Abstract

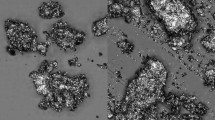

The effect of the thermally grown oxide (TGO) formation on the lifetime of the thermal barrier coatings (TBC) with MCrAlY-bondcoats (BC) is reviewed. A number of factors affecting the TGO-formation and TBC-failure are discussed including the coating microstructure, geometrical (coating roughness and thickness) and processing parameters. Under given testing conditions for a specific EB-PVD-TBC-system forming a flat, uniform alumina TGO a critical TGO-thickness for TBC-failure can be defined. This TGO-morphology is, however, not necessarily optimum for obtaining long TBC-lifetime, which can be extended by formation of TGO’s with an uneven TGO/BC interface. In contrast, APS-TBC-systems are prone to formation of intrinsically inhomogeneous TGO-morphologies. This is attributed to non-uniform depletion of Y and Al underneath rough MCrAlY-surfaces as well as due to the commonly observed repeated-cracking/re-growth of the TGO during temperature cycling. The latter phenomenon depends on the exposure temperature and the mechanical properties of the APS-TBC. In both types of TBC-systems the TGO-formation and TBC-lifetime appear to be very sensitive to the manufacturing parameters, such as vacuum quality during bondcoat spraying and temperature regime of the bondcoat vacuum heat-treatment.

Similar content being viewed by others

References

Goward GW (1998) Surf Coat Technol 108–109(1–3):73

Gleeson B (2006) J Propul Power 22–2:375

Evans AG, Mumm DR, Hutchinson JW, Meier GH, Pettit FS (2001) Prog Mater Sci 46:505

Quadakkers WJ, Tyagi AK, Clemens D, Anton R, Singheiser L (1999) In: Hampikian JM, Dahotre NB (eds) Elevated temperature coatings: surface and technology III. The Minerals, Metals & Materials Society, pp 119–130

Niranatlumpong P, Ponton CB, Evans HE (2000) Oxid Met 53(3–4):241

Busso EP, Wright L, Evans HE et al (2007) Acta Mater 55:1491

Tolpygo VK, Clarke DR, Murphy KS (2001) Surf Coat Technol 146–147:124

Evans HE, Strawbridge A, Carolan RA, Ponton CB (1997) Mater Sci Eng A 225:1

Quadakkers WJ, Shemet V, Sebold D, Anton R, Wessel E, Singheiser L (2005) Surf Coat Technol 199(1):77

Janakiraman R, Meier GH, Pettit FS (1999) Metall Mater Trans A 30:2905

Pint BA (2003) J Amer Ceram Soc 86(4):686

Nijdam TJ, Marijnissen GH, Vergeldt E, Kloosterman AB, Sloof WG (2006) Oxid Met 66:269

Schulz U, Menzebach M, Leyens C, Yang YQ (2001) Surf Coat Technol 146–147(5/6):117

Subanovic M, Sebold D, Vassen R, Wessel E, Naumenko D, Singheiser L, Quadakkers WJ (2008) Mater Corros 59(6):463

Wessel E, Kochubey V, Naumenko D, Niewolak L, Singheiser L, Quadakkers WJ (2004) Scripta Mater 51(10):987

Mercer C, Faulhaber S, Yao N, McIlwrath K, Fabrichnaya O (2006) Surf Coat Technol 201:1495

Evans AG, Crumley GB, Demaray RE (1983) Oxid Met 20(5/6):193

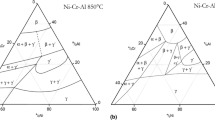

Naumenko D, Gleeson B, Wessel E, Singheiser L, Quadakkers WJ (2007) Metall Mater Trans 38A:2974

Hsueh CH, Haynes JA, Lance MJ et al (1999) J Amer Ceram Soc 82(4):1073

Tang F, Schoenung J (2005) Scripta Mater 52:905

Ahrens M, Vaßen R, Stoever D (2002) Surf Coat Technol 161:26

Trunova O, Beck T, Herzog R, Steinbrech RW, Singheiser L (2008) Surf Coat Technol 202:5027

Fox P, Tatlock GJ (1989) Mater Sci Technol 5:816

Czech N, Schmitz F, Stamm W (1994) Surf Coat Technol 68–69:17

Massalski TB (1996) ASM binary alloy phase diagrams. ASM International, Materials Park, OH

Achar DRG, Munoz-Arroyo R, Singheiser L, Quadakkers WJ (2004) Surf Coat Technol 187:272

Muñoz-Arroyo R, Clemens D, Tietz F, Anton R, Quadakkers J, Singheiser L (2001) Mater Sci Forum 369–372:165

Täck U (2004) The influence of cobalt and rhenium on the behaviour of MCrAlY coatings (PhD thesis) Tech. Univ. Freiberg 25:151, 169

Toscano J, Gil A, Hüttel T, Wessel E, Naumenko D, Singheiser L, Quadakkers WJ (2007) Surf Coat Technol 202:603

Lechner C, Seume J (eds) (2003) Stationaere Gasturbinen. Springer-Verlag, Berlin Heidelberg, Germany, p 749

Jansson B, Schalin M, Selleby M, Sundaman B (1993) In: Bale CW, Irins GA (eds) Computer software in chemical and extractive metallurgy. Canadian Institute of Metals, Quebec, p 57

Saunders N (2000) Ni-DATA information. Thermotech Ltd., Surrey Technology Centre, Surrey, UK

Echsler H, Renusch D, Schütze M (2004) Mater Sci Technol 20:307

Quadakkers WJ, Holzbrecher H, Briefs KG, Beske H (1989) Oxid Met 32(12):67

Pint BA, Martin JR, Hobbs LW (1993) Oxid Met 39:167

Reddy KPR, Smialek JL, Cooper AR (1982) Oxid Met 17(5/6):429

Karadge M, Zhao X, Preuss M, Xiao P (2006) Scripta Mater 54:639

Toscano J, Wessel E, Vassen R, Naumenko D, Singheiser L, Quadakkers WJ (2008) Mater Corros 59(6):501

Kofstad P (1988) High temperature corrosion. Elsevier, London

Yanar NM, Pettit FS, Meier GH (2006) Metall Mater Trans 37A:1563

Gil A, Shemet V, Vassen R, Subanovic M, Toscano J, Naumenko D, Singheiser L, Quadakkers WJ (2006) Surf Coat Technol 201:3824

Toscano J, Vaßen R, Gil A, Subanovic M, Naumenko D, Singheiser L, Quadakkers WJ (2006) Surf Coat Technol 201:3906

Nijdam TJ, Sloof WG (2008) Oxid Met 69:1

Gudmundsson B, Jacobson BE (1989) Thin Solid Films 173(1):99

Nijdam TJ, Jeurgens LPH, Chen JH, Sloof WG (2005) Oxid Met 64(5/6):355

Schulz U, Bernardi O, Ebach-Stahl A et al (2008) Surf Coat Technol 203:160

Lau H, Leyens C, Schulz U, Friedrich C (2003) Surf Coat Technol 165:217

Davis JR (ed) (1997) Heat resistant materials, ASM specialty handbook. ASM International, Materials Park, OH, p 305

Ajdelsztajn L, Hulbert D, Mukherjeea A, Schoenung JM (2007) Surf Coat Technol 201:9462

Wasilkowska A, Bartsch M, Messerschmidt U et al (2003) J Mater Process Technol 133:218

Acknowledgements

The authors are grateful to the following colleagues in the Institute for Energy Research of the Forschungszentrum Jülich for assistance in the materials procurement and experimental work: R. Vassen, K·H. Rauwald, H. Cosler, E. Wessel, M. Subanovic, and J. Toscano. Part of the present work was funded by the German Research Foundation (Grant No. NA-615-1) and German federal ministry for economy and technology (Grant No. 0326888D).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Naumenko, D., Shemet, V., Singheiser, L. et al. Failure mechanisms of thermal barrier coatings on MCrAlY-type bondcoats associated with the formation of the thermally grown oxide. J Mater Sci 44, 1687–1703 (2009). https://doi.org/10.1007/s10853-009-3284-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3284-3