Abstract

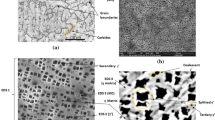

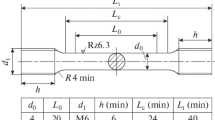

Turbine blades and vans operated in an aggressive gas environment usually suffer from combined oxidation and cycle loading effects. The surface oxide layer will result in premature failure and lead to a significant reduction in the service lifetime. The effects of prior oxidation-induced damage under a simulated combustion-gas environment on the fatigue lifetime of the directionally solidified (DS) nickel-based superalloy DZ125 with and without an oxidation-resistant coating were presented. The fatigue lifetime of uncoated samples is adversely affected by prior oxidation exposure. The deterioration of fatigue lifetime in uncoated samples is associated with surface microstructural degradation, which occurs during prior exposure. However, the presence of MCrAlY coating is beneficial for the sample’s lifetime under high stress. Further scanning electron microscopy (SEM) analysis demonstrates that the coating does not contribute to the initiation mode of fatigue cracks.

Similar content being viewed by others

References

Li J, Wang HM. Microstructure and mechanical properties of rapid directionally solidified Ni-base superalloy René 41 by laser melting deposition manufacturing. Mater Sci Eng A. 2010;527(18–19):4823.

Pollock TM, Tin S. Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propuls Power. 2006;22(2):361.

Huang J, Shi DQ, Yang XG. A physically based methodology for predicting anisotropic creep properties of Ni-based superalloys. Rare Met. 2016;35(8):606.

Li FL, Fu R, Feng D, Tian ZL. Hot workability characteristics of Rene88DT superalloy with directionally solidified microstructure. Rare Met. 2015;34(1):51.

Shi DQ, Hu XA, Wang JK, Yu HC, Yang XG, Huang J. Effect of notch on fatigue behaviour of a directionally solidified superalloy at high temperature. Fatigue Fract Eng Mater Struct. 2013;36(12):1288.

Xie G, Zhang J, Lou LH. Effect of heat treatment atmosphere on surface recrystallization of a directionally solidified Ni-base superalloy. Scr Mater. 2008;59(8):858.

Jo CY, Cho HY, Kim HM. Effect of recrystallisation on microstructural evolution and mechanical properties of single crystal nickel base superalloy CMSX-2. Part 1-Microstructural evolution during recrystallisation of single crystal. Mater Sci Technol. 2003;19(12):1665.

Gordon AP, Neu RW, McDowell DL. Effect of pre-exposure on crack initiation lifetime of a directionally solidified Ni-base superalloy. Int J Fatigue. 2009;31(12):393.

Gordon AP. Crack initiation modeling of a directionally-solidified nickel-base superalloy. Atlanta: Georgia Institute of Technology; 2006. 25.

Kupkovits RA, Neu RW. Thermomechanical fatigue of a directionally-solidified Ni-base superalloy: smooth and cylindrically-notched specimens. Int J Fatigue. 2010;32(8):1330.

Findley KO, Evans JL, Saxena A. A critical assessment of fatigue crack nucleation and growth models for Ni-and Ni, Fe-based superalloys. Int Mater Rev. 2011;56(1):49.

Kupkovits RA. Thermomechanical fatigue behavior of the directionally-solidified nickel-base superalloy CM247LC. Atlanta: Georgia Institute of Technology; 2009. 18.

Neu RW, Sehitoglu H. Thermomechanical fatigue, oxidation, and creep: part II. Life prediction. Metall Trans A. 1989;20(9):1769.

Rezai-Aria F, Rémy L. An oxidation fatigue interaction damage model for thermal fatigue crack growth. Eng Fract Mech. 1989;34(2):283.

Hou NX, Yu QM, Wen ZX, Yue ZF. Low cycle fatigue behavior of single crystal superalloy with temperature gradient. Eur J Mech A Solids. 2010;29(4):611.

Yu J, Li JR, Zhao JQ, Han M, Shi ZX, Liu SZ, Yuan HL. Orientation dependence of creep properties and deformation mechanism in DD6 single crystal superalloy at 760 °C and 785MPa. Mater Sci Eng A. 2013;560(1):47.

Shi D, Liu J, Yang X, Qi H, Wang J. Experimental investigation on low cycle fatigue and creep–fatigue interaction of DZ125 in different dwell time at elevated temperatures. Mater Sci Eng A. 2010;528(1):233.

Xia P, Yang L, Yu J, Sun X, Guan H, Hu Z. Influence of direction of notch on thermal fatigue property of a directionally solidified nickel base superalloy. Rare Met. 2011;30(1):472.

Yuen A, Leverant GR. Fatigue crack propagation in two classes of directionally solidified eutectic alloys. Metall Trans A. 1976;7(9):1443.

Lin YC, Chen XM, Wen DX, Chen MS. A physically-based constitutive model for a typical nickel-based superalloy. Comput Mater Sci. 2014;83(2):282.

Alam MZ, Satyanarayana DVV, Chatterjee D, Sarkar R, Das DK. Effect of prior cyclic oxidation on the creep behavior of directionally solidified (DS) CM-247LC alloy. Mater Sci Eng A. 2012;536(3):14.

Jeong HW, Seo SM, Choi BG, Yoo YS, Ahn YK, Lee JH. Effect of long-term thermal exposures on microstructures and mechanical properties of directionally solidified CM247LC alloy. Met Mater Int. 2013;19(5):917.

Alam MZ, Chatterjee D, Venkataraman B, Varma VK, Das DK. Effect of cyclic oxidation on the tensile behavior of directionally solidified CM-247LC Ni-based superalloy at 870 °C. Mater Sci Eng A. 2010;527(23):6211.

Nicholls JR. Advances in coating design for high-performance gas turbines. MRS Bull. 2003;28(9):659.

Itoh Y, Saitoh M, Ishiwata Y. Influence of high-temperature protective coatings on the mechanical properties of nickel-based superalloys. J Mater Sci. 1999;34(16):3957.

Naumenko D, Shemet V, Singheiser L, Quadakkers WJ. Failure mechanisms of thermal barrier coatings on MCrAlY-type bondcoats associated with the formation of the thermally grown oxide. J Mater Sci. 2009;44(7):1687.

Xie Y, Yang Y, Wang M, Hou J. MCrAlY/TaC metal matrix composite coatings produced by electrospark deposition. Acta Metall Sin. 2013;26(2):173.

Hejrani E, Sebold D, Nowak WJ, Mauer G, Naumenko D, Vassen R, Quadakkers WJ. Isothermal and cyclic oxidation behavior of free standing MCrAlY coatings manufactured by high-velocity atmospheric plasma spraying. Surf Coat Technol. 2017;313(3):191.

Kowalewski R, Mughrabi H. Influence of a plasma-sprayed NiCrAlY coating on the low-cycle fatigue behaviour of a directionally solidified nickel-base superalloy. Mater Sci Eng A. 1998;247(1):295.

Yang X, Li S, Qi H. Effect of high-temperature hot corrosion on the low cycle fatigue behavior of a directionally solidified nickel-base superalloy. Int J Fatigue. 2015;70(1):106.

Antolovich SD, Baur R, Liu S. A mechanistically based model for high temperature LCF of Ni base superalloys. In: Proceedings of the Fourth International Symposium on Superalloys, Pennsylvania; 1980. 605.

Acknowledgements

This study was financially supported by National Basic Research Program of China (No. 2015CB057401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, SL., Qi, HY. & Yang, XG. Oxidation-induced damage of an uncoated and coated nickel-based superalloy under simulated gas environment. Rare Met. 37, 204–209 (2018). https://doi.org/10.1007/s12598-017-0931-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0931-8