Abstract

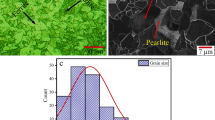

Activated flux gas tungsten arc welding of 316L austenitic stainless steel plates was carried out using different multicomponent fluxes composed of various oxides. The performance of these fluxes was further compared with SiO2 flux for different weld characteristics such as macro and microstructure. Hardness and residual stress analysis on weld beads were carried out. Electrochemical corrosion tests were conducted, to study the corrosion behaviors of the weld. Tool wear pattern and mechanism were analyzed. Among all used multicomponent fluxes, flux composed of 40% SiO2, 35% TiO2, 15% MoO3, and 10% NiO named Flux-3 provided better weld quality. A better depth of penetration with fine dendritic grain structure was obtained using a Flux-3. Better conceived residual stress from higher depth-to-width ratio of weld using Flux-3 is supported by XRD stress analysis. A lower corrosion rate was observed in the welds using Flux-3. Tool wear in welding with Flux-3 was higher compared with welding without any flux.

Similar content being viewed by others

References

K. Hariharan, G. Balachandran, and M.S. Prasad, Application of Cost-Effective Stainless Steel for Automotive Components, Mater. Manuf. Process., 2009, 24(12), p 1442–1452. https://doi.org/10.1080/10426910903179989

Y.H. Kim, K.Y. Kim, and Y.D. Lee, Nitrogen-Alloyed, Metastable Austenitic Stainless Steel for Automotive Structural Applications, Mater. Manuf. Process., 2004, 19(1), p 51–59. https://doi.org/10.1081/AMP-120027498

S. Kou, Welding Metallurgy, Wiley, Hoboken, 2002. https://doi.org/10.1002/0471434027

P. Sharma and D.K. Dwivedi, Comparative Study of Activated Flux-GTAW and Multipass-GTAW Dissimilar P92 Steel-304H ASS Joints, Mater. Manuf. Process., 2019, 34(11), p 1195–1204. https://doi.org/10.1080/10426914.2019.1605175

J.P. Oliveira, T.M. Curado, Z. Zeng, J.G. Lopes, E. Rossinyol, J.M. Park, N. Schell, F.M. Braz Fernandes, and H.S. Kim, Gas Tungsten Arc Welding of As-Rolled CrMnFeCoNi High Entropy Alloy, Mater. Des., 2020, 189, p 108505.

M. Ragavendran and M. Vasudevan, Laser and Hybrid Laser Welding of Type 316L(N) Austenitic Stainless Steel Plates, Mater. Manuf. Process., 2020, 35(8), p 922–934. https://doi.org/10.1080/10426914.2020.1745231

S. Lathabai, B.L. Jarvis, and K.J. Barton, Comparison of Keyhole and Conventional Gas Tungsten Arc Welds in Commercially Pure Titanium, Mater. Sci. Eng. A, 2001, 299(1–2), p 81–93. https://doi.org/10.1016/S0921-5093(00)01408-8

A.M. Sales, E.M. Westin, and B.L. Jarvis, Effect of Nitrogen in Shielding Gas of Keyhole GTAW on Properties of Duplex and Superduplex Welds, Weld. World, 2017, 61(6), p 1133–1140.

D.S. Howse and W. Lucas, Investigation into Arc Constriction by Active Fluxes for Tungsten Inert Gas Welding, Sci. Technol. Weld. Join., 2000, 5(3), p 189–193.

A. Kulkarni, D.K. Dwivedi, and M. Vasudevan, Study of Mechanism, Microstructure and Mechanical Properties of Activated Flux TIG Welded P91 Steel-P22 Steel Dissimilar Metal Joint, Mater. Sci. Eng. A, 2018, 731, p 309–323.

P.J. Modenesi, E.R. Apolinário, and I.M. Pereira, TIG Welding with Single-Component Fluxes, J. Mater. Process. Technol., 2000, 99(1), p 260–265.

Y. Morisada, H. Fujii, and N. Xukun, Development of Simplified Active Flux Tungsten Inert Gas Welding for Deep Penetration, Mater. Des., 2014, 54, p 526–530. https://doi.org/10.1016/j.matdes.2013.08.081

K.D. Ramkumar, B.M. Kumar, M.G. Krishnan, S. Dev, A.J. Bhalodi, N. Arivazhagan, and S. Narayanan, Studies on the Weldability, Microstructure and Mechanical Properties of Activated Flux TIG Weldments of Inconel 718, Mater. Sci. Eng. A, 2015, 639, p 234–244.

S. Tathgir and A. Bhattacharya, Activated-TIG Welding of Different Steels: Influence of Various Flux and Shielding Gas, Mater. Manuf. Process., 2016, 31(3), p 335–342. https://doi.org/10.1080/10426914.2015.1037914

R.S. Vidyarthy and D.K. Dwivedi, Activating Flux Tungsten Inert Gas Welding for Enhanced Weld Penetration, J. Manuf. Process., 2016, 22, p 211–228. https://doi.org/10.1016/J.JMAPRO.2016.03.012

X. Wang, J. Huang, Y. Huang, D. Fan, and Y. Guo, Investigation of Heat Transfer and Fluid Flow in Activating TIG Welding by Numerical Modeling, Appl. Therm. Eng., 2017, 113, p 27–35.

K.-H. Tseng and C.-Y. Hsu, Performance of Activated TIG Process in Austenitic Stainless Steel Welds, J. Mater. Process. Technol., 2011, 211(3), p 503–512. https://doi.org/10.1016/J.JMATPROTEC.2010.11.003

T.-S. Chern, K.-H. Tseng, and H.-L. Tsai, Study of the Characteristics of Duplex Stainless Steel Activated Tungsten Inert Gas Welds, Mater. Des., 2011, 32(1), p 255–263. https://doi.org/10.1016/j.matdes.2010.05.056

M. Vasudevan, Effect of A-TIG Welding Process on the Weld Attributes of Type 304LN and 316LN Stainless Steels, J. Mater. Eng. Perform., 2017, 26, p 1325.

S. Jayakrishnan, P. Chakravarthy, and A. Muhammed Rijas, Effect of Flux Gap and Particle Size on the Depth of Penetration in FBTIG Welding of Aluminium, Trans. Indian Inst. Met., 2017, 70(5), p 1329–1335. https://doi.org/10.1007/s12666-016-0929-1

S. Jayakrishnan and P. Chakravarthy, Flux Bounded Tungsten Inert Gas Welding for Enhanced Weld Performance—A Review, J. Manuf. Process., 2017, 28, p 116–130. https://doi.org/10.1016/j.jmapro.2017.05.023

D. Pandya, A. Badgujar, and N. Ghetiya, A Novel Perception Toward Welding of Stainless Steel by Activated TIG Welding: A Review, Mater. Manuf. Process., 2021, 36(8), p 877–903. https://doi.org/10.1080/10426914.2020.1854467

M. Kuo, Z. Sun, and D. Pan, Laser Welding with Activating Flux, Sci. Technol. Weld. Join., 2001, 6(1), p 17–22.

A. Babbar, A. Kumar, V. Jain, and D. Gupta, Enhancement of Activated Tungsten Inert Gas (A-TIG) Welding Using Multi-component TiO2-SiO2-Al2O3 Hybrid Flux, Measurement, 2019, 148, p 106912. https://doi.org/10.1016/j.measurement.2019.106912

H.L. Lin and T.M. Wu, Effects of Activating Flux on Weld Bead Geometry of Inconel 718 Alloy TIG Welds, Mater. Manuf. Process., 2012, 27(12), p 1457–1461.

H.-Y. Huang, Effects of Shielding Gas Composition and Activating Flux on GTAW Weldments, Mater. Des., 2009, 30(7), p 2404–2409. https://doi.org/10.1016/J.MATDES.2008.10.024

S.G. Nayee and V.J. Badheka, Effect of Oxide-Based Fluxes on Mechanical and Metallurgical Properties of Dissimilar Activating Flux Assisted-Tungsten Inert Gas Welds, J. Manuf. Process., 2014, 16(1), p 137–143. https://doi.org/10.1016/J.JMAPRO.2013.11.001

E. Ahmadi and A.R. Ebrahimi, Welding of 316L Austenitic Stainless Steel with Activated Tungsten Inert Gas Process, J. Mater. Eng. Perform., 2015, 24(2), p 1065–1071. https://doi.org/10.1007/s11665-014-1336-6

V. Maduraimuthu, M. Vasudevan, V. Muthupandi, A.K. Bhaduri, and T. Jayakumar, Effect of Activated Flux on the Microstructure, Mechanical Properties, and Residual Stresses of Modified 9Cr-1Mo Steel Weld Joints, Metall. Mater. Trans. B Process. Metall. Mater. Process. Sci., 2012, 43(1), p 123–132.

D. Patel and S. Jani, Techniques to Weld Similar and Dissimilar Materials by ATIG Welding—An Overview, Mater. Manuf. Process., 2020, 00(00), p 1–16. https://doi.org/10.1080/10426914.2020.1802040

S. Lu, H. Fujii, H. Sugiyama, and K. Nogi, Mechanism and Optimization of Oxide Fluxes for Deep Penetration in Gas Tungsten Arc Welding, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2003, 34A(9), p 1901–1907.

S.A. Kumar and P. Sathiya, Experimental Investigation of the A-TIG Welding Process of Incoloy 800H, Mater. Manuf. Process., 2015, 30(9), p 1154–1159. https://doi.org/10.1080/10426914.2015.1019092

K. Devendranath Ramkumar, S. Dev, V. Saxena, A. Choudhary, N. Arivazhagan, and S. Narayanan, Effect of Flux Addition on the Microstructure and Tensile Strength of Dissimilar Weldments Involving Inconel 718 and AISI 416, Mater. Des., 2015, 87, p 663–674. https://doi.org/10.1016/j.matdes.2015.08.075

D. Fan and Y. Huang, Study on Activating Tig Welding for Aluminium Alloys, Weld. World, 2013, 49(1), p 22–25. https://doi.org/10.1007/BF03266459

M. Vasudevan, Effect of A-TIG Welding Process on the Weld Attributes of Type 304LN and 316LN Stainless Steels, J. Mater. Eng. Perform., 2017, 26(3), p 1325–1336. https://doi.org/10.1007/s11665-017-2517-x

J. Sivakumar, M. Vasudevan, and N.N. Korra, Effect of Activated Flux Tungsten Inert Gas (A-TIG) Welding on the Mechanical Properties and the Metallurgical and Corrosion Assessment of Inconel 625, Weld. World, 2021, 65(6), p 1061–1077. https://doi.org/10.1007/s40194-020-01061-4

R.S. Vidyarthy and D.K. Dwivedi, Analysis of the Corrosion Behavior of an A-TIG Welded SS 409 Weld Fusion Zone, J. Mater. Eng. Perform., 2017, 26(11), p 5375–5384. https://doi.org/10.1007/S11665-017-3022-Y

K.D. Ramkumar, P.S. Goutham, V.S. Radhakrishna, A. Tiwari, and S. Anirudh, Studies on the Structure-Property Relationships and Corrosion Behaviour of the Activated Flux TIG Welding of UNS S32750, J. Manuf. Process., 2016, 23, p 231–241. https://doi.org/10.1016/j.jmapro.2016.05.006

W. Chuaiphan and L. Srijaroenpramong, Effect of Welding Speed on Microstructures, Mechanical Properties and Corrosion Behavior of GTA-Welded AISI 201 Stainless Steel Sheets, J. Mater. Process. Technol., 2014, 214(2), p 402–408.

A.V. Bansod, A.P. Patil, and S. Shukla, Effect of Heat on Microstructural, Mechanical and Electrochemical Evaluation of Tungsten Inert Gas Welding of Low-Nickel ASS, Anti-Corrosion Methods Mater., 2018, 65(6), p 605–615.

G. Shit, M.V. Kuppusamy, and S. Ningshen, Corrosion Resistance Behavior of GTAW Welded AISI Type 304L Stainless Steel, Transactions of the Indian Institute of Metals, 2019, 72, p 2981–2995.

H. Ozden and K.T. Gursel, Service Life of Tungsten Electrodes in Hyperbaric Dry Underwater Welding Service Life Diagrams Were Developed for Two Types of Commonly Used Tungsten Electrodes, Weld. J., 2005, 84(6), p 94–99.

P. Sahoo, T. Debroy, and M.J. McNallan, Surface Tension of Binary Metal—Surface Active Solute Systems under Conditions Relevant to Welding Metallurgy, Metall. Trans. B, 1988, 19(3), p 483–491. https://doi.org/10.1007/BF02657748

S. Tathgir, D.W. Rathod, and A. Batish, Process Enhancement Using Hydrogen-Induced Shielding: H2-Induced A-TIG Welding Process, Mater. Manuf. Process., 2020, 35(10), p 1084–1095. https://doi.org/10.1080/10426914.2020.1765251

L. Backman and E.J. Opila, Thermodynamic Assessment of the Group IV, V and VI Oxides for the Design of Oxidation Resistant Multi-Principal Component Materials, J. Eur. Ceram. Soc., 2019, 39(5), p 1796–1802. https://doi.org/10.1016/j.jeurceramsoc.2018.11.004

P. Sharma and D.K. Dwivedi, Study on Flux Assisted-Tungsten Inert Gas Welding of Bimetallic P92 Martensitic Steel-304H Austenitic Stainless Steel Using SiO2–TiO2 Binary Flux, Int. J. Press. Vessel. Pip., 2021, 192, p 104423.

Y. Feng, Z. Luo, Z. Liu, Y. Li, Y. Luo, and Y. Huang, Keyhole Gas Tungsten Arc Welding of AISI 316L Stainless Steel, Mater. Des., 2015, 85, p 24–31. https://doi.org/10.1016/J.MATDES.2015.07.011

H.Y. Huang, S.W. Shyu, K.H. Tseng, and C.P. Chou, Evaluation of TIG Flux Welding on the Characteristics of Stainless Steel, Sci. Technol. Weld. Join., 2005, 10(5), p 566–573. https://doi.org/10.1179/174329305X48329

A.A. Ogwu, T.H. Darma, and E. Bouquerel, Electrical Resistivity of Copper Oxide Thin Films Prepared by Reactive Magnetron Sputtering, J. Achiev. Mater. Manuf. Eng., 2007, 24(1), p 172–177.

A.J. Hassan, Study of Optical and Electrical Properties of Nickel Oxide (NiO) Thin Films Depo-Sited by Using a Spray Pyrolysis Technique, J. Mod. Phys., 2014, 5, p 2184–2191. https://doi.org/10.4236/jmp.2014.518212

P. Dutta, Y. Joshi, and C. Franche, Determination of Gas Tungsten Arc Welding Efficiencies, Exp. Therm. Fluid Sci., 1994, 9(1), p 80–89.

S. Kumar and A.S. Shahi, Effect of Heat Input on the Microstructure and Mechanical Properties of Gas Tungsten Arc Welded AISI 304 Stainless Steel Joints, Mater. Des., 2011, 32(6), p 3617–3623.

H. Schönmaier, R. Krein, M. Schmitz-Niederau, and R. Schnitzer, Influence of the Heat Input on the Dendritic Solidification Structure and the Mechanical Properties of 2.25Cr-1Mo-0.25V Submerged-Arc Weld Metal, J. Mater. Eng. Perform., 2021, 30(10), p 7138–7151. https://doi.org/10.1007/s11665-021-05922-x

Y.C. Lin and P.Y. Chen, Effect of Nitrogen Content and Retained Ferrite on the Residual Stress in Austenitic Stainless Steel Weldments, Materials Science and Engineering, 2001, 307, p 165–171.

ASTM, Standard Practice for Calculation of Corrosion Rates and Related Information (ASTM G 102, 1999), p 1–7. https://doi.org/10.1520/G0102-89R10.

S. Tanhaei, K. Gheisari, and S.R. Alavi Zaree, Effect of Cold Rolling on the Microstructural, Magnetic, Mechanical, and Corrosion Properties of AISI 316L Austenitic Stainless Steel, Int. J. Miner. Metall. Mater., 2018, 25(6), p 630–640. https://doi.org/10.1007/s12613-018-1610-y

H. Ferreira Gomes De Abreu, S. Santana De Carvalho, P. De Lima Neto, R. Pires, D. Santos, N. Freire, P. Maria De Oliveira Silva, S. Souto, and M. Tavares, Deformation Induced Martensite in an AISI 301LN Stainless Steel: Characterization and Influence on Pitting Corrosion Resistance, Mater. Res., 2007, 10(4), p 359–366.

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, Hoboken, 2005.

V. Kuzucu, M. Aksoy, and M.H. Korkut, The Effect of Strong Carbide-Forming Elements Such as Mo, Ti, V and Nb on the Microstructure of Ferritic Stainless Steel, J. Mater. Process. Technol., 1998, 82(1–3), p 165–171.

K. Touileb, A. Ouis, R. Djoudjou, A.C. Hedhibi, H. Alrobei, I. Albaijan, B. Alzahrani, E.S.M. Sherif, and H.S. Abdo, Effects of ATIG Welding on Weld Shape, Mechanical Properties, and Corrosion Resistance of 430 Ferritic Stainless Steel Alloy, Metals (Basel), 2020, 10(3), p 404. https://doi.org/10.3390/met10030404

S.P. Sridhar, S. Arun Kumar, and P. Sathiya, A Study on the Effect of Different Activating Flux on A-TIG Welding Process of Incoloy 800H, Adv. Mater. Sci., 2016, 16(3), p 26–37. https://doi.org/10.1515/adms-2016-0014

V. Tandon, M.A. Thombre, A.P. Patil, R.V. Taiwade, and H. Vashishtha, Effect of Heat Input on the Microstructural, Mechanical, and Corrosion Properties of Dissimilar Weldment of Conventional Austenitic Stainless Steel and Low-Nickel Stainless Steel, Metallogr. Microstruct. Anal., 2020, 9(5), p 668–677. https://doi.org/10.1007/s13632-020-00681-y

M. Dadfar, M.H. Fathi, F. Karimzadeh, M.R. Dadfar, and A. Saatchi, Effect of TIG Welding on Corrosion Behavior of 316L Stainless Steel, Mater. Lett., 2007, 61(11–12), p 2343–2346. https://doi.org/10.1016/j.matlet.2006.09.008

T. Ramkumar, M. Selvakumar, P. Narayanasamy, A.A. Begam, P. Mathavan, and A.A. Raj, Studies on the Structural Property, Mechanical Relationships and Corrosion Behaviour of Inconel 718 and SS 316L Dissimilar Joints by TIG Welding without Using Activated Flux, J. Manuf. Process., 2017, 30, p 290–298. https://doi.org/10.1016/J.JMAPRO.2017.09.028

F. Matsuda, M. Ushio, and T. Kumagai, Study on Gas-Tungsten-Arc Electrode (Report 1): Comparative Study of Characteristics of Oxide-Tungsten Cathode (Welding Physics, Process & Instrument), Trans. JWRI, 1986, 15(1), p 13–19.

Acknowledgments

The authors would like to acknowledge Department of Metallurgical and Materials Engineering, Veer Surendra Sai University of Technology, Burla, for providing facilities to carry out this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sahu, N., Panda, D., Badjena, S.K. et al. Multicomponent Flux for Improved Penetration and Metallurgical Properties Using A-GTAW. J. of Materi Eng and Perform 32, 4237–4248 (2023). https://doi.org/10.1007/s11665-022-07383-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07383-2