Abstract

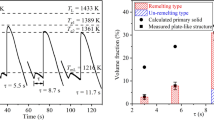

The solidification behavior of Ti–48Al–8Nb alloy under nonequilibrium solidification conditions was studied by electromagnetic levitation technique. The solidification conditions are different undercooling (ΔT) under the same cooling condition and different cooling methods at the same undercooling condition, respectively. In different undercooling conditions, when the undercooling is above a critical value (ΔT* ≈ 211 K), a remarkable morphological transition from typical hypoperitectic solidification to a sole solidification of the β phase resulting in the suppression of the peritectic reaction occurs. For melts with different cooling conditions at the same undercooling (ΔT ≈ 85 K), the melt was rapidly cooled by quenching them in cooling media. With cooling rate increasing, a transition from β phase to peritectic α phase solidification mode is revealed for Ti–48Al–8Nb alloy.

Similar content being viewed by others

References

Lin JP, Zhao LL, Li GY, Zhang LQ, Song XP, Ye F, Chen GL. Effect of Nb on oxidation behavior of high Nb containing TiAl alloys. Intermetallics. 2011;19(2):131.

Clemens H, Mayer S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv Eng Mater. 2013;15(4):191.

Lin YZ, Fu GS, Cao R, Chen JH, Hu DW. Compression damage and fracture behaviors of γ-TiAl based alloys. Rare Met. 2014;38(2):334.

Muñoz-Moreno R, Ruiz-Navas EM, Srinivasarao B, Torralba JM. Microstructural development and mechanical properties of PM Ti–45Al–2Nb–2Mn–0.8 vol% TiB2 processed by field assisted hot pressing. J Mater Sci Technol. 2014;30(11):1145.

Liu Y, Hu R, Kou HC, Wang J, Zhang TB, Li JS, Zhang J. Solidification characteristics of high Nb-containing γ-TiAl-based alloys with different aluminum contents. Rare Met. 2015;34(6):381.

Kim YW. Ordered intermetallic alloys, part III: gamma titanium aluminides. JOM. 1994;46(7):30.

Weimer MJ, Kelly TJ. Overview of TiAl implementation at GE aviation. In: 17th Aero Mat Conference & Exposition. Washington; 2006. 15.

Huang SC. Titanium aluminum alloys modified by chromium and niobium and method of preparation. US Patent 4879092.

Li JB, Liu Y, Liu B, Wang Y, Liang XP, He YH. Microstructure characterization and mechanical behaviors of a hot forged high Nb containing PM-TiAl alloy. Mater Charact. 2014;95:148.

Tian SG, Wang Q, Yu HC, Sun HF, Li QY. Microstructure and creep behaviors of a high Nb–TiAl intermetallic compound based alloy. Mater Sci Eng, A. 2014;614:338.

Bystrzanowski S, Bartels A, Clemens H, Gerling R, Schimansky FP, Dehm G, Kestler H. Creep behaviour and related high temperature microstructural stability of Ti–46Al–9Nb sheet material. Intermetallics. 2005;13(5):515.

Liu GH, Li XZ, Su YQ, Liu DM, Guo JJ, Fu HZ. Microstructure, microsegregation pattern and the formation of B2 phase in directionally solidified Ti–46Al–8Nb alloy. J Alloys Comp. 2012;541(15):275.

Ding XF, Lin JP, Zhang LQ, Wang HL, Hao GJ, Chen GL. Microstructure development during directional solidification of Ti–45Al–8Nb alloy. J Alloys Comp. 2010;506(1):115.

Loser W, Lindenkreuz HG, Hermann R, Shuleshova O, Woodcock TG. Recalescence behaviour of binary Ti–Al and ternary Ti–Al–Nb undercooled melts. Mater Sci Eng, A. 2005; 413(SI): 398.

Zhang YK, Gao J, Kolbe M, Klein S, Yang C, Yasuda H, Herlach DM, Gandin ChA. Phase selection and microstructure formation in undercooled Co–61.8 at% Si melts under various containerless processing conditions. Acta Mater. 2013;61(13):4861.

Lapin J, Gabalcova Z, Pelachova T. Effect of Y2O3 crucible on contamination of directionally solidified intermetallic Ti–46Al–8Nb alloy. Intermetallics. 2011;19(3):396.

Chen GL, Xu XJ, Teng ZK, Wang YL, Lin JP. Microsegregation in high Nb containing TiAl alloy ingots beyond laboratory scale. Intermetallics. 2007;15(5–6):625.

Hecht U, Witusiewicz V, Drevermann A, Zollinger J. Grain refinement by low boron additions in niobium-rich TiAl-based alloys. Intermetallics. 2008;16(8):969.

Oehring M, Stark A, Paul JDH, Lippmann T, Pyczak F. Microstructural refinement of boron-containing β-solidifying γ-titanium aluminide alloys through heat treatments in the β phase field. Intermetallics. 2013;32:12.

Appel F, Oehring M. γ-Titanium Aluminide Alloys: Alloy Design and Properties. In: Peters C, Leyens M, editors. Titanium and titanium alloys. Weinheim: Wiley; 2003. 89.

Johnson DR, Chihara K, Inui H, Yamaguchi M. Microstructural control of TiAl–Mo–B alloys by directional solidification. Acta Mater. 1998;46(18):6529.

Schwaighofer E, Rashkova B, Clemens H, Stark A, Mayer S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics. 2014;46:173.

Chen YZ, Liu F, Yang GC, Liu N, Yang CL, Zhou YH. Suppression of peritectic reaction in the undercooled peritectic Fe–Ni melts. Scripta Mater. 2007;57(8):779.

Shuleshova O, Loser W, Holland-Moritz D, Herlach DM. Solidification and melting of high temperature materials: in situ observations by synchrotron radiation. J Mater Sci. 2012;47(11):4497.

Huang SC, Hall EI. The effects of Cr additions to binary TiAl-base alloys. Metall Mater Trans. 1991;22(11):2619.

Acknowledgments

This research was financially supported by the National Basic Research Program of China (No. 2011CB605503) and the 111 Project of Northwestern Polytechnical University (No. B08040).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

He, T., Hu, R., Yang, JR. et al. Transition of solidification path in nonequilibrium solidification of Ti–48Al–8Nb alloy. Rare Met. 35, 48–53 (2016). https://doi.org/10.1007/s12598-015-0630-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0630-2