Abstract

The high metabolic flexibility and biodiversity of microalgae make them promising systems for the production of chemicals and high-value metabolites to be utilized in various industrial applications. Currently, microalgae are primarily cultivated in phototrophic processes or in fermenters using glucose as substrate. However, such configurations are often too costly for the majority of potential applications and require improvements. The use of acetate as substrate to enhance biomass productivity and reduce cost and environmental impacts is a promising solution. In a future bio-based economy, acetate can serve as an excellent intermediate to link many industrial facilities, as it can be synthesized using different technologies from renewable resources as CO2 and waste. This work provides a detailed description of acetate synthesis processes alternative to the conventional methanol carbonylation, including the pros and cons of each: aerobic and anaerobic fermentations; thermochemical treatments; C1 gas fermentation; microbial electrosynthesis and artificial photosynthesis. Additionally, the utilization of acetate as substrate for microalgae growth in mixotrophic and heterotrophic conditions is reviewed, covering key metabolic and engineering aspects (strains, yields, growth rate, inhibition, productivity, process configuration). These aspects serve as guidelines for a rationale design of an algal cultivation process based on acetate as a carbon source. Finally, the review critically assesses the state of the art of coupling of acetate-rich streams with algal biomass production, highlighting the pros and cons and addressing the main knowledge gaps to be filled through future research.

Similar content being viewed by others

1 Introduction

Natural ecosystem pollution and climate change are leading researchers to develop renewable and sustainable alternatives, such as carbon–neutral bio-based technologies. Among these alternatives, microalgae represent promising biological systems for producing chemicals of industrial interest, including fatty acids, carbohydrates (i.e. starch), proteins, pigments and antioxidants (Metting 1996; Shimizu 1996; Spolaore et al. 2006). However, the minimum production cost (5–10 € kg−1) of microalgal biomass hinders many potential industrial applications (Di Caprio et al. 2019b; Ruiz et al. 2016). As a result, microalgae are currently primarily used to produce high value-added products like omega-3 fatty acids, pigments and nutraceutical integrators (Araújo et al. 2021). To broaden the application of microalgae in the production of commodities for entry into larger markets (e.g. feed, food, biofuels, bioplastics), the primary challenge lies in reducing production costs. The high charges arise mainly from the material and energy required to build and operate the cultivation facilities and the expenses related to biomass harvesting and downstream processing (Ruiz et al. 2016). Therefore, this biotechnological field needs strategies to improve resource management and increase the productivity and yields of microalgal biomass.

The main limitations of common microalgal cultivations are related with light supply, which is severely limited by sunlight availability (day/night cycles, weather conditions) and by cellular self-shading as biomass concentration increases during cultivation. Consequently, the productivity of microalgae cultivated in industrial plants is typically strongly constrained by the rate of light supply and the surface/volume ratio of the reactors (Pérez-López et al. 2017). Heterotrophic and mixotrophic cultivations could represent efficient strategies to overcome these limitations and reduce production costs (Abiusi et al. 2020; Ruiz et al. 2022). Organic substrates can serve as an additional source of carbon and energy for microalgae, feeding light-independent metabolic pathways. By utilizing heterotrophy, higher biomass, lipid and protein productivity can be achieved, but it comes at the cos of CO2 generation (Morales-Sánchez et al. 2017; Ruiz et al. 2022). In the presence of both light and organic substrate, some microalgae can grow in a mixotrophic mode, a combination of phototroph and heterotroph metabolisms that has the potential to reduce the metabolic emission of CO2 to zero (Abiusi et al. 2020).

Despite the potential advantages, organic carbon substrate can become a major cost with a high impact on process sustainability (Ruiz et al. 2022). Sugars, such as glucose and sucrose, currently serve as the primary organic substrates in biotechnological fermentations of microalgae (Jeon et al. 2014; Jin et al. 2021a; Ruiz et al. 2022).

These sugars are typically derived from terrestrial crops, in competition with the food industry (Barbosa et al. 2023). To address these issues, there is a need to replace these sugars with cheaper and less environmentally impactful organic substrates. In this framework, acetate represents a gainful alternative carbon source for microalgae (Abiusi et al. 2020; Kim et al. 2021; Lim et al. 2018), presenting several advantages: (a) its cost (0.44–0.46 € kg−1) is lower than that of glucose (0.55–0.78 € kg−1) (Alibaba.com Limited, 2024); (b) acetate can be produced from C1 gases (CO2 and CO), and from solid and liquid wastes, through different processes, such as anaerobic fermentation (AF), microbial electrosynthesis (MES) (Christodoulou and Velasquez-Orta 2016; Ragsdale and Pierce 2008; Turon et al. 2016) or by electrochemical processes based on inorganic catalysts (Liu et al. 2015b). Consequently, acetate emerges as a promising link in a circular economy framework that includes microalgae biorefineries.

The primary objective of this review is to present the current state of the art of conventional and innovative processes for synthesizing acetate and to offer key guidelines on integrating acetate synthesis with its valorization by microalgal metabolism into the production of value-added products. To this aim, we examine the main engineering and physiological associated with acetate metabolism in microalgae. This review provides essential information to consider when designing microalgae cultivation processes. The pros and cons of various alternative strategies for acetate production on an industrial scale are discussed considering their integration with microalgae cultivations.

The review is structured as follows: Sect. 2 describes the various processes that can be employed to produce acetate; Sect. 3 outlines general aspects of microalgae growth and metabolism when utilizing acetate in mixotrophic and heterotrophic conditions; in Sect. 4 we describe and critically discuss the process configurations to integrate different acetate production systems with microalgae cultivation.

In this work the term “acetate” is used to indicate both the protonated and ionic (dissociated) form, except than when specifically indicated.

All production costs cited in this work are referred to the year at which the estimation was made. These costs are subject to variations over time due to changes in energy and raw material prices. The reported costs are the most recent ones found in the scientific literature.

2 Acetate synthesis

The aim of this section is to provide an overview of the different processes for acetate production, aiming to understand the pros and cons of their integration with microalgae cultures. The primary process currently employed globally for industrial-scale acetate production is based on chemical synthesis from fossil sources, and it is detailed in the first section. Subsequently, alternative processes to obtain acetate are described and discussed (Fig. 1). These include the bacterial fermentation process used to produce vinegar and processes already operated at industrial scale that generate acetate as a waste or by-product (Table 1). Additionally, various promising innovative processes, currently tested only at the laboratory or pilot scale, are described.

2.1 Current industrial synthesis of acetate

Currently, about 85% of acetate is produced from petroleum-derived precursors such as methanol, acetaldehyde, ethane, ethylene, butane (Kiefer et al. 2021; Pal and Nayak 2017), with metal-catalyzed methanol carbonylation being the primary exploited process (Kiefer et al. 2021). Acetate produced through this process is mainly transformed into important monomers used in the production of polymeric materials. For example, the vinyl acetate monomer, when polymerized, yields polyvinyl acetate (Pal and Nayak 2017).

In 2021, the global market of acetate reached a volume of 17.3 million tons, with expected growth in the coming years (Kiefer et al. 2021). The production cost of acetate through methanol carbonylation was estimated to be 0.30 € kg−1 in 2016 (Christodoulou and Velasquez-Orta 2016; Kiefer et al. 2021; Li et al. 2016; Lim et al. 2018). However, methanol carbonylation has a carbon footprint of about 1.4–1.9 kg CO2 eq. per kg of acetate produced (Medrano-García et al. 2019) significantly contributing to annual CO2 emissions and associated air pollution.

Various biotechnological processes offer the potential to produce “green acetate”, making its production independent from non-renewable resources and enhancing ecological sustainability. Currently, only 10% of acetate is generated biotechnologically, with its significance mainly confined to vinegar production (Kiefer et al. 2021) due to the food purity and quality regulations mandating vinegar of biological origin (Vidra and Németh 2018). The limited production of acetate from biotechnological processes is primarily attributed to higher costs (Xu et al. 2011).

2.2 Alternative processes to synthesize acetate

2.2.1 Acetate from sugars by aerobic fermentation

The synthesis of acetate from sugars by aerobic fermentation is one of the most established processes for acetate production, originating from the traditional manufacturing of vinegar in the food sector.

This process involves a two-step fermentation of sugar-rich sources: the first step is the alcoholic fermentation of sugars, transformed into ethanol by yeasts; the second step is the incomplete oxidation of ethanol by acetic acid bacteria (AAB), mainly from the Acetobacter genus. This fermentation leads to the generation of 2 mol of acetate and 2 mol of CO2 for each glucose mole (Vidra and Németh 2018). In general, AAB represents a group of strictly aerobic bacteria capable of converting sugars, ethanol or alcohols into acetate as a final product.

For this two-stage fermentation process, various established methods for acetate production exist, such as the Orleans process and the German process (or generator method) (Vidra and Németh 2018). More recently, other technologies such as the submerged method and the use of immobilized cells for fermentation are under investigation in order to increase the rate and the productivity of the process (Vidra and Németh 2018). However, productivity can be affected by different factors, including the composition of the AAB species involved. Acetate productivities for this process are reported to range between 0.09 and 3.2 g L−1 h−1 (Vidra and Németh 2018). Concerning acetate concentrations, values between 66 and 206 g L−1 have been reached using different operation modes. The yield of ethanol conversion to acetate typically falls between 0.91 and 0.96 g g−1 (Vidra and Németh 2018).

The production cost of acetate from conventional fermentation is remarkably higher than that of conventional methanol carbonylation, ranging from 0.9 € to 1.5 € per kg of acetate (Pal and Nayak 2017). Additionally, the acetate produced through this process is typically not pure but is released into a medium that still contain bacteria, cell fragments, and residual substrates. Separation processes to recover pure acetate from this process are still under study and optimization (Vidra and Németh 2018).

2.2.2 Thermochemical conversion of biomass to acetate

Thermochemical treatments can be utilized to convert organic molecules of biomass into acetate. Depending on the conditions employed, thermochemical processes can be classified as pyrolysis, hydrothermal carbonization (HTC) and hydrothermal liquefaction (HTL). All share the common aspect of thermal decomposition of biomass into different solid (char), liquid and gaseous end-products under oxygen deficient conditions. During thermochemical treatments, acetate can be produced from the decomposition of a wide group of biomolecules such as cellulose, hemicellulose and lignin, allowing its synthesis from various sources of biomass (Sarchami et al. 2021). Pyrolysis is carried out on solid dry biomass at temperatures between 300 and 800 °C. The liquid fraction recovered by condensation of products from the pyrolysis reactor is known as “bio-oil”. It contains a notable water content (up to 30%) (Sarchami et al. 2021; Yanik et al. 2007), and water-soluble compounds such as acetate, which is one of the predominant constituents, at concentrations between 5 and 157 g L−1 (Sarchami et al. 2021).

HTC is a thermal decomposition of biomass carried out at lower temperatures (170–300 °C) in a water-rich environment (> 75%), in closed reactors under high pressure (2–6 MPa) (Heidari et al. 2019). Due to these operative differences, HTC is more suitable than pyrolysis for treating biomasses with high water content (e.g. sludges, organic solid wastes). HTL is similar to HTC, but with the difference that higher temperatures (240–400 °C) and pressures (4–22 MPa) are employed to increase the yield of bio-oil over solid char (Gollakota et al. 2018).

Thermochemical conversions have the advantage of allowing acetate to be obtained under similar operative conditions from several biomass wastes or by-products, with higher rates than biological conversions (treatment times are usually below 2 h) and by using even recalcitrant starting materials (e.g. lignin). However, for all thermochemical processes, a main drawback is the low selectivity of the acetate synthesis, resulting in a complex solution of products in which acetate is mixed with other organic compounds, many of which have antimicrobial properties.

In the process water obtained from HTC and HTL, acetate is usually among the predominant organic acids in solution, with values ranging between 0.7 and 33 g L−1 (depending on the operative conditions) (Panisko et al. 2015; Sarkar et al. 2020; Stemann et al. 2013; Weiner et al. 2014). In the process water from HTC, acetate was reported to contribute about 5 to 50% of the total organic carbon (Kambo et al. 2018; Stemann et al. 2013; Weiner et al. 2014), while in process water from HTL it was reported to be between 13 and 20% of the total carbon (Panisko et al. 2015). In the bio-oil obtained from pyrolysis, the produced acetate typically constitutes between 1.5 and 15% of the total dry mass (Sarchami et al. 2021). A fraction of the treated biomass is even missed as CO2 gas (Wang et al. 2018).

Other organic acids commonly found in HTC and HTL water include formic acid, lactic acid, glycolic acid and propionic acid. Additionally, phenols, hydroxymethylfurfural (HMF) and furfural are antimicrobial compounds typically produced in HTC and HTL process water (Ahmad et al. 2018; Panisko et al. 2015; Stemann et al. 2013). In the bio-oil from pyrolysis, more than 400 compounds are reported, among which glycolaldehyde, acetol and levoglucosan are the main compounds present along with acetate (Sarchami et al. 2021).

To avoid relevant inhibition of microalgae growth, a purification phase of the acetate should be applied. Different technologies can be exploited to purify the liquid fraction, such as for instance distillation, membrane separation and solvent extraction (Sarchami et al. 2021). However, it should be considered that the purification of acetate from these streams is still at an early phase of development, and substantial work is still required to achieve operations that can be scaled up with a reasonable efficiency and cost.

The concentration of acetate in the liquid phase obtained by thermochemical processes can be strongly affected by process parameters such as solid/liquid ratio, temperature, reaction time, and the kind of biomass fed. Therefore, an alternative or complementary approach to purify acetate can be adjusting the operative conditions of the thermochemical treatments to increase the selectivity towards acetate synthesis. For instance, boric acid allowed an increase in selectivity during pyrolysis, resulting in obtaining acetate at 91% purity in the liquid phase (Hou et al. 2021), while increasing the temperature of HTC from 190 to 225 °C remarkably enhanced the selectivity toward acetate (Kambo et al. 2018).

Thermochemical processes have the advantage of being easily scalable. Pyrolysis is a conventional technology that is already widely applied at industrial scale for the production of biochar from different biomasses.

HTC was mainly studied with the aim to stabilize solid wastes by producing a solid hydrochar as the main product, while the organic acids in the process water are currently considered mainly as by-products. HTC and HTL are recent technologies; however, such kinds of processes are already being tested at the prototype and industrial scale to treat different biomasses (e.g. by the company Ingelia, Spain). Hydrothermal treatments were not typically carried out with the aim to obtain acetate, therefore information about the economic feasibility of its production is still scarce. Some preliminary assessments indicated that it could be feasible, but more studies are required (Sarchami et al. 2021).

Thermochemical treatments have been even applied to depolymerize conventional non-biodegradable plastics, such as poly-ethylene, polypropylene and others; however, in such applications, acetate was not reported as a main product in the bio-oil fraction under the tested conditions (Anuar Sharuddin et al. 2016; Seshasayee and Savage 2020).

2.2.3 Acetate from anaerobic fermentation of wastes and wastewater

Anaerobic fermentation is the most established biotechnological process for the conversion of complex organic wastes and wastewaters (which include food and agricultural wastes, livestock manure, agro-industrial by-products, etc.) into biogas, a gaseous mixture mainly consisting in CH4, CO2 and, in smaller quantity, H2S and H2. In this process, acetate can be produced as an intermediate product. This process follows different phases: hydrolysis, acidogenesis (production of organic acids), acetogenesis (production of acetate and H2) and methanogenesis (conversion of H2 and acetate to methane) (Ramos-Suarez et al. 2021). Therefore, acetate can be obtained as a by-product of acidogenic fermentation, as a by-product of dark fermentation (H2 synthesis by the acetogenesis phase) and as a residual by-product of a complete anaerobic digestion (AD) process (carried out until the methanogenesis phase). Acidogenic fermentation, which includes the first two steps of anaerobic digestion (hydrolysis and acidogenesis), is carried out by facultative and obligate anaerobic bacteria. It can be used to convert complex molecules present in effluents into simple monomers, including acetate, which is readily available for subsequent microbial metabolization (You et al. 2021). During hydrolysis, organic compounds as carbohydrates, lipids and proteins, are broken down into monomers by hydrolytic bacteria. After that, during the acidogenesis fermentation stage, bacteria convert hydrolysis products into alcohols, aldehydes, CO2 and volatile fatty acids (VFAs), including acetate, propionate and butyrate. The proportions of these VFAs can vary from 75:15:10 to 40:40:20 (Meegoda et al. 2018). The process is carried out by anaerobic fermentative bacteria with the Clostridium genus being the dominant one (Ghimire et al. 2015). This genus can also be responsible for the concomitant production of H2 and CO2.

The exploitation of mixed microbial cultures in this process is preferable to increase and stabilize the degradation yield of different substrates by leveraging the affinity of different microbial species toward various substrates (Jobard et al. 2014). Furthermore, using a pure culture of specific microorganisms would require sterilization processes that would be technically unfeasible (Wong et al. 2014). The concentration and purity of acetate produced by acidogenesis can vary depending on the type of starting feedstock (Ramos-Suarez et al. 2021). Typical acetate concentrations in effluents range from 0.3 to 29 g L−1, while total VFA can attain titers higher than 50 g L−1 (Ramos-Suarez et al. 2021).

Dark fermentation is the process in which anaerobic fermentation includes the acetogenic phase, converting alcohols and organic acids into acetate, CO2 and H2 by acetogenic bacteria (Guo et al. 2010). The aim is to maximize the synthesis of H2 from biomasses and wastewaters by inhibiting methanogenesis through different methods, including chemical suppression, low pH regulation, short retention times, and thermal treatment of the inoculum (Jain et al. 2022).

In waste feedstocks, biodegradable pollutants can be expressed as biodegradable Chemical Oxygen Demand (COD), representing the fraction of total COD that can be biodegraded by heterotrophic microorganisms. Under ideal conditions, the biodegradable COD present in the waste feedstock is largely (up to 50–80%) transformed into soluble metabolites during dark fermentation (Sarma et al. 2015), a large part of which is converted into acetate and butyrate through the following reactions (considering the oxidation of glucose):

The process is not CO2 free, since as at least 1 mol of CO2 is produced for every mole of acetate.

As mentioned above, the acetate:butyrate ratio (A:B) within dark fermentation effluents is variable, and can be affected by the composition of the bacterial community, which is largely influenced by temperature. For example, higher proportions of acetate (60–70%) are generally obtained when dark fermentation is conducted under thermophilic (50–70 °C) or hyperthermophilic (> 80 °C) conditions (Meegoda et al. 2018). A prediction of VFA proportions from dark fermentation can also be obtained by considering the chemical composition of the waste (Turon et al. 2016). The reported acetate concentration in dark fermentation effluents varies in a range of 0.06–12.8 g L−1, while butyric acid can attain up to 14.8 g L−1 (Turon et al. 2016; Uyar et al. 2009).

An increase in the organic loading rate (OLR) can result in higher accumulation of VFAs, leading to a reduction in H2 generation (Gómez et al. 2011); however, a higher concentration of carbohydrates is also correlated with increased H2 production (Ntaikou et al. 2010). Lastly, pH can strongly affect the microbial communities in fermenters by affecting biochemical pathways (Moon et al. 2015). A significant decrease in pH (which can be caused by VFA production) shifts hydrogenesis towards solventogenesis (the biochemical production of solvents such as ethanol, butanol and acetone) (Hawkes et al. 2007).

Acetate represents a by-product of dark fermentation that can be exploited as a growth medium for different microorganisms, including microalgae (Turon et al. 2016). In this way, even other compounds, such as ammonium and phosphates, can be valorized as nutrients. Direct effluent valorization can also be considered as a wastewater treatment process, in which existing pollutants, expressed as COD, total nitrogen (TN) and total phosphorus (TP), can be removed by microalgae. Moreover, the valorization of dark fermentation effluents can be useful to increase the economic sustainability of the bio-H2 production process.

The final possible step of anaerobic fermentation is the methanogenesis step, which consists of the production of methane performed by obligate anaerobic archaea. Methanogenesis is the concomitant fermentation of acetate to CO2 and CH4 and oxidation of H2 to H2O. The acetoclastic route uses acetate as an electron acceptor, while the hydrogenotrophic route uses H2 and CO2 to carry out CH4 production (Meegoda et al. 2018). Therefore, methanogens inevitably consume acetate reducing its concentration. The liquid waste resulting from methanogenesis is the anaerobic digestate, which is enriched mainly in inorganic elements such N and P. The high concentration of N and P, along with other minerals, makes digestate particularly promising and studied as a source of nutrients for microalgae cultivation (Bauer et al. 2021; Monlau et al. 2015; Rossi et al. 2023). The residual concentration of VFAs in the digestate ranges between 0.1 and 1 g L−1 (Monlau et al. 2015; Rossi et al. 2023). Given the high P/COD and N/COD ratio and the limited concentration of VFAs, the digestate has been valorized for microalgal growth mainly as a nitrogen and phosphorus source in phototrophic or mixotrophic cultures. Indeed, sole heterotrophic growth on digestate would be carbon-limited, hindering the complete removal of P and N. However, through photosynthetic metabolism and CO2 fixation, complete removal of P and N can be attained (Chong et al. 2022; Rossi et al. 2023). The N in the effluents of anaerobic fermentation is mainly in the ammonium form, with NH4–N values ranging between 300 and 5500 mg L−1 (Chong et al. 2022; Rossi et al. 2023), significantly higher than the inhibiting concentrations reported for microalgae (9–50 mg L−1) (Chong et al. 2022), thus requiring dilution or pre-treatments before use. In addition, these streams are mainly produced from complex feed and wastes, and consequently the presence of residual pollutants is a common issue to be taken into account, such as the presence of heavy metals (Cu, Pb, Cr, As) and organic pollutants (pesticides, solvents, drugs) (Tawfik et al. 2022). Additionally, digestate is even characterized by a high content of residual bacterial flora, which can remarkably increase the issue of bacterial contamination when used as feed for microalgae.

2.2.4 Acetate from C1 gas fermentation

Another biotechnological method for acetate production is by gas fermentation, where C1 gases (CO and CO2) and H2 are converted into acetate and other valuable products (e.g. ethanol, butanol, butyrate, caproate, 2,3-butanediol) through the Wood-Ljungdahl pathway (WLP). Acetogens, a group of metabolically different strict anaerobic prokaryotes belonging to at least 23 genera, utilize the WLP as a mechanism for the reductive synthesis of acetyl-coenzyme A (acetyl-CoA) and acetyl-CoA derived products from CO2 or CO. The WLP consists of two metabolic branches: the methyl and the carbonyl branch. In the methyl branch, a molecule of CO2 is reduced through six reactions into methyl-CoFeSP, consuming 1 ATP molecule during the conversion step of formate into formyl-tetrahydrofolate. The carbonyl branch involves a reaction catalyzed by the carbon monoxide dehydrogenase/acetyl-CoA synthase (CODH/ACS) enzyme complex. This complex catalyzes the reduction of CO2 to CO, and subsequently the formation of acetyl-CoA by combining the CO with CoA and the methyl originating from the methyl branch (Ragsdale and Pierce 2008). When acetyl-CoA is converted to acetate, 1 molecule of ATP is generated, thus making this pathway neutral for ATP production (Katsyv and Müller 2020; Schuchmann and Müller 2014).

To generate ATP for biomass synthesis, the autotrophic growth of acetogens is strictly dependent on the chemiosmotic energy conservation process, based on the production of an electrochemical ion gradient across the cell membrane, which is used to synthetize ATP via a membrane-bound FOF1ATP synthase. The formation of the ion (H+ or Na+) motive force is driven by two different membrane-bound respiratory enzyme complex that both use reduced ferredoxin (Fd2−) as a reductant in the formation of the electrochemical gradient. The Rnf complex transfers electrons from Fd2− to NAD+, resulting in the production of NADH as end product. Instead, the Ech complex transfers electrons from Fd2− to 2 H+, leading to the generation of H2 (Katsyv and Müller 2020; Rosenbaum and Müller 2021; Schuchmann and Müller 2014). The Fd2− necessary for ion gradient formation is obtained from H2 oxidation (Rosenbaum and Müller 2021).

Ethanol production through gas fermentation is a reality on a commercial scale through the U.S. based company Lanzatech (Illinois, USA), which uses a proprietary evolved strain of Clostridium autoethanogenum and CO-rich steel mill waste gases as feed (Köpke and Simpson 2020). Recently, Lanzatech also implemented acetone and isopropanol production on a pilot-scale using genetically modified strains of C. autoethanogenum and a syngas blend of 50% CO, 10% H2, 20% CO2 and 20% N2 as feed (Liew et al. 2022).

In contrast, acetate production through gas fermentation has not yet reached a commercial scale. Nevertheless, the potential cost for acetate production through anaerobic fermentation starting from CO was estimated to be 4.72 € kg−1 (Christodoulou and Velasquez-Orta 2016).

Below the catabolic reactions for acetate production:

The most investigated acetogenic strains for acetate production are homo-acetogenic species (e.g. Acetobacterium woodii, Thermoanaerobacter kivui and Moorella thermoacetica), which generate acetate as main product, and, in some cases, formate as a by-product. The gas mixture most commonly used as feed is CO2 and H2. The H2–CO2 feed has the high advantage of being a CO2 negative route, while the CO feed produces 2 mol of CO2 for each mole of acetate. However, H2 is less soluble in water than CO, and reaction 3 has a lower ΔG°, while the estimated current cost of green H2 is quite high (3.3–6.5 € kg−1) (Muron et al. 2022). Despite this high cost, it should be considered that the European Commission aims to reduce the cost of green H2 to less than 1.8 € kg−1 by 2030 (European Commission 2022), which will support the economic sustainability of the CO2–H2 feed in bioprocesses.

An acetate production of up to 30 g L−1 was reported for M. thermoacetica, with a maximum acetate productivity of 0.5 g L−1 h−1, and a 91% C-mol C-mol−1 yield, in a bubble column reactor continuously fed with H2/CO2 = 2.3 (Hu et al. 2016). The highest reported acetate titer is 59 g L−1 for A. woodii, with a 93% C-mol C-mol−1 yield and a maximum productivity of 0.78 g L−1 h−1, achieved in a continuously gassed stirred tank reactor fed with H2/CO2 = 2.4. The same authors additionally developed a continuous fermentation process in submerged membrane reactor with full cell retention, achieving a very high maximum productivity of 6.2 g L−1 h−1 (Kantzow et al. 2015). In addition to homo-acetogens, Clostridium species also become highly selective towards acetate production when grown with H2–CO2 feed. For instance, Clostridium ljungdahlii can produce up to 18.5 g L−1 of acetate with an 81% C-mol C-mol−1 yield and a 0.74 g L−1 h−1 productivity in chemostat reactor fed with H2/CO2 = 4 (Molitor et al. 2019).

Acetate production by acetogenic bacteria can be accompanied by the production of other organic compounds. Formic acid represents one of the main collateral products found in gas fermentation effluents, reaching up to 5 g L−1 (Groher and Weuster-Botz 2016). The presence of other organic compounds, including ethanol, butyrate and lactate, can depend on the microbial species and operating parameters (e.g. the partial pressures of the used syngas) (Groher and Weuster-Botz 2016; Kantzow and Weuster-Botz 2016). The problem of product selectivity is one of the main limitations in gas fermentation, not only for acetate production but also for other products of interest (e.g. ethanol, 2,3 butanediol). Indeed, the presence of other compounds reduces the acetate C-yield and leads to problems in the downstream process for acetate purification.

Currently, one of the main limitations in the industrial scale-up of acetate production from gas fermentation of CO2–H2 feedstock is the low economic value of acetate. In this context, sustainability can be increased by integrating acetate synthesis process with a process for its utilization as substrate for other microbial productions with higher added value, in two-stage bioprocesses, such as the production of proteins and fatty acids with microalgae (Bae et al. 2022; Molitor et al. 2019).

2.2.5 Microbial electrosynthesis (MES) of acetate

Microbial electrosynthesis (MES) is another potential strategy for producing acetate from CO2 in a carbon negative process. MES is based on microbial electrochemical cells composed of an anode, where the oxidation of H2O into O2 takes place, generating electrons and H+, and a cathode, where electrons reduce CO2 into acetate and other organic compounds (Jung et al. 2020). The cathode and anode are separated by a membrane permeable to H+ (Bakonyi et al. 2023).

In MES, microorganisms grow on the cathode and catalyze CO2 reduction to acetate. Microorganisms can transfer electrons inside and outside their cells via a direct extracellular electron transfer mechanism, based on redox-active proteins, outer membrane c-type cytochromes, or through an indirect mediated electron transfer, based on exogenous or endogenous redox mediators (Zhao et al. 2021). Both anodes and cathodes are typically made of carbon-based material, such as graphite, due to their low cost, high specific area, good electrical conductivity and biocompatibility (Bakonyi et al. 2023). However, modifying the carbon cathode with metal nanoparticles or organic molecules (e.g. chitosan) can enhance microbial electrosynthesis of acetate by up to 7 folds, due to the increased electron transfer rate (Zhang et al. 2012). The synthesis of acetate in MES is catalyzed by acetogens. However, to date, there is no experimental evidence supporting the direct electron uptake ability of acetogens. Despite the HCO3− reduction to acetate is thermodynamically more favorable than H+ reduction to H2 (Acetate Ecell = − 1.1 V, H2 Ecell = − 1.23 V) (Rabaey and Rozendal 2010), electron transfer from the cathode appears to occur using H2 as an intermediary electron carrier. This is supported by experimental observations where acetate synthesis mainly occurs at potential below H2 evolution (Agostino and Rosenbaum 2018; Bajracharya et al. 2017; Lovley 2022). The typical reactions that summarize the MES of acetate are:

Higher potentials are typically applied in MES cells to overcome kinetic limitations. The Ecat values typically applied are between − 0.40 and − 2.6 V, resulting in acetate volumetric productivities between 0.2 mg L−1 d−1 and 18.7 g L−1 d−1, membrane-based productivity between 0.02 and 196.8 g m−2 d−1, Faradaic efficiencies between 30 and 100% and maximum acetate titers between 0.002 and 11 g L−1 (Bajracharya et al. 2017; Dessì et al. 2023; LaBelle and May 2017; May et al. 2016).

Pure or mixed cultures can serve as biocatalysts for acetate MES. Among pure cultures, A. woodii, C. ljungdahlii and Sporomusa ovata are the most commonly employed strains (Bajracharya et al. 2015; May et al. 2016; Nevin et al. 2011). Pure cultures ensure more efficient control of microbial growth and acetate productivity, allowing for a higher purity of the final product. Against, mixed cultures can be advantageous due to the unnecessary sterilization steps (May et al. 2016), their syntrophic way of life and their higher resistance to environmental stress (Cristiani et al. 2022; Kushkevych et al. 2019). Nevertheless, acetate production could be negatively affected by the presence of methanogens in mixed culture inoculum, responsible of acetoclastic or hydrogenotrophic methanogenesis. This results is a competition between acetogens and methanogens (Cristiani et al. 2022; Molenaar et al. 2017), with consequent reduction in acetate purity and conversion efficiency. In fact, the Faradaic electron conversion into acetate is, on average, lower for mixed cultures as compared to pure cultures, with values typically around 50% for mixed cultures and 80–85% for pure cultures (May et al. 2016).

LaBelle and May estimated the electrical energy cost to produce 1 kg of acetate with MES to be between 15.4 and 33.6 kWh. Considering a price for green electricity of 0.02 € kWh−1, their estimated electricity cost to produce 1 kg of acetate ranges between 0.31 and 0.67 € kg−1 (LaBelle and May 2017), which is comparable to conventional production processes. However, other factors (e.g. acetate purification, depreciation) were not included in the estimation. A more comprehensive assessment predicted an acetate production cost by MES of 1.67 € kg−1, about 5.5 folds higher than conventional methanol carbonylation (Christodoulou and Velasquez-Orta 2016).

Despite its high potential, further studies and improvements in terms of electrode materials, biocatalysts and reactor configuration and design are still necessary to scale up acetate production using MES.

The integration of acetate synthesis by MES with other biotechnological processes is a promising strategy to enhance overall economic and environmental sustainability. For example, by the integration of MES with anaerobic fermentation, the acetate production cost could be reduced about 6 folds to 0.28 € kg−1 (Christodoulou and Velasquez-Orta 2016). In this context, the possibility of obtaining acetate in a saline solution (the catholyte) is particularly attractive for integration with microalgae cultivations. Microalgae could be cultivated directly on the catholyte containing acetate, avoiding additional purification steps after acetate synthesis.

2.2.6 Acetate synthesis by artificial photosynthesis

Artificial photosynthesis is an emerging technology that mimics natural plant photosynthesis to produce value-added carbon molecules from sunlight, water, and CO2, resulting in a carbon-negative process. Currently, various abiotic and biotic approaches are under development for acetate production:

-

Photovoltaic powered electroreduction of CO2 to acetate.

It is a CO2 electrolysis cell that performs water splitting (H2O oxidation to O2 + H+ + e−) at the anode and CO2 reduction to acetate in a single or two-step process at the cathode. All electrodes are made of inorganic catalysts (Ag, Cu and IrO2) powered by renewable electricity generated by photovoltaic systems (Hann et al. 2022). The single-step electrochemical CO2 reduction to acetate usually reports a carbon selectivity lower than 15% and a total CO2 conversion efficiency lower than 2%. The two-step (CO2 → CO, CO → acetate) electrochemical cell allows achieving a carbon selectivity up to 57%, corresponding to a 25% of the fed CO2 converted into acetate, with a productivity of 3.4 g d−1 and attaining a final acetate concentration up to 45 g L−1 (Hann et al. 2022). Ethylene, propionate, n-propanol and ethanol are other organic compounds produced by the same system at lower concentrations. A relevant factor to take into account in this production system is the acetate to electrolyte ratio, as too high electrolyte concentration can inhibit microalgae in a successive integration step (Hann et al. 2022).

-

Photoelectrochemical CO2 reduction to acetate.

In these systems, CO2 is reduced to acetate using inorganic photocatalysts under direct light irradiance (Yang et al. 2017). Photochemical CO2 reduction exploits photosensitive materials, such as semiconductor-based, plasmon-assisted, and dye-sensitized systems, allowing direct UV and/or visible light conversion into chemical energy (Kan et al. 2022). For instance, applying a Fe–Cu oxide catalyst at − 0.4 V under 100 mW cm−2 illumination enabled the conversion of CO2 to acetate with an 80% Faradaic efficiency and 8–15 mg L−1 acetate concentration (Yang et al. 2017). A catalyst made of SiW9V3 and indium achieved up to 96% Faradaic efficiency (Zha et al. 2020), while 91.2–91.8 efficiency were obtained with a nitrogen-doped nanodiamond catalyst at potentials between − 0.8 and − 1.0 V (Liu et al. 2015b).

-

Bioelectrochemical photoreduction of CO2 into acetate.

These are microbial electrosynthesis systems in which the utilization of light sensitive anodes or cathode is integrated with electroactive microorganisms. These systems are photoactive MES exposed to light irradiation (Gupta et al. 2021; Kong et al. 2023; Liu et al. 2015a). For instance, a system made of molybdenum-doped bismuth vanadate deposited on fluorine-doped tin oxide glass (FTO/BiVO4/Mo) was designed to obtain a photoanode. This system achieved 62% Faradic efficiency, converting 1% of solar energy into acetate, and achieving 385 mg L−1 acetate concentration (Bian et al. 2020). Liu and co-workers synthetized an electrochemical system using Si and TiO2 nanowires as photocathode and photoanode, respectively, both illuminated. The photocathode was inoculated with an S. ovata-based biofilm, generating up to 6 g L−1 acetate from CO2 with a 90% Faradaic efficiency (Liu et al. 2015a).

-

Photosynthetic biohybrid systems.

These systems employ microbial non-photosynthetic cells functionalized with light sensitive inorganic nanoparticles to give them the capacity to harness light as an additional energy source (S. Jin et al. 2021a, b; Sakimoto et al. 2016; Zhang et al. 2018). Acetogenic bacteria are utilized, employing inorganic semiconductors to harvest light and providing reducing equivalents to the Wood-Ljungdahl pathway for CO2 reduction. Intracellular gold nanoparticles or extracellular membrane-bound CdS nanoparticles serve as photosensitizers, enabling non-photosynthetic acetogens, like M. thermoacetica, C. autoethanogenum and S. ovata, to perform efficient artificial photosynthesis (Jin et al. 2021 b; Sakimoto et al. 2016; Zhang et al. 2018).

The acetate concentration produced with such systems range between 80 and 730 mg L−1 (Jin et al. 2021b; Sakimoto et al. 2016; Zhang et al. 2018).

Although all artificial photosynthesis technologies are extremely promising options for abiotic and biotic CO2 conversion into acetate, for large-scale applications further efforts are needed to enhance the CO2-reducing rate, device stability, carbon-conversion efficiency and selectivity towards acetate. In addition, the residual concentration of other organic compounds and salts (electrolytes) should be carefully assessed case-by-case to avoid inhibition issues when the catholyte solution containing acetate is used for microalgae cultivation.

3 Mixotrophic and heterotrophic growth of microalgae by using acetate as C/energy source

Microalgae can grow using different metabolic pathways. In the absence of an organic substrate, microalgae can employ phototrophic metabolism, where CO2 serves as the source of C, and light acts as the source of energy. When an organic substrate, such as acetate, is available, microalgae can utilize heterotrophic metabolism, where the organic substrate serves as both the source of C and energy. If the organic substrate is present in conjunction with light and CO2, microalgae can simultaneously employ both phototrophic and heterotrophic metabolism. This condition is referred to as mixotrophy. In the following paragraphs, the metabolic aspects of utilizing acetate through mixotrophy and heterotrophy are described.

3.1 Acetate uptake and metabolism

To understand how microalgae can utilize acetate as a carbon source and how it is converted into other metabolites, a description of the metabolism is provided below. The pathways illustrated in Fig. 2 refer to the assimilation and conversion of acetate in both heterotrophic and mixotrophic conditions. It should be noted that acetate metabolism has been primarily studied in the microalga Chlamydomonas reinhardtii. However, it can be expected that such findings are applicable to many other microalgal species, particularly those belonging to the Chlorophyta division.

Overview of acetate metabolism and related metabolic pathways in microalgae. MCT: mono-carboxylic/proton transporter protein; ACS: acetyl-CoA synthetase; ICL: isocitrate lyase; MAS: malate synthase; CS: citrate synthase; ACO: aconitase; SCDH: succinate dehydrogenase; FH: fumarase; MDH: malate dehydrogenase; IDH: isocitrate dehydrogenase; α-KGDH: α-ketoglutarate dehydrogenase; SCS: succinyl coenzyme A synthetase; MME: malic enzyme (malate dehydrogenase decarboxylating); PFL: pyruvate formate lyase; ACC: acetyl-CoA carboxylase; FAS: fatty acid synthase; ACSL: acyl-CoA synthetase; GPAT: glycerol-3-phosphate-acyltransferase; LPAAT: lysophosphatidic acid acyltransferase; PAP: phosphatidic acid phosphohydrolase; DGAT: diacylglycerol acyltransferase. TCA cycle: tricarboxylic acids cycle

The initial step of acetate uptake involves its assimilation from the culture medium towards the intracellular cytosol. In eukaryotic cells, this step is carried out by the mono-carboxylic/proton transporter protein (Perez-Garcia et al. 2011), which is a member of the Major Facilitator Superfamily, a group of secondary active transporters (Rédei 2008). Once in the cytosol, acetate is converted into acetyl-CoA, an activated form of acetate, by the acetyl-CoA synthetase, at the expense of one ATP molecule (De Swaaf et al. 2003; Martinez-Blanco et al. 1992; Van den Berg et al. 1996). Acetyl-CoA can enter the mitochondria, where it can feed the oxidative metabolism through the tricarboxylic acid (TCA) cycle (Perez-Garcia et al. 2011). By the TCA cycle, acetyl-CoA serves as an energy source, yielding 1 ATP, 2 CO2, 3 NADH and 1 FADH2. NADH and FADH2 can be further oxidized in the oxidative phosphorylation to produce additional ATP. Considering the production yields of 1.5 ATP/FADH2 and 2.5 ATP/NADH, a total of 9 net ATP molecules can be generated from the complete oxidation of one molecule of acetate. Acetyl-CoA can be used even in the anabolism, as a precursor for various molecules as fatty acids, amino acids, nitrogenous bases and even carbohydrates like glucose and starch (Johnson and Alric 2013). The glyoxylate cycle plays a fundamental role in building new cells from acetate. Through the glyoxylate cycle acetyl-CoA can be converted into succinate, which can be further converted into oxaloacetate and phosphoenolpyruvate, precursors of glucose that can be synthesized by the gluconeogenesis pathway. Glucose obtained in this manner can be a precursor for nucleic acids via the pentose phosphate pathway. Succinate and oxaloacetate can also act as precursors for amino acid biosynthesis (Kunze et al. 2006; Morales-Sánchez et al. 2015). The glyoxylate cycle occurs in glyoxysomes in eukaryotic microalgae and in the cytosol in cyanobacteria (Zhang and Bryant 2015). This cycle is feasible by the expression and the activity of two key enzymes, the isocitrate lyase and the malate synthase (Kornberg and Madsen 1958; Kunze et al. 2006; Morales-Sánchez et al. 2015). Both the glyoxylate cycle and the TCA cycle represent fundamental crossroads in metabolism that link acetyl-CoA to oxidative catabolism and biosynthetic pathways (Kunze et al. 2006; Martínez-Reyes and Chandel 2020).

Globally, this overview of acetate metabolism shows that microalgae can utilize acetate as the sole carbon and energy source to produce new cells and accumulate biomolecules of industrial interest, such as starch, proteins and triacylglycerols (TAGs).

The expression of isocitrate lyase and the malate synthase can be induced in cultivation media containing acetate. For instance, an increase in isocitrate lyase activity was observed with rising acetate concentration in Scenedesmus obliquus cultures under heterotrophic conditions (Combres et al. 1994). Furthermore, acetate assimilation can vary depending on enzymatic activity in different microalgal species. For example, Pyrobotris stellata can grow with acetate only under light (mixotrophic conditions) while Chlorella pyrenoidosa can do so even in the dark (heterotrophic conditions), due to different regulation of glyoxylate cycle enzymes (Merrett 1967). It should also be considered that only some species of microalgae can grow under heterotrophic conditions (Morales-Sánchez et al. 2015). Therefore, when developing a process in which microalgae are fed with acetate, it should be assessed whether the employed microalgae strain can grow heterotrophically with acetate or if it requires light.

Acetyl-CoA also represents the precursor for the de novo lipid biosynthesis that occurs in chloroplasts (Ran et al. 2019). The initial reaction of this metabolic pathway is catalyzed by acetyl-CoA carboxylase, involving the conversion of acetyl-CoA into malonyl-CoA (Li-Beisson et al. 2015). Subsequently, the malonyl group of this compound is transferred by the enzyme Malonyl-CoA:ACP (Acetil Carrier Protein) acyltransferase to an acetyl carrier protein. The synthesis of 16–18 carbon fatty acids involves elongating the carbon chains through a series of reactions, including (in order) condensation, reduction, dehydration and additional reduction reactions (Ran et al. 2019). The main enzyme involved in this synthesis is the fatty acid synthase (FAS).

Fatty acids serve as the precursors of TAGs, which can be synthesized through the same pathway found in plant cells. Fatty acids, generated by FAS, are transported to the cytosol, towards the endoplasmic reticulum (ER), in the form of acyl-CoA (synthesized by the long-chain acyl-CoA synthetase). In the ER, the initial reaction of the TAG biosynthesis is catalyzed by the glycerol-3-phosphate-acyltransferase and consists in the esterification between acyl chains and hydroxyl groups of glycerol-3-phosphate. The lysophosphatidic acid generated from this reaction is transformed into phosphatidic acid by lysophosphatidic acid acyltransferase. Phosphatidic acid serves as the precursor for both TAGs and phospholipids (Zienkiewicz et al. 2016). In the case of TAGs, phosphatidic acid phosphohydrolase catalyzes the dephosphorylation of phosphatidic acid into diacylglycerols (DAGs). Finally, DAGs are further acetylated by the diacylglycerol acyltransferase, leading to the formation of TAGs (Ran et al. 2019). Alternatively, TAGs can be synthesized from acyl-CoA derived from lipids already present inside cells, such as phospholipids. In this case, the enzyme diacylglycerol acyltransferase catalyzes the transfer of an acyl group from the phospholipids to DAG, generating TAGs (Dahlqvist et al. 2000). The regulation of TAG biosynthesis is usually stimulated by the depletion of nutrients as N (high C/N ratio), that hinder cell duplication, forcing microalgae to the accumulation of the organic carbon in excess in the form of TAGs (Di Caprio 2021). However, microalgae can also accumulate starch in the same conditions. The mechanisms determining the rate of TAG biosynthesis and the interplay between starch and TAG accumulation remains a controversial process to be better understood (Dahlqvist et al. 2000; Li-Beisson et al. 2015; Ran et al. 2019; Zienkiewicz et al. 2016).

Furthermore, under mixotrophic conditions, the supply of acetate can generate an additional carbon flux, increasing the C/N ratio and stimulating higher TAG accumulation. Additionally, acetate oxidation produces extra CO2, which can be utilized in the Calvin cycle (Abiusi et al. 2020; Li et al. 2014), providing additional carbon for the synthesis of metabolites such as lipids and starch, thereby allowing for higher C-yields (Abiusi et al. 2020). Mixotrophy applied in closed bioreactor can allow achieving acetate utilization with C-yield (C-mol C-mol−1) up to ⁓100% (Abiusi et al. 2020). While mixotrophy can enhance overall biomass productivity and product yields, some studies highlighted that the presence of exogenous carbon sources may be associated with a reduction in photosynthetic activity (Liu et al. 2009). This phenomenon was observed C. reinhardtii, where the presence of acetate caused a down-regulation of Rubisco, reducing the contribution of the Calvin cycle (Gérin et al. 2014).

The supply of acetate in heterotrophic conditions can allow to microalgae cells to grow independently of light availability, which is often limited by the surface/volume ratio of bioreactors. This independence could enable the achievement of biomass concentrations and productivities one or two orders of magnitude higher than typical values achieved in phototrophic conditions (Jin et al. 2021a).

However, it should be considered that the complete absence of light in heterotrophic processes can inhibit some metabolic pathways that are typically regulated by light in algal cells. In this context, pigments are among the most widely studied products, for which light-dependent biosynthetic pathways have been found (Flórez-Miranda et al. 2017; Leong and Chang 2023). A possible strategy to overcome this problem is to carry out two-stage processes in which microalgae are first cultivated in heterotrophic conditions to attain high biomass concentration in a short time, and then the culture is exposed to light for a limited time sufficient to induce the synthesis of the light-stimulated metabolite, as it has been done for lutein (Flórez-Miranda et al. 2017; Leong and Chang 2023).

3.2 Microalgae growth inhibition by acetate

Acetate can have inhibitory effects on microorganisms, including microalgae. In C. reinhardtii, high concentrations of acetate can be toxic, adversely affecting growth rate and yield (Chen and Johns 1994). These negative effects can result in an increased lag phase or even the complete absence of growth, leading to cell death (Zuo et al. 2012).

The ionic form of acetate, CH3COO−, is a weak base (Kb = 5.40 ∙ 10−10), while its protonated undissociated form, CH3COOH, is a weak acid (Ka = 1.77 ∙ 10−5). Consequently, medium alkalinization or acidification can be induced when these species are supplied or consumed, requiring a specific pH control system. While this is typically not problematic in bioreactors, where the pH can be effectively controlled, it may be a problem in laboratory cultivations using flasks if an appropriate buffer is not employed. Even with a good pH control system, acetate can still have negative effects (Lacroux et al. 2020). Indeed, acetate, in its neutral undissociated form, can passively enter cells through diffusion. Once in the cytosol, where the pH is neutral, it dissociates causing intracellular acidification and the accumulation of acetate ions (Herrero et al. 1985; Russell 1992). The resulting acidification of the cytosol can compromise the proton gradient used for ATP generation, while high concentration of acetate ions can cause osmotic stress, hindering the transport of nutrients such as sugars and phosphate (Kiefer et al. 2021; Noda et al. 1982; Sheu et al. 1972). Therefore, it is crucial to control the concentration of undissociated CH3COOH in the culture medium to prevent growth inhibition. The fraction of CH3COOH/CH3COO− varies in function of pH. The dependence of CH3COOH concentration and pH can be derived from Eqs. 8 and 9:

From which the Eq. 10 can be derived.

By Eq. 10, the concentration of undissociated CH3COOH can be directly determined based on the total concentration (Ctot) and the pH of the culture medium. The Eq. 10 enables an easy determination of the conditions at which the culture can be maintained without attaining CH3COOH concentration higher than the threshold for inhibitory or toxic effects. If the medium is kept at pH sufficiently higher than the pKa (4.75), CH3COOH concentration can be maintained sufficiently low. It is important to note that, despite acetate has been assessed in several studies as substrate for microalgae, there is scarce information about the inhibition concentrations of CH3COOH, beyond which negative effects on microalgae become evident. In one study, inhibition threshold concentrations of CH3COOH were determined for different microalgal strains. The values found varied between 41 and 207 mg L−1 (0.68–3.45 mM), depending on the strain (Lacroux et al. 2020). In detail, these values were 47.2 mg L−1 for Tetradesmus obliquus (generally known as Scenedesmus obliquus), 88.5 mg L−1 for Chlorella sorokiniana; 150 mg L−1 and 100 mg L−1 for C. reinhardtii CC-124 and CC-400 respectively, and 207 mg L−1 for Auxenochlorella protothecoides (Lacroux et al. 2020). In another study conducted with a different C. reinhardtii strain, in continuous cultures, significant inhibition was found at Ctot = 400 mg L−1, at pH = 6.9 ± 0.5, corresponding to substantially lower CH3COOH concentrations, around 0.02–0.12 mM (Chen and Johns 1994). For Chlorella regularis the growth rate increased until Ctot = 3 mM and was suppressed at 40 mM, at pH 6.5–6.8, corresponding to CH3COOH = 0.4–0.7 mM. For Haematococcus pluvialis the specific growth rate remains stable at Ctot from 7.5 to 30 mM (Kobayashi et al. 1992).

In Fig. 3 it is shown how the concentration of CH3COOH can be kept below the inhibition thresholds when the culture medium is at different pH, with varying Ctot from 0.006 to 1.2 M (0.36–72 g L−1). For lower Ctot, avoiding inhibition may be possible even at pH 5, while for the higher concentrations, only a pH above 8 can ensure a level of undissociated CH3COOH below the inhibition threshold. These conditions can be reasonably maintained in bioreactors for neutrophil microalgae (as Chlorella sp. and Scenedesmus sp.) that typically have optimal pH around 7. For example, with an initial pH of 8, C. sorokiniana can grow mixotrophically even in the presence of 12.5 g L−1 acetate in the culture medium. (Lacroux et al. 2021). Acidophil microalgae, like Galdieria sulphuraria (optimal pH 2.0) (Abiusi et al. 2022), are disadvantaged in cultivation with acetate, unless working at very low Ctot (since CH3COOH ≈ Ctot). G. sulphuraria UTEX 2919 growth was completely inhibited at Ctot ≥ 600 mg L−1, at pH = 2, corresponding to CH3COOH = 10 mM, and reductions in the growth rate were observed at Ctot > 150 mg L−1 (Portillo et al. 2022), corresponding to CH3COOH = 2.5 mM, falling within the same range found for other strains (Lacroux et al. 2020). Cyanobacteria as Arthrospira platensis (Spirulina) have optimal pH around 9–10, which is particularly promising for cultivation with acetate. However, scientific literature lacks sufficient information about the ability of A. platensis to grow on acetate. Some studies found that A. platensis growth improves with acetate addition (Chang et al. 2013; Chen et al. 1996; Matsudo et al. 2015), however information is missing about the effective yield, specific growth rate and inhibition threshold concentration.

Predicted undissociated CH3COOH concentration from acid–base equilibrium reactions. a Fraction of acetate CH3COO− and undissociated CH3OOH as function of pH. b Concentration of undissociated CH3OOH as function of pH for different Ctot (CH3OOH + CH3COO−) values. The two dotted lines indicate the minimum and maximum inhibition threshold concentrations reported in literature for different microalgae (0.68–3.45 mM)

When using acetate-rich effluents as a source of acetate, the possibility to dilute the effluent to keep acetate below the inhibition threshold should be taken into account. Moreover, the presence of other organic acids, as butyric acid, can lead to additional and more relevant inhibitory effects (Lacroux et al. 2020).

Fed-batch reactors are a possible solution for suppling a high amount of acetate while maintaining CH3COOH concentration below inhibition threshold values, as reported in various studies (De Swaaf et al. 2003; Karimian et al. 2022; Liu et al. 2021; Perez-Garcia et al. 2011; Van Wagenen et al. 2015; Zhang et al. 1999).

Another potential strategy could be increasing the cellular concentration of the inoculum to maintain high cell-to-acetate ratio, thereby diluting the intracellular concentration of acetate and H+ (Pessi et al. 2023). However, this approach could potentially reduce the biomass productivity of the process.

While it is known that the undissociated CH3COOH can passively penetrate the plasmatic membrane and causes negative effects inside cells, the related physiological mechanisms in microalgae are poorly understood. A study indicates that the entry of undissociated CH3COOH inside C. reinhardtii cells at pH 5 and 6 induces programmed cell death. Under these conditions, DNA began to degrade in fragments within 30 min, intracellular H2O2 content increases in 10 min, with significant damages to the photosystem II, and a relevant reduction of Fv/Fm and CO2 adsorption rate (Zuo et al. 2012). This study indicates that such effects were mainly related to the penetration of CH3COOH, as other hydrophilic acids did not induce the same issues. However, the same study suggests that the threshold concentration of CH3COOH at which negative effects are observed is affected by the pH, since no effects were found at pH 7 with [CH3COOH] = 0.84 mM (Ctot = 150 mM), while relevant cell death was observed at pH 5 with [CH3COOH] = 0.36 mM (Ctot = 1 mM). However, the magnitude of the effects regarding the interaction between pH and CH3COOH appears to be secondary when compared to the those due to the undissociated CH3COOH concentration (Lacroux et al. 2020). Yet, acetate induces the release of volatile organic compounds, including C6 green leaf volatiles and terpenoids, which exhibit antimicrobial activity even on cells that have not been exposed to acetate (Zuo et al. 2012).

Similar impacts have been observed for the yeast Saccharomyces cerevisiae (Casal et al. 2008; Semchyshyn et al. 2013). In this case, the generation of reactive oxygen species has been reported, with an increase in the activity of antioxidant enzymes, such as superoxide dismutase and catalase, causing a pro-oxidant effect (Semchyshyn et al. 2013).

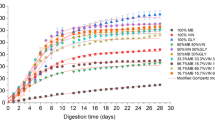

3.3 Yields and kinetics of microalgae grown on acetate

The aim of this section is to compare the growth kinetics and yields of various microalgae using acetate as substrate. A comprehensive overview of the updated available information is reported in Table 2, 3, 4 and 5. It is important to note that, despite in the scientific literature there are hundreds of studies involving microalgae cultivation in media containing acetate, only a few of them have estimated kinetics and yield parameters. Therefore, the comparison of parameters in the following tables should be approached carefully due to variations in the experimental setup among these studies, limiting the possibility to make strong general conclusions.

In a batch reactor, the heterotrophic growth of microalgae on acetate can be described by the following system of differential equations:

With µ the specific growth rate, which is function of acetate concentration (S) in the culture media. The term YX/S is the biomass yield on acetate (dX/dS). Biomass yield (YX/S) represents an expression of the efficiency of acetate conversion into microalgal biomass and can be expressed in g g−1 or Cmol-X Cmol S−1 (with the latter often calculated assuming 50% carbon content in the microalgal biomass). In some cases, an additional term m is included in the expression to predict the consumption of substrate not associated with biomass production (Chen and Johns 1996a).

The Monod model (Eq. 13) had been commonly used to describe the dependence of µ on acetate (S) (Endo et al. 1977; Turon et al. 2015a)

where µmax is the maximum specific growth rate and KS is the Monod half-saturation constant. The Monod model does not account for inhibitory phenomena, for which the Haldane Model (Eq. 14) has been typically employed. It has been applied to different microorganisms, including microalgae (Andrews 1968; Chen and Johns 1994; Shoener et al. 2019).

The Haldane model represents a modification of the Monod model, to which an inhibition term from substrate is added. The term \({K}_{i}\) is the inhibition constant, a number representing the highest substrate concentration to obtain a specific growth rate equal to one-half of the maximum specific growth rate obtained in absence of inhibition. When applied to acetate and microalgae this model has been generally used at a fixed pH, without distinguishing between CH3COOH and CH3COO− forms (Chen and Johns 1994), despite CH3COOH being the main inhibitory species. When the Monod model is applied, µmax can be achieved by working at S > > KS. However, in the case of substrate inhibition, the inhibitory effect can hinder the achievement of the expected µmax. In presence of a substrate that inhibits the growth, it is possible to calculate the maximum attainable specific growth rate (\({\upmu }_{{\text{max}},{\text{i}}}\)) by Eq. 15.

The acetate concentration at which \({\mu }_{max,i}\) is attained can be calculated by Eq. 16.

Through these equations, it is possible to obtain a quantitative assessment and prediction of the kinetic behavior of microalgae cultivated in the presence of acetate, making it feasible to design a process to maximize biomass productivity.

Several microalgal species can grow using acetate as substrate for heterotrophic metabolism. Green algae belonging to the genera Scenedesmus, Chlorella, Haematococcus and Chlamydomonas have been more widely studied (Table 2). Under heterotrophic conditions, the highest maximum specific growth rate (µmax) have been reported for C. sorokiniana (5.9 d−1, td = 2.8 h) and C. regularis (6.72 d−1, td = 2.5 h) at 35 °C and 37 °C, respectively. H. pluvialis is the species for which the lowest heterotrophic µmax values were reported, ranging between 0.05 and 0.25 d−1 at temperature between 16 and 33 °C (Table 2). For each microorganism, µ is a function of parameters such as temperature and pH. The effect of temperature on heterotrophic growth on acetate of C. sorokiniana showed an increment of the µmax from 2.2 to 5.9 d−1 for a temperature increment from 25 to 35 °C (Turon et al. 2015b). For H. pluvialis, a temperature increment from 16 to 25 °C increased the µmax from 0.07 to 0.21 d−1, while a reduction was observed for higher temperatures (Hata et al. 2001). Only for H. pluvialis data on the effect of pH on heterotrophic growth were found (Table 2), with an increase of µmax as pH increased from 6.14 to 7.85, and a decrease at higher pH values (Hata et al. 2001). In other studies, the effect of pH was not investigated, and it was usually maintained constant at values between 6.5 and 7.2 (Table 2).

The Monod semi-saturation constant (KS) for acetate was determined in only a few papers, with values ranging from 0.085 to 2.1 mM (Table 2).

The Haldane model has rarely been used to describe growth of microalgae on acetate. However, for C. reinhardtii it was crucial to describe the substrate-dependent inhibition observed for Ctot > 0.4 g L−1 (6.7 mM) at pH 6.9, as the drop in the µ at high acetate concentration could not be predicted by the Monod model (Chen and Johns 1994). The \({{\text{S}}}_{{\text{max}},{\text{i}}}\) has been calculated only for C. reinhardtii, which, to the best of our knowledge, is the only strain for which both KS and Ki are reported in the literature. It corresponds to 0.25 g L−1 (4.1 mM), at pH 6.9. Despite the high interest on using acetate as substrate for microalgae, it is a remarkable gap that only one study has reported values for KS and Ki, which are two important parameters to determine the optimal acetate concentration and acetate feeding strategy. Moreover, it would be more reasonable to obtain these values directly for the undissociated form (CH3COOH), which is the main species that induces inhibition, and for which the concentration can be adjusted by selecting an adequate pH and Ctot (Fig. 3).

The YX/S is usually fixed as a constant value in microalgae modelling; however, it can even change as a function of acetate concentration, due to inhibition and as a consequence of substrate consumption for maintenance. For C. reinhardtii, a reduction in the YX/S from 0.51 to 0.13 g g−1 was reported when Ctot was increased from 0.29 to 3.30 g L−1 (Chen and Johns 1994), likely due to inhibition given by CH3COOH at higher Ctot. Reductions in the yields have been even observed in yeasts like S. cerevisiae and Candida (Men Chung Tseng and Wayman 1975). The Pirt model (Eq. 17) was used to determine the variation of the YX/S as a consequence of substrate consumption for maintenance, without considering substrate inhibition.

where Yg represents the true yield for biomass synthesis. For C. reinhardtii, the maintenance term m was estimated to be 0.011 g g−1 h−1 (Chen and Johns 1996a). The Pirt model works better in CSTR because lower acetate concentrations can be maintained. To take into account the YX/S variation due to acetate inhibition, the Eqs. 18 and 19 have been proposed for microalgae (Chen and Johns 1994).

The YX/S value reported in heterotrophic conditions vary between 0.13 and 0.55 g g−1 and between 0.38 and 0.64 Cmol,X Cmol,S−1, for C. reinhardtii and C. sorokiniana (Table 2). The constants α and β need to be experimentally determined (Chen and Johns 1996a). Models that incorporate the effects of substrate inhibition are more adequate for batch cultivation, as higher substrate concentrations are employed (Chen and Johns 1996a).

Acetate has been more frequently used in mixotrophy, as this cultivation mode could allow higher yields and growth rates than heterotrophy (Table 2,3 4 and 5). Moreover, certain species like Phaeodactylum tricornutum cannot grow without light due to the absence of substrate transporters (Zaslavskaia 2001). In mixotrophy, the highest µmax is reported for C. sorokiniana at 35 °C (5.6 d−1, td = 2.9 h) (Table 3).

Under mixotrophic conditions, growth rate can be enhanced by the parallel activity of photosynthesis and acetate uptake, providing both energy and carbon to the metabolic pathways essential for algal growth. To confirm this, µmax must be determined for the same strain in photoautotrophic, mixotrophic and heterotrophic conditions. Different studies have compared these conditions (Table 4). In all these studies, the highest µmax was observed in mixotrophy. For four of them, for C. sorokiniana, T. obliquus, C. regularis and H. pluvialis, µmax in mixotrophy (µmax,mixo) was approximately equal to the sum of µmax in sole phototrophic (µmax,photo) and heterotrophic (µmax,hetero) condition (µmax,mixo = µmax,photo + µmax,hetero). Further evidence for additive pathways was provided by experiments in which dichlorophenyl-dimethylurea (DCMU) was added. DCMU is a specific inhibitor of photosystem II. When DCMU was added to mixotrophic cultivations, the growth rate dropped to the same value attained in heterotrophic conditions (Kobayashi et al. 1992; Turon et al. 2015b).

The µmax,hetero is usually comparable to µmax,photo, consequently µmax,mixo is close to being double (Table 4). In different studies, the experimentally measured µmixo was below the sum µmax,photo + µmax,hetero. This is likely due to light and CO2 limitations in the mixotrophic experimental setup that make µphoto < µmax,photo. In other cases it is even possible that µmixo > µphoto + µhetero, when µphoto is measured in CO2-limited conditions and does not correspond to µmax,photo. In this case, the CO2 releases by acetate oxidation in mixotrophic condition can increase the photosynthetic activity (Pessi et al. 2023). The best way to account for light and CO2 dependence is to use models to determine µphoto from the light and CO2 supply rate provided to the reactor, including factors as reactor geometry and biomass concentration, as explained in detail in previous works (Lee et al. 2015). Even if mixotrophy can allow for higher µmax, the observed µ can quickly drop as the increase in biomass concentration starts to limit light penetration, making µmixo ⁓ µhetero.

In some studies, detailed metabolic models have been used. The mixotrophic growth of Chlorella was modelled in a metabolomic model that includes 188 reactions and 173 metabolites to describe heterotrophic and mixotrophic growth on acetate and other organic substrates, allowing the prediction of results from several experimental studies (Pessi et al. 2023). However, such a model required the estimation of 16 different kinetic parameters and needs further improvements to include the effect of relevant factors such as pH and T.

Mixotrophy allows to obtain better results even for the biomass yield on acetate (YX/S), as compared to heterotrophy. Indeed, coupling phototrophy and heterotrophy enables the recycling of CO2 released from acetate catabolism, fixing it through photosynthesis. In closed photobioreactors where acetate has been supplied as the sole carbon source to C. sorokiniana, without any gas exchange, the released CO2 was completely converted into biomass by the photosynthetic pathway, obtaining CmolX CmolS−1 = 0.94 (Abiusi et al. 2020). Besides CO2 recycling, mixotrophic growth can make cells independent from acetate for energy generation (provided by photosynthesis), directing a large portion of carbon from acetate towards biomass (Boyle and Morgan 2009).

In many studies, the yield on acetate in mixotrophic cultivation has been calculated without distinguish between C provided by CO2 and C provided by acetate (Lacroux et al. 2022, 2021). Such studies reported yields > 1 because the carbon from the additional fed CO2 was not subtracted from the calculation of the yield. This type of calculation is not recommended because it does not allow the determination of how much of the carbon in the biomass came from acetate and how much came from CO2. Due to this uncertainty, these yields were not included in Table 3. To eliminate the CO2 contribution from the C-yield, different methods have been used, such as subtracting the carbon from CO2 fixation determined from a phototrophic control test (Turon et al. 2015b), using acetate as the sole C source (Abiusi et al. 2020), or employing chemicals to selectively inhibit photosynthetic activity (Kobayashi et al. 1992; Turon et al. 2015b). Similar to heterotrophy, in mixotrophy, growth parameters such as µmax and YX/S can strongly vary when factors such as temperature, pH and acetate concentration change. For example, in mixotrophic conditions, the µmax of C. sorokiniana increased from 4.14 ± 0.35 to 5.65 ± 0.55 d−1 with an increase in temperature from 25 to 35 °C (Turon et al. 2015b). The effect of pH on mixotrophic growth with acetate was tested on different species, finding that pH 7.0 is the optimal value, while cell growth is reduced in the pH range from 6 to 9, and it is completely inhibited at pH 5 and pH 10 (Lacroux et al. 2020). As we mentioned in the previous paragraph, pH must be efficiently controlled to avoid too high CH3COOH concentration, but the inhibition threshold of CH3COOH can even change depending on the pH (Lacroux et al. 2020). Biomass productivity represents a crucial factor in microalgal bioprocesses. Limited biomass productivity is considered a major challenge affecting the economical sustainability of microalgae cultivation in photoautotrophic conditions, mainly due to limited light penetration inside reactors (Ruiz et al. 2016). The organic carbon provided by acetate can sustain cell growth independently of light supply, significantly enhancing biomass productivity compared to light dependent growth. Mixotrophic conditions can improve biomass productivity (rX) compared to phototrophic conditions, due to the increase in µmax (µmax,mixo = µmax,photo + µmax,hetero) and the reduced dependence of µ on light (Table 4). The highest rX found in mixotrophy is 2.74 g L d−1, for C. sorokiniana SAG 211/8 K, which is + 85% the rX of the same strain in phototrophic condition (Abiusi et al. 2020). Unfortunately, the comparison of rX for the same strains in the three configurations was rarely reported. There is also limited data on microalgal biomass productivity in heterotrophy with acetate. Despite the scarcity of data, a much higher rX is expected for heterotrophic cultivations than those reported for phototrophic and mixotrophic conditions since, in heterotrophy, the growth rate is light-independent and high growth rate can be maintained even at high biomass concentration. Indeed, for C. sorokiniana and Scenedesmus acuminatus cultivated on glucose, productivities up to 73 and 91 g L−1 d−1 have been reported, respectively (Jin et al. 2021a, 2020). Similar values are expected to be achievable even with acetate by implementing an appropriate fed-batch feeding to avoid substrate inhibition.

Since one of the main expected advantages of acetate utilization is the replacement of the conventional and costly glucose as organic substrate, it is useful to compare acetate with glucose in terms of efficiency for microalgae utilization (Barbosa et al. 2023; Ruiz et al. 2022). Acetate and glucose have the same C content (40% by mass). Glucose oxidation produces 2.8 kJ mol−1, while acetate oxidation produces 0.8 kJ mol−1. In terms of metabolic energy yield, 1 mol of acetate produces 9 ATP, while 1 mol of glucose is expected to produce between 29 and 32 ATP (Flurkey 2010). When normalized for mass, these values become quite comparable; indeed, they correspond to 0.15 ATP g−1 for acetate and 0.16–0.18 ATP g−1 for glucose. Therefore, acetate is expected to have a biomass to substrate mass yield about 6–17% lower than glucose, which is in agreement with experimental data obtained in heterotrophy (Table 5). However, to the best of our knowledge, only one study available in the current literature actually measured the yield obtained for both glucose and acetate utilization (Patel et al. 2022). More experimental data would be needed to make more reliable comparisons.

For what concerns kinetic parameters, when µmax was estimated under comparable experimental conditions for both acetate and glucose, the values found for acetate were typically between 4 and 37% lower than for glucose (Table 5).

These data indicate that acetate is a promising substrate for the development of mixotrophic and heterotrophic processes at an industrial scale. It can maintain productivity and yields comparable to conventional glucose, with the added advantage to be produced through different processes that can be less expensive and more integrable within a sustainable circular economy framework.

In general, the preliminary critical analysis presented here indicates that acetate could efficiently replace conventional sugars like glucose in both heterotrophy and mixotrophy under properly designed processes for microalgae cultivations.

4 Two-phase processes: acetate synthesis—microalgae cultivation

As we presented in the previous paragraphs, there are various ways to produce acetate from different sources such as various biomasses, wastes, by-products, gases and petroleum sources. Methanol carbonylation is the conventional process currently employed for producing acetate from fossil sources, contributing to increased GHG emissions. Pure acetate can be used in every kind of process configuration, and its utilization will not be discussed here since the main focus of this work is to describe and discuss the utilization of acetate obtained from alternative processes.