Abstract

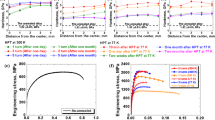

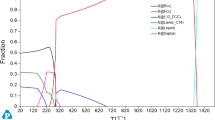

Fe35Ni35Cr20Mn10 high-entropy alloy wire with a diameter of 0.45 mm, prepared by continuous cold-drawing from a rod with a diameter of 6.34 mm, was subjected to high-temperature annealing at 600, 700, 800, 900, and 1000 °C for 1 h. The microstructure and mechanical properties in different states were investigated by microscopy observations and tensile testing. The wire in the as-drawn state exhibited the highest strength but the lowest elongation because of its fine multilayer structure and high dislocation density. Annealing, particularly at higher temperatures, considerably reduced the yield strength and caused significant recovery in both the elongation and strain-hardening exponent. Increasing the annealing temperature significantly decreased the dislocation density, notably coarsened the recrystallized grains, and significantly increased the fraction of twin boundaries and mean widths of annealing twins. The yield strength was found to be positively related to the dislocation density, and the elongation exhibited a negative relationship. In addition to the decrease in dislocation density, the formation of annealing twins played an important role in enhancing the elongation.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

J.W. Yeh, S.K. Chen, S.J. Lin et al., Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

B. Cantor, I.T.H. Chang, P. Knight et al., Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375, p 213–218.

B.R. Anne, S. Shaik, M. Tanake et al., A crucial Review on Recent Updates of Oxidation Behavior in High Entropy alloys, SN Appl. Sci., 2021, 3(3), p 1–23.

D.B. Miracle and O.N. Senkov, A critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448–511.

S. Gorsse, D.B. Miracle, and O.N. Senkov, Mapping the World of Complex Concentrated Alloys, Acta Mater., 2017, 135, p 177–187.

J. Cieslak, J. Tobola, K. Berent et al., Phase Composition of AlxFeNiCrCo High Entropy Alloys Prepared by Sintering and Arc-Melting Methods, J. Alloy. Compd., 2018, 740, p 264–272.

W. Zhang, P.K. Liaw, and Y. Zhang, Science and Technology in High Entropy Alloys, Sci. China Mater., 2018, 61(1), p 2.

L. Zhou, F. Fang, X. Zhou et al., Cementite Nano-crystallization in Cold Drawn Pearlitic Wires Instigated by Low Temperature Annealing, Scripta Mater., 2016, 120(1), p 5–8.

X. Cao and W. Wu, The Establishment of a Mechanics Model of Multi-Strand Wire Rope Subjected to Bending Load with Finite Element Simulation and Experimental Verification, Int. J. Mech. Sci., 2018, 142, p 289–303.

Z. Wang, J. Chen, C. Besnard et al., In Situ Neutron Diffraction Investigation of Texture-Dependent Shape Memory Effect in a Near Equiatomic NiTi alloy, Acta Mater., 2021, 202, p 135–148.

L. Kunˇcická, A. Macháˇcková, L. Krátká et al., Analysis of Deformation Behaviour and Residual Stress in Rotary Swaged Cu/Al Clad Composite Wires, Materials, 2019, 12, p 3462.

C.R. Chaplin, Failure Mechanisms in Wire Ropes, Eng. Fail. Anal., 1995, 2, p 45–47.

X. Zhang, N. Hansen, A. Godfrey et al., Dislocation-Based Plasticity and Strengthening Mechanisms in Sub-20nm Lamellar Structures in Pearlitic Steel Wire, Acta Mater., 2016, 114(1), p 176–183.

L. Zhou, F. Fang, J. Zhou et al., Strain-Induced Coarsening of Ferrite Lamella in Cold Drawn Pearlitic Steel Wire, Mater. Sci. Eng. A, 2020, 771(13), p 1–7.

D. Li, C. Li, T. Feng et al., High-entropy Al0.3CoCrFeNi Alloy Fibers with High Tensile Strength and Ductility at Ambient and Cryogenic Temperatures, Acta Mater., 2017, 123, p 285–294.

H.S. Cho, S.J. Bae, Y.S. Na et al., Influence of Reduction Ratio on the Microstructural Evolution and Subsequent Mechanical Properties of Cold-Drawn, J. Alloys Compnd., 2020, 821, p 153526.

X. Ma, J. Chen, X. Wang et al., Microstructure and Mechanical Properties of Cold Drawing CoCrFeMnNi High Entropy alloy, J. Alloy. Compd., 2019, 795, p 45–53.

W. Huo, F. Fang, H. Zhou et al., Remarkable Strength of CoCrFeNi High-Entropy Alloy Wires at Cryogenic and Elevated Temperatures, Scripta Mater., 2017, 141, p 125–128.

J.-P. Liu, J.-X. Chen, T.-W. Liu et al., Superior Strength-Ductility CoCrNi Medium-Entropy Alloy Wire, Scripta Mater., 2020, 181, p 19–24.

J.-X. Chen, T. Li, Y. Chen et al., Ultra-Strong Heavy-Drawn Eutectic High Entropy Alloy Wire, Acta Mater., 2023, 243, 118515.

J. Zhou, H.C. Liao, H. Chen et al., Microstructure and Tensile Mechanical Behavior of a Single-Phase Fe35Ni35Cr20Mn10 Heigh Entropy Alloy, J. Mater. Eng. Perform., 2021, 30(5), p 3352–3362.

J.W. Bae, J. Moon, M.J. Jang et al., Deep Drawing Behavior of CoCrFeMnNi High-Entropy Alloys, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2017, 48(9), p 4111–4120.

G.K. Williamson and R.E. Smallman, Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the x-ray Debye-Scherrer Spectrum, Phil. Mag., 1956, 1, p 34–46.

R. Sedlacek, W. Blum, J. Kratochvil et al., Subgrain formation During Deformation: Physical Origin and Consequences, Metall. Mater. Trans. A, 2002, 33, p 319–327.

Z.H. Han, S. Liang, J. Yang et al., A Superior Combination of Strength-Ductility in CoCrFeNiMn High-Entropy Alloy Induced by Asymmetric Rolling and Subsequent Annealing Treatment, Mater Charact, 2018, 145, p 619–626.

Lu. Xu He, T.Z. Liu, and Y. Yao, Micromechanical Modeling of Work Hardening for Coupling Microstructure Evolution, Dynamic Recovery and Recrystallization: Application to High Entropy alloys, Int. J. Mech. Sci., 2020, 177, 105567.

H. Feng, L. Wang, S. Cui et al., Microstructure and Strengthening Mechanisms of Nano-Lamellar Structures in Ultra-Strong Drawn Iron Wires, Scr. Mater., 2021, 200, 113906.

Y. Jin, B. Lin, M. Bernacki et al., Annealing Twin Development During Recrystallization and Grain Growth In Pure Nickel, Mater. Sci. Eng. A, 2014, 597, p 295–303.

Y. Wu, C. Liu, H. Liao et al., Joint Effect of Micro-Sized Si Particles and Nano-Sized Dispersoids on the Flow Behavior and Dynamic Recrystallization of Near-Eutectic Al-Si Based Alloys During Hot Compression, J. Alloy. Compd., 2021, 856, 158072.

B. Bacroix, S. Queyreau, D. Chaubet et al., The Influence of the Cube Component on the Mechanical Behaviour of Copper Polycrystalline Samples in Tension, Acta Mater., 2018, 160, p 121–136.

J.P. Liu, J.X. Chen, T.W. Liu et al., Superior Strength-Ductility CoCrNi Medium-Entropy Alloy Wire, Scr. Mater., 2020, 181, p 19–24.

Y.J. Xu, K. Du, C.Y. Cui et al., Deformation Twinning with Zero Macroscopic Strain in a Coarse-Grained Ni-Co-Based Superalloy, Scr. Mater., 2014, 77, p 71–74.

R.B. Nair, H.S. Arora, S. Mukherjee et al., Exceptionally High Cavitation Erosion and Corrosion Resistance of a High Entropy alloy, Ultrason. Sonochem., 2018, 41, p 252–260.

B. Cai, B. Liu, S. Kabra et al., Deformation Mechanisms of Mo Alloyed FeCoCrNi High Entropy Alloy: In Situ Neutron Diffraction, Acta Mater., 2017, 127, p 471–480.

J. Zhou, H.C. Liao, H. Chen et al., Mechanical Behaviors of Cold-Rolled and Subsequently Annealed Fe35Ni35Cr20Mn10 High-Entropy Alloy, J. Mater. Eng. Perform., 2021, 30(11), p 8145–8156.

S.K. Putatunda, C. Martis, and J. Boileau, Influence of Austempering Temperature on the Mechanical Properties of a Low Carb on Low Alloy Steel, Mater. Sci. Eng. A, 2011, 528(15), p 5053–5055.

H. Shahmir, T. Mousavi, J. He et al., Microstructure and Properties of a CoCrFeNiMn High-Entropy Alloy Processed by Equal-Channel Angular Pressing, Mater. Sci. Eng. A, 2017, 705, p 411–419.

J. Zhou, H. Liao, H. Chen, and A. Huang, Effects of Hot-Forging and Subsequent Annealing on Microstructure and Mechanical Behaviors of Fe35Ni35Cr20Mn10 High-Entropy Alloy, Mater Charact, 2021, 178, p 111251.

X. Zhang, H. Wang, R.O. Scattergood et al., Mechanical Properties of Cyromilled Nanocrystalline Zn Studied by the Miniaturized Disk Bend Test, Acta Mater., 2002, 50(13), p 3527–3533.

J.Y. He, H. Wang, H.L. Huang et al., A Precipitation-Hardened High-Entropy Alloy with Outstanding Tensile Properties, Acta Mater., 2016, 102, p 187–196.

P. Li, S. Liu, L. Zhang et al., Grain Refinement of A356 Alloy by Al-Ti-B-C Master Alloy and its Effect on Mechanical Properties, Mater. Des., 2013, 47, p 522–528.

S. Mahajan, Critique of Mechanisms of Formation of Deformation, Annealing and Growth Twins: Face-Centered Cubic Metals and Alloys, Scr. Mater., 2013, 68(2), p 95–99.

L. Lu, Z.S. You, and K. Lu, Work Hardening of Polycrystalline Cu with Nanoscale Twins, Scr. Mater., 2012, 66(11), p 837–842.

B. Gludovatz, A. Hohenwarter, D. Catoor et al., A Fracture-Resistant High-Entropy Alloy For Cryogenic Applications, Science, 2014, 345(6201), p 1153–1158.

T.C. Lee, I.M. Robertson, and H.K. Birnbaum, TEM in situ Deformation Study of the Interaction of Lattice Dislocations with Grain Boundaries In Metals, Phil. Mag., 1990, 62(1), p 131–153.

P. Gao, Z. Ma, J. Gu et al., Exceptional High-Strain-Rate Tensile Mechanical Properties in a CrCoNi Medium-Entropy Alloy, Sci. China Mater., 2022, 655(3), p 811–819.

Acknowledgments

This work was supported by the Open Project of Jiangsu Key Laboratory (Grant No.: BM2016023) and Transformation Project of Scientific and Technological Achievements in Jiangsu Province (Grant No.: BA2020023).

Author information

Authors and Affiliations

Contributions

MS performed investigation, data curation, writing—original draft preparation, and formal analysis. HL provided supervision, writing—review & editing, methodology, and funding acquisition. JZ did supervision, methodology, and investigation. GL analyzed methodology, investigation, and data curation. ZC prepared methodology and investigation. TY approved data curation. XL done data curation

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, M., Liao, H., Zhou, J. et al. Effect of High-Temperature Annealing on Microstructure and Mechanical Properties of Extremely Deformed Fe35Ni35Cr20Mn10 High-Entropy Alloy Wire. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-09061-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09061-3