Abstract

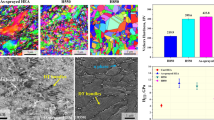

Herein, the deep drawability and deep drawing behavior of an equiatomic CoCrFeMnNi HEA and its microstructure and texture evolution are first studied for future applications. The CoCrFeMnNi HEA is successfully drawn to a limit drawing ratio (LDR) of 2.14, while the planar anisotropy of the drawn cup specimen is negligible. The moderate combination of strain hardening exponent and strain rate sensitivity and the formation of deformation twins in the edge region play important roles in successful deep drawing. In the meanwhile, the texture evolution of CoCrFeMnNi HEA has similarities with conventional fcc metals.

Similar content being viewed by others

References

1. Y. Zhang, T.T. Zuo, Z. Tang, M. C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu: Prog. Mater. Sci., 2014, vol. 61, pp. 1-93.

2. S. Guo, C. Ng, J. Lu, and C.T. Liu: J. Appl. Phys., 2011, vol. 109, pp. 103505.

3. K.-Y. Tsai, M.-H. Tsai, and J.-W. Yeh: Acta Mater., 2013, vol. 61, pp. 4887-4897.

4. P.-K. Huang, J.-W. Yeh, T.-T. Shun, and S.-K. Chen: Adv. Eng. Mater., 2004, vol. 6, pp. 74-78.

5. Y. Zhang, X. Yang, and P.K. Liaw: JOM, 2012, vol. 64, pp. 830-838.

6. C.-L. Lu, S.-Y. Lu, J.-W. Yeh, and W.-K. Hsu: J. Appl. Crystallogr., 2013, vol. 46, pp. 736-739.

7. O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle: Intermetallics, 2011, vol. 19, pp. 698-706.

8. Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw: Adv. Eng. Mater., 2008, vol. 10, pp. 534-538.

9. D.B. Miracle, J.D. Miller, O.N. Senkov, C. Woodward, M.D. Uchic, and J. Tiley: Entropy, 2014, vol. 16, pp. 494-525.

10. B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Mater. Sci. Eng. A, 2004, vol. 375-377, pp. 213-218.

11. J.-W. Yeh, S.-K. Chen, S.-J. Lin, J.-Y. Gan, T.-S. Chin, T.-T. Shun, C.-H. Tasu, and S.-Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299-303.

12. S. Ranganathan: Curr. Sci., 2003, vol. 85, pp. 1404-1406.

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan, and T. Li: Sci. Rep., 2014, vol. 4.

14. B. Zhang, M.C. Gao, Y. Zhang, and S.M. Guo: Calphad, 2015, vol. 51, pp. 193-201.

15. F. Otto, A. Dlouhy, Ch. Somsen, H. Bei, G. Eggeler, and E.P. George: Acta Mater., 2013, vol. 61, pp. 5743-5755.

16. E. Ghassemali, R. Sonkusare, K. Biswas, and N.P. Gurao: J. Alloys Comp., 2017, vol. 710, pp. 539-546.

17. A.J. Zaddach, C. Niu, C.C. Koch, and D.L. Irving: JOM, 2013, vol. 65, pp. 1780-1789.

18. B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. Goerge, and R.O. Ritchie: Science, 2014, vol. 345, pp. 1153-1158.

ASTM E517-00: Standard Test Method for Plastic Strain Ratio r for Sheet Metal, Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2000, pp. 1–8.

20. R. Hill: J. Mech. Phy. Solids, 1958, vol. 6, pp. 236-249.

Dessault Systemes, ABAQUS Online Documentation-Abaqus Analysis User’s Manual, 2012.

22. K. Chung, K. Ahn, D.-H. Yoo, K.-H. Chung, M.-H. Seo, and S.-H. Park: Int. J. Plasticity, 2011, vol. 27, pp. 52-81.

23. G. Dini, A. Najafizadeh, R. Ueji, and S.M. Monir-Vaghefi: Mater. Des., 2010, vol. 31, pp. 3395-3402.

24. O. Bouaziz, S. Allain, C.P. Scott, P. Cugy, and D. Barbier: Curr. Opin. Solid State Mater. Sci., 2011, vol. 15, pp. 141-168.

25. J.G. Kim, S. Hong, N. Anjabin, B.H. Park, S.K. Kim, K.-G. Chin, S. Lee, and H.S. Kim: Mater. Sci. Eng. A, 2015, vol. 633, pp. 136-143.

26. A. Bintu, G. Vincze, C.R. Picu, A.B. Lopes, J.J. Gracio, and F. Barlat: Mater. Sci. Eng. A, 2015, vol. 629, pp. 54-59.

27. B.C. De Cooman, K.-G. Chin, and J. Kim: in: M. Chiaberge (Ed.), New Trends and Developments in Automotive system Engineering, In Tech, Rijeka, 2011.

28. M. Jain, J. Allin, and M.J. Bull: Mater. Sci. Eng. A, 1998, vol. 256, pp. 69-82.

29. M.R. Stoudt and R.E. Ricker: Metall. Mater. Trans., 2002, vol. 33A, pp. 2883-2889.

30. K.-G. Chin, C.-Y. Kang, S.Y. Shin, S. Hong, S. Lee, H.S. Kim, K.-H. Kim, and N.J. Kim: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2922-2928.

31. Y. Lou, S.J. Lim, and H. Huh: Met. Mater. Int., 2013, vol. 19, pp. 697-705.

32. M. Koyama, T. Sawaguchi, K. Ogawa, T. Kikuchi, and M. Murakami: Mater. Sci. Eng. A, 2008, vol. 497, pp. 353-357.

33. M.R. Berrahmoune, S. Berveiller, K. Inal, and E. Patoor: Mater .Sci. Eng. A, 2006, vol. 438-440, pp. 262-266.

34. P.P. Bhattacharjee, G.D. Sathiaraj, M. Zaid, J.R. Gatti, C. Lee, C.-W. Tsai, and J.-W. Yeh: J. Alloys Comp., 2014, vol. 587, pp. 544-552.

35. N.-J. Park: Met. Mater., 1998, vol. 4, pp. 467-471.

36. S.-H. Chio, J.-H. Cho, K.H. Oh, K. Chung, and F. Barlat: Int. J. Mech. Sci., 2000, vol. 42, pp. 1571-1592.

37. Y. Zhou, J. Savoie, and J.J. Jonas: Mater. Sci. Forum, 1994, vol. 157-162, pp. 879-884.

38. J. Savoie, Y. Zhou, J.J. Jonas, and S.R. Macewen: Acta Mater., 1996, vol. 44, pp. 587-605.

Acknowledgments

This research was supported by the Future Material Discovery Program of the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT and Future Planning (MSIP) of Korea (2016M3D1A1023384).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 11, 2016.

Rights and permissions

About this article

Cite this article

Bae, J.W., Moon, J., Jang, M.J. et al. Deep Drawing Behavior of CoCrFeMnNi High-Entropy Alloys. Metall Mater Trans A 48, 4111–4120 (2017). https://doi.org/10.1007/s11661-017-4189-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4189-4