Abstract

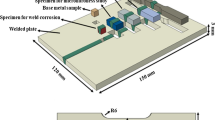

AISI 409 (SS 409) ferritic stainless steel is generally used as the thick gauge section in freight train wagons, in ocean containers, and in sugar refinery equipment. Activating the flux tungsten inert gas (A-TIG) welding process can reduce the welding cost during fabrication of thick sections. However, corrosion behavior of the A-TIG weld fusion zone is a prime concern for this type of steel. In the present work, the effect of the A-TIG welding process parameters on the corrosion behavior of a weld fusion zone made of 8-mm-thick AISI 409 ferritic stainless-steel plate has been analyzed. Potentiodynamic polarization tests were performed to evaluate the corrosion behavior. The maximum corrosion potential (E corr) was shown by the weld made using a welding current of 215 A, a welding speed of 95 mm/min, and a flux coating density of 0.81 mg/cm2. The minimum E corr was observed in the weld made using a welding current of 190 A, a welding speed of 120 mm/min, and a flux coating density of 1.40 mg/cm2. The current study also presents the inclusive microstructure–corrosion property relationships using the collective techniques of scanning electron microscopy, energy-dispersive x-ray spectroscopy, and x-ray diffraction.

Similar content being viewed by others

References

T. Balusamy, S. Kumar, and T.S.N. Sankara, Narayanan, Effect of Surface Nanocrystallization on the Corrosion Behaviour of AISI, 409 Stainless Steel, Corros. Sci., 2010, 11, p 3826–3834

C.J. Van Niekerk, M. Du Toit, M.W. Erwee, C.J. Van Niekerk, M. Du Toit, and M.W. Erwee, Sensitization of AISI, 409 Ferritic Stainless Steel During Low Heat Input Arc Welding, Weld. World, 2012, 5, p 54–64

A.K. Lakshminarayanan and V. Balasubramanian, Characteristics of Laser Beam and Friction Stir Welded AISI, 409M Ferritic Stainless Steel Joints, J. Mater. Eng. Perform., 2012, 4, p 530–539

A.K. Lakshminarayanan, K. Shanmugam, and V. Balasubramanian, Fatigue Crack Growth Behavior of Gas Metal Arc Welded AISI, 409 Grade Ferritic Stainless Steel Joints, J. Mater. Eng. Perform., 2009, 7, p 917–924

T.C. Scalise, M.C.L. de Oliveira, I.J. Sayeg, and R.A. Antunes, Sensitization Behavior of Type 409 Ferritic Stainless Steel: Confronting DL-EPR Test and Practice W of ASTM A763, J. Mater. Eng. Perform., 2014, 6, p 2164–2173

R.S. Vidyarthy and D.K. Dwivedi, in Seventh International Conference on Creep, Fatigue and Creep-Fatigue Interaction, Indira Gandhi Centre for Atomic Research, Kalpakkam, Tamil Nadu, India, 19-22 January 2016, pp. 898–903

S. Anttila, P. Karjalainen, and S. Lantto, Mechanical Properties of Ferritic Stainless Steel Welds in Using Type 409 and 430 Filler Metals, Weld. World, 2013, 3, p 335–347

C.R. Thomas and R.L. Apps, in Proceedings of American Society for Testing and Materials (1980), pp. 161–183

M. Du Toit, G.T. Van Rooyen, and D. Smith, Heat-Affected Zone Sensitization and Stress Corrosion Cracking in 12% Chromium Type 1.4003 Ferritic Stainless Steel, Corrosion, 2007, 5, p 395–404

H. Zheng, X. Ye, L. Jiang, B. Wang, Z. Liu, and G. Wang, Study on Microstructure of Low Carbon 12% Chromium Stainless Steel in High Temperature Heat-Affected Zone, Mater. Des., 2010, 10, p 4836–4841

M. van Warmelo, D. Nolan, J. Norrish, M. van Warmelo, D. Nolan, J. Norrish, M. van Warmelo, D. Nolan, and J. Norrish, Mitigation of Sensitisation Effects in Unstabilised 12%Cr Ferritic Stainless Steel Welds, Mater. Sci. Eng. A, 2007, 1-2, p 157–169

R.S. Vidyarthy and D.K. Dwivedi, Activating Flux Tungsten Inert Gas Welding for Enhanced Weld Penetration, J. Manuf. Process., 2016, 22, p 211–228

R.S. Vidyarthy, D.K. Dwivedi, and V. Muthukumaran, Optimization of A-TIG Process Parameters Using Response Surface Methodology, Mater. Manuf. Process., 2017, April, p 1–9

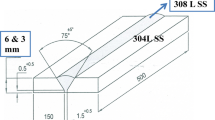

R.S. Vidyarthy, A. Kulkarni, and D.K. Dwivedi, Study of Microstructure and Mechanical Property Relationships of A-TIG Welded P91-316L Dissimilar Steel Joint, Mater. Sci. Eng. A, 2017, 695, p 249–257

R.S. Vidyarthy, D.K. Dwivedi, and M. Vasudevan, Influence of M-TIG and A-TIG Welding Process on Microstructure and Mechanical Behavior of 409 Ferritic Stainless Steel, J. Mater. Eng. Perform., 2017, 3, p 1391–1403

E. Kapilashrami, V. Sahajwalla, and S. Seetharaman, Slag Formation During High Temperature Interactions between Refractories Containing SiO2 and Iron Melts with Oxygen, Ironmak. Steelmak., 2004, 6, p 509–513

L.R. Bhagavathi, G.P. Chaudhari, and S.K. Nath, Mechanical and Corrosion Behaviour of Plain Low Carbon Dual-Phase Steels, Mater. Des., 2011, 1, p 433–440

J.R. Scully and D.W. Taylor, ASM Handbook, Vol 13, 9th ed., ASM, New York, 1987, p 458

C.J. van Niekerk and M. du Toit, Sensitization Behaviour of 11-12% Cr AISI, 409 Stainless Steel during Low Heat Input Welding, J. South. Afr. Inst. Min. Metall., 2011, 111, p 243–256

R.A. Luk and J.A. Davis, Intergranular Corrosion in 12 Percent Chromium Ferritic Stainless Steels, ASTM Int., 1978, 656, p 233–247

J.F. Li, Z.W. Peng, C.X. Li, Z.Q. Jia, W.J. Chen, and Z.Q. Zheng, Mechanical Properties, Corrosion Behaviours and Microstructures of 7075 Aluminium Alloy with Various Aging Treatments, Trans. Nonferrous Met. Soc. China, 2008, 4, p 755–762

Z. Szklarska-Smialowska and J. Mankowski, Crevice Corrosion of Stainless Steels in Sodium Chloride Solution, Corros. Sci., 1978, 11, p 953–960

J. Zhu, L. Xu, Z. Feng, G.S. Frankel, M. Lu, and W. Chang, Galvanic Corrosion of a Welded Joint in 3Cr Low Alloy Pipeline Steel, Corros. Sci., 2016, 111, p 391–403

S.E. Lott and R.C. Alkire, The Role of Inclusions on Initiation of Crevice Corrosion of Stainless-Steel. 1. Experimental Studies, J. Electrochem. Soc., 1989, 4, p 973–979

J.M. Vitek and R.L. Klueh, Precipitation Reactions during the Heat Treatment of Ferritic Steels, Metall. Trans. A, 1983, 6, p 1047–1055

A.S.M. Paroni, N. Alonso-Falleiros, and R. Magnabosco, Sensitization and Pitting Corrosion Resistance of Ferritic Stainless Steel Aged at 800 °C, Corrosion, 2006, 11, p 1039–1046

M.L. Greeff, The Influence of Welding Parameters on the Sensitisation Behaviour of 3Cr12, University of Pretoria, Pretoria, 2006

J.K. Kim, Y.H. Kim, J.S. Lee, and K.Y. Kim, Effect of Chromium Content on Intergranular Corrosion and Precipitation of Ti-Stabilized Ferritic Stainless Steels, Corros. Sci., 2010, 5, p 1847–1852

K.C. Mills and B.J. Keene, Factors Affecting Variable Weld Penetration, Int. Mater. Rev., 1990, 4, p 185–216

L. Antoni and B. Baroux, Cyclic Oxidation Behaviour of Stainless Steels, Appl. Automot. Exhaust Lines Rev. Métall., 2002, 2, p 177–188

D.D.N. Singh, in COFA-1997 (1997), pp. 169–211

Acknowledgments

The authors gratefully acknowledge the financial support provided to this study by the Board of Research in Nuclear Sciences (BRNS) under the Grant No. 36(2)/14/70/2014-BRNS/10416, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vidyarthy, R.S., Dwivedi, D.K. Analysis of the Corrosion Behavior of an A-TIG Welded SS 409 Weld Fusion Zone. J. of Materi Eng and Perform 26, 5375–5384 (2017). https://doi.org/10.1007/s11665-017-3022-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-3022-y