Abstract

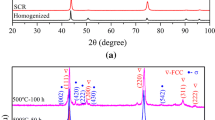

The effects of cold rolling and subsequent annealing on the microstructure and mechanical behaviors of Fe35Ni35Cr20Mn10 (in at.%, unless otherwise stated) high-entropy alloys (HEAs) were investigated by microstructure observation and mechanical property testing. The cold rolling results in a significant rise in the strength of the prepared HEA but a great reduction in the fracture elongation. The dominant fine subgrain structure and much higher density of dislocations in the as-rolled sample are responsible for this phenomenon. The combined effects of the significantly decreased dislocation density, obviously coarsened recrystallization grains, and considerable reduction in the amount and significant coarsening in the size of the annealing twins with the annealing temperature decreased the yield strength, but the elongation improved significantly. The prepared Fe35Ni35Cr20Mn10 HEA annealed at 800 °C for 1 h after cold rolling has a good combination of strength and elongation, with a high yield strength of ~ 336 MPa, a high ultimate tensile strength of ~ 525 MPa, and an excellent elongation to fracture of ~ 44%.

Similar content being viewed by others

Data Availability

No additional data are available.

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng., A, 2004, 375–377, p 213–218.

W.Y. Huo, F. Fang, X.D. Liu, S.Y. Tan, Z.H. Xie and J.Q. Jiang, Fatigue Resistance of Nanotwinned High-Entropy Alloy Films, Mater. Sci. Eng., A, 2019, 739(2), p 26–30.

M. Glienke, M. Vaidya, K. Gururaj, L. Daum, B. Tas, L. Rogal, K.G. Pradeep, S.V. Divinski and G. Wilde, Grain Boundary Diffusion in CoCrFeMnNi High Entropy Alloy: Kinetic Hints Towards a Phase Decomposition, Acta Mater., 2020, 195(15), p 304–316.

R. Gawel, Ł Rogal, J. Dąbek, M. Wójcik-Bania and K. Przybylski, High Temperature Oxidation Behaviour of Non-equimolar AlCoCrFeNi High Entropy Alloys, Vacuum, 2021, 184, p 109969.

N.D. Stepanov, D.G. Shaysultanov, M.S. Ozerov, S.V. Zherebtsov and G.A. Salishchev, Second Phase Formation in the CoCrFeNiMn High Entropy Alloy After Recrystallization Annealing, Mater. Lett., 2016, 185(15), p 1–4.

Y. Deng, C.C. Tasan, K.G. Pradeep, H. Springer, A. Kostka and D. Raabe, Design of a Twinning-Induced Plasticity High Entropy Alloy, Acta Mater., 2015, 94, p 124–133.

P. Lu, T.W. Zhang, D. Zhao, S.G. Ma, Q. Li, T. Wang and Z.H. Wang, Effects of Stress States and Strain Rates on Mechanical Behavior and Texture Evolution of the CoCrFeNi High-Entropy Alloy: Experiment and Simulation, J. Alloys Compd., 2021, 851, p 156779.

J.W. Qiao, S.G. Ma, E.W. Huang, C.P. Chuang, P.K. Liaw and Y. Zhang, Microstructural Characteristics and Mechanical Behaviors of AlCoCrFeNi High-Entropy Alloys at Ambient and Cryogenic Temperatures, Mater. Sci. Forum, 2011, 688, p 419–425.

S.J. Zinkle and L.L. Snead, Designing Radiation Resistance in Materials for Fusion Energy, Annu. Rev. Mater. Res., 2014, 44(1), p 241–267.

B.B. Bian, N. Guo, H.J. Yang, R.P. Guo, L. Yang, Y.C. Wu and J.W. Qiao, A Novel Cobalt-Free FeMnCrNi Medium-Entropy Alloy with Exceptional Yield Strength and Ductility at Cryogenic Temperature, J. Alloys Compd., 2020, 827, p 153981.

J.G. Gigaxa, O. El-Atwani, Q. McCulloch, B. Aytuna, M. Efe, S. Fensin, S.A. Maloy and N. Li, Micro- and Mesoscale Mechanical Properties of an Ultra-Fine Grained CrFeMnNi High Entropy Alloy Produced by Large Strain Machining, Scr. Mater., 2020, 178, p 508–512.

N.A.P. Kiran Kumar, C. Li, K.J. Leonard, H. Bei and S.J. Zinkle, Microstructural Stability and Mechanical Behavior of FeNiMnCr High Entropy Alloy Under Ion Irradiation, Acta Mater., 2016, 113, p 230–244.

V.N. Voyevodin, S.A. Karpov, G.D. Tolstolutskaya, M.A. Tikhonovsky, A.N. Velikodnyi, I.E. Kopanets, G.N. Tolmachova, A.S. Kalchenko, R.L. Vasilenko and I.V. Kolodiy, Effect of Irradiation on Microstructure and Hardening of Cr-Fe-Ni-Mn High-Entropy Alloy and Its Strengthened Version, Philos. Mag., 2020, 100, p 822–836.

Z. Wu, H. Bei, F. Otto, G.M. Pharr and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-Component Equiatomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140.

V. Randle and G. Owen, Mechanisms of Grain Boundary Engineering, Acta Mater., 2006, 54, p 1777–1783.

V. Randle, M. Coleman and M. Waterton, The Role of Σ9 Boundaries in Grain Boundary Engineering, Metall. Mater. Trans. A, 2011, 42(3), p 582–586.

X.L. An, C.L. Chua, L. Zhou, J. Ji, B.L. Shen and P.K. Chu, Controlling the Corrosion Behavior of CoNiFe Medium Entropy Alloy by Grain Boundary Engineering, Mater. Charact., 2020, 164, p 110323.

C.L. Hu, S. Xia, H. Li, T.G. Liu, B.G. Zhou, W.J. Chen and N. Wang, Improving the Intergranular Corrosion Resistance of 304 Stainless Steel by Grain Boundary Network Control, Corros. Sci., 2011, 53(5), p 1880–1886.

Q. Deng, Y.J. Tang, Y.F. Tan, X.H. Tan, Y. Yang and H. Xu, Effect of Grain Boundary Character Distribution on Soft Magnetic Property of Face-Centered Cubic FeCoNiAl0.2 Medium-Entropy Alloy, Mater. Charact., 2020, 159, p 110028.

X.J. Guan, F. Shi, H.M. Ji and X.W. Li, Gain Boundary Character Distribution Optimization of Cu-16at.%Al Alloy by Thermomechanical Process: Critical Role of Deformation Microstructure, Mater. Sci. Eng.: A, 2019, 765, p 138299.

Y. Liu, Y. He and S.L. Cai, Gradient Recrystallization to Improve Strength and Ductility of Medium-Entropy Alloy, J. Alloys Compd., 2021, 853, p 157388.

R.J. Vikram, S. Gaddam, R. Kalsar, S. Acharya and S. Suwas, A Fractal Approach to Predict the Oxidation and Corrosion Behavior of a Grain Boundary Engineered Low SFE High Entropy Alloy, Materialia, 2019, 7, p 100398.

Y.X. He, H.X. Yang, C.D. Zhao, Y. Zhang, X.Y. Pan, J.S. Li and J. Wang, Enhancing Mechanical Properties of Al0.25CoCrFeNi High-Entropy Alloy Via Cold Rolling and Subsequent Annealing, J. Alloys Compd., 2020, 830, p 154645.

P. Asghari-Rad, P. Sathiyamoorthi, N.T. Nguyen, J.W. Bae, H. Shahmir and H.S. Kim, Fine-Tuning of Mechanical Properties in V10Cr15Mn5Fe35Co10Ni25 High-Entropy Alloy Through High-Pressure Torsion and Annealing, Mater. Sci. Eng.: A, 2020, 771, p 138604.

F. Shi, R.H. Gao, X.J. Guan, C.M. Liu and X.W. Li, Application of Grain Boundary Engineering to Improve Intergranular Corrosion Resistance in a Fe-Cr-Mn-Mo-N High-Nitrogen and Nickel-Free Austenitic Stainless Steel, Acta Metall. Sin. (Engl. Lett.), 2020, 33, p 789–798.

T.G. Liu, S. Xia, D.H. Du, Q. Bai, L.F. Zhang and Y.H. Lu, Grain Boundary Engineering of Large-Size 316 Stainless Steel Via Warm-Rolling for Improving Resistance to Intergranular Attack, Mater. Lett., 2019, 234, p 201–204.

C.L. Chen and M.J. Tan, Effect of Grain Boundary Character Distribution (GBCD) on the Cavitation Behaviour During Superplastic Deformation of Al7475, Mater. Sci. Eng.: A, 2002, 338(1–2), p 243–252.

X. He, L. Liu, T. Zeng and Y. Yao, Micromechanical Modeling of Work Hardening for Coupling Micro-structure Evolution, Dynamic Recovery and Recrystallization: Application to High Entropy Alloys, Int. J. Mech. Sci., 2020, 177, p 105567.

Y.N. Wu, C.M. Liu, H.C. Liao, J.H. Jiang and A.B. Ma, Joint Effect of Micro-sized Si Particles and Nano-sized Dispersoids on the Flow Behavior and Dynamic Recrystallization of Near-Eutectic Al-Si Based Alloys During Hot Compression, J. Alloys Compd., 2021, 856, p 158072.

G.K. Williamson and R.E. Smallman III., Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-ray Debye–Scherrer Spectrum, Philos. Mag., 1956, 1(1), p 34–46.

E.O. Hall, The Deformation and Ageing of Mild Steel: III Discussion of Results, Proc. Phys. Soc. Sect. B, 1951, 64, p 747–753.

R.W. Armstrong, The (Cleavage) Strength of Pre-cracked Polycrystals, Eng. Fract. Mech., 1987, 28, p 529–538.

N. Hansen, Hall–Petch Relation and Boundary Strengthening, Scr. Mater., 2004, 51, p 801–806.

S.Y. Chen, K.K. Tseng, Y. Tong, W.D. Li, C.W. Tsai, J.W. Yeh and P.K. Liaw, Grain Growth and Hall–Petch Relationship in a Refractory HfNbTaZrTi High-Entropy Alloy, J. Alloy. Compd., 2019, 795, p 19–26.

D. Liu, X. Jin, N. Guo, P.K. Liaw and J.W. Qiao, Non-equiatomic FeMnCrNiAl High-Entropy Alloys with Heterogeneous Structures for Strength and Ductility Combination, Mater. Sci. Eng.: A, 2021, 818, p 141386.

H. Shahmir, T. Mousavi, J. He, Z.P. Lu, M. Kawasaki and T.G. Langdon, Microstructure and Properties of a CoCrFeNiMn High-Entropy Alloy Processed by Equal-Channel Angular Pressing, Mater. Sci. Eng., A, 2017, 705, p 411–419.

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An and Z.P. Lu, A Precipitation-Hardened High-Entropy Alloy with Outstanding Tensile Properties, Acta Mater., 2016, 102, p 187–196.

M.J. Yao, K.G. Pradeep, C.C. Tasan and D. Raabe, A Novel, Single Phase, Non-equiatomic FeMnNiCoCr High-Entropy Alloy with Exceptional Phase Stability and Tensile Ductility, Scr. Mater., 2014, 72–73, p 5–8.

P. Sathiyamoorthi, P. Asghari-Rad, J.W. Bae and H.S. Kim, Fine Tuning of Tensile Properties in CrCoNi Medium Entropy Alloy Through Cold Rolling and Annealing, Intermetallics, 2019, 113, p 106578.

X.L. An, H. Zhao, T. Dai, H.G. Yua, Z.H. Huang, C. Guo, P.K. Chu and C.L. Chu, Effects of Heat Treatment on the Microstructure and Properties of Cold-Forged CoNiFe Medium Entropy Alloy, Intermetallics, 2019, 110, p 106477.

X. Zhang, H. Wang, R.O. Scattergood, J. Narayan and C.C. Koch, Mechanical Properties of Cyromilled Nanocrystalline Zn Studied by the Miniaturized Disk Bend Test, Acta Mater., 2002, 50(13), p 3527–3533.

N. Kamikawa, K. Sato, G. Miyamoto, M. Murayama, N. Sekido, K. Tsuzaki and T. Furuhara, Stress-Strain Behavior of Ferrite and Bainite with Nano-precipitation in Low Carbon Steels, Acta Mater., 2015, 83, p 383–396.

L. Meng and I. Baker, Nitriding of a High Entropy FeNiMnAlCr Alloy, J. Alloy. Compd., 2015, 645, p 376–381.

E. Bailey and P.B. Hirsch, The Dislocation Distribution, Flow Stress, and Stored Energy in Cold-Worked Polycrystalline Silver, Philos. Mag., 1960, 5(53), p 485–497.

A. Hughes and N. Hansen, Microstructure and Strength of Nickel at Large Strains, Acta Mater., 2000, 48, p 2985–3004.

J.Y. He, C. Zhu, D.Q. Zhou, W.H. Liu, T.G. Nieh and Z.P. Lu, Steady State Flow of the FeCoNiCrMn High Entropy Alloy at Elevated Temperatures, Intermetallics, 2014, 55, p 9–14.

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler and E.P. George, Temperature Dependencies of the Elastic Moduli and Thermal Expansion Coefficient of an Equiatomic, Single-Phase CoCrFeMnNi High-Entropy Alloy, J. Alloy. Compd., 2015, 623, p 348–353.

S. Mahajan, Critique of Mechanisms of Formation of Deformation, Annealing and Growth Twins: Face-Centered Cubic Metals and Alloys, Scr. Mater., 2013, 68(2), p 95–99.

Y.C. Xin, L.C. Lv, H.W. Chen, C. He, H.H. Yu and Q. Liu, Effect of Dislocation-Twin Boundary Interaction on Deformation by Twin Boundary Migration, Mater. Sci. Eng., A, 2016, 662, p 95–99.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345(6201), p 1153–1158.

L. Lu, Z.S. You and K. Lu, Work Hardening of Polycrystalline Cu with Nanoscale Twins, Scr. Mater., 2012, 66(11), p 837–842.

Acknowledgments

This work was funded by National Major Basic Research Project of China (Grant No.: 613321). The authors thank Dr. Aiqun Xu for TEM observation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that: No conflict of interest exists in the submission of this manuscript, and manuscript is approved by all authors for publication. The work described was original research that has not been published previously, and not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, J., Liao, H., Chen, H. et al. Mechanical Behaviors of Cold-Rolled and Subsequently Annealed Fe35Ni35Cr20Mn10 High-Entropy Alloy. J. of Materi Eng and Perform 30, 8145–8156 (2021). https://doi.org/10.1007/s11665-021-06016-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06016-4