increased (from triangle, square to hexagonal), meaning that MNs with a triangular base will fail first due to buckling. Also, the penetration of microneedles was tested by keeping factors such as needle length and interspacing constant, and changing only the cross-sectional shape of the MNs. This showed that triangular and square base microneedles possess higher penetration potentials compared to hexagonal microneedles [48]. The viability of immunization by the transcutaneous route using dissolvable microneedles with varying needle shapes to deliver ovalbumin (OVA) was studied by Li et al. [49]. It was found that geometry plays an essential role in penetration efficiency and mechanical profile of microneedles because more than 95% of the cone-shaped dissolvable MNs penetrated the skin and the penetration ratio was only 40% in the case of cone-cylinder dissolvable MNs. The hexagonal pyramidal and rectangular-shaped dissolvable MNs showed less penetration efficiency than the cones owing to its dimension. The cone dissolvable MNs also showed 80% fraction of dissolution to the length of needle, while cone cylindrical dissolvable MNs recorded a meager 40%. Zoudani et al. [50] developed a new type of microneedle consisting of a cone with an array of hemispheres. This was proposed to be an improvement over dissolving microneedles of conventional shapes. It was claimed that the drug flux and final drug concentration were higher in tissues due to the unique structure of the hemisphere, resulting in the resolution of inadequate dose administration, which is a common problem in dissolving microneedles.

Tip diameter and sharpness

An investigation assessed the penetration depth and insertion force of MNs in ex vivo skin samples using microneedles with varying tip diameters (5, 15, 24, and 37 µm). It was observed that skin penetration increased linearly with smaller microneedle tip diameters. It was also concluded that force at initial drop increases linearly with the tip diameter and is directly related to the r (radius) of the tip. However, as the tip diameters cross a certain threshold (> 80 µm), the force at initial drop is directly proportional to r2, leading to the conclusion that smaller tip diameters (< 15 µm) are needed for smooth penetration of microneedles into the skin [51].

Force of application

Efficient delivery of drug also depends on the force applied to the microneedles and the elasticity of the skin. If the skin is too elastic, the microneedles push the skin instead of piercing the skin to deliver the drug, resulting in low efficiency of delivery [52]. Dissolvable microneedles have been shown to have an inconsistent release of encapsulated drugs into the skin as the physicochemical property of the skin does not allow complete insertion of dissolvable MNs. A new type of micropillar-dissolvable MNs was fabricated by Lee et al. [53]. The micropillars act like applicators helping in equally distributing the force across the microneedles giving proper insertion into the skin and allowing for a uniform release of the encapsulated drug into the stratum corneum.

Dose limitations

Microneedles have a small drug-loading capacity due to their size constraints. As a result, achieving a continuous drug release or patches with larger doses becomes impractical as microneedle patches need to be applied with higher frequencies to meet daily dose requirements. However, this might lead to poor patient compliance. Improving the solubility of poorly soluble drugs will result in greater drug loading onto microneedle patches. Considerable research has been done on solubilization techniques to improve the hydrophilicity of poorly soluble drugs. One such example is the work done by Kearney et al. [54] on developing hydrogel microneedles with reservoirs. Co-solvents such as PEG 400 and propylene glycol were used to improve the solubility of the hydrophobic drugs, olanzapine and atorvastatin. In vitro permeation study found a direct correlation between the drug loading effect and permeation because increasing the concentration of the drug in the liquid reservoir resulted in a multi-fold increase in permeation across the porcine membrane with the drugs reaching the target compartment within 15 min of MNs application.

Sustained release in microneedles

One of the problems with microneedle delivery is the sustained drug release in the body, which needs extensive patch-wearing hours for optimal drug administration. In a study, easily separated microneedles were used to reduce the time a patch stays on the skin and records sustained drug release. The concept behind separable microneedles is that medications that are coated on dissolvable microneedles, when applied, create cracking at the tip-base contact and allow the microneedles to split and penetrate the skin, eliminating the need to leave the patch on the skin for long periods, enabling good patient compliance and generation of only blunt waste material which can be safely discarded [55]. Li et al. [56] developed separable microneedles using biocompatible polylactic acid–polylactic-co-glycolic acid (PLA–PLGA) for controlled release of levonorgestrel (LNG) and impart mechanical strength to deliver LNG for better control on fertility. PLA-PLGA microneedles underwent slow biodegradation after insertion coupled with the hydrophobicity of LNG resulting in sustained delivery of LNG of over 45 days in vivo, with the release profile comparable to ideal kinetics of once-a-month contraceptive patches [56]. Similarly, effervescent MNs have also been developed to reduce patch application time and provide sustained release of LNG for > 1 month [57].

Materials for constructing microneedles

The materials used for manufacturing MNs are crucial in determining their therapeutic efficacy, manufacturing process, distribution within the body, and stability of entrapped molecules. Previously, materials such as glass, silicon, and metals were commonly used for creating microneedles, which were classified as either biodegradable or non-biodegradable. Non-biodegradable materials like metals, silicon, and ceramics are still used, while biodegradable materials such as polysaccharides and polymers have gained increased interest due to their biocompatibility and ability to overcome natural barriers. Recent advances in polymer technology have facilitated the use of biocompatible polymers in fabricating MNs that possess desirable physicochemical properties, can be easily fabricated, and are compatible with loaded bioactives and physiological functions. To be suitable for bioapplications, the material used for MNs should have excellent tensile strength, biocompatibility, and must be safe for both socioeconomic and health reasons. In some cases, the material must also be able to modulate drug distribution in a sustainable or controlled manner [58]. Additionally, the material should be easily moldable and resilient enough to withstand fabrication and transportation while also degrading effectively within the biological system. Some of the materials for creating MNs are discussed below.

Silicon

Silicon is commonly used in making biochemical detectors, drug delivery devices, and medical implants. Its biocompatibility has been studied for several years, but evidences of its safety are limited. Non-porous silicon has been shown to have low toxicity, which is why it is commonly used in drug delivery. However, there is a risk of chipping or breaking off in tissues during treatment because silicon is brittle, but workers have found that functionalizing silicon with nontoxic metals like gold increases their effectiveness. One example of an FDA-approved device that uses silicon is Micronject® [58]. It would be interesting to investigate the long-term effects of using silicon MNs on tissues since most studies have only reported short-term use. Silicon is expensive to produce and requires a sterile environment. Typically, isotropic and/or anisotropic wet and/or electrochemical deposition processes are used to create MNs profiles on the surface of a silicon chip. For porous MNs, the silicon must be deeply etched on the backside and then matched to the front side sequence. This process requires precise alignment and irradiation. A recent production process for creating MNs for deep brain medication infusion involves attaching a silicon backing layer with predetermined pores to a glass sheet using electrochemical methods [59]. Researchers have created silicon MN grids to deliver gene siRNA to the outer ear of rats and also manufactured long, porous silicon MNs for drug administration. However, solid silicon cannot be broken down by body enzymes and may cause inflammation and stiffness. On the other hand, porous silicon has shown bioactive capability and can bind to healthy cells, making it a biocompatible material [60]. Permeable silicon can be hydrolyzed by biological organisms in alkaline environments, and high-porosity silicon is used in sustainable drug carriers. The release rate of drugs from porous silicon depends on how they interact with the material. It might be surprising to learn that, despite the challenges involved in producing silicon MNs, silicon still has the largest market share in the industry. This is due to the demanding and expensive multi-component production process, as well as the need for specialized sterile equipment. Furthermore, the standard sizes of silicon MNs may not be sufficient for certain medical applications such as drawing blood or accessing blood vessels and nerves. This is because current production techniques for constructing silicon MNs are incompatible with fast manufacturing and lack the flexibility that fabrication techniques like 3D bioprinting can offer [36].

Metals

MNs are made of metals due to their advantageous mechanical and biomedical properties, such as high durability and toughness. Although metals are stronger than silicon, they are less prone to breakage. However, the use of metal MNs for skin penetration may cause negative reactions [61].

Carbohydrates

MNs utilize carbohydrates, such as cellulose, sugars, hyaluronic acid, and synthetic derivatives, either alone or in combination, as an essential component. These carbohydrates are easily recognized and absorbed by the skin and are similar to the natural microenvironment. MNs are specialized tools that can penetrate the skin layers and produce localized or systemic effects. Polysaccharides are macromolecules that have been widely used to create MNs because of their unique physical properties. The diverse range of organic compounds found in complex carbohydrates allows for tunable features and functions in the design and engineering of MNs. Carbohydrate-based microarrays can improve bioactive delivery, detection, and natural defense due to their significant capabilities. Carbohydrates are considered safe for use in MNs as they are metabolized and excreted by the renal system. However, their physical properties and interactions with pharmacological agents can affect drug release, penetration, and biological activity. Properties such as polymer weight, moisture content, and contact with active substances can influence the rate of drug release. Carbohydrates can be categorized as disposable, dissolvable, or lipophilic polymers, and these properties can impact in vivo behavior. Chitin and starch are disposable, dextran and sodium chondroitin sulfate are dissolvable, and methylacrylated hyaluronic acid is a lipophilic polymeric microarray. Using carbohydrates in MNs has numerous advantages including physical compatibility, non-toxicity, biodegradability, and renewable nature, although there are also various obstacles related to their use such as the lack of standardization, variability in form due to source and processing, and inherent changes that may occur over time or during development [62]. The use of carbohydrate-based microneedles can offer several benefits and drawbacks, depending on the specific type.

Sugars

Sugars are a desirable substrate for fabricating MNs due to their safety and biodegradable. Maltose is the most commonly used sugar, but other sugars such as xylitol, trehalose, galactose, mannitol, and sucrose have been used. These natural sugars play an important role in drug delivery systems and can exert specific biochemical actions based on their molecular configurations and chemical bonding. There are passive and active drug targeting methods using sugars for targeted drug delivery to tissues, organs, and cells. In spite of this, there is a dearth of literature regarding the effective and appropriate use of sugars for transdermal drug delivery to the epidermis and/or dermis. Researchers have designed and produced sugar MNs for percutaneous drug delivery and their sizes ranged from 150 to 2 mm and were made of maltose blended with active biomolecules. To test their tolerance on healthy human skin, a clinical trial was conducted on 10 healthy adult volunteers. Microneedles that were 500 µm in size and contained 5% of ascorbate-2-glycoside were embedded into the forearm, cut off, leaving them in the skin. These microneedles dissolved spontaneously through hydrolysis, releasing ascorbate into the epidermis and dermis [63].

Hyaluronic acid

The bioadhesive joint and matrix proteins contain an important component called hyaluronic acid (HA), which is a negatively charged biopolymer that is highly soluble in water. To address skin cancer, dextran nanoparticles were loaded into cross-linked HA MNs to create a nanotechnology-based delivery system. The nanoparticles were evaluated using an acid degradable polymeric matrix consisting of a dextran derivative, alginate, glucose oxidase, and programmed cell death protein-1 (PD1). This microdevice works by converting glucose to gluconic acid, which triggers the release of antibodies at the site of the melanoma [64]. MNs were fabricated with tips containing HA that dissolved within 30 s. The study assessed topical administration and permeability using fluorescein isothiocyanate labeling (FITC). In vivo experiments showed a burst release in the first 30 s, with nearly complete dissolution of the tagged dextran within five minutes. MNs produced comparable pharmacokinetic profiles to subcutaneous injection in rats with type 2 diabetes, indicating possible utility as a substitute therapy for type 2 diabetes [36]. In a different study, HA MNs were combined with adipose-derived stromal vascular fraction cells and polymers to improve the healing of diabetic wounds. The cells with HA microneedles demonstrated better wound healing effect compared to using cells alone indicating a new approach to wound healing [65].

Cellulose

Carboxymethylcellulose and hydroxypropyl methylcellulose are hydrophilic polymers that possess various characteristics such as viscosity modifiers, adhesives, emulsifiers, and coating materials. These polymers are utilized to fabricate microneedles for the treatment of Alzheimer's disease, where donepezil HCL is used and the tip, which is loaded with hydroxypropyl methylcellulose for animal/human testing, revealed that drug release commenced within 5 min of insertion, and complete dissolution of microarrays occurred in the skin within 15 min [66]. To promote hair regrowth, MNs were developed using carboxymethylcellulose-loaded with valproic acid. The release of valproic acid was found to be increased and compared to topical formulations leading to an increase in hair follicle regrowth [67].

Starch

Starch is a commonly used biodegradable polymer in medical applications due to its ease of use and ability to form films. However, it can be brittle and is often combined with other polymers. Pullulan, a hydrophilic biomacromolecule produced by Aureobasidium pullulans in starch and sugar-based fermentation, is a vital biomaterial in medical use. It has novel properties including excellent resistance to oxygen, strength, stability, transparency, film-forming ability, and non-toxicity and lack of mutagenicity. This makes it an ideal component for manufacturing MNs. While starch is a popular biopolymer, the exceptional qualities of pullulan make it an essential ingredient for biomedical applications, particularly in the production of MNs [63].

Chitosan

Chitosan and chitin-derived biopolymers have been employed in creating MNs mostly for hydrophilic drugs, hormones, proteins, and peptides. Chitosan, owing to its acidic nature, and positive charge that enhances adhesion to tissue and mucosal surfaces. It is broken down through the hydrolysis of acetylated residues, and its rate of degradation is affected by its degree of deacetylation and molecular weight. Chitosan has been acknowledged by the FDA as generally recognized as safe (GRAS), and it is extensively utilized in wound dressing, repairing cartilage, and producing MNs for regulated and prolonged administration of drugs. To enhance the performance of chitosan MNs, a biodegradable material composed of poly (l-lactide-co-d, l-lactide) was utilized to prevent the formation of impressions after piercing, and impressions were found to be absent after six hours. In vivo experiments showed that half of the antigen was released in the initial two days, and a minor fluorescence was evident during the manufacturing process of MNs [68]. Chitosan has garnered significant attention as a biomaterial for transdermal and topical drug delivery due to its biodegradability, biocompatibility, and ability to form films. The amine and hydroxyl groups on chitosan allow for modification to achieve desired functionalities and strength. Moreover, chitosan does not elicit an immune response inside the body, making it an ideal biomaterial for the fabrication of MNs [69, 70].

Polymers

Microneedles (MNs) have become increasingly popular as a transdermal drug delivery technique due to their ease of use, simple administration, and potential for improved patient compliance. The ability to produce customized MNs that can encapsulate a broad range of pharmaceuticals and biomolecules, as well as their performance as diagnostic tools, demonstrate their significance in the field. In the beginning, biopolymer-based microneedles were preferred due to their safety, biocompatibility, and biodegradability. However, synthetic polymers with enhanced physical resilience, pliability, and ductility have demonstrated greater potential for commercialization. Microneedles made from synthetic polymers have been used to administer vaccines, protein/enzyme-based therapeutics, and cytotoxic drugs. MNs are made from a variety of synthetic polymers including like polylactic acid, polystyrene, polyvinylpyrrolidone, poly(methylvinyl ether), polyglycolic acid, poly(lactic-co-glycolic acid), and polycaprolactone [1, 71]. The Gantrez® AN139-containing MNs were manufactured using the micromolding technique. These needles had a height of 600 µm and a width of 300 µm. Studies using optical coherence tomography revealed that these MNs penetrated the skin 460 µm deep. MNs penetrated the skin with force greater than 0.03 Newton per needle [72]. MNs containing amphotericin was fabricated using Gantrez® AN-119 by micromolding technique. Properties of MNs were explored using two different concentrations of amphotericin B 4% and amphotericin B 8%. For the 8% drug concentration limit, the load displacement value per needle was measured at 0.54N, and for the 4% limit, it was measured at 0.65N. According to the Franz diffusion studies, 88.88% of the drug successfully reached the skin and the zone of inhibition against Candida albicans for 8% drug-loaded MNs was 40 nm [73]. Micromolding was used to fabricate doxorubicin (DOX)-containing polystyrene MNs. Stability studies revealed that adding DOX to MNs improved the stability of DOX. Through scanning electron microscopy, the length of MNs which was found to be 451.02 ± 8.07 µm and the tip diameter was 1.93 ± 0.49 µm. Skin integrity evaluation revealed that skin disruption was not caused by the base of the MNs, and transepidermal water loss (TEWL) experiments further supported this claim [74]. The administration of meloxicam through MNs improved its anti-inflammatory effects. PVA and polyvinylpyrrolidone were combined to fabricate MNs in a 9:1 ratio. Axial needle fracture force for these MNs was 0.9N, and 100% of meloxicam was released in 1 h with drug deposition of 63.37% in the skin, which was 2.58 times more than meloxicam solution [75].

Glass

Glass is used in MNs production because it is simple to use, easily sterilized, biocompatible, and able to bear high pressure and temperatures [76]. To develop an intraocular device, hollow glass MNs were combined with polydimethylsiloxane (PMDS). Glass provided sufficient strength to pierce the eye, and PMDS was employed as the substrate since it provided flexibility to the device. It was discovered that delivery of 6-aminoquinolone and Rose Bengal using this device was clog-free and unaffected by their chemical characteristics and molecular weight [77]. Similar experiment was conducted for delivery of micro- and nanoparticles to the suprachoroidal space via single MNs to reduce the frequency of dosing [78].

Ceramics

Ceramics are crystalline complexes consisting of mixtures of metal and nonmetal compounds, such as silicon and nitrogen, calcium and oxygen, and aluminum and oxygen (alumina). Ceramics can be used to fabricate MNs since they are physically and chemically inert. Their biocompatibility and ease of production make them one of the favorite candidates for manufacturing of MNs [79]. Delivery of memantine was explored using ceramic nanoporous microneedles, which were prepared using micromolds and double replication process. Thickness, diameter, and reservoir capacity were the factors that influenced drug release from the MNs, although salt concentration and buffer volume had no bearing on the release profile of the drug. The order of release also changed as memantine concentration changed. It used zero-order kinetics for loading at 50 and 100 mg/ml, while first-order kinetics was observed for 35 mg/ml [80]. Both extraction and transdermal drug administration can be done using ceramic MNs. Microporous MNs were prepared using centrifugal casting. Pore size was found to be 1–1.5 µm. These pores improved the biocompatibility, drug loading, and physical stability of the microporous MNs. These MNs had a 95% penetration efficiency, and the skin recovery time was 30 min. Appropriate porosity with good interconnectivity and surface area resulted in detection of glucose in just 15 min with high precision. Insulin delivered via these MNs was found at the depth of 600 µm. In Franz diffusion apparatus, 80% of total insulin was delivered in 4.5 h, indicating that microporous ceramic MNs could be utilized for high loading and faster release of larger molecules [81].

Microneedles fabrication techniques

3D printing

3D printing or additive fabrication is a technology that uses virtual computer-aided designs (CADs) to create physical objects by continuously creating layers. 3D printing provides a wide variety of prototyping and manufacturing processes and one-step manufacturing of highly complex and reproducible objects [82]. 3D printing is a form of photopolymerization technology, which includes continuous layer polymerization of UV-sensitive polymers via a healing process. Digital light processing (DLP), stereolithography (SLA), and two-photon polymerization (TPP) are examples of these technologies [83].

Continuous liquid interface production (CLIP)

The CLIP dead zone eliminates the need to mechanically separate and reorient materials so that MNs production can continuously progress instead of layer-by-layer. Since mechanical separation and realignment steps in traditional processes limit the speed, the continuous movement of CLIP reduces the manufacturing time of MNs by leveraging computer-assisted design files without increasing the manufacturing time at the same time. Continuous production has several advantages including the ability to produce small, delicate, and complex MNs without fear of damage during processing, making it the perfect technique for the manufacture of MNs for the transdermal delivery of drugs [84].

Two-photon polymerization (TPP)

In all 3D manufacturing techniques, the high-precision TPP technology has produced more pointed microneedle arrays with more tunable designs [85]. TPP is based on a nonlinear optical process, two-photon absorption (TPA), in which a single atom or molecule excites from a lower energy level by simulating two photons simultaneously [86]. A laser pulse can produce high peak power within a very short period, and when concentrated in a material, it can produce very high power photon flux. Because diversity, availability, and correct material selection are important factors in structural resolution, components and products in every manufacturing process must also consider these factors for TPP [87]. Within a volume smaller than the wavelength of the laser, two-photon polymerization can occur. By employing high initialization efficiency photoinitiators, managing incident laser intensity, and adjusting laser focus scanning rate, lower than 100 nm structural features may be created. Two-photon polymerization is a new rapid prototype technology that can be used to make microneedles, as well as microneedle arrays of a wider geometric range [88].

Microstereolithography (μSL)

Microstereolithography (μSL) technology has been widely used in many areas over the years especially in biomedical and tissue engineering. Currently, μSL-designed devices include tissue scaffolds, cardiovascular stents, and nerve guidance conduits [89]. A quick prototype method called visible light dynamic mask microstereolithography is used to manufacture microneedles. Additive manufacturing involves layer-by-layer construction of the structure using a computer model. Dynamic mask microstereolithography was carried out in a report using commercial rapid prototype systems that contained digital microscope devices (DMDTMs). Dynamic masks are applied to specifically polymerize light-sensitive materials. The processing timeframes connected with visible-light dynamic mask microstereolithography are significantly shorter than those associated with other quick prototype methods because all layers of materials are polymerized simultaneously [90].

Photolithography

MNs may be produced via photolithography, a well-known microelectronic and microfluidics production technology, in a variety of forms and designed lengths [91]. The MNs formed by photolithography are strongly influenced by the presence of microlens, which deposits the polymer on a convergence path resulting in sharper MNs compared to the cylindrical MNs formed by planar photomasks. In planar photomasks, ultraviolet light passes through the lens with a small deviation (about straight), resulting in a more narrowly oriented cylindrical MNs, while, in a microscope-embedded photomask, UV light passing through the lenses is refracted and converged, leading to the formation of MNs with sharp tips. The lens equation is used as a prediction model for approving MNs length and giving three times the actual length prediction by correlating the microlens focal length. This discrepancy may be due to the flat-convex surface of the microscope, which does not allow light refraction, such as conventional convex lenses [92].

Dry etching

Dry etching is a photolithographical method used to fabricate microneedles with controlled density and shape, and the formation of MNs with cylindrical symmetry is made possible by the lack of crystal plane effects [93]. In this technique, inert or reactive gases are utilized at low pressure. Dry etching is grouped into reactive ion etching (RIE), which uses chemical processes, and ion-beam milling, which mainly uses physical processes [4]. The flexibility of needle shape and density is one of the key benefits of dry etching [94]. In dry etching, high energy, unidirectional electrodes ionize an inert gas such as argon or sulfur hexaflouride. Since the ions impact the silicon substrate rapidly, and in a single route, anisotropic etching is used. The exposed silicon is etched throughout the manufacturing process, but the region protected by the oxide film (sacrificial layer) or photoresistant rarely gets etched. High-pressure plasma etching is a chemical process that employs strong energy to produce a chemically reactive plasma gas as a result of the interaction of the plasma with the surface of the substrate, which turns it into a volatile material that is blasted away and the substrate is isotropically etched. Reactive ion etching employs both physical and chemical methods. Anisotropic and isotropic etching can be controlled by plasma and projectile etching [94].

Wet etching

Due to simultaneous sequential manufacture employing many silicon wafers at once, wet etching provides cheaper tool costs and allows mass production. Nevertheless, it is only suitable for low aspect ratio designs. A single crystal silicon wafer is immersed in chemical etchant solutions during wet etching to either produce an anisotropic (where the etch rate varies for various crystal planes) or an isotropic etch (there is the same etch rate in all directions) [93]. The microneedle arrays fabricated through this method are usually made from standard silicon wafers with exceptional precision and repeatability using potassium hydroxide (KOH). Wet etching is a popular micromachining technology that has advantages over dry etching such as lower processing and production costs. Wet etching of silicon to generate microneedles is a complicated process, but in a study, microneedles shape was regulated using the crystal structure of silicon and its associated etch properties in KOH [95].

Laser methods

Laser ablation

A laser is impinged on a metal plate to generate a bulge in this technique. This top-down technique used to process materials like metals allows the establishment of an inverse mold creating a pattern of microneedles [96]. Laser ablation inscribes the plate into a three-dimensional shape. In this technique, light pulses are employed to give the bulge a specific shape on a metal plate in order to build MNs array. When a substrate is exposed to a laser beam, for example, a carbon dioxide laser beam, energy is absorbed and it is heated to evaporate or sublimate [76]. Solid metallic arrays are made using laser ablation [96].

Laser cutting

An infrared laser is used in this process to cut flat metallic sheets into the shape of microneedles. To develop a 3D MN, 2D MN is bent to 90 degrees. MNs arrays are created by cutting stainless steel or titanium sheets into MN shapes [96]. Laser cutting is typically utilized to create metallic MNs; stainless steel is the most commonly preferred material [76]. Using AutoCAD software, the necessary geometry, shape, and structural dimensions of the MNs are generated. The MNs are washed in hot water at 90 °C from the plane of the base following the laser beam for the predefined shape of the needle. After that, MNs are electropolished in order to remove burr, reduce thickness, and sharpen the tips. This approach can be utilized to develop not only one row of MNs of different geometries, but also rows of metallic MNs with two dimensions [13].

Molding technique

Micromolding

Micromolding involves the utilization of molds to replicate a master structure. This method is also known as solvent casting method. Polydimethylsiloxane (PDMS), which has excellent stability, good thermostability, flexibility, reproducibility of the master structure as well as less adhesion (beneficial to peel off the MNs from female mold), is used to make the majority of the molds [97]. Moreover, a single master template can create many PDMS molds. The fabrication of MNs patches of several polymers, including natural polymers, synthetic or semisynthetic polymers, is done by using micromolding technique [96]. The micromolding process comprises of six main steps: constructing a male MNs mold, female MNs mold, casting the polymeric solution onto the female mold and forcing it into the cavities of the mold by centrifugation, removing bubbles by centrifugation or vacuum, curing MNs by drying (hot air oven or air dry) or photo-crosslinking, and peeling the MNs patch off the female molds [97]. The benefits of this technique include relatively simple, low-cost MNs synthesis at an ambient temperature [13].

Injection molding

Of the available micromolding methods (reaction injection molding, hot embossing, and thermal forming), micro-injection molding is preferentially used. Micro-injection molding is an extension of injection molding, which can make the method of creating products with micron characteristics more effective and affordable. It is a technique that transfers the micron accuracy of metallic molds with microstructures to molded products. Granulated thermoplastic material passes through a hopper and subsequently to a heated barrel, where it melts. Then, to compensate for material shrinkage, this substance is pumped under pressure into cavity of the mold and held there for a predetermined amount of time. The procedure is repeated after a specified period of time has passed after the material solidifies into the shape of the mold and is expelled. Micro-injection molding provides great repeatability, exact dosing, and high injection flow rates after the plasticization and polymer melt injection are segregated [14]. Major drawback of this method is managing the small size, since the commonly used screw is of size of 15–150 mm, and the equipment used in the process [98].

Methods of characterization of microneedles

Microneedle characterization is a key step in their development since it helps to ensure that they are safe, effective, and reliable. Several fundamental methods are frequently used to characterize microneedles.

Geometrical properties

Geometrical evaluation is an important method of microneedle characterization because it impacts penetration depth, tissue damage, and effectiveness of drug delivery. Some of the most important needle geometry parameters are:

Needle length

Needle length is the measurement from the base of the needle to the tip. The depth of penetration into the skin or other tissues can be affected by the needle length. Shorter needles, for example, can be used for transdermal administration of drugs, whilst longer needles can be employed for intramuscular injections.

Needle diameter

Needle diameter denotes the thickness of the needle. The needle diameter can influence the amount of force required to pierce the skin or other tissues. Thinner needles may not be as painful and need less energy to pierce the skin, but they may bend or break more easily [99].

Needle tip

The form of the needle tip is referred to as the tip shape. The form of the tip can influence penetration depth and tissue injury. Conical tips, for example, may cause less tissue injury than blunt points but may not penetrate as deeply.

Needle spacing and arrangement

The distance between the needles on the microneedle device, in addition to the way they are arranged, such as in a linear or array pattern, are collectively referred to as needle spacing and arrangement. The spacing and arrangement of microneedles can impact the density and area of skin covered, as well as the degree of penetration and drug delivery effectiveness [100].

Mechanical properties

Mechanical properties of microneedles relate to the qualities of the microneedles that govern their behavior when exposed to mechanical forces. These characteristics have significance because they impact the effectiveness of the microneedles during usage.

Stiffness

The resistance of the microneedles to bending or deformation when exposed to an external force is measured as stiffness. It is frequently expressed in terms of the Young’s modulus, which is the proportion of stress to strain. Microneedles with a higher stiffness require more power to enter the skin, but they are less likely to bend or break during usage [101].

Strength

Strength is a measure of the maximal stress that microneedles can bear before fracturing or breaking. It is a crucial quantity since it dictates how much force the microneedles can apply to the skin without breaking. Higher strength microneedles may penetrate deeper into the skin without breaking.

Elasticity

Elasticity is a measure of the capacity of the microneedles to recover to its original shape after being deformed. It is an essential characteristic since it impacts the skin-penetration capacity of the microneedles and keep their form while in use. Highly elastic microneedles regain their original shape easily making them less prone to shatter or deform during usage [101].

Surface properties

Surface roughness

This feature refers to the irregularities or peaks and valleys on the surface of the microneedle. Surface roughness influences the adherence of the microneedles to the skin or other surfaces, as well as its capacity to administer medications or collect samples. A smooth surface may improve adherence, but a rough surface may improve penetration and retention inside the skin. Techniques such as atomic force microscopy (AFM) or profilometry can be employed in order to quantify surface roughness.

Surface chemistry

Surface chemistry, which relates to the composition of the microneedle surface and its capacity to interact with the surrounding environment, is another essential surface feature. The surface chemistry of the microneedle can impact its adherence to the skin or other surfaces, as well as its ability to administer drugs or collect samples. A surface with a high degree of hydrophilicity, for example, may encourage greater skin wetting and penetration, whereas a hydrophobic surface may have lesser skin adhesion but may be more suited for some types of drug molecules. Surface chemistry can be studied using X-ray photoelectron spectroscopy (XPS) or Fourier transform infrared spectroscopy (FTIR) [102,103,104].

Surface wettability

Surface wettability is another key surface characteristic that could impact microneedles performance. The term, wettability, describes the capacity of a liquid to cover the surface of a solid substance. The surface wettability of the microneedles can influence how well they can penetrate the skin to administer drugs or collect samples. A highly wettable surface may promote greater skin penetration and drug administration. In contrast, a less wettable surface may have poorer skin adherence but may be more suited for specific types of drug molecules. Techniques like evaluation of contact angle can be used to gauge surface wettability.

Biocompatibility

The ability of a material or device to interact with living tissues without causing an adverse response. In the case of microneedles, biocompatibility is important to ensure that the device can be used safely and effectively in humans or animals without causing harm or discomfort. In vitro or in vivo tests to measure the cytotoxicity, immunogenicity, and inflammatory response of the MNs are frequently used in biocompatibility testing [10, 105].

Morphological characterization

Using techniques like transmission electron microscopy (TEM), scanning electron microscopy (SEM), or atomic force microscopy (AFM), the morphological profile of microneedles may be determined by studying their physical characteristics. The morphology of MNs is widely evaluated using SEM in order to ascertain the length, shape, and base diameter of MNs arrays and individual MN diameters. Techniques like SEM, AFM, and TEM are utilized by researchers to optimize as well as customize MNs for specific biomedical applications [105].

Permeation evaluation

In the permeation test, especially ex vivo permeation study, the rate and percentage of drug penetration across the skin using microneedles are measured. This method usually involves sample preparation and assessment of permeation of the biomolecules across an excised skin. The permeation assessment is carried out immediately after fabricating the microneedles. In this stage, a barrier between the donor and receptor compartments is created by properly mounting the skin tissue onto a diffusion cell. While the receptor compartment serves as a sink for drug molecules that cross the skin, the donor compartment contains the drug-loaded microneedles. For the purpose of simulating physiological circumstances, the entire system is kept at a constant temperature. The drug concentration in the receptor compartment is continuously monitored during the permeation test. The drug molecules that penetrate the skin can be estimated using a variety of analytical methods, including high-performance liquid chromatography (HPLC) and UV–visible spectrophotometry. Researchers can evaluate the effects of microneedle characteristics, including length, density, geometry, and surface changes, on drug delivery efficiency by examining the drug permeation profile. The permeation test offers significant information on the improvement in drug permeation attained by microneedles in comparison with conventional delivery techniques. It aids in choosing the ideal microneedle production and design parameters based on specific drug candidates. The test also permits the evaluation of formulation parameters that may affect drug absorption via the microchannels made by the microneedles, such as drug concentration, viscosity, and pH. Nway et al. [106] performed in vitro and in vivo permeation tests using a Franz diffusion cell and an 8-week-old mice model, respectively. The in vitro permeation test was done on neonatal porcine skin. For that, the skin sample was carefully excised to obtain a subcutaneous layer of the skin. The receptor compartment of the Franz cell was maintained at 37 ± 2 °C and was stirred constantly at 600 rpm using an in-built magnetic starring. The medium used for the test was PBS (pH 7.4), and the experiment was done at various predetermined time points up to 24 h. The quantity of permeated drug was determined using an analytical technique previously developed for the study. The study is usually carried out using controlled treatments such as placebo, negative control, and positive control groups [107].

Animal study using microneedles delivery system

Microneedles are usually tested in vivo to investigate vital factors including biosafety of the array, and the in vivo pharmacodynamic and pharmacokinetic profiles of the active pharmaceutical ingredient. Animals including mice, monkeys, guinea pigs, and rabbits could be used for in vivo evaluations. Additionally, different factors, including TEWL (transepidermal water loss), skin inflammation or irritation, and bioavailability, are assessed in animal studies. The Delfin vapometer is used for TEWL testing both before and after administration of microneedles [108]. To buttress the importance of animal study in MNs delivery, BALB/c mice of both sexes were utilized to evaluate the delivery and immunogenicity of formulations of diphtheria toxoid (DT) adjuvanted with N-trimethylchitosan (TMC) and administered transcutaneously using microneedles,. DT-loaded N-trimethylchitosan nanoparticles, a mixture of N-trimethylchitosan plus diphtheria toxoid (TMC/DT), or diphtheria toxoid solitary were administered to the mice three times, each time with a three-week delay between each dose. Two distinct 300-µm microneedle arrays were used to administer the formulations intradermally to the skin either before or after microneedling. Alum-adjuvanted diphtheria toxoid was administered subcutaneously (SC) as a positive control. The mice were slaughtered three weeks following their most recent vaccination. Total blood from the femoral artery was taken shortly before the animal was put to death, and ELISA was used to identify the antibodies (IgG, IgG1 and IgG2a) in the sera mobilized by the DT-loaded MNs [109].

For SARS-CoV-2 investigation, MNs loaded with SARS-CoV-2-S1fRS09 or SARS-CoV-2-S1 protein were inoculated intracutaneously into female C57BL/6 mice (each set of five animals), with PBS serving as the negative control. Mice were likewise supplemented with equal dose of immunogens after two weeks following the initial immunization. Two mice per group were exposed to gamma irradiation under clinical sterilization to assess the preliminary impact of gamma radiation on the MNs-SARS-CoV-2 vaccination. At weeks 0, 1, 2, 3, and 4, mice were bled through saphenous vein, and ELISA was used to evaluate blood samples for SARSCoV-2-S1 antibodies. It was discovered that MNs vaccines generated higher humoral responses compared to conventional needle injections [110]. In an in vivo drug delivery trial of a combined patch consisting hydrogel-based microneedles loaded with donepezil hydrochloride, male Sprague–Dawley rats were employed. Prior to the experiment, the rats were allowed to acclimatize in a week and rat hair at the back region was removed 24 h before the experiment to reduce or eliminate interference of hair with the application of MNs. Rats were placed under isoflurane anesthesia (2–4% in oxygen) to make MNs administration easier. Rat skin was squeezed, and four MNs set on an adhesive foam border were placed on the back of all the rats using firm finger pressure. Films containing donepezil hydrochloride were placed to the back of the arrays with the drug filling up to 2.5 mg/kg or 5 mg/kg. A Scotchpak®M and Duro®tak adhesive (grade 387–2054) film, an occlusive transdermal backing, was placed on top of the arrays to hold the integrated patch in place, and this was wrapped with Micropore® tape. At predetermined intervals up to 24 h, blood samples (200 µL) were obtained through tail vein bleeds at defined sampling point. Following heart puncture, the Sprague–Dawley rats were killed and blood was withdrawn into heparinized tubes and RP-HPLC analysis of all above samples were performed. The concentration of donepezil HCl in plasma was found to be 51.8 ± 17.6 ng/mL, confirming MNs as an effective delivery system for donepezil HCl [111].

Methotrexate (MTX)-loaded hyaluronic acid-dissolving microneedle patches and methotrexate microneedles were evaluated in BALB/c mice in vivo. To assess the therapeutic and unfavorable effects of different doses of methotrexate-loaded microneedles, a psoriasis mouse model was used. The mice were separated into six groups of five mice each and the first five groups were subjected to topical administration of IMQ (imiquimod) cream (15 mg/day) on their left ears for 6 consecutive days. The control group included mice that did not receive any imiquimod (IMQ) cream topical administration. Every day, a single MN patch was placed on the ear of a mouse as part of the microneedle treatment. To ascertain the minimum dose (LD), median dose (MD), and maximum dose (HD) for all groups, additional ear swelling or thickness was assessed using a vernier caliper, and a psoriasis-like lesion was also determined. In IMQ-administrated BALB/c mice, it was discovered that application of MTX-loaded microneedles on the skin lesions lessened epidermal hyperplasia, lowered IL-23 and IL-17 production, and eventually decreased the inflammation of the skin similar to psoriasis. Additionally, when correlated with oral treatment, the MN-assisted transdermal MTX delivery demonstrated increased efficacy to prevent lesions from exacerbating and produced a comparable therapeutic impact at a lower dose, which could produce negligible systemic toxicity. Considering all of its benefits over traditional delivery methods, the methotrexate-loaded hyaluronic acid dissolving microneedle patch has the potential to replace psoriasis medication in the near future [112].

Therapeutic applications of MNs

Protein and peptide delivery

Calcitonin gene-related peptide (CGRP) is a neuropeptide responsible for inducing neuropathic pain. It is secreted by the sensory nerve endings. Xie et al. [113] selectively targeted CGRP using a microneedle patch which produced a local analgesic effect. CGRP8-37 is a model anti-CGRP peptide. A dissolving microneedle patch was fabricated using sodium carboxymethyl cellulose (SCMC) with CGRP8-37 dissolved in the polymeric solution. Three different rat models for diabetes, neuropathic pain, and nerve injury models were used to investigate the efficacy of the microneedles. Analgesia was observed in the local area without disrupting normal pain function. Polyethylene glycol diacrylate (PEGDA) was used by Liu et al. [114] to fabricate microneedles by photopolymerization. Although small molecules can be loaded in the process of formulation of microneedles, peptides can degrade in the photopolymerization process. Hence, they used a safer method for loading gap junction inhibitor (gap 26) on PEGDA microneedles by exploiting the ability of the polymer to swell in an aqueous solution. The peptide exhibited inhibition of collagen-1 in keloid scar. Furthermore, glucagon-like peptide 1 (GLP1) is an intestinal hormone that regulates the blood glucose level by stimulating insulin production in the presence of higher sugar levels and vice versa in hypoglycaemic conditions. GLP1 is an extremely unstable molecule with a very short half-life and is easily degradable. Lixicenatide is an analog to GLP1 which was delivered using a bilayer dissolving microneedle fabricated using PVP, wherein the peptide was concentrated in the tip region. In a study using db db mice, the blood glucose level was decreased upon application of the transdermal patch [115].

Vaccine delivery

A proof-of-concept work by Patil et al. [116] used the spike glycoprotein of SARS-CoV-2 for the formulation of a noninvasive microneedle vaccine. PLGA microparticles were used to separately encapsulate each of the surface spike protein and adjuvants, Alhydrogel® and AddaVax™. The hydrogel of nanoparticles along with sodium alginate was fabricated into microneedles using PDMS mold. Preclinical studies confirmed antigen-specific humoral immunity as well as cellular immunity. In a study, dissolvable microneedle patch fabricated using polyvinyl pyrrolidone was used for prophylactic delivery of a highly conservative epitope, Qßvirus-like particles, to induce immunity against human papilloma virus (HPV). The amount of HPV 16 L2 IgG antibody mobilized was equal to that of subcutaneous vaccine, by administering a very small amount of the dose compared to the subcutaneous vaccine [117]. In another study, comparative analysis of dermal vaccination and traditional intramuscular route against influenza virus (H1N1) was investigated. Compared with intramuscular injection, the microneedle triggered higher IgG response and higher number of antibody-secreting cells specific to H1N1 in the bone marrow. Increased action of follicular T-cells and rapid virus clearance from lungs and improved survival of rats was observed [118]. Prophylaxis against Staphylococcus enterotoxin B (SEB) was carried out using dissolving microneedles. Prophylaxis using recombinant SEB recorded high titer value of SEB-specific antibody and the challenge study against SEB toxin produced complete protection of the mouse [119].

Hormone therapy

A microneedle patch fabricated using PLGA and PLA was used to deliver the contraceptive, levonorgestrel. The unique design of the microneedle patch by introducing a bubble between the MNs and its backing layer enables the detachment of the needles and backing layer within five seconds after application. The needles remain in the skin and produce sustained release of the contraceptive drug with prolonged activity [120]. A dissolvable microneedle patch containing human parathyroid hormone for the treatment of osteoporosis was fabricated by Naito et al. [121] using micromolding method. The shelf life of parathyroid hormone in microneedles at room temperature was sixfold higher in comparison with that of solution of parathyroid hormone. The patch containing the hormone exhibited high bioavailability of the hormone (~ 100%) in rats. In the rat model of osteoporosis, the thinning of bone density was slowed down after administration of the microneedle patch containing the hormone. Microneedle patch made of PVA was loaded with parathyroid hormone for promotion of collagen production via stimulation of transforming growth factor, Smad3 and mTOR pathway in order to accelerate wound healing [122].

Pain treatment