Abstract

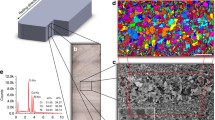

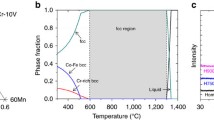

Alloys with combined outstanding strength and excellent ductility are highly desirable for many structural applications. However, alloys subjected to deformation at very high strain rates and/or cryogenic temperatures usually suffer from very limited ductility. Here, we demonstrate that a bulk CrCoNi medium-entropy alloy presents exceptional combination of high strength and excellent ductility during deformation at high strain rates over a wide temperature range. Full tensile stress-strain curves at a high strain rate of 2000 s−1 and temperatures down to 77 K were successfully obtained using an electromagnetic Hopkinson tension bar system attached with a cooling device, revealing high true ultimate tensile strength (σUTS,T) of 1.8 GPa and true strain of ∼54% at σUTS,T. These outstanding mechanical properties were mainly attributed to profuse deformation twinning. Both high strain rate and cryogenic temperature promoted deformation twinning. Grain refinement caused by deformation twinning, dislocation slip and dynamic recrystallisation added to work hardening and the excellent tensile strain.

摘要

拥有优异的力学强度和拉伸塑性对于结构合金是非常重要的. 然而, 合金在高应变速率或者低温下变形时通常拉伸塑性非常有限. 本 文展示了块体CrCoNi中熵合金在高应变速率和低温下优异的综合拉 伸力学性能. 我们使用一种带冷却装置的电磁霍普金森拉杆装置得到 了在2000 s−1和77 K下完整的拉伸力学曲线. 结果表明合金在1.8 GPa下 具有超高的拉伸真应力(σUTS,T), 在σUTS,T下的拉伸真应变为∼54%. 该合 金优异的力学性能主要归因于大量变形孪晶的启动. 高应变速率和低 温都促使了孪晶的形成. 变形孪晶、滑移、动态再结晶引起的晶粒细 化促进了加工硬化, 从而增加了拉伸塑性.

Similar content being viewed by others

References

Callister WD, Rethwisch DG. Materials Science and Engineering: An Introduction, the ninth ed., New York: John Wiley & Sons Inc., 2006

Zhang Y, Zuo TT, Tang Z, et al. Microstructures and properties of high-entropy alloys. Prog Mater Sci, 2014, 61: 1–93

Gao X, Lu Y, Zhang B, et al. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy. Acta Mater, 2017, 141: 59–66

Hu X, Daehn GS. Effect of velocity on flow localization in tension. Acta Mater, 1996, 44: 1021–1033

Gludovatz B, Hohenwarter A, Thurston KVS, et al. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat Commun, 2016, 7: 1–8

Gwalani B, Gorsse S, Choudhuri D, et al. Modifying transformation pathways in high entropy alloys or complex concentrated alloys via thermo-mechanical processing. Acta Mater, 2018, 153: 169–185

Liu J, Guo X, Lin Q, et al. Excellent ductility and serration feature of metastable CoCrFeNi high-entropy alloy at extremely low temperatures. Sci China Mater, 2019, 62: 853–863

Gludovatz B, Hohenwarter A, Catoor D, et al. A fracture-resistant high-entropy alloy for cryogenic applications. Science, 2014, 345: 1153–1158

Christian JW, Mahajan S. Deformation twinning. Prog Mater Sci, 1995, 39: 1–157

Zhao B, Huang P, Zhang L, et al. Temperature effect on stacking fault energy and deformation mechanisms in titanium and titanium-aluminium alloy. Sci Rep, 2020, 10: 3086

Huang S, Li W, Lu S, et al. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scripta Mater, 2015, 108: 44–47

Zhu YT, Liao XZ, Wu XL. Deformation twinning in nanocrystalline materials. Prog Mater Sci, 2012, 57: 1–62

Zhang TW, Ma SG, Zhao D, et al. Simultaneous enhancement of strength and ductility in a NiCoCrFe high-entropy alloy upon dynamic tension: Micromechanism and constitutive modeling. Int J Plast, 2020, 124: 226–246

Guo Y, Du B, Liu H, et al. Electromagnetic Hopkinson bar: A powerful scientific instrument to study mechanical behavior of materials at high strain rates. Rev Sci Instruments, 2020, 91: 081501

Curtze S, Kuokkala VT. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater, 2010, 58: 5129–5141

Wang L, Qiao JW, Ma SG, et al. Mechanical response and deformation behavior of Al0.6CoCrFeNi high-entropy alloys upon dynamic loading. Mater Sci Eng-A, 2018, 727: 208–213

Khan AS, Liu H. Variable strain rate sensitivity in an aluminum alloy: Response and constitutive modeling. Int J Plast, 2012, 36: 1–14

Khan AS, Yu S. Deformation induced anisotropic responses of Ti-6Al-4V alloy. Part I: Experiments. Int J Plast, 2012, 38: 1–13

Gao P, Zhu SQ, An XH, et al. Effect of sample orientation and initial microstructures on the dynamic recrystallization of a magnesium alloy. Mater Sci Eng-A, 2017, 691: 150–154

Wang X, Huang C, Zou B, et al. Dynamic behavior and a modified Johnson-Cook constitutive model of Inconel 718 at high strain rate and elevated temperature. Mater Sci Eng-A, 2013, 580: 385–390

Hu M, Song W, Duan D, et al. Dynamic behavior and microstructure characterization of TaNbHfZrTi high-entropy alloy at a wide range of strain rates and temperatures. Int J Mech Sci, 2020, 182: 105738

Cao CM, Tong W, Bukhari SH, et al. Dynamic tensile deformation and microstructural evolution of ALCrMnFeCoNi high-entropy alloys. Mater Sci Eng-A, 2019, 759: 648–654

Slone CE, Chakraborty S, Miao J, et al. Influence of deformation induced nanoscale twinning and FCC-HCP transformation on hardening and texture development in medium-entropy CrCoNi alloy. Acta Mater, 2018, 158: 38–52

Haase C, Barrales-Mora LA. Influence of deformation and annealing twinning on the microstructure and texture evolution of face-centered cubic high-entropy alloys. Acta Mater, 2018, 150: 88–103

Suwas S, Ray RK. Crystallographic Texture of Materials. London: Springer, 2014, 123

Zhang Z, Sheng H, Wang Z, et al. Dislocation mechanisms and 3D twin architectures generate exceptional strength-ductility-toughness combination in CrCoNi medium-entropy alloy. Nat Commun, 2017, 8: 14390

Ma Y, Yuan F, Yang M, et al. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures. Acta Mater, 2018, 148: 407–418

Liao XZ, Huang JY, Zhu YT, et al. Nanostructures and deformation mechanisms in a cryogenically ball-milled Al-Mg alloy. Philos Mag, 2003, 83: 3065–3075

Zhu SQ, Yan HG, Liao XZ, et al. Mechanisms for enhanced plasticity in magnesium alloys. Acta Mater, 2015, 82: 344–355

Wang YB, Liao XZ, Zhao YH, et al. The role of stacking faults and twin boundaries in grain refinement of a Cu-Zn alloy processed by high-pressure torsion. Mater Sci Eng-A, 2010, 527: 4959–4966

Moussa C, Bernacki M, Besnard R, et al. About quantitative EBSD analysis of deformation and recovery substructures in pure tantalum. IOP Conf Ser-Mater Sci Eng, 2015, 89: 012038

Konijnenberg PJ, Zaefferer S, Raabe D. Assessment of geometrically necessary dislocation levels derived by 3D EBSD. Acta Mater, 2015, 99: 402–414

Sun JL, Trimby PW, Yan FK, et al. Shear banding in commercial pure titanium deformed by dynamic compression. Acta Mater, 2014, 79: 47–58

Zheng Z, Balint DS, Dunne FPE. Rate sensitivity in discrete dislocation plasticity in hexagonal close-packed crystals. Acta Mater, 2016, 107: 17–26

Zhu YT, Liao XZ, Wu XL. Deformation twinning in bulk nanocrystalline metals: Experimental observations. JOM, 2008, 60: 60–64

Yang M, Yan D, Yuan F, et al. Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength. Proc Natl Acad Sci USA, 2018, 115: 7224–7229

(Rusty) Gray III GT. High-strain-rate deformation: Mechanical behavior and deformation substructures induced. Annu Rev Mater Res, 2012, 42: 285–303

Wang Y, Zhang Y, Godfrey A, et al. Cryogenic toughness in a low-cost austenitic steel. Commun Mater, 2021, 2: 44

Deng Y, Tasan CC, Pradeep KG, et al. Design of a twinning-induced plasticity high entropy alloy. Acta Mater, 2015, 94: 124–133

You ZS, Lu L, Lu K. Tensile behavior of columnar grained Cu with preferentially oriented nanoscale twins. Acta Mater, 2011, 59: 6927–6937

Acknowledgements

The authors acknowledge the scientific and technical input and support from the Australian Microscopy and Microanalysis Research Facility node at the University of Sydney. Liao X was supported by the Australian Research Council (DP190102243).

Author information

Authors and Affiliations

Contributions

Liao X, Song M, and Li Y designed the study; Gao P prepared, acquired and analysed the microstructural data; Ma Z, Suo T, and Li Y conducted the mechanical tests; Gu J, Ni S, and Song M prepared the materials; Gao P, Liao X, and Mai YW wrote the paper. All authors discussed the results and contributed to the paper.

Corresponding authors

Additional information

Conflict of interest

The authors declare that they have no conflict of interest.

Peng Gao received his PhD degree in 2021 from the University of Sydney. He is employed as a research assistant at the School of Aerospace, Mechanical and Mechatronic Engineering, the University of Sydney. His research interest involves high/medium-entropy alloys, light alloys, microstructural characterisation and in-situ microscopy.

Zihao Ma is currently pursuing his PhD degree at the School of Aeronautics, Northwestern Polytechnic University (NPU). He is studying the mechanical behavior and microstructure evolution of high-entropy alloys under dynamic impact.

Min Song is a professor and vise dean of Powder Metallurgy Research Institute at Central South University. He serves as associate editor of Materials Characterization. He received his PhD degree in 2005 at Dartmouth College, USA. His current research interests involve the deformation mechanisms of metallic materials, including: metals and alloys, bulk nanocrystalline materials, HEAs and metal matrix composites.

Yulong Li is a professor of Civil Aviation School and a chair professor at the School of Aeronautics, NPU. He received his PhD degree in solid mechanics from NPU in 1992. His research interests include dynamic response and failure of structures under impact loading, constitutive relationship for materials, experimental techniques for high-strain-rate behaviors of materials, as well as, numerical simulation of materials and structures under impact.

Xiaozhou Liao received his PhD degree in physics from the University of Sydney. He is currently a professor at the School of Aerospace, Mechanical and Mechatronic Engineering, the University of Sydney. He uses advanced electron microscopy to examine materials at the atomic scale, laying the groundwork for the design of superior materials for a wide range of applications.

Rights and permissions

About this article

Cite this article

Gao, P., Ma, Z., Gu, J. et al. Exceptional high-strain-rate tensile mechanical properties in a CrCoNi medium-entropy alloy. Sci. China Mater. 65, 811–819 (2022). https://doi.org/10.1007/s40843-021-1798-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-1798-6