Abstract

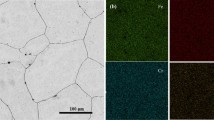

A single-phase Fe35Mn10Cr20Ni35 (presented in at.%, unless otherwise stated) high-entropy alloy (HEA) was synthesized by an electric arc melting plus copper mold casting method. The microstructure was characterized by X-ray diffraction, scanning electron microscopy and transmission electron microscopy. The thermostability of the prepared alloy was examined by differential scanning calorimetry. The mechanical behavior was examined by a tensile test. The prepared Fe35Mn10Cr20Ni35 alloy possesses a simple FCC phase structure with excellent structural stability. This alloy has a good combination of strength and ductility. It is observed that the prepared HEAs, either in the as-cast state or in the as-homogenized state, have a considerably higher strain hardening exponent than common alloys during tensile deformation, and the deformation mechanism was determined to be that first dislocation slipping and then twinning support continuous plastic deformation.

Similar content being viewed by others

Data Availability

No additional data are available.

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng., A, 2004, 375–377, p 213–218.

C. Zhu, Z.P. Lu and T.G. Nieh, Incipient Plasticity and Dislocation Nucleation of FeCoCrNiMn High-Entropy Alloy, Acta Mater., 2013, 61(8), p 2993–3001.

H. Jiang, L. Jiang, K. Han, Y. Lu, T. Wang, Z. Cao and T. Li, Effects of Tungsten on Microstructure and Mechanical Properties of CrFeNiV0.5Wx and CrFeNi2V0.5Wx High-Entropy Alloys, J. Mater. Eng. Perform., 2015, 24(12), p 4594–4600.

W.Q. Wu, S. Ni, Y. Liu and M. Song, Effects of Cold Rolling and Subsequent Annealing on the Microstructure of a HfNbTaTiZr High-Entropy Alloy, J. Mater. Res., 2016, 31(24), p 3815–3823.

M.H. Tsai and J.W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2(3), p 107–123.

X. Chen, Y.W. Sui, J.Q. Qi, Y.Z. He, F.X. Wei, Q.K. Meng and Z. Sun, Microstructure of Al1.3CrFeNi Eutectic High Entropy Alloy and Oxidation Behavior at 1000 °C, J. Mater. Res., 2017, 32(11), p 2109–2116.

S.G. Ma and Y. Zhang, Effect of Nb Addition on the Microstructure and Properties of AlCoCrFeNi High Entropy Alloy, Mater. Sci. Eng., A, 2012, 532, p 480–486.

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin and J.W. Yeh, Microstructure and Wear Behavior of AlxCoCrFeNiTiy High-Entropy Alloys, Acta Mater., 2011, 59(16), p 6308–6317.

Y. Guo, L. Liu, Y. Zhang, J. Qi, B. Wang, Z. Zhao, J. Shang and J. Xiang, A Superfine Eutetic Microstructure and the Mechanical Properties of CoCrFeNiMox High-Entropy Alloys, J. Mater. Res., 2018, 33(19), p 1–8.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345(6201), p 1153–1158.

Z.M. Li, K.G. Pradeep, Y. Deng, D. Raabe and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, 534(7606), p 227–230.

Y.P. Lu, X.Z. Gao, L. Jiang, Z.N. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao and T.J. Li, Directly Cast Bulk Eutectic and Near-Eutectic High Entropy Alloys with Balanced Strength and Ductility in a Wide Temperature Range, Acta Mater., 2017, 124(1359–6454), p 143–150.

Z. Wang, I. Baker, Z.H. Cai, S. Chen, J.D. Poplawsky and W. Guo, The Effect of Interstitial Carbon on the Mechanical Properties and Dislocation Substructure Evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 High Entropy Alloys, Acta Mater., 2016, 120, p 228–239.

J.Y. He, H. Wang, Y. Wu, X.J. Liu, H.H. Mao, T.G. Nieh and Z.P. Lu, Precipitation Behavior and its Effects on Tensile Properties of FeCoNiCr High-Entropy Alloys, Intermetallics, 2016, 79, p 41–52.

B. Cantor, Multicomponent and High Entropy Alloys, Entropy, 2014, 16(9), p 4749–4768.

N. Stepanov, T.M. Ikhonovsky, N. Yurchenko, D. Zyabkin and G. Salishchev, Effect of Cryo-Deformation on Structure and Properties of CoCrFeNiMn High-Entropy Alloy, Intermetallics, 2015, 59, p 8–17.

O.N. Senkov, G.B. Wilks, J.M. Scott and D.B. Miracle, Mechanical Properties of NbMoTaW and VNbMoTaW Refractory High Entropy Alloys, Intermetallics, 2011, 19(5), p 698–706.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, MicroStructures and Properties of High-Entropy Alloys, Prog. Mater Sci., 2014, 61, p 1–93.

M. Feuerbacher, M. Heidelmann and C. Thomas, Hexagonal High-entropy Alloys, Mater. Res. Lett., 2015, 3(1), p 1–6.

Z.M. Li and D. Raabe, Strong and Ductile Non-equiatomic High-Entropy Alloys: Design, Process. Microstruc Mech Propert JOM, 2017, 69(11), p 2099–2106.

Y. Zhou, D. Zhou, X. Jin, L. Zhang, X. Du and B. Li, Design of Non-Equiatomic Medium-Entropy Alloys, Sci. Rep., 2018, 8(1), p 1–9.

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka and D. Raabe, Design of a Twinning-Induced Plasticity High Entropy Alloy, Acta Mater., 2015, 94, p 124–133.

J. Gubicza, P.T. Hung, M. Kawasaki, J. Han, Y.K. Zhao, Y.F. Xue and J.L. Lábár, Influence of Severe Plastic Deformation on the Microstructure and Hardness of a CoCrFeNi High-Entropy Alloy: A Comparison with CoCrFeNiMn, Mater. Charact., 2019, 154, p 304–314.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang and P.K. Liaw, Refractory High-Entropy Alloys, Intermetallics, 2010, 18, p 1758–1765.

Y.T. Qiao, Y. Tang, S. Li, Y.C. Ye, X.Y. Liu, L.A. Chu and S.X. Bai, Preparation of TiZrNbTa Refractory High-Entropy Alloy Powder by Mechanical Alloying with Liquid Process Control Agents, Intermetallics, 2020, 126, p 106900.

V.N. Voyevodin, S.A. Karpov, G.D. Tolstolutskaya, M.A. Tikhonovsky, A.N. Velikodnyi, I.E. Kopanets, G.N. Tolmachova, A.S. Kalchenko, R.L. Vasilenko and I.V. Kolodiy, Effect of Irradiation on Microstructure and Hardening of Cr-Fe-Ni-Mn High-Entropy Alloy and its Strengthened Version, Phil. Mag., 2020, 100(7), p 822–836.

C. Li, X. Hu, T. Yang, N.K. Kumar, B.D. Wirth and S.J. Zinkle, Neutron Irradiation Response of a Co-Free High Entropy Alloy, J. Nuclear Materialia, 2019, 527, p 151838.

J.G. Gigaxa, O. El-Atwani, Q. McCulloch, B. Aytuna, M. Efe, S. Fensin, S.A. Maloy and N. Li, Micro- and Mesoscale Mechanical Properties of an Ultra-Fine Grained CrFeMnNi High Entropy Alloy Produced by Large Strain Machining, Scripta Mater., 2020, 178, p 508–512.

B.B. Bian, N. Guo, H.J. Yang, R.P. Guo, L. Yang, Y.C. Wu and J.W. Qiao, A Novel Cobalt-Free FeMnCrNi Medium-Entropy Alloy with Exceptional Yield Strength and Ductility at Cryogenic Temperature, J. Alloy. Compd., 2020, 827, p 153981.

N.A.P. Kiran Kumar, C. Li, K.J. Leonard, H. Bei and S.J. Zinkle, Microstructural Stability and Mechanical Behavior of FeNiMnCr High Entropy Alloy under Ion Irradiation, Acta Mater., 2016, 113, p 230–244.

Z. Wu, H. Bei, F. Otto, G.M. Pharr and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-Component Equiatomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140.

H.Y. Liu, C. Gu, K. Zhai and C.D. Wang, Strengthening and Toughening the FeNiCrMn Medium Entropy Alloy by Novel Ultrafine Precipitate Networks, Vacuum, 2021, 184, p 109995.

X. Yang, Y. Zhang and P.K. Liaw, Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys, Procedia Eng., 2012, 36, p 292–298.

H.F. Sheng, M. Gong and L.M. Peng, Microstructural Characterization And Mechanical Properties of an Al0.5CoCrFeCuNi High-Entropy Alloy in as-cast and Heat-Treated/Quenched Conditions, Mater. Sci. Eng. A, 2013, 567, p 14–20.

Z.Q. Fu, W.P. Chen, H.M. Wen, D.L. Zhang, Z. Chen, B.L. Zheng, Y.Z. Zhou and E. J. , Lavernia, Microstructure and Strengthening Mechanisms in an FCC Structured Single-Phase Nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 High-Entropy Alloy, Acta Mater., 2016, 107, p 59–71.

A. Emamifar, B. Sadeghi, P. Cavaliere and H. Ziaei, Microstructural Evolution and Mechanical Properties of AlCrFeNiCoC High Entropy Alloy Produced Via Spark Plasma Sintering, Powder Metall., 2019, 62(1), p 61–70.

C. Wang, W. Ji and Z.Y. Fu, Mechanical Alloying and Spark Plasma Sintering of CoCrFeNiMnAl High-Entropy Alloy, Adv. Powder Technol., 2014, 25(4), p 1334–1338.

P.P. Bhattacharjee, G.D. Sathiaraj, M. Zaid, J.R. Gatti, C. Lee, C.W. Tsai and J.W. Yeh, Microstructure and Texture Evolution during Annealing of Equiatomic CoCrFeMnNi High-Entropy Alloy, J. Alloy. Compd., 2014, 587, p 544–552.

T.T. Shun, C.H. Hung and C.F. Lee, The Effects of Secondary Elemental Mo or Ti Addition in Al0.3CoCrFeNi High-Entropy Alloy on Age Hardening at 700 °C,J. Alloys Compd., 2010, 495(1), p 55–58.

Y.D. Wu, Y.H. Cai, T. Wang, J.J. Si, J. Zhu, Y.D. Wang and X.D. Hui, A Refractory Hf25Nb25Ti25Zr25 High-Entropy Alloy with Excellent Structural Stability and Tensile Properties, Mater. Lett., 2014, 130, p 277–280.

M.J. Yao, K.G. Pradeep, C.C. Tasan and D. Raabe, A Novel, Single Phase, Non-Equiatomic FeMnNiCoCr High-Entropy Alloy with Exceptional Phase Stability and Tensile Ductility, Scripta Mater., 2014, 72–73, p 5–8.

Z.W. Wang and I. Baker, Interstitial Strengthening of a f.c.c. FeNiMnAlCr High Entropy Alloy, Mater. Lett., 2016, 180, p 153–156.

R. Wei, H. Sun, Z.H. Han, C. Chen, T. Wang, S.K. Guan and F.S. Li, Strengthening of Fe40Mn 40Co10Cr10 High Entropy Alloy Via Mo/C Alloying, Mater. Lett., 2018, 219, p 85–88.

H.T. Jeong and W.J. Kim, Microstructures and Mechanical Properties of the Non-Equiatomic FeMnNiCoCr High Entropy Alloy Processed by Differential Speed Rolling, Mater. Sci. Eng., A, 2018, 727, p 38–42.

C. Ng, S. Guo, J. Luan, Q. Wang, J. Lu, S. Shi and C.T. Liu, Phase Stability and Tensile Properties of Co-Free Al0.5CrCuFeNi2 High-Entropy Alloys, J. Alloys Compd., 2014, 584, p 530–537.

G.K. Williamson and R.E. Smallman, Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the x-ray Debye-Scherrer Spectrum, Phil. Mag., 1956, 1(1), p 34–46.

R. Das and S. Sarkar, Williamson Hall Plot Analysis of the x-ray diffraction result of synthesized silver nanocubes for the determination of their elastic properties, Adv. Sci. Lett., 2016, 22(1), p 145–148.

E. Schafler, M. Zehetbauer and T. Ungàr, Measurement of Screw and Edge Dislocation Density by Means of x-ray Bragg Profile Analysis, Mater. Sci. Eng., A, 2001, 319–321, p 220–223.

M Komarasamy, K Alagarsamy, and RS Mishra, Serration Behavior and Negative Strain Rate Sensitivity of Al0.1CoCrFeNi High Entropy Alloy, Intermetallics, 2017, 84, 20–24

R.B. Nair, H.S. Arora, S. Mukherjee, S. Singh, H. Singh and H.S. Grewal, Exceptionally High Cavitation Erosion and Corrosion Resistance of a High Entropy Alloy, Ultrason. Sonochem., 2018, 41, p 252–260.

HY Su, D Lv, Y Li, and HK Chen, The Discussion on the Formula of Strain Hardening Index (n value), Physical Testing and Chemical Analysis (Part A:Physical Testing), 2006, 42, p. 621. (In Chinese)

S.K. Putatunda, C. Martis and J. Boileau, Influence of Austempering Temperature on the Mechanical Properties of A Low Carbon Low Alloy Steel, Mater. Sci. Eng., A, 2011, 528(15), p 5053–5059.

J.W. Bae, J. Moon, M.J. Jang, D.H. Ahn, S.H. Joo, J. Jung, D. Yim and H.S. Kim, Deep Drawing Behavior of CoCrFeMnNi High-Entropy Alloys, Metall. Mater. Trans. A., 2017, 48(9), p 4111–4120.

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen and C.T. Liu, Ductile CoCrFeNiMox High Entropy Alloys Strengthened by Hard Intermetallic Phases, Acta Mater., 2016, 116, p 332–342.

A.J. Zaddach, R.O. Scattergood and C.C. Koch, Tensile Properties of Low-Stacking Fault Energy High-Entropy Alloys, Mater. Sci. Eng., A, 2015, 636, p 373–378.

BF Wang, C Wang, B Liu, and XY Zhang, 2019 Dynamic Mechanical Properties and Microstructure of an (Al0.5CoCrFeNi)0.95Mo0.025C0.025 High Entropy Alloy, Entropy, 21(12), 1154

M.R. Barnett, M. Senadeera, D. Fabijanic, K.F. Shamlaye, J. Joseph, S.R. Kada, S. Rana, S. Gupta and S. Venkatesh, A Scrap-Tolerant Alloying Concept based on High Entropy Alloys, Acta Mater., 2020, 200, p 735–744.

F. Yang, L.M. Dong, X.J. Hu, X.F. Zhou, F. Fang, Z.H. Xie and J.Q. Jiang, Microstructural Features and Tensile Behaviors of a Novel FeMnCoCr High Entropy Alloys, Mater. Lett., 2020, 275, p 128154.

N. Kumar, Q. Ying, X. Nie, R.S. Mishra, Z. Tang, P.K. Liaw, R.E. Brennan, K.J. Doherty and K.C. Cho, High Strain-Rate Compressive Deformation Behavior of the Al0.1CrFeCoNi High Entropy Alloy, Mater. Design, 2015, 86, p 598–602.

G. Laplanche, A. Kostka, O.M. Horst, G. Eggeler and E.P. George, Microstructure Evolution and Critical Stress for Twinning in the CrMnFeCoNi High-Entropy Alloy, Acta Mater., 2016, 118, p 152–163.

J. Joseph, P. Hodgson, T. Jarvis, X.H. Wu, N. Stanford and D.M. Fabijanic, Effect of Hot Isostatic Pressing on The Microstructure and Mechanical Properties of Aadditive manufactured AlxCoCrFeNi High Entropy Alloys, Mater. Sci. Eng., A, 2018, 733, p 59–70.

Acknowledgments

This work was funded by National Major Basic Research Project of China (Grant No.: 613321). The authors thank Dr. Aiqun Xu for TEM observation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that no conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors for publication. The work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part.

Ethical Approval

All the authors listed have approved the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zhou, J., Liao, H., Chen, H. et al. Microstructure and Tensile Mechanical Behavior of a Single-Phase Fe35Mn10Cr20Ni35 High-Entropy Alloy. J. of Materi Eng and Perform 30, 3352–3362 (2021). https://doi.org/10.1007/s11665-021-05700-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05700-9