Abstract

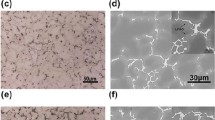

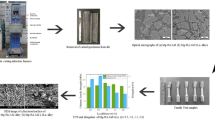

The study investigates the effects of individual and combined additions of gadolinium (Gd) and misch metal (MM) on the microstructure and mechanical properties of Mg–4Al and Mg–9Al alloys. The results show that the additions significantly alter the microstructure and grain size of the base alloys. Mg–4Al based alloys have globular morphology, whereas Mg–9Al based alloys have dendritic morphology. The addition of alloying elements, Gd and MM, introduces rectangular-shaped Al2Gd phase and needle-shaped Al11RE3 phase, respectively. The best mechanical properties at room temperature are shown by Mg–9Al–2Gd alloy with tensile strength and elongation of 214 MPa and 6.0%, respectively, whereas Mg–4Al–2Gd alloy exhibits the best properties at elevated temperature (150 °C) with tensile strength and elongation of 172 MPa and 14.0%, respectively. The study also reports the microhardness value of different phases along with the cast alloys. Eutectic Mg17Al12 phase shows the highest hardness (VHN 92) followed by lamellar Mg17Al12 (VHN 83) and α-Mg matrix (VHN 68).

Similar content being viewed by others

References

Asl KM, Tari A, Khomamizadeh F. The effect of different content of Al, RE and Si element on the microstructure, mechanical and creep properties of Mg–Al alloys. Mater Sci Eng A. 2009;523(1–2):1.

Saidpour H. Lightweight High Performance Materials for Car Body Structures. In: NTI Technology Conference, London, 2004:14.

Mustafa KK. Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol. 2008;39(9):851.

Xiaoquin Z, Quodong W, Yizhen L, Yanping Z, Wenjiang D, Yunhu Z. Influence of beryllium and rare earth additions on ignition-proof magnesium alloys. J Mater Proc Tech. 2001;112(1):17.

Friedrich H, Schumann S. Research for a “new age of magnesium” in the automotive industry. J Mater Proc Technol. 2001;17(3):276.

Yong YI, Yongge F, Yongjian T. Effect of lanthanum-praseodymium-cerium mischmetal on mechanical properties and microstructure of Mg–A1 alloys. J Wuhan Univ Technol. 2011;26(1):102.

Wang J, Shi N, Wang L, Cao Z, Wang L, Li J. Effect of zinc and mischmetal on microstructure and mechanical properties of Mg–Al–Mn alloy. J Rare Earth. 2010;28(5):794.

Zhang J, Liu S, Leng Z, Zhang M, Meng J, Wu R. Microstructures and mechanical properties of heat-resistant HPDC Mg–4Al-based alloys containing cheap misch metal. Mater Sci Eng A. 2011;528(6):2670.

Rzychon T, Kielbus A. Effect of rare earth elements on the microstructure of Mg–Al alloys. JAMME. 2006;17(1–2):149.

Xue S, Sun YS, Ding SS, Bai Q, Bai J. Effects of calcium additions on microstructure and creep behaviour of AE42 alloy. Mater Sci Technol. 2008;21(7):847.

Luo A. Recent magnesium alloy development for elevated temperature applications. Int Mater Rev. 2004;49(1):13.

Li KJ, Li QA, Jing XT, Chen J, Zhang XY. Effects of Sb, Sm, and Sn additions on the microstructure and mechanical properties of Mg–6Al–1.2Y–0.9Nd alloy. Rare Met. 2009;28(5):516.

Wang QD, Peng JG, Michel S, Blandin JJ. Effects of aging on the microstructures and mechanical properties of extruded AM50 + xCa magnesium alloys. Rare Met. 2006;25(4):377.

Cizek J, Prochazka I, Smola B, Stulikova I, Ocenasek V. Influence of deformation on precipitation process in Mg–15 wt%Gd alloy. J Alloys Compd. 2007;430(1–2):92.

Wang X, Du W, Liu K, Wang Z, Li S. Microstructure, tensile properties and creep behaviors of as-cast Mg–2Al–1Zn–xGd (x = 1, 2, 3, and 4 wt%) alloys. J Alloys Compd. 2012;522:78.

Dargusch MS, Pettersen K, Nogita K, Nave MD, Dunlop GL. The effect of aluminium content on the mechanical properties and microstructure of die cast binary magnesium–aluminium alloys. Mater Trans. 2006;47(4):977.

Dahle AK, Lee YC, Nave MD, Schaffer PL, StJohn DH. Development of the As-cast microstructure in magnesium–aluminium alloys. J Light Met. 2001;1:61.

Ma YT, Zhang XG, Liu HB, Meng LG. Effects of Er on the microstructure and properties of AZ31 magnesium alloy prepared via the EMS process. Rare Met. 2010;29(4):339.

Peng QM, Wu YM, Fang DQ, Meng J, Wang LM. Microstructures and properties of Mg–7Gd alloy containing Y. J Alloys Compd. 2007;430(1–2):252.

Rokhlin LL, Dobatkina TV, Nikitina NI. Constitution and properties of the ternary magnesium alloys containing two rare-earth metals of different subgroups. Mater Sci Forum. 2003;419:291.

Lee YC, Dahle AK, StJohn DH. The role of solute in grain refinement of magnesium. Metall Mater Trans A. 2000;3(11):2895.

Luo A. Understanding the solidification of magnesium alloys. In: Third International Magnesium Conference. (Eds. G.W. Lorimer), Manchester, UK. 1996. 449.

Reed-Hill RE. Physically Metallurgy Principles. 2nd ed. New York: Litton Educational Publishing; 2008.

Qiu D, Zhang MX. Effect of active heterogeneous nucleation particles on the grain refining efficiency in an Mg–10 wt% Y cast alloy. J Alloys Compd. 2009;488(1):260.

Gharghouri MA, Weatherly GC, Embury JD. The interaction of twins and precipitates in a Mg–7.7at.% Al alloy. Philos Mag A. 1998;78(5):1137.

Mahmudi R, Kabirian F, Nematollahi Z. Microstructural stability and high-temperature mechanical properties of AZ91 and AZ91 + 2RE magnesium alloys. Mater Des. 2011;32(5):2583.

Mordike BL, Ebert T. Magnesium: properties—applications—potential. Mater Sci Eng A. 2001;302(1):37.

Regev M, Aghoin E, Rosen A, Bamberger M. Creep studies of coarse-grained AZ91D magnesium castings. Mater Sci Eng A. 1998;252(1):6.

Caceres CH, Davidson CJ, Griffiths JR, Newton CL. Effects of solidification rate and ageing on the microstructure and mechanical properties of AZ91 alloy. Mater Sci Eng A. 2002;325(1–2):344.

Dieter GE. Mechanical Metallurgy. 3rd ed. London: McGraw-Hill Book Company; 1986. 182.

Hultgren R, Mitchell DW. Grain refinement of magnesium alloys without superheating. Trans AIME. 1945;161:323.

Fleischer RL. Solution hardening. Acta Metall. 1961;9(11):996.

Labusch R. A statical theory of solid solution hardening. Phys Status Solidi B. 1970;41(2):659.

Guo X, Li P, Zeng DJ. Electron theory research in Mg–Y Alloy. Chin Rare Earth Soc. 2003;21(6):672.

Ardell AJ. Precipitation hardening. Metall Mater Trans A. 1985;16(12):2131.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, L.K., Joseph, P., Srinivasan, A. et al. Microstructure and mechanical properties of gadolinium- and misch metal-added Mg–Al alloy. Rare Met. 41, 3205–3213 (2022). https://doi.org/10.1007/s12598-017-0928-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0928-3