Abstract

Protein-rich waste is an abundantly available resource that is currently used mainly as animal feed and fertilizers. Valorisation of protein waste to higher value products, particularly commodity chemicals such as precursors for polymers, has attracted significant research efforts. Enzyme-based approaches, being environmentallyfriendly compared to their chemical counterparts, promise sustainable processes for conversion of protein waste to valuable chemicals. This review provides a general overview on valorisation of protein waste and then further summarises the use of enzymes in different stages of the valorisation process—protein extraction and hydrolysis, separation of individual amino acids and their ultimate conversion into chemicals. Case studies of enzymatic conversion are presented for different amino acids including glutamic acid, lysine, phenylalanine, tyrosine, arginine and aspartic acid. The review compares the different enzyme reactors and operation modes for amino acid conversion. The emerging opportunities and challenges in the field are discussed: engineering powerful enzymes and integrating innovative processes for industrial application at a low cost.

Similar content being viewed by others

References

Tuck C O, Pérez E, Horváth I T, Sheldon R A, Poliakoff M. Valorization of biomass: Deriving more value from waste. Science. 2012, 337(6095): 695–699

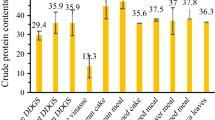

Lammens T M, Franssen M C R, Scott E L, Sanders J P M. Availability of protein-derived amino acids as feedstock for the production of bio-based chemicals. Biomass and Bioenergy. 2012, 44: 168–181

Sanders J, Scott E, Weusthuis R, Mooibroek H. Bio-refinery as the bio-inspired process to bulk chemicals. Macromolecular Bioscience. 2007, 7(2): 105–117

Nyachoti C M, House J D, Slominski B A, Seddon I R. Energy and nutrient digestibilities in wheat dried distillers’ grains with solubles fed to growing pigs. Journal of the Science of Food and Agriculture. 2005, 85(15): 2581–2586

Gunkel G, Kosmol J, Sobral M, Rohn H, Montenegro S, Aureliano J. Sugar cane industry as a source of water pollution—Case study on the situation in Ipojuca river, Pernambuco, Brazil. Water, Air, and Soil Pollution. 2007, 180(1–4): 261–269

Regulation (EC) No 1069/2009 of the European Parliament and of the Council, 21 October 2009. Laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation)

Bals B D, Dale B E. Developing a model for assessing biomass processing technologies within a local biomass processing depot. Bioresource Technology. 2012, 106: 161–169

Simon R D, Weathers P. Determination of the structure of the novel polypeptide containing aspartic acid and arginine which is found in cyanobacteria. BBA—Protein Structure. 1976, 420(1): 165–176

Obst M, Steinbüchel A. Microbial degradation of poly (amino acid)s. Biomacromolecules. 2004, 5(4): 1166–1176

Könst P M, Turras P M C C D, Franssen M C R, Scott E L, Sanders J P M. Stabilized and immobilized Bacillus subtilis arginase for the biobased production of nitrogen-containing chemicals. Advanced Synthesis & Catalysis. 2010, 352(9): 1493–1502

Yasmin A, Sadiq Butt M, Sameen A, Shahid M. Physicochemical and amino acid profiling of cheese whey. Pakistan Journal of Nutrition. 2013, 12(5): 455–459

Sari Y W, Alting A C, Floris R, Sanders J P M, Bruins M E. Glutamic acid production from wheat by-products using enzymatic and acid hydrolysis. Biomass and Bioenergy. 2014, 67: 451–459

Karr-Lilienthal L K, Grieshop C M, Spears J K, Fahey G C Jr. Amino acid, carbohydrate, and fat composition of soybean meals prepared at 55 commercial U.S. soybean processing plants. Journal of Agricultural and Food Chemistry, 2005, 53(6): 2146–2150

Latshaw J D, Musharaf N, Retrum R. Processing of feather meal to maximize its nutritional value for poultry. Animal Feed Science and Technology. 1994, 47(3–4): 179–188

Chang S K, Ismail A, Yanagita T, Esa N M, Baharuldin M T H. Biochemical characterisation of the soluble proteins, protein isolates and hydrolysates from oil palm (Elaeis guineensis) kernel. Food Bioscience. 2014, 7: 1–10

Han J, Liu K. Changes in composition and amino acid profile during dry grind ethanol processing from corn and estimation of yeast contribution toward DDGS proteins. Journal of Agricultural and Food Chemistry. 2010, 58(6): 3430–3437

Meussen B J, van Zeeland A N T, Bruins M E, Sanders J P M. A fast and accurate UPLC method for analysis of proteinogenic amino acids. Food Analytical Methods. 2014, 7(5): 1047–1055

Scott E, Peter F, Sanders J. Biomass in the manufacture of industrial products-the use of proteins and amino acids. Applied Microbiology and Biotechnology. 2007, 75(4): 751–762

Hu C, Reddy N, Luo Y, Yan K, Yang Y. Thermoplastics from acetylated zein-and-oil-free corn distillers dried grains with solubles. Biomass and Bioenergy. 2011, 35(2): 884–892

Lammens T M, Nôtre J L, Franssen M C R, Scott E L, Sanders J P M. Synthesis of biobased succinonitrile from glutamic acid and glutamine. ChemSusChem. 2011, 4(6): 785–791

Ogata K, Uchiyama K, Yamada H. Microbial formation of cinnamic acid from phenylalanine. Agricultural and Biological Chemistry. 1966, 30(3): 311–312

Schneider J, Wendisch V F. Biotechnological production of polyamines by Bacteria: Recent achievements and future perspectives. Applied Microbiology and Biotechnology. 2011, 91(1): 17–30

Schneider J, Wendisch V F. Putrescine production by engineered Corynebacterium glutamicum. Applied Microbiology and Biotechnology. 2010, 88(4): 859–868

Arifin B, Bono A, Farm Y Y, Ling A L L, Fui S Y. Protein extraction from palm kernel meal. Journal of Applied Sciences. 2009, 9(17): 2996–3004

Bals B, Teachworth L, Dale B, Balan V. Extraction of proteins from switchgrass using aqueous ammonia within an integrated biorefinery. Applied Biochemistry and Biotechnology. 2007, 143(2): 187–198

Gu Z, Glatz C E. Aqueous two-phase extraction for protein recovery from corn extracts. Journal of Chromatography. B, Analytical Technologies in the Biomedical and Life Sciences. 2007, 845(1): 38–50

Fountoulakis M, Lahm H W. Hydrolysis and amino acid composition analysis of proteins. Journal of Chromatography. A. 1998, 826(2): 109–134

Ozols J. Amino acid analysis. Methods in Enzymology. 1990, 182: 587–601

Provansal M M P, Cuq J L A, Cheftel J C. Chemical and nutritional modifications of sunflower proteins due to alkaline processing formation of amino acid cross-links and isomerization of lysine residues. Journal of Agricultural and Food Chemistry. 1975, 23(5): 938–943

Sari Y W, Bruins M E, Sanders J P M. Enzyme assisted protein extraction from rapeseed, soybean, and microalgae meals. Industrial Crops and Products. 2013, 43(1): 78–83

Bals B, Brehmer B, Dale B, Sanders J. Protease digestion from wheat stillage within a dry grind ethanol facility. Biotechnology Progress. 2011, 27(2): 428–434

Brandelli A, Daroit D J, Riffel A. Biochemical features of microbial keratinases and their production and applications. Applied Microbiology and Biotechnology. 2010, 85(6): 1735–1750

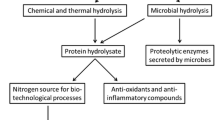

Tavano O L. Protein hydrolysis using proteases: An important tool for food biotechnology. Journal of Molecular Catalysis. B, Enzymatic. 2013, 90: 1–11

O’Loughlin I B, Murray B A, Kelly P M, FitzGerald R J, Brodkorb A. Enzymatic hydrolysis of heat-induced aggregates of whey protein isolate. Journal of Agricultural and Food Chemistry. 2012, 60(19): 4895–4904

Hara Y. The separation of amino acids with an ion-exchange membrane. Bulletin of the Chemical Society of Japan. 1963, 36(11): 1373–1376

Sandeaux J, Fares A, Sandeaux R, Gavach C. Transport properties of electrodialysis membranes in the presence of arginine I. Equilibrium properties of a cation exchange membrane in an aqueous solution of arginine chlorhydrate and sodium chloride. Journal of Membrane Science. 1994, 89(1–2): 73–81

Kattan Readi O M, Gironès M, Nijmeijer K. Separation of complex mixtures of amino acids for biorefinery applications using electrodialysis. Journal of Membrane Science. 2013, 429: 338–348

Readi O M K, Gironès M, Wiratha W, Nijmeijer K. On the isolation of single basic amino acids with electrodialysis for the production of biobased chemicals. Industrial & Engineering Chemistry Research. 2013, 52(3): 1069–1078

Teng Y, Scott E L, Van Zeeland A N T, Sanders J P M. The use of Llysine decarboxylase as a means to separate amino acids by electrodialysis. Green Chemistry. 2011, 13(3): 624–630

Kattan Readi O M, Rolevink E, Nijmeijer K. Mixed matrix membranes for process intensification in electrodialysis of amino acids. Journal of Chemical Technology and Biotechnology (Oxford, Oxfordshire). 2014, 89(3): 425–435

Yvon M, Rijnen L. Cheese flavour formation by amino acid catabolism. International Dairy Journal. 2001, 11(4–7): 185–201

Lammens T M, De Biase D, Franssen MC R, Scott E L, Sanders J P M. The application of glutamic acid a-decarboxylase for the valorization of glutamic acid. Green Chemistry. 2009, 11(10): 1562–1567

De Biase D, Tramonti A, John R A, Bossa F. Isolation, overexpression, and biochemical characterization of the two isoforms of glutamic acid decarboxylase from Escherichia coli. Protein Expression and Purification. 1996, 8(4): 430–438

Kang T J, Ho N A T, Pack S P. Buffer-free production of gammaaminobutyric acid using an engineered glutamate decarboxylase from Escherichia coli. Enzyme and Microbial Technology. 2013, 53(3): 200–205

Thu Ho N A, Hou C Y, Kim W H, Kang T J. Expanding the active pH range of Escherichia coli glutamate decarboxylase by breaking the cooperativeness. Journal of Bioscience and Bioengineering. 2013, 115(2): 154–158

Dinh T H, Ho N A T, Kang T J, McDonald K A, Won K. Salt-free production of γ-aminobutyric acid from glutamate using glutamate decarboxylase separated from Escherichia coli. Journal of Chemical Technology and Biotechnology (Oxford, Oxfordshire). 2014, 89(9): 1432–1436

Park H, Ahn J, Lee J, Lee H, Kim C, Jung J K, Lee H, Lee E G. Expression, immobilization and enzymatic properties of glutamate decarboxylase fused to a cellulose-binding domain. International Journal of Molecular Sciences. 2012, 13(1): 358–368

Hossain G S, Li J, Shin H D, Chen R R, Du G, Liu L, Chen J. Bioconversion of L-glutamic acid to a-ketoglutaric acid by an immobilized whole-cell biocatalyst expressing L-amino acid deaminase from Proteus mirabilis. Journal of Biotechnology. 2014, 169(1): 112–120

Ödman P, Wellborn W B, Bommarius A S. An enzymatic process to a-ketoglutarate from L-glutamate: The coupled system L-glutamate dehydrogenase/NADH oxidase. Tetrahedron, Asymmetry. 2004, 15(18): 2933–2937

Pukin A V, Boeriu C G, Scott E L, Sanders J P M, Franssen M C R. An efficient enzymatic synthesis of 5-aminovaleric acid. Journal of Molecular Catalysis. B, Enzymatic. 2010, 65(1–4): 58–62

Liu P, Zhang H, Lv M, Hu M, Li Z, Gao C, Xu P, Ma C. Enzymatic production of 5-aminovalerate from L-lysine using L-lysine monooxygenase and 5-aminovaleramide amidohydrolase. Scientific Reports. 2014, 4: 5657

Nishi K, Endo S, Mori Y, Totsuka K, Hirao Y. US Patent, 0003497, 2005-01-06

Ben-Bassat A, Huang L L, Lowe D J, Patnaik R, Sariaslani F S. US Patent, 8003356, 2011-08-23

Xue Z, McCluskey M, Cantera K, Ben-Bassat A, Sariaslani F S, Huang L. Improved production of p-hydroxycinnamic acid from tyrosine using a novel thermostable phenylalanine/tyrosine ammonia lyase enzyme. Enzyme and Microbial Technology. 2007, 42(1): 58–64

Nakamura N, Fujita M, Kimura K. Purification and properties of Larginase from Bacillus subtilis. Agricultural and Biological Chemistry. 1973, 37(12): 2827–2833

Könst P M, Franssen M C R, Scott E L, Sanders J P M. A study on the applicability of L-aspartate a-decarboxylase in the biobased production of nitrogen containing chemicals. Green Chemistry. 2009, 11(10): 1646–1652

Williamson J M, Brown G M. Purification and properties of Laspartate-a-decarboxylase, an enzyme that catalyzes the formation of β-alanine in Escherichia coli. Journal of Biological Chemistry. 1979, 254(16): 8074–8082

Shen Y, Zhao L, Li Y, Zhang L, Shi G. Synthesis of β-alanine from L-aspartate using L-aspartate-a-decarboxylase from Corynebacterium glutamicum. Biotechnology Letters. 2014, 36(8): 1681–1686

Zisapel N. Drugs for insomnia. Expert Opinion on Emerging Drugs. 2012, 17(3): 299–317

Le Nôtre J, Scott E L, Franssen M C R, Sanders J P M. Biobased synthesis of acrylonitrile from glutamic acid. Green Chemistry. 2011, 13(4): 807–809

Lammens T M, Franssen M C R, Scott E L, Sanders J P M. Synthesis of biobased N-methylpyrrolidone by one-pot cyclization and methylation of γ-aminobutyric acid. Green Chemistry. 2010, 12(8): 1430–1436

Bhattacharya R, Vijayaraghavan R. Promising role of a-ketoglutarate in protecting against the lethal effects of cyanide. Human and Experimental Toxicology. 2002, 21(6): 297–303

Aussel C, Coudray-Lucas C, Lasnier E, Cynober L, Ekindjian O G. a-Ketoglutarate uptake in human fibroblasts. Cell Biology International, 1996, 20(5): 359–363

Barrett D G, Yousaf M N. Poly(triol a-ketoglutarate) as biodegradable, chemoselective, and mechanically tunable elastomers. Macromolecules. 2008, 41(17): 6347–6352

Ueno H. Enzymatic and structural aspects on glutamate decarboxylase. Journal of Molecular Catalysis. B, Enzymatic. 2000, 10(1–3): 67–79

Zweers J C, Barák I, Becher D, Driessen A J M, Hecker M, Kontinen V P, Saller M J, Vavrová L, van Dijl J M. Towards the development of Bacillus subtilis as a cell factory for membrane proteins and protein complexes. Microbial Cell Factories. 2008, 7(1): 10

Park S J, Kim E Y, Noh W, Park H M, Oh Y H, Lee S H, Song B K, Jegal J, Lee S Y. Metabolic engineering of Escherichia coli for the production of 5-aminovalerate and glutarate as C5 platform chemicals. Metabolic Engineering. 2013, 16(1): 42–47

Kind S, Wittmann C. Bio-based production of the platform chemical 1,5-diaminopentane. Applied Microbiology and Biotechnology. 2011, 91(5): 1287–1296

Kaneko T, Thi T H, Shi D J, Akashi M. Environmentally degradable, high-performance thermoplastics from phenolic phytomonomers. Nature Materials. 2006, 5(12): 966–970

Sariaslani F S. Development of a combined biological and chemical process for production of industrial aromatics from renewable resources. Annual Review of Microbiology. 2007, 61(1): 51–69

Könst P M, Franssen MC R, Scott E L, Sanders J P M. Stabilization and immobilization of Trypanosoma brucei ornithine decarboxylase for the biobased production of 1,4-diaminobutane. Green Chemistry. 2011, 13(5): 1167–1174

Mateo C, Palomo J M, Fernandez-Lorente G, Guisan J M, Fernandez-Lafuente R. Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme and Microbial Technology. 2007, 40(6): 1451–1463

Sheldon R A. Enzyme immobilization: The quest for optimum performance. Advanced Synthesis & Catalysis. 2007, 349(8–9): 1289–1307

Weetall H H, Pitcher W H Jr. Scaling up an immobilized enzyme system. Science, 1986, 232(4756): 1396–1403

Rios G M, Belleville M P, Paolucci D, Sanchez J. Progress in enzymatic membrane reactors—A review. Journal of Membrane Science. 2004, 242(1–2): 189–196

Howaldt M W, Kulbe K D, Chmiel H. Choice of reactor to minimize enzyme requirement: 1. Mathematical model for one-substrate Michaelis-Menten type kinetics in continuous reactors. Enzyme and Microbial Technology, 1986, 8(10): 627–631

Safdar M, Sproß J, Jänis J. Microscale immobilized enzyme reactors in proteomics: Latest developments. Journal of Chromatography. A. 2014, 1324: 1–10

Zhang Z, Donaldson A A, Ma X. Advancements and future directions in enzyme technology for biomass conversion. Biotechnology Advances. 2012, 30(4): 913–919

Teng Y, Scott E L, Sanders J P M. The selective conversion of glutamic acid in amino acid mixtures using glutamate decarboxylase—A means of separating amino acids for synthesizing biobased chemicals. Biotechnology Progress. 2014, 30(3): 681–688

Bornscheuer U T, Huisman G W, Kazlauskas R J, Lutz S, Moore J C, Robins K. Engineering the third wave of biocatalysis. Nature. 2012, 484(7397): 185–194

Agyei D, Shanbhag B K, He L. Enzyme engineering (immobilization) for food applications. In: Improving and Tailoring Enzymes for Food Quality and Functionality. Amsterdam: Elsevier. 2015, 213–235

Bornscheuer U T, Huisman G W, Kazlauskas R J, Lutz S, Moore J C, Robins K. Engineering the third wave of biocatalysis. Nature. 2012, 485(7397): 185–194

Author information

Authors and Affiliations

Corresponding author

Additional information

Dedicated to the 120th Anniversary of Tianjin University

Rights and permissions

About this article

Cite this article

Kumar, M.B.A., Gao, Y., Shen, W. et al. Valorisation of protein waste: An enzymatic approach to make commodity chemicals. Front. Chem. Sci. Eng. 9, 295–307 (2015). https://doi.org/10.1007/s11705-015-1532-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-015-1532-4