Abstract

Phycobiliproteins, carotenoids and fucoxanthin are photosynthetic pigments extracted from microalgae and cyanobacteria with great potential biotechnological applications, as healthy food colorants and cosmetics. Phycocyanin possesses a brilliant blue color, with fluorescent properties making it useful as a reagent for immunological essays. The most important source of phycocyanin is the cyanobacterium Arthrospira platensis, however, recently, the Rhodophyta Galdieria sulphuraria has also been identified as such. The main obstacle to the commercialization of phycocyanin is represented by its chemical instability, strongly reducing its shelf-life. Moreover, the high level of purity needed for pharmaceutical applications requires several steps which increase both the production time and cost. Microalgae (Chlorella, Dunaliella, Nannochloropsis, Scenedesmus) produce several light harvesting carotenoids, and are able to manage with oxidative stress, due to their free radical scavenging properties, which makes them suitable for use as source of natural antioxidants. Many studies focused on the selection of the most promising strains producing valuable carotenoids and on their extraction and purification. Among carotenoids produced by marine microalgae, fucoxanthin is the most abundant, representing more than 10% of total carotenoids. Despite the abundance and diversity of fucoxanthin producing microalgae only a few species have been studied for commercial production, the most relevant being Phaeodactylum tricornutum. Due to its antioxidant activity, fucoxanthin can bring various potential benefits to the prevention and treatment of lifestyle-related diseases. In this review, we update the main results achieved in the production, extraction, purification, and commercialization of these important pigments, motivating the cultivation of microalgae as a source of natural pigments.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Phycobiliproteins

Phycobiliproteins (PBPs) are brilliantly colored protein-pigments of the photosynthetic light-harvesting antenna complexes produced by some algae, such as Rhodophyta, Cryptomonads, Glaucophytes and, particularly, by Cyanobacteria. The biological importance of these compounds in Cyanobacteria is evidenced by the great amount of PBPs they produce, which can represent up to 50–60% of the total soluble proteins in some organisms [1], such as Arthrospira platensis or A. maxima. In fact, PBPs are the principal accessory pigments of cyanobacteria. In these organisms, PBPs are also nitrogen storage compounds, and are decomposed when nitrogen starvation occurs [2, 3]. PBPs are generally classified based on their absorption maximum (Amax) in the visible region of the spectrum. The most common PBPs are phycocyanin (PC, Amax = 610–625 nm, blue), allophycocyanin (APC, Amax = 650–660 nm, blue green) and phycoerythrin (PE, Amax = 490–570 nm, red). Their structure is shown in Fig. 1 [4,5,6,7,8]. The main components of these pigments are protein subunits α and β, which form the “monomeric” unit (αβ). Various units self-assemble into the PBPs, which, in vivo, are organized on the thylakoid membrane to form larger protein complexes, the phycobilisomes [9] (Fig. 2a [10, 11]). The number and type of PBPs composing the phycobilisome is variable both in individual organisms of a species (due to environmental acclimation of the organism) and among species [12]. The general phycobilisome structure is sketched in Fig. 2b. The protein’s brilliant color is due to the prosthetic groups: covalently bound tetrapyrrole derivatives (such as phycocyanobilin (Fig. 3a) or phycoerythrobilin, (Fig. 3b)), protected by the protein backbone and blocked in a geometry (extended conformation) suitable to efficiently funnel light energy (from PE to PC and, finally, to APC) towards the chlorophyll photosystem center [9]. In the phycobilisome, the pigment with the highest energy state, PE, always occupies the outermost position of the complex. Inwards follows PC and, finally, next to the photosynthetic chlorophyll center, the pigment with the lowest energy state, APC, as sketched in Fig. 2b.

When extracted and not engaged in the energy transfer processes, these molecules exhibit a fluorescence characterized by a very high quantum yield. Thanks to their remarkable characteristics, PBPs have several biotechnological applications in food, cosmetic, pharmaceutical, and biomedical sectors. Among PBPs, PC has by far the largest market. The increasing utilization of these water-soluble pigments is boosted by their safe and healthy nature, as it is evidenced by the numerous papers published in the last years [1, 3, 13,14,15,16,17,18,19,20,21].

PBPs are used as natural cosmetic dyes or as fluorescent probes (APC and PE in particular) in flow cytometry and immunoassays. A. platensis (Spirulina) blue aqueous extracts, containing PC and APC, are approved by EFSA (Regulation (EU) No. 1333/2008 and No. 231/2012) as foodstuff coloring. The US FDA classifies PC (21CFR73.1530) as a natural food color additive. PC and PBPs therapeutic activities as antioxidant, anti-inflammatory, neuroprotective, anti-cancer and immunomodulatory have been reported [1, 3, 13, 14, 18, 19, 21, 23,24,25,26,27].

The commercial value of a PBP is strongly dependent on its purity grade, which is usually evaluated by the ratio between the value of PBP absorption maximum in the visible region of the spectrum and the absorbance value at 280 nm, which is related to the total amount of proteins detectable in the product. PBP purity greater than 0.7 is considered as food grade, greater than 1.5 as cosmetic grade, greater than 3.9 as reactive grade and greater than 4.0 as analytical grade. Usually, a purity greater than 3.0 is required to be used as fluorescent agent, while analytical grade PC is required for biomedical and therapeutic applications [28, 29]. Despite the increasing demand of safe natural products, the widespread use of PBPs is still limited by the costs of large-scale biomass production [30,31,32] as well as of extraction and purification methods.

1.1 Extraction and purification methods

Both extraction and purification are still too expensive, rather complex, and time-consuming, while industry needs simple, cheap and easily scalable, procedure to achieve a sustainable production of PBPs [3, 14, 22, 29, 33,34,35]. In addition, climate change due to the increase in emissions of carbon dioxide and other greenhouse gases, and the worldwide growing environmental deterioration, due to heavy pollution, are requiring industries to urgently align with current guidelines and regulations towards a progressive reduction of carbon dioxide emissions as well as energy consumption, boosting a “green revolution” based on the adoption of sustainable processes. Thus, there is a high industrial and commercial interest for sustainable, environmentally friendly, green chemistry extraction/purification processes to provide PBPs (particularly PC) of various purity grades on large scale while using a minimum number of steps, due to increasing world demand of safe, non-toxic, healthy bio-products.

Tan et al. [17] recently reviewed the research trends of PBPs using a bibliometric approach. They found that the principal issues addressed in the documents were the optimization of microalgae culture parameters and PBPs extraction methods. Moreover, bioactivity properties and extraction of PBPs turned out to be the future research priorities.

Indeed, a quick bibliography survey can easily show the growing interest on the extraction and purification of these compounds, that is proved by the growing number of published documents over the last years. As an example, a survey made on 1st August 2022, based on the Scopus database (combining the terms phycobiliprotein, phycocyanin, phycoerythrin, allophycocyanin, extraction and purification, and eliminating spurious documents) evidenced that in 2021 the number of published documents [83] was more than four time higher that ten years before [19]. In Fig. 4 is reported the number of documents per year from 2000 to 2021 retrieved in the survey, while in Fig. 5 is reported the number of documents retrieved in the same period, using the same database, in relation to the extraction (Fig. 5a) and purification (Fig. 5b) method adopted. Most often various extraction and, particularly, various purification methodologies are combined and used in sequence to achieve a better result.

The literature survey evidenced that ultrasound-assisted extraction was the most used PBPs extraction method (Fig. 5a). Ultrasound-assisted extraction is considered a green process [36]. It requires short operation time and low solvent consumption, allowing to achieve high yields, but the increase of temperature in the PBPs samples, which are temperature-sensitive compounds, must be controlled and avoided to preserve PBPs’ functionalities [3, 34]. Ultrasound-assisted extraction is, in principle, suitable to large scale PBPs extraction, but a relatively low purity degree is generally achieved [37,38,39]. Other green methodologies applied to PBPs extraction are high pressure processes, pulsed electric field-assisted and microwaves-assisted extraction. Although it is reported that high pressure processes (such as hydrostatic pressure processing, in which pressures around 300–600 MPa are applied, and high-pressure homogenization, in which lower pressures, usually up to 400 MPa, are applied [40]) may exhibit low selectivity [34], good results have been reported for PC extraction [41]. In addition to being considered eco-friendly, this methodology is also suitable to large scale production of PBPs. Other two processes considered green are pulsed electric field-assisted and microwaves-assisted extraction. However, the increase in temperature of the samples, caused by both methods, and the possible electrode corrosion and metal leaking in pulsed electric field-assisted extraction, are drawbacks limiting the application of these methods to the extraction of PBPs [34, 36]. Enzymatic-assisted extraction and repeated freeze–thawing are other two popular methods (Fig. 5a). Enzymatic-assisted extraction can ensure high yield, but it is not particularly suitable to large scale production of PBPs because of the high cost of the commercially available enzymes [36]. On the contrary, repeated freeze-thawing, though time consuming, it is particularly attractive thanks to its simplicity, reproducibility, and moderate cost. Therefore, it is commonly used to treat small quantity of biomass. In fact, repeated freeze–thawing efficiently lyses cells and ensures a higher purity respect to other approaches [3, 34]. However, it cannot be considered a general method since the cells of some cyanobacterial or algal species are too stiff to be broken by freeze–thawing and require a different approach. Indeed, a single preferrable PBPs extraction method does not exist, instead it must be chosen and optimised for each species. In addition, the type of biomass (fresh, spray-dried, freeze-dried, oven-dried, etc.) used as pigment source must be considered when choosing the optimal extraction method.

As concerns purification methods, Fig. 5b shows how ammonium sulfate precipitation (or salting out) was the most exploited one. Indeed, ammonium sulfate salting out is widely used in protein purification procedures [42], including PBPs [43], and is most often applied as pre-purification step, to obtain highly purified PBPs [44] (see Table 1). The highest PBPs purity is usually achieved by column chromatography, particularly ion exchange chromatography, or exploiting liquid (especially aqueous) two-phase systems [1, 35]. However, column chromatography is difficult to scale up, while aqueous two-phase systems are more suitable for large scale PBPs production [18]. Very recently membrane chromatography has been advantageously exploited to obtain analytical grade PBPs [29, 45, 46]. This methodology is interesting because fundamentally “green”, cost-effective, environmentally friendly, and suitable to be used on an industrial scale [47]. Table 1 shows a summary of PBP extraction and purification procedures available in the literature.

1.2 Main environmental factors affecting the productivity of phycocyanin

As previously mentioned, currently, among the PBPs, PC occupies the largest market area as it is widely used in the food sector. Nowadays, commercial production of PC relies almost exclusively on Arthrospira (Spirulina) biomass. Arthrospira extracts were approved for use in candy, chewing gum and other types of confectionery in the US in 2013 and 2014 [104] while EU approved Arthrospira extracts in 2013 as food coloring [105]. The decision was based upon the fact that Arthrospira has been consumed for centuries and its consumption is considered safe worldwide [106]. Therefore, information on production, extraction and purification of PC come mostly from Arthrospira cultures.

1.2.1 Light intensity and spectra

Both light intensity and wavelength can strongly modify the productivity and concentration of PC in the biomass. In general, acclimation to low light, achieved either by exposing cells to low intensity incident light or by increasing the density of cultures, entails a raise in both chlorophyll and PC contents [31]. In A. platensis cultures, during the logarithmic growth phase, the percentage of chlorophyll a (Chl a) doubled from 0.8% to 1.6% of dry weight, while the percentage of PC increased from an initial value of 3% up to 12–14% depending on the strain and light spectra at which cultures were grown [32].

Considering the high market value of PC, artificial light is often used for the production. Fluorescent lamps and light emitting diodes (LEDs) are used for the microalgal cultivation, with different spectrum and energy conversion efficiency. Fluorescence tubes have the advantage to deliver light irradiance at a 360 degree angle and are usually characterized by much larger emission bands compared to LEDs. However, due to small size, light weight, durability efficiency of energy conversion and longer operating life, LEDs have attracted the interest of algal biomass producers. LEDs have several advantages that have promoted their diffusion as the light source for the purpose of microalgae growth, and recent studies on the growth of A. platensis were conducted using fluorescent lamps [32, 107].

The cyanobacterium A. platensis grown under illumination with lights of different colors (white, orange and blue) shows absorption peaks in the blue and red part of the spectrum (440 and 680 nm), due to Chl a, and in the orange part (620 nm) due to PC (Fig. 6). The ratio between the PC peak at 620 nm and that of Chl a at 680 nm is higher for cells grown under blue light than under the orange and white light, indicating an increase in PC content under blue light.

In-vivo light absorption spectra of A. platensis cells grown under white, orange and blue lights, adapted from [32]

It has been proposed that blue light creates an unbalance between the two photosystems, with an excess of energy at the PSI side and a deficiency at the PSII side of the photosynthetic electron transport chain of A. platensis [32, 108]. It is well known that cyanobacteria invest much more of their chlorophyll a in PSI than in PSII [109, 110]. This unbalance between the two photosystems is compensated for by the light-harvesting phycobilisomes (PBSs) which are mainly associated to PSII [111]. In this way cyanobacteria maintain a balanced excitation distribution between the two photosystems enabling the production of both ATP and NADPH necessary for growth. Under blue light, the PBSs do not absorb blue photons efficiently, as their short wavelength of 450 nm does not coincide with the absorption spectrum of PC (peaking at 620 nm). Therefore, under blue light, PBSs hardly transfer any energy to PSII. On the other hand, Chl a, which is more abundant in PSI, can transfer energy to PSI efficiently. Moreover, in cyanobacteria β-carotene, which absorbs blue light efficiently, is more abundant in PSI than in PSII, thus further contributing to photosynthesis light harvesting by PSI. Therefore, under blue light, PSII experiences a severe shortage of photons in comparison to PSI, with a strong limitation in the linear electron transport. Consequently, cell acclimate to blue light by enhancing the production of PBSs normally serving the PSII, so to restore the balance between the two photosystems. However, this strategy is ineffective towards growth since PBSs do not absorb blue light. These facts strongly support the findings that cultures grown under blue light have a much lower growth rate compared to orange and white lights, but a significantly higher PC content [32]

There is a consensus that blue light increases PC concentration in Arthrospira cells, while it is less effective in promoting growth which was much higher when culture was grown under white or orange lights [32, 112]. Therefore, a two-step strategy to produce Arthrospira biomass enriched in PC could be employed, starting by growing the culture under orange or white light, and once the culture has reached the stationary phase, shifting the light to blue to further enhance PC content. As synthesis of PC requires high amount of nitrogen, and the exposure to blue light can stimulate protein synthesis [113, 114], it is important to avoid nitrogen deprivation during the accumulation step, which may occur at the end of the growth phase. The lack of nitrogen in this step may even cause a reduction of the PC concentration, since PC would be used by cells as source of nitrogen [2]. Therefore, it is advisable to use a two-step process to improve the economic feasibility of the process [115].

1.2.2 Influence of nitrogen source on productivity of phycocyanin

PC is an intracellular nitrogen source, and it can be used in prolonged nitrogen-limited conditions [2, 32]. Thus, the content of PC can be strongly affected by the nature of the nitrogen source and its concentration in the culture medium. Depletion of nitrate in the culture medium leads to the reduction of PC while an excess of nitrate could lead to its inhibition [116]. According to [116], the optimal nitrate concentration for high PC concentration is in the range between 1200 and 1600 mg/l. Addition of glutamate and succinic acid to Zarrouk medium enhanced the PC concentration by about 20% [116]. The reason for this increase of PC content is that glutamate and succinyl-coenzyme A are among the intermediate metabolites in the biosynthesis of tetrapyrroles including phycobilin in cyanobacteria cells [116]. The type of nitrogen source plays an important role in the production and concentration of PC in the biomass. Studies carried out in A. platensis using different sources of nitrogen (NaNO3, KNO3, NH4NO3, (NH4)2SO4, NH4Cl, and urea), have shown that the highest PC production was attained by using (NH4)2SO4. Higher biomass productivity was also accompanied by high PC content (11.3%) [117].

Ammonium is a more reduced form of nitrogen than nitrate and this may account for the better culture performance, particularly in the cyanobacterium Arthrospira whose protein content is very high (60–70%). However, at a pH of above 9, typical of Arthrospira cultures, ammonia (NH3) is the dominant chemical species, and its diffusion through the cell membrane results in ammonia accumulation inside the cell and consequent toxic effect [118]. Ammonia causes damage to the manganese (Mn) cluster of the oxygen-evolving complex of the PSII complex, causing a considerable increase of sensitivity of PSII to photodamage [119]. Chlorophyll fluorescence measurements showed that the PSII damage is related to the light intensity, and that the inhibition of the PSII performance by ammonia is not relieved neither by re-incubating the cells in the dark, nor by reducing the ammonia concentration [120]. A. platensis cultures with high biomass density and without pH regulation resulted less susceptible to ammonia inhibition, most likely through the faster assimilation of ammonia present in the medium [121]. Nonetheless, care is needed when ammonium salts are used as a nitrogen source in Arthrospira cultures, particularly when pH is uncontrolled as it may occur in large scale ponds. Moreover, at high pH a consistent amount of ammonia is lost by outgassing, contributing to the increase of greenhouse gas released in the atmosphere, and to an increase in costs. For these reasons, ammonium should be supplied in a fed-batch way to prevent accumulation. The most used nitrogen source remains NaNO3 as it can be supplied in a large amount to the culture (2.5 g/l in Zarrouk medium) without incurring in toxicity problems. Similar problems can be foreseen for the use of digestate for biomass production of cyanobacteria. This waste represents an excellent source of nitrogen and phosphorus as well as other minor nutrients. The amount of ammoniacal nitrogen in digestates ranges between 500 and 2000 mg/l, therefore it is inevitable to operate a dilution with fresh water. At the present the use of digestate in EU countries seems to be restricted to the production of biomass for use as feed. The legislation however doesn’t specifically allow or prohibit the use of slurry to grow algae as it is permitted for land plants used in the feed chain [122].

1.2.3 Effect of high dissolved oxygen concentrations and light–dark cycle

Large raceway ponds equipped with paddle wheels are usually characterized by low turbulence, and in Arthrospira cultures, faster mixing achieved by increasing to rotation of the paddle wheels or by other means can cause breakage of filaments, and foam formation, and a consistent increase in production costs. Oxygen removal is therefore usually limited and O2 concentration of 300–400% of air saturation are very frequent particularly in the afternoon [123]. Mass transfer coefficient can vary greatly in each section of the reactor: Kla is higher in proximity of the paddle wheel (about 164 h−1) while in the channel and bends it drops dramatically (below 1 h−1). This is a clear indication that cultures are poorly mixed, not allowing for an adequate stripping of oxygen [124]. Oxygen stripping can be improved by placing a sump where air is injected. However, care is needed with filamentous cyanobacteria such as Arthrospira, as the injection of air under pressure may result a fragmentation and flotation of the trichomes.

The negative effect of oxygen on culture productivity of mass cultures has been overlooked for many years. Torzillo et al. [125] reported evidence that, in Arthrospira cultures, a concentration of oxygen above 30 mg L−1 had a negative effect on both growth and biomass protein content. However, the problem of oxygen toxicity becomes evident when cultivating microalgae in closed systems [126]. Only a few studies have addressed the potential role of singlet oxygen as a marker for resilience to excess light environments, and to find out whether singlet oxygen resilience correlates with a strain's robustness in excess light environments.

Hiday and Belay [127] followed the daily time course in the photosynthetic pigments in cultures of Arthrospira grown in large scale ponds (0.5 ha). Larger variations in the PC content correlated with higher dissolved oxygen concentrations in the pond. PC content fluctuated according to an opposite trend to that of the oxygen concentration. It was evident that the lowest level of PC coincided with that of the peak of oxygen [127].

The concentration of PC can also change during the day as the illumination conditions vary, decreasing as light increases. Changes in PC are particularly evident in low density cultures, particularly in summer. The PC content is usually higher in the morning particularly in low density cultures. Usually, in Arthrospira cultures exposed to high light, there is an accumulation of carbohydrates during the day. Because of nocturnal respiration of carbohydrates, the concentration of PC can result significantly higher in the morning [127, 128]. Therefore, the time of biomass harvesting can affect the PC content in the biomass.

1.2.4 Effect of temperature

Because of seasonal and diurnal fluctuations, light and temperature represent the major biological limitations for biomass production of microalgae. However, as pointed out by Borowitzka [129], temperature plays the most important role on productivity, and therefore it should probably be the first parameter for strain selection. In the case of A. platensis, laboratory experiments have shown that the maximum biomass yield is obtained when Arthrospira is grown at the optimal temperature of 35 °C [130,131,132,133]. However, outdoors, in open ponds, culture temperature can fluctuate from 15 °C in the early morning hours to about 35 °C in the middle of day, causing a significant reduction in productivity and changes of the biomass composition [127]. Using different strains acclimated to the different temperatures at different times of the year can be useful to extend the cultivation period and attain higher productivities year-round. This strategy has been successfully tested with Arthrospira at Earthrise Farm in California, USA [134].

Studies carried out on Synechococcus sp. PCC 7002, whose optimal temperature for growth is 38 °C, reported that when the strain was grown at 15 °C there was a loss of blue color by the cell in a similar manner to nutrient starvation [135]. The amount of PBP and chlorophyll decreased while there was a strong accumulation of glycogen. By contrast, when the cells were grown with urea as a nitrogen source, cells grew normally without any sign of chlorosis. The authors hypothesized that the defect in nitrogen assimilation was most likely due to an inefficiency of transport of nitrate across the cytoplasmic membrane.

Summing up, the PC production by cyanobacteria (and by Arthrospira in particular) strongly depends on maintaining the optimal conditions of temperature and light intensity at which cells are exposed, two environmental factors that can strongly change along the year and during the day. The culture system can affect the temperature profile and light uptake. The control of temperature is more easily achieved in a closed system, and more difficult to implement in open ponds. In this system, it is frequently observed that temperature does not rise fast enough in the morning in comparison to light which goes up very fast, and this desynchronization between the raise in light and temperature may causes cell photoinhibition [136, 137].

1.3 Strain selection

Surprisingly, while the cultivation of Arthrospira for industrial purposes, dates several decades back, the progress made in the selection of newer more productive strains is minimal. Indeed, any enhancement in strain performance would reflect immediately in industrial applications. Factors discouraging from planning a systematic strain selection activity are the necessity to have a large collection of strains which requires considerable manpower for its maintenance, and the too large variation in PC content determined by environmental factors which makes more complicate the evaluation of differences between strains. Moreover, it is worth to point out that because of the high morphological plasticity of Arthrospira strains, the selected laboratory strains once transferred in mass cultured may perform significantly different compared to the original laboratory strain. Indeed, outdoors, strains are subject to strong variability in the environmental factors, particularly light, temperature and oxygen exposure, and to hydrodynamic stress caused by mixing, which can strongly modify the morphology of trichomes and their biochemical composition. Prolonged cultivation of the same strain can generate phenotypes with improved performance, with higher resilience to temperature and light stress. This may justify the reluctance of the grower to change their strain, together with the necessity to guarantee a constant production and consistent biochemical characteristic of the product. In addition, employing higher PC content strains for industrial production must prove to be economically advantageous, compared to conventional strains. In other words, the increase in PC content should not be achieved at the expense of a reduced biomass production. Therefore, biomass productivity of the strain, is thus an important aspect that should not be overlooked during strain selection. Moreover, it often happens that the producer of the pigment is usually not the grower, and producers are interested in cheaper biomass rather than high concentration of the pigment in the biomass (Vonshak, personal communication).

Strain selection of a NaCl tolerant mutant of A. platensis, showed that the PC production was 12.2% as compared to its wildtype counterpart when cultivated in a nitrate and bicarbonate sufficient medium (40 and 60 mM, respectively) at pH 9.0 under phototrophic conditions [138]. Among 13 cyanobacteria species investigated, Arthrospira sp., Pseudanabaena sp. and Synechococcus elongatus might be the promising candidates for PC, PE and APC sources, respectively, for commercial production purposes [139]. Interestingly, the specific growth rate and biomass productivity of Synechocystis sp. were significantly higher than the other cyanobacteria. This was attributed to a higher surface to volume ratio (S/V) that allows this cyanobacterium to uptake more nutrients [140].

A comparison of the biochemical composition of different A. platensis strains from different geographical areas (Algeria, Chad, USA) was carried out. The Arthrospira strain from USA showed the highest PC content (% of dry weight) compared to the other strains [141].

In Table 2 shows the PC content found in different Arthrospira strains. To make the comparison among the different strains easier, the culture conditions are specified. The geographic origin of the strain and depositary institution is also indicated.

1.4 Production of C-PC with Galdieria sulphuraria: an alternative to Arthrospira

Galdieria sulphuraria is a red (Rhodophyta) polyextremophilic microalga which can tolerate very low pH (as low as 0.2), temperature up to 57 °C [77, 143, 144], and high osmotic pressure, up to 400 g L−1 of sugar, and 2–3 M of salt. Similarly, to Arthrospira, it contains only chlorophyll a, and accessory photosynthetic pigments are represented by blue PBPs, PC and APC. This organism can growth heterotrophically (in the dark), in which organic substrates represent the source of both carbon and electrons, as well as autotrophically (in the light) in which reducing power is generated via water splitting by PSII, while the source of carbon is CO2. It can also grow mixotrophically, that is, a combination of heterotrophy and autotrophy [145,146,147,148]. Their rather unique ability to cope with very harsh growth conditions strongly reduce the risk of contamination even in heterotrophy, making this organism very attractive to produce PC and proteins (up to 72%), which are also richer in essential amino acids compared to those from Arthrospira and Chlorella [146]. Since this organism, contrary to Arthrospira, does not have a record history of its use as food and feed, it is considered a potential novel food by the EU regulation, therefore it needs to go through the procedure of admission as novel food before the approval [148]. Autotrophic cultivation of Galdieria requires a careful choice of the cell density and of the light supply to avoid risk of photoinhibition [146]. This phenomenon can occur after a strong dilution of a dense culture where most cells are acclimated to low light and thus may suffer of the suddenly raise in the specific light supply. Although this problem can be easily managed in laboratory by temporarily reducing the light supply, it may represent a problem when working with large scale bioreactors under solar light. The risk of photoinhibition is less relevant with mixotrophic cultures, particularly when they are grown according to an “oxygen balanced” regime, in which the supply of substrate, and thus the oxygen uptake is balanced with photosynthesis [145]. This culture mode allows to maintain the reactor closed and thus reduces the risk of contamination which may occur through the injection of air in the reactor.

Under heterotrophic conditions, PC content is very low, ranging from 0.3 to 0.6% DW, in cultures grown on glucose and glycerol, respectively. The PC content resulted 40-fold higher and 20-fold higher in cultures grown under autotrophically [147]. These results indicated that heterotrophy inhibits pigment synthesis particularly in cells grown on glucose. [148]. Heterotrophic cells grown on glucose became yellowish while those grown on glycerol still maintained the green color. The pigmentation was restored in glucose grown cells when it is totally consumed. PC content ranging between 0.8 and 1.2% of dry weight was reported by [149] in G. sulphuraria strain 074G under heterotrophy conditions in carbon-limited cultures and nitrogen sufficient cultures, while the PC content dropped to 0.1% in nitrogen deficient cells. Therefore, despite the much higher volumetric productivity attained with heterotrophic cultures, the PC content in this biomass is too low for economic extraction, with limitation of the commercial applications. Indeed, according to EU regulations, the concentration of pigment in the source determines whether the extract can be considered as a food extract with coloring property (> 3% of dry weight) or just a natural food additive (< 3% dry weight) [150]. Moreover, while food extracts are considered food ingredients and are used in clean label food products, the natural additives require an “E” number. Therefore, due to PC content, PC extracts obtained from heterotrophic Galdieria biomass fall into the additives categories, while PC extracts from autotrophic and mixotrophic cultures would enter in the first category, not requiring any labelling.

A strategy to conjugate the high biomass accumulation with high level of PC in G. sulphuraria was proposed [151]. It consists of sequential production of biomass in heterotrophy followed by dilution and exposure of cells to light to induce synthesis of PC. By this way it was possible to raise the PC content up to 13.88%, that is, higher than that attained by growing cells autotrophically or mixotrophically. Although this strategy may be appealing, the economic comparison between autotrophic, mixotrophic, and sequential heterotrophic/autotrophic needs to be assessed. The sequential heterotrophic/autotrophic strategy entails the need to strongly dilute the culture before exposure to light which increases the cost of harvesting, particularly with unicellular microalgae (Table 3).

Another thermoacidophile red microalga, Cyanidioschyzon merolae, belonging to the order Cyanidiophyceae of the phylum Rhodophyta, has been proposed for PC production [152]. Similarly to G. sulphuraria, it thrives at pH between 0.5 and 3, and tolerates temperatures as high as 56 °C. Indeed, expressed sequence tags and high-throughput genomic sequence reads covering > 70% of the G. sulphuraria genome were compared to the genome of Cyanidioschyzon merolae, and more than 30% of the Galdieria sequences did not relate to any of the Cyanidioschyzon genes [153]. Contrary to Galdieria which has a large metabolic flexibility, C. merolae is an obligate photoautotrophic organism, which restricts its cultivation to autotrophic conditions (light and CO2). Interestingly, it lacks a cell wall, which makes it possible to extract PC with high degree of purity (up to 9.9) just using osmotic shock and centrifugation. The PC of C. merolae resulted stable to pH 4–5 up to 80 °C. Because of the high degree of purity of PC produced using this species, without applying time consuming and expensive purification procedures, its employment may be evaluated for production of analytical/reagent grade PC. However, the effective performance of this species needs to be assessed in mass cultures, where hydrodynamic stress could strongly hamper its cultivation.

1.5 Attempts to enhance phycocyanin stability

PC molecule proved to be very sensitive to environmental factors such as temperature, pH, and light, which can cause blue color to fade up to a total loss of color. This fact strongly hampers its utilization in food and cosmetics. Therefore, several efforts have been devoted to finding out the optimal conditions preventing PC degradation and thus increase its shelf-life. Different stabilization techniques have been proposed, by using preservatives as well as formulation processes. Food grade PC is usually used to assess its degradation, which is commonly determined by UV–vis spectrophotometry at 620 nm. The stability of the PC molecule is also influenced by its purity. A comparison between reactive grade PC and food grade, determined a higher thermostability in food grade PC [154]. However, it is worth noting that a hard purification procedure can affect the pigment stability. In general, gentle extraction and purification procedures are expected to better preserve PC stability. Most of the studies on PC stability have been carried out on PC extracted from Arthrospira (Spirulina) platensis, which is nowadays the major source of PC utilized worldwide.

1.5.1 Effect of temperature and use of preservatives to enhance the thermal stability

Temperature influences the stability of PC [[155] and references therein]. The stability of total PBPs from 13 isolated cyanobacteria after 24 h of incubation at − 20 °C resulted variable. The loss of PBP content ranged between 4.88% and 15.94%. The highest stability of total PBPs was observed in Pseudanabaena sp. (reduced by 4.88%), whereas PBP content from Desertifilum sp. extracts decreased the most by 15.94% over 24 h [156]. These findings may indicate that the stability of PBPs may be related to cyanobacteria species and/or strains. Recently, heterologous expression of phycocyanin derived from the thermophilic cyanobacterium Thermosynechococcus elongatus, was applied in the mesophilic cyanobacterium Synechocystis sp. 6803 to produce thermostable PC [103]. Importantly, the yields of PC in the Synechocystis mutant strains resulted comparable to that of native PC in wild-type Synechocystis, while the thermostability properties of PC matched those from T. elongatus [103].

Very often, experiments on the effect of temperature are associated to the use of preservatives to improve the pigment stability. Incubation of PC from Arthrospira biomass at temperatures between 47 and 64 °C, in a pH range of 5.5–6.0, caused a reduction in the concentration by 50% [157]. Adding 20–40% glucose or sucrose and heating to 60 °C for 15 min, the CR (relative concentration) value of PC at pH 7.0 was maintained at around 62–70%, and the half-life increased from 19 min to 30–44 min. The addition of 2.5% sodium chloride had an even better preservative effect on PC at pH 7.0 since 76% of the PC concentration was retained [157].

PC was found to be stable at temperature as high as 45 °C, but the stability decreased proportionally between 45 and 70 °C. Sodium chloride (20% w/w) was an effective stabilizing agent for PC, and its efficacy was higher at higher concentrations used [158].

Consistently to other studies, at temperature of 74 °C the degradation of PC was increased (t½ 9.7 min, pH 6.0) [159]. However, stability of PC can vary significantly within the species studied. A different thermostability was found between the extracts of the cyanobacterium A. platensis and the polyextremophile G. sulphuraria (Rhodophyta) incubated at temperatures between 25 and 55 °C. In this Rhodophyta the PC absorbance remained stable (95% of initial value) until 55 °C and decreased steadily within 55 and 75 °C, down to 39% of the initial value. In the case of A. platensis, PC extracts started to degrade already at 45 °C losing 18% of absorbance at 620 nm, while at 75 °C the absorbance was reduced to only 20% of initial value [146]. Similar findings were also reported by [77], and by [160] who found that PC from G. sulphuraria was more stable than that from A. platensis under all conditions, especially in the range of 50–65 °C, and in neutral environment of pH 7. After 30 min incubation at 60 °C and pH 7, the color preservation rate of PC from G. sulphuraria and A. platensis were 86.66% and 60.83%, respectively.

The higher thermostability showed by the PC extracted from G. sulphuraria is likely the result of a long adaptation process of the organism to the extreme environment (temperature up to 57 °C) where it still thrives. In conclusion, temperatures lower than 45 °C are generally considered optimal to preserve PC stability.

1.5.2 Effect of pH

The pH of the PC extract is another environmental factor that can destabilize the pigment. The pH of the solution can also modify the color of the PC solution. At neutral pH, the PC color is perceived as blue, while at acidic pH it is green. The optimal pH range for PC was found to be between 5.0 and 6.0 [158]. Usually, acid compounds are added to beverages to provide tartness and tangy taste to balance the sweetness of sugar added to beverages. It was reported that Arthrospira extracts lost 60% of the absorbance at 620 nm moving from pH 5.5 to 3.5, while within the same range of pH, Galdieria extract maintained 100% of the absorbance. Thereafter, the stability declined in a linear manner reaching about 30% of the initial value at pH 1.5. [146] As said above, this significantly greater tolerance to high acidity showed by G. sulphuraria PC extract is probably the result of a long-term adaptation of this organism to extremely acidic environments, with pH as low as 0.2.

1.5.3 Effect of light

Several studies have assessed the degradation kinetics of aqueous solutions of PC evaluating temperature or light as accelerating factors using a first order kinetic model, and both environmental factors have been studied separately to evaluate the effect [158, 161]. Pérez-Rico et al. [162], have developed an empirical model able to predict the effect of temperature and light combined in the degradation ratio of this pigment at selected storage condition. They reported that exposure of PC to a photon flux density of 50 and 100 µmol m−2 s−1 resulted in a decrease in the concentration according to a dose-dependent pattern. The light-induced degradation resulted dependent on pH; at pH 6, the pigment degradation was lower compared to pH 5 and pH 7.0. The final protein concentration declined by 20% after continuous exposure to a photon flux density of 100 µmol m−2 s−1 for 36 h, independently of the pH of the solution. Therefore, to preserve PC, the best storage condition is in the dark.

1.5.4 Uses of preservatives

Since degradation of the protein structure of PC strongly affects its color and bioactivity, preservatives are added to ensure a longer shelf life of the product [[155] and references therein]. Both the chemical composition and the preservative concentration are relevant aspects since the resulting mixture must not affect the human health. The most used preservatives are mono or di-saccharide (glucose, fructose, saccharose, lactose, maltose) and the polyol sorbitol [71, 154], organic acids (citric, ascorbic, benzoic), and sodium chloride and calcium chloride among inorganic salts. Among the acidic preservatives, citric acid performs better. Indeed, with citric acid, 67% of the PC remained stable after 45 days compared to less 3% for the control [163]. This result is explained by both the decrease of pH of the solution caused by the addition of citric acid, and by its chelating property.

1.6 Market

The commercial value of PC is strongly dependent on its purity grade. The commercial price of PC as a colorant in food and cosmetics industries (the largest market) is about 0.35 US$ and 135 US$ per gram respectively, and can reach 4600 US$ per gram for therapeutic and diagnostic applications [169].

Figure 7 reports the production volume (tons) forecasted within the period 2020–2027 [22]. By 2027 the total volume of PC production is expected to raise 7.2-fold in Middle East & African countries, to a maximum near ninefold for European countries. During the same period, the calculated CAGR (compound annual growth rate) is expected to range within about 33% for Middle East & Africa countries to near 41% for European Union (Fig. 7 insert).

Production volume of phycocyanin by countries. AP, Asia–Pacific; NA, North America; EU, European Union; MEA, Middle East & Africa. Insert shows the CAGR (%) calculated within the period 2000–2027. Data source [21] adapted

The increasing demand of powder is due to its use as alternative for synthetic color in food and beverages, being PC preferred by consumers attracted by organic and natural ingredient-based food products, and by regulations which are posing increasing constraints to the use of synthetic colors. Western Europe is the biggest consumer of this product (around 33%) and that 80% of PC produced is used in the food industry. Pharmaceutical, is another promising sector which will likely see a sizeable increase by 2030. In 2020, PC turnover accounted for more than $12 million, and it’s expected to rise to 36 million $ with a CAGR of 10%. Other than the generally recognized antioxidant properties attributed to PC, its use for cancer diagnosis generates further demand in pharmaceutical industry. By 2030 the turnover of the global PC market is expected to exceed $400 Million with an estimate CAGR of 9.6% within 2021–2030 [164].

Figure 8 shows the share of PC among food, cosmetic and analytical/reactive recorded in 2020. It can be seen, the largest part of PC is destinated to food, while the part used for pharmaceutical purposes, is incomparably lower (only 4.4 kg). Yet, when the comparison is made based on market value, the analytical-reactive grade surpasses that of cosmetic, owing to its much higher price.

Comparison of the different PC sectors and their respective market value. Due to its very low production size (4.4 kg), the analytical/reactive grade market volume cannot be appreciated (A/R = analytical/reactive grade). Data source [21], adapted

The key players of the PC market include Earthrise Nutritionals LLC, Bluetec Naturals Co., DDW Inc., DIC Corporation, Japan Algae Co. Ltd., Phyco-Biotech Laboratories, Cyanotech corp, Parry Nutraceuticals Qingdao ZolanBio Co. Ltd., Sigma-Aldrich Corporation, and Yunnan Green A Biological Project Co. Ltd, BueBiotech int. GmbH, Algosource.

1.6.1 Concluding remarks

PBPs are valuable, safe and healthy bio-compounds with many bio-technological applications and an increasing global market. However, their large-scale production is still restrained by the complexity and high cost of the available extraction and purification methods. In fact, PBPs extraction and purification procedures usually involve numerous steps, which reduce product yield and increase the costs, impairing the exploitation at a large scale. Most of the proposed procedures are often time-consuming, and can affect the quality of the final product, since PBPs are photo- and temperature-sensitive.

A few published works have addressed these critical issues. For example, proposed procedures are characterized by a minimum number of steps so as to reduce the production time and cost. Generally, in those studies, the ordinary approach characterized by two distinct phases (extraction followed by purification) was avoided. For example, stirred fluidized bed chromatography [63, 165], aqueous two-phase systems [166], glycerol-based natural deep eutectic solvents [167], three-dimensional printed anion exchange monoliths [168] and three phase partitioning processes [88, 97] have been successful applied directly on cyanobacteria or algae biomass, obtaining crude extracts of commercial interest, having good purity grade. Recently, an innovative extraction/purification method, based on ultrasound cell lysis in ammonium sulphate solution, was exploited to obtain PC from fresh A. platensis biomass [169]. In this process PBPs extraction was decoupled from biomass cell lysis, and the pigment recovered in a subsequent extraction step, obtaining a crude PC extract of elevated purity grade and concentration. However, the economic feasibility of this procedure should be proved on an industrial scale. New PC microalgal strains need to be isolated and selected from nature. An example is represented by the Rhodophyta G. sulphuraria which has recently attracted the attention of researchers owing to the large metabolic flexibility, and its capacity to grow under prohibitive conditions for the majority of other PC producers. However, the production cost with other PC producers, such as Arthrospira need to be addressed.

2 Primary carotenoids in microalgae

2.1 Metabolic pathways of carotenoids synthesis in microalgae

Carotenoids exist in a large variety of colors ranging from yellow to orange, red and purple. They are composed of eight isoprene units with a 40-carbon skeleton, generally consisting of a polyene chain with nine conjugated double bonds and an end group at both ends of the polyene chain. The five-carbon (C5) ubiquitous precursor metabolites isopentenyl diphosphate (IPP) and dimethylallyl diphosphate (DMAPP) are necessary to produce carotenoids. Two distinct routes, the MEP (methylerythritol phosphate) pathway and the MVA (mevalonate) pathway, contribute in the synthesis of these compounds in biological systems [170].

The biosynthetic pathway of carotenoids is reported in Fig. 9. Isopentenyl pyrophosphate (IPP, C5) and its isomer dimethylallyl diphosphate (DMAPP, C5) are converted at a ratio of 3:1 to geranylgeranyl pyrophosphate (GGPP, C20) via the methylerythritol phosphate pathway (MEP) in the chloroplast. In a further reaction, phytoene synthase condenses two molecules of GGPPS into (15Z)-phytoene (C40), which is then desaturated and isomerized into lycopene via phytoene desaturases, ζ-carotene isomerase, ζ-carotene desaturase, and carotene isomerase [171].

Scheme of carotenoid synthesis pathways in microalgae. The microalgae Dunaliella sp. (red border, diameter: 9–11 μm), Nannochloropsis sp. (green border, diameter: 2–4 μm), Scenedesmus (yellow border, 11–18 μm long, 3.5–7 μm wide) and Chlorella sp. (orange border, diameter 2–10 μm) are presented as principal producers of β-carotene, violaxanthin, lutein, and lycopene, respectively. Dashed lines indicate still unclear pathways

The initial step of carotenogenesis, which enables the creation of both α-carotene and β-carotene in algae, involves lycopene. A crucial branching point is the determination of the proportion of lutein coming from α-carotenoids, and β-carotene, coming from β-carotenoids. Zeaxanthin, which can derive from β-carotene, is epoxidized to violaxanthin, via antheraxanthin (xanthophyll cycle of violaxanthin). The other xanthophyll derived from violaxanthin are: (i) neoxanthin, by a violaxanthin de-epoxidase-like enzyme recently reported [172], which can be converted to dinoxanthin, which, in turns, generates vaucheriaxanthin and peridin, (ii) diadinoxanthin, that can be de-epoxidated to diatoxanthin (diadinoxanthin cycle). Both diadinoxanthin and dinoxanthin can be converted into fucoxanthin, by an enzymatic pathway still unclear.

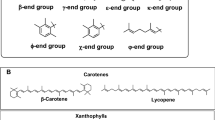

Carotenoids may be divided into two classes based on their chemical composition: carotenes and xanthophylls. While xanthophylls, which include β-cryptoxanthin, lutein, zeaxanthin, astaxanthin, fucoxanthin, neoxanthin, and peridinin, are carotenoids with oxygen atoms, carotenes, such as lycopene, α-carotene, β-carotene and γ-carotene, lack oxygen.

Carotenoids are divided into primary and secondary. The major carotenoids, such as certain xanthophylls and ß-carotene, are often found in the chloroplast and are directly involved in photosynthesis due to their function in the collection of light energy.

Under stress conditions (nutrient deficiency, high light, salt stress, high/low temperature), the photosynthetic system would not be able to effectively use the absorbed light energy, and the dissipation process might be activated. Additionally, a consistent supply of secondary carotenoids can be developed to serve as a free radical and reactive oxygen species quencher.

2.2 Main microalgal strains high producer of carotenoids

When microalgal cells receive a signal of high reductive state level inside the cells, specific actions are started to dissipate the accumulated electrons. These methods entail the synthesis of antioxidant carotenoids such as lutein, the xanthophyll cycle pigments violaxanthin, antheraxanthin, and zeaxanthin, as well as loroxanthin and fucoxanthin, which are largely found in the marine microalgae Phaeodactylum and Isochrysis [173,174,175].

The xanthophyll cycle is activated by the thylakoid lumen acidification, with the activation of the enzyme violaxanthin-de-epoxidase, leading to the synthesis of zeaxanthin, via antheraxanthin [176, 177]. In diatoms and dinoflagellate, such as Phaeodactylum and Isochrysis, respectively [173] an additional xanthophyll cycle can be found, consisting in diadinoxanthin, which can be de-epoxidized to diatoxanthin [178]. Thanks to the induction of these cycles, the reduction of the singlet oxygen inside the cell is activated, and the cellular damage can be avoided or reduced. The carotenoids production of some of the most studied and productive microalgal strains is reported in Table 4.

Haematococcus pluvialis, Chlorella species, Dunaliella salina, Scenedesmus species, Botryococcus braunii, Nannochloropsis species, Coelastrella striolata, Chlorococcum species, and some diatoms are known for producing β-carotene, lutein, canthaxanthin, astaxanthin, and fucoxanthin among the microalgae [171, 185, 195, 196].

The green microalga Chlorella vulgaris is well-known for its use as supplemental nutrition and for having a high protein and chlorophyll content in its biomass. A significant quantity of lutein, β -carotene, and zeaxanthin (1.18 mg g−1, 0.31 mg g−1, and 0.24 mg g−1, respectively) with good bioavailability have also been recorded for this microalga [197]. Interesting results have been reported in Chlorella strains for the production of lutein, as primary carotenoids, under heterotrophic conditions [198]. In particular, up to 5.3 mg g−1 of lutein has been extracted from heterotrophic culture, and around 7.5 mg g−1 in mixotrophic cultivation [199, 200]. Lutein production and choice of culture medium may depend on the strain and the cultivation conditions: for C. protothecoides and C. pyrenoidosa, under heterotrophic conditions, glucose is preferred, while under phototrophic conditions the highest lutein increase is obtained with acetate.

Dunaliella salina, a green unicellular microalga that primarily produces β-carotene, may also be regarded as a strong carotenoid producer. In this microalga, the pigment begins to build up in lipid structures on one side of the cell, and eventually it fills the entire cell.

It is possible to improve the synthesis of carotenoids in the green microalga Asterarcys quadricellulare, a potential good producer of carotenoids, by regulating the medium composition, pH, salinity, light quality, intensity, and duration [201]. The amount of β-carotene, lutein, astaxanthin, and canthaxanthin it can generate per dry gram of biomass is 47.0, 28.7, 15.5 and 14.0, respectively.

Scenedesmus can produce significant levels of lutein, which turns cells from green to yellow, and is a significant source of antioxidant carotenoids. A strain of S. obliquus isolated from Kapulukaya Reservoir (Kırıkkale, Turkey) has been found to produce a considerable amount of carotenoids, mainly found as -trans forms of lutein, β-carotene, α carotene, zeaxanthin, cis-neoxanthin, 9-or 9’-cis-α-carotene, 13-or 13’-cis-lutein, 13-or 13’-cis-β-Carotene, 9-or 9’-cis-lutein, cis-lutein, 9-or 9’-cis-β-Carotene, high amount of carotenoids, among them, the most abundant were all-trans isomers of lutein and β-carotene, being 83.74% (2.52 mg g−1) in total carotenoids [202]. These results are interesting since they demonstrate that there is a large variety of microalgae that may be considered a valuable source of natural chemicals.

2.3 Main environmental factors affecting the production of primary carotenoids

The over-reduction of the photosynthetic chain and the production of free radicals are caused by variables that have an impact on growth and photosynthetic efficiency. Optimal nutrient composition, and optimal values of light intensity, pH, salinity and temperature, are some of the parameters that vary according to the strain, specie, and origin. Among these parameters, a crucial one is light intensity. The photosynthetic system has various physiological restrictions that prevent it from utilizing light irradiation above a certain level of intensity. Despite being a useful method for accumulating antioxidant compounds, inducing the synthesis of carotenoids through exposure to stress conditions like high light, nutrient limitation-starvation, excessive low or high temperature, or salinity stress is not suitable in terms of biomass productivity, as in these circumstances growth is severely impacted.

2.3.1 Light intensity

The microalga Chlamydomonas reinhardtii, which is regarded as a model organism for physiological and biochemical investigations on photosynthesis, has been used extensively in research in this respect. In this microalga, zeaxanthin production was triggered within 10 min of exposure to 800 mol photons m−2 s−1, while a partial induction of the cycle was seen at 300–350 mol photons m−2 s−1 [177, 203, 204].

With the activation of the other xanthophyll cycle, the synthesis of diatoxanthin by the de-epoxidation of diadinoxanthin, microalgal cells promptly react to excessive light intensities. In P. tricornutum, the conversion of diadinoxanthin to diatoxanthin is very quick, as it can happen in outdoor cultures exposed to direct sunlight in as little as 15 min.

Lutein is among the powerful antioxidant carotenoid reported to be enhanced in high light conditions. As a main carotenoid, this pigment is naturally present in most photosynthetic cells, and under conditions of photo-oxidative stress, its production may rise. Under conditions of 1900 mol photons m−2 s−1 and 35 °C, the microalga Scenedesmus almeriensis in a tubular photobioreactor outdoors produced extremely high levels of lutein (around 5 mg m−2 d−1) [205]. The simultaneous presence of high light and heat was the cause of this increase. In fact, this microalgal strain typically thrives best at temperatures between 25 and 28 °C.

Another key carotenoid that often rises in content with increased light exposure is β-carotene, which is naturally present in microalgal cells but may be over-synthesized in certain conditions.

Among the microalgae with a reputation for being a good producer of this molecule, surely Dunaliella salina is one of the most promising. In a lab setting, with a light intensity of 200–1200 mol photons m−2 s−1, at 30 °C, a production rate of 13.5 mg −1 d−1 has been reported [206].

Studies on a strain of Tetraselmis sp. showed that under a light intensity of 170 µmol photons m−2 s−1, the lutein and β-carotene content increased to 3.17 and 3.21 mg g−1 of dry weight, respectively [207]. In addition to the light stress, this strain was subjected to the quite high temperature of 30 °C, revealing a thermotolerance that is a suitable characteristic for cultivation under extreme conditions.

2.3.2 Nutrient limitation or starvation

Sulfur is essential for maintaining protein synthesis, hence its lack or restriction results in a sharp decrease in protein content, which in turn affects photosynthetic activity and slows development. In closed photobioreactors, the drop in photosynthetic oxygen evolution and the presence of oxygen respiration may result in the formation of extremely low oxygen contents or even anaerobic conditions, a very strong reductive environment [208]. The microalga C. reinhardtii has been the subject of many investigations for its capacity to produce hydrogen in the absence of sulfur. Interestingly, and the xanthophyll cycle was strongly induced with a significant increment in antheraxanthin, zeaxanthin, and violaxanthin levels. The amounts of the other xanthophylls, lutein and β-carotene, also rose [177]. Additionally, anaerobiosis also induced the same reaction over a longer period but in a complete medium (5 h, instead of some minutes). Antheraxanthin and zeaxanthin dropped after aerobic conditions had been achieved, along with lutein and β-carotene, suggesting the occurrence of a recovery.

The xanthophyll cycle is induced in Nannochloropsis gaditana by a sulfur restriction or deprivation, with an increase in violaxanthin and zeaxanthin as was seen in the case of nitrogen [209].

Since nitrogen is an essential component of proteins and enzymes, the lack of this nutrient in the culture medium strongly affects both the growth and biomass composition. Dunaliella's ability to produce β-carotene under conditions of intense light exposure is increased by nitrogen deprivation. The combination of nitrogen starvation and exposure to the light intensity of 200 mol photons m−2 s−1 induced an increment in β-carotene to reach levels of 2.7% of the biomass [210].

Under both severe light stress and nitrogen deficiency, the increase of this pigment has been linked to the production of total fatty acids [211]. The production of this carotenoid and the fatty acid biosynthetic pathway are strongly related, which may be explained by the fact that β-carotene is stored in lipid globules. This element is quite intriguing and demonstrates how the metabolic pathways in microalgae are closely linked to provide an effective and efficient response to stressors.

The xanthophyll cycle is induced in Nannochloropsis gaditana by nitrogen restriction or deprivation, which results in an increase in violaxanthin and zeaxanthin. In [209] the cells underwent sulfur limitation or starvation after cultivation on complete medium to produce a sizeable quantity of biomass. In this instance, xanthophyll pigments were enhanced in the biomass. Given that this pigment participates in the formation of zeaxanthin via antheraxanthin, the violaxanthin rise was less pronounced. The high induction of carotenoids synthesis is signaled by its increase, which points to violaxanthin's de-novo synthesis.

Phosphorus has a crucial role in the cellular composition of DNA, RNA, and phospholipids as well as the control of enzyme activity, metabolic pathways, and ATP synthesis. It can be provided as polyphosphate or orthophosphate, and its inclusion in the medium composition ensures that photosynthetic activity will be effective [212].

The xanthophyll cycle is induced in Nannochloropsis gaditana by phosphorus restriction or deprivation, with an increase in violaxanthin and zeaxanthin, as shown in the case of nitrogen [209].

2.3.3 Salt stress

Salt stress is one of the most significant abiotic variables influencing the development and productivity of microalgae. Some microalgae have developed saline environment adaptation methods, and in these unfavorable environments, they may control the creation of osmoregulatory chemicals that can assist the cells in dealing with stress. Particularly, osmotic stress can cause a rise in the concentration of various polar lipids, such as glycolipids and phospholipids, in chloroplasts and cellular membranes. As previously mentioned, several carotenoids depend on lipid production for their placement, and frequently, lipid production is closely related to the synthesis of carotenoids.

In fact, an excess of the ions Na+ and Cl− reduces the osmotic potential of the environment, which in turn reduces water intake, resulting in a wide range of bioenergetic and biochemical alterations in photosynthetic species under salt stress. The effects of salt stress on microalgal cells result in modifications and effects at several levels, including changes in membrane permeability, ion homeostasis blockade, increased catabolism of lipids and biopolymers, and altered yield of energy-producing activities.

Salt stress can be used as a strategy to encourage the synthesis of carotenoids, since like other stressors it may have a significant influence on the growth rate of microalgal cultures and also lower photosynthetic activity. An increase in NaCl concentration inhibited the growth of Chlorella zofingiensis while the quantity of carotenoids was enhanced [213].

The effect on lutein production in C. vulgaris has been reported by [214]. The results showed that using different levels of salinity stress, the highest increase of lutein content (11.36 mg g−1) was induced by a salt concentration of 35 ppt, the highest tested. The influence of high light intensity and salt stress was investigated also in Scenedesmus sp. by [215]. The authors reported the production of 6.45 mg g−1 of lutein, with NaCl 156 mmol L−1, under exposure to 160 µmol photons m−2 s −1. In a strain of Scenedesmus grown on 10 g L−1 of NaCl the increase of carotenoids content was observed, particularly the xanthophyll component [216].

According to [217] salt stress in the range of 0.34 M to 0.51 M caused a decline in the growth rate in C. vulgaris. This decline may be related to an imbalance in ion homeostasis, which reduces photosynthetic activity, affects light utilization and the metabolism of carbohydrates, which is involved in osmotic regulation, and leads to the accumulation of reactive oxygen species. As with nitrogen, sulfur, or phosphorus restriction, this is thought to be a catalyst for the induction of carotenoids synthesis, therefore in this instance, the poor biomass productivity can also be linked to a high carotenoids production.

2.4 Extraction of carotenoids from microalgal cells

Conventional solvent extraction techniques using organic solvents are used to obtain carotenoids from microalgae. The polarity, solubility, and chemical stability of the carotenoids to be extracted determine whether conventional extraction should be carried out using organic or aqueous solvents.

Non-polar solvents (n-hexane, dichloromethane, dimethyl ether, diethyl ether) or polar solvents (acetone, methanol, ethanol, biphasic combinations of various organic solvents) can be utilized according to the polarity of the target carotenoid,

For the recovery of carotenoids from microalgae, the use of green solvents (environmentally safe and non-toxic solvents) like ethanol, limonene, and biphasic mixes of water and organic solvents has been examined. Due to the high cost of manufacturing and extensive solvent use, the economic feasibility of carotenoid extraction from microalgal species is currently low.

Thus, interest in the use of unconventional extraction techniques has grown recently. These unconventional extraction techniques have quick extraction times, little solvent usage, improved recovery, and more selectivity, among other benefits [218,219,220,221,222,223,224,225,226]. The most used extraction methods are briefly described.

2.4.1 Microwave-assisted extraction (MAE)

Due to the presence of algaenan and sporopollenin in their cell walls, breaking down microalgal cells can be a challenging task [224]. Additionally, the efficiency of traditional cell disruption and extraction methods is poor. When microwave radiation is used at a frequency close to 2.45 GHz, polar molecules vibrate, resulting in inter- and intramolecular friction.

Two marine microalgae, Dunaliella tertiolecta (Chlorophyta) and Cylindrotheca closterium (Bacillariophyta), were subjected to microwave irradiation for the extraction of pigments. [219] examined the effectiveness of this method in comparison to traditional methods. All techniques used on D. tertiolecta produced quick pigment extraction. The optimum extraction method for C. closterium pigments was determined to be MAE, bringing benefits in speed, repeatability, homogenous heating, and high extraction yields.

2.4.2 Ultrasound-assisted extraction (UAE)

UAE is based on ultrasound cavitation. Ultrasound waves of high strength and low frequency are used to perform ultrasonic extraction. Low intensity-high frequency (100 kHz–1 MHz) and high intensity-low frequency (> 1 MHz) ultrasound can be distinguished from one another (20–100 kHz). UAE is affordable, it dramatically shortens the extraction time, and increases extraction yields.

4.66 mg of β-carotene per g of dry weight was extracted using ultrasonic assistance from the microalga Arthrospira platensis [38]. For enhanced extraction, several parameters (amplitude, duty cycle, sonication period, and depth of horn immersed in solution) were tuned.

The ideal parameters for the greatest amount of β-carotene extraction from this alga were 80% amplitude, 33% duty cycle, 0.5 cm of horn depth in the solution, and 10 min of ultrasonication. The extraction of lutein, β -carotene, and α-carotene from Chlorella vulgaris has also been carried out using UAE [227]. The highest extraction levels were, respectively, 4.844 ± 0.780, 0.258 ± 0.020, and 0.275 ± 0.040 mg g−1 of dry weight biomass.

2.4.3 Subcritical fluid extraction

Subcritical fluid extraction uses liquefied subcritical fluids as the extraction solvent. Compared to supercritical fluid extraction, subcritical fluid extraction operates at comparatively modest temperatures and pressures. Moreover, using ethanol modified subcritical 1,1,1,2-tetrafluoroethane, the carotenoids and chlorophyll-a can be efficiently extracted [170].

2.4.4 Electrotechnologies-assisted extraction

Electrotechnologies including pulsed electric field (PEF), moderate electric field (MEF), and high-voltage electric discharges (HVED), are other non-thermal and environmentally friendly methods of extraction which target intracellular chemicals from bio-suspensions.

Carotenoids extracted from Chlorella vulgaris with pulses of milliseconds (5 kV/cm–40 ms) or microseconds (20 kV/cm–75 s) were extracted with an 80% greater efficiency. Up to 73% of carotenoid extraction was achieved in the microalgae Heterochlorella luteoviridis when MEF and ethanol were used as the solvent (180 V, 75 mL/100 mL of ethanol solution) [228].

2.4.5 Pressurized liquid extraction (PLE)

The primary benefit of employing PLE is that it enables quick extraction while consuming less solvent. In PLE, solvents are extracted under pressure and temperature conditions that are always below their critical points.

Carotenoids have been extracted using PLE from freeze-dried macro- and microalgal biomass. Pressurized liquid extractions produced extraordinary levels of extraction of fucoxanthin in Phaeodactylum tricornutum, up to 26.1 mg g−1 DW [229]. In the instance of Neochloris oleoabundans, pressurized liquid extraction was used to recover the bioactive carotenoids lutein, carotenoid monoesters, and violaxanthin [230].

In comparison to maceration, soxhlet extraction, and ultrasound-assisted extraction, pressurized liquid extraction (PLE) demonstrated greater extraction efficiency for the extraction of carotenoids and chlorophylls from the green microalga Chlorella vulgaris (UAE) [231].

2.4.6 High pressure homogenization (HPH) treatment and enzyme-assisted extraction

Since microalgal cells are not easy to disrupt, recovering carotenoids can be aided by a physical or enzymatic pre-treatment before extraction. One such approach is HPH, which uses high intensity fluid stress to cause cell breakdown (50–400 MPa). It has important advantages over conventional physical milling methods, including simplicity of use, commercial viability, repeatability, and high throughput [170].

2.4.7 Supercritical fluid extraction (SFE)

SFE includes extraction utilizing supercritical fluids, or fluids at a temperature and pressure above their critical limit. Due to their low viscosity and high diffusivity, supercritical fluids have better solvating and transport qualities than liquids.

SFE was used to produce the maximum carotenoid output in Scenedesmus obliquus at 250 bar and 60 °C [232].

2.5 Purification of carotenoids

To ensure that the carotenoids maintain their qualities, when they reach the consumer, further methods are required after the process of extracting the carotenoids. These strategies include purifying the compounds of interest, removing any leftover cell debris, and preserving the molecules [233]. Carotenoids obtained from microalgae are as pure as those found in other natural sources. The Willstatter technique is the foundation of the traditional approach for purifying carotenoids [180].

To prevent product degradation, this purification method uses salts (NaOH or KOH) as saponification agents at low temperatures (below 60 °C), followed by organic solvents (such as hexane or blends of ethanol, water, and dichloromethane) that will later be removed in order to obtain the desired carotenoid products. This time-consuming method of purification is presently being superseded by several chromatographic methods that have been compiled and thoroughly discussed in numerous publications [234, 235].

After the carotenoids have been extracted and purified, air, light, or heat may cause the final products to degrade [180]. The stability of standard solutions of carotenoids, such as lutein, lycopene, zeaxanthin, α and β-carotene, β-cryptoxanthin, and zeaxanthin, was examined after the extraction. With the exception of lycopene, these studies found that the carotenoid standard solutions (0.05–5 g mL−1) did not degrade and could be kept at − 70 °C for 6 months [236,237,238].

2.6 Application of some most representative primary carotenoids

Carotenoids are in very high demand in the healthcare and pharmaceutical industries because they are pro-vitamin A and have potent antioxidant properties (Table 5).

As an example, regular consumption of 9-(Z) neoxanthin may reduce the chance of developing lung cancer [241].

Violaxanthin and its derivatives have been shown to have potent lipid peroxidation inhibition characteristics and are reported in the literature to have antioxidant effects [242]. Additionally, 2,2-diphenyl-1-picrylhydrazyl (DPPH) and 2,2-azobis-3-ethylbenzthiazoline-6-sulphonic acid (ABTS) radical tests were used to demonstrate the radical scavenger properties of violaxanthin derived from the microalgae Eustigmatos cf. polyphem [176].

In ophthalmological areas, zeaxanthin plays a large and vital function. It shields the visual organ from near UV rays and reduces the risk of age-related macular degeneration, and is naturally found in the central macula of the eye [243]. Its potential as a natural dye indicates its use in food, as antioxidant in cosmetics, and in the coloring of fish and fowl [244]. Zeaxanthin has been reported to be beneficial in treating cardiovascular issues and may help diabetic individuals from developing pancreatic and lung cancer [245]. This xanthophyll is helpful in adjuvant therapy because it can lead melanoma cells to apoptosis.

Antioxidant and photo-protective qualities are present in lycopene. It exhibits anti-cancerous properties in human colon, breast, prostate, liver, and lymphocyte cell lines [246]. It combats high blood pressure issues and early arthrosclerosis by enhancing endothelial function and reducing oxidative stress. Lycopene maintains blood cholesterol levels by acting as a hypolipidemic in a manner similar to statins [247]. Daily dosages of lycopene strengthen the skeletal system, improve intercellular connections of gap junctions, and maintain glucose homeostasis. According to [246], lycopene-induced tumor metastasis was inhibited as a result of regulated cell cycle progressions.

An in vivo study in high cholesterol-fed rats found that algal lycopene obtained from Chlorella marina displayed stronger antioxidant and anti-inflammatory effects compared to the lovastatin and trans-lycopene derived from tomatoes.

Although, at the industrial level, marigold is the primary source of lutein production, many microalgal strains are able to produce a considerable amount of lutein [248]. A crucial aspect to be considered is that, while lutein from marigolds is esterified, it is found in free forms in microalgae, which are more easily absorbed than esterified forms [249], with various benefits for human health: antioxidant, light-filtering and anti-inflammatory activity, eye protection, potential therapeutic benefits for many chronic diseases, lower risk of cancer.

The antioxidant lutein can protect eyes, brain, and skin from damage. Like zeaxanthin, it shields the eyes from harmful UV and blue light, earning the moniker "eye vitamin." It protects against age-related macular degeneration and cataract by lowering the amount of plasma factor D. It is also effective as a chemotherapeutic agent [250]. It is a chemical that actively fights prostate, breast, and colon cancers. Consuming lutein can also reduce the risk of developing lung cancer and early atherosclerosis. It lessens the consequences of neurodegenerative diseases brought on by inflammation. It is extensively used in chicken as a feather colorant, a yolk color enhancer, and as an additive in baby food, drugs, and cosmetics.

It is widely known that β-carotene has anti-inflammatory, antioxidant, immune, dermo-, hepato-, and retino-protective properties [251]. This pigment is widely used in the cosmetic and food coloring industries [241]. It has been claimed that this pigment plays a protective function from malignancies of the breast, colon, lungs, liver, and skin.

Apoptosis, cell differentiation, and proliferation may all be maintained by β-carotene, which can also improve gap junction intercellular communications and lessen the detrimental effects of H2O2 on them [244]. Its frequent inclusion in the diet guards against liver fibrosis and night blindness.

2.7 Market

The global market for carotenoids was estimated to be worth $1.24 billion in 2016 and $1.53 billion in 2021 [252]. Their worldwide economic value is determined by consumer demand and the cost of extraction.