Abstract

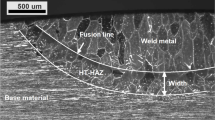

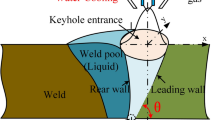

Keyhole gas tungsten arc welding (GTAW) is a relatively new variant used for fabrication of pressure equipment where up to 10-mm-thick material can be autogenously welded in one pass. As the shielding gas used for keyhole mode is typically Ar + 5% H2, the suitability of this method for welding of duplex stainless steels has been investigated. Duplex UNS S31803 and superduplex UNS S32750 schedule 40 seamless pipe was welded using a closed square butt joint configuration. Shielding gas compositions were applied with increasing nitrogen content in argon or argon-hydrogen mixtures. An investigation of the completed welds included examinations of the microstructure, corrosion and mechanical properties of the weld metal. All shielding gases resulted in high-quality welds free from defects, showed high strength and excellent corrosion resistance. Hydrogen additions increased the weld metal nitrogen loss and resulted in lower austenite formation. Ar + 5% H2 showed up to 20 vol.% less austenite than the gas types containing nitrogen and also showed the lowest impact toughness. At least 2% nitrogen would be recommended for optimizing the phase balance and impact toughness. Taking all aspects into account, Ar + 2% N2 is the preferred shielding gas for welding duplex and superduplex with the keyhole GTAW process.

Similar content being viewed by others

References

CSIRO JIP report (1997) High productivity welding of stainless steels—final report for project 94-17

Jarvis BL (2001) Keyhole gas tungsten arc welding: a new process variant. Ph.D. thesis, University of Wollongong

Tusek J, Suban M (2000) Experimental research of the effect of hydrogen in argon as a shielding gas in arc welding of high-alloy stainless steel. Int J Hydrog Energy 25(4):369–376

Murphy AB, Tanaka M, Tashiro S, Sato T, Lowke JJ (2009) A computational investigation of the effectiveness of different shielding gas mixtures for arc welding. J Phys D Appl Phys 42(11):115–205

Alvarez-Armas I (2008) Duplex stainless steels: brief history and some recent alloys. Recent Patents on Mechanical Engineering 1(1):51–57

Hertzman S, Jargelius-Pettersson RFA, Blom R, Eriksson J, Kivineva E (1996) Influence of shielding gas composition and welding parameters on the N-content and corrosion properties of welds in N-alloyed stainless steel grades. ISIJ Int 36(7):968–976

Ogawa K, Miura M (1991) Hydrogen cracking in duplex stainless steel weldments. Weld Int 5:691–696

Shinozaki K, Ke L, North TH (1992) Hydrogen cracking in duplex stainless steel weld metal. Weld J 11:387-s–396-s

NORSOK M-601:2016 (2016) Welding and inspection of piping, Norwegian Technology Standards Institution, 34pp.

NACE Standard MR0175-15/ISO 15156 (1999) Standard material requirements, sulfide stress cracking resistant metallic materials for oilfield equipment. NACE Int., Houston 164pp

Karlsson L (2012) Welding of duplex stainless steels—a review of current recommendations. Weld World 56(5/6):65–76

Davison RM, Redmond JD (1991) A guide to using duplex stainless steels. Mater des 12(4):187–192

Gunn R (1997) Duplex stainless steels: microstructure, properties and applications. Woodhead Publishing, Cambridge 216 pp

Holmberg B (1997) How to perform welding in duplex stainless steels to obtain optimum weld metal properties. Stainless Steel World 9(2):28–33/ACOM 13(3):1–7

Bonnefois B, Soulignac P, Charles J (1991) Some aspects on nitrogen introduction in the duplex weld pool. Proc. Duplex Stainless Steels ‘91, Beaune, France 1:469–478

Jonsson O, Liljas M, Stenvall P (1991) The role of nitrogen in longitudinal welding of tubing in duplex stainless steels, Proc. Duplex Stainless Steels ’91, Beaune, France, 1:461–468

Urmston SA, Creffield GK, Cole MA, Huang W (1995) Effect of nitrogen containing shielding gases on weldability and corrosion performance of duplex stainless steels. Proc. Duplex Stainless Steels ‘94, Glasgow, Scotland, Paper 27:2:12pp.

Valiente Bermejo MA, Karlsson L, Svensson LE, Hurtig K, Rasmuson H, Frodigh M, Bengtsson P (2015) Effect of shielding gas on welding performance and properties of duplex and superduplex stainless steel welds. Weld World 59(2):239–249

Westin EM, Johansson MM, Bylund L-Å, Pettersson RFA (2014) Effect on microstructure and properties of super duplex stainless steel welds when using backing gas containing nitrogen and hydrogen. Weld World 58(3):347–354

Sales AM, Westin EM, Colegrove P (2016) Effect of nitrogen in backing gas on duplex root weld properties of heavy-walled pipe. Welding in the World 60(5):877–882

Vagn Hansen J, Nielsen TS, Aastrup P (1995) Root surface quality requirements—high efficiency purging or pickling? Proc. Duplex Stainless Steels ‘94, Glasgow, Scotland, TWI, 2, 13pp.

Westin EM, Serrander D (2012) Welding stainless steels—experience with water heaters. Weld World 56:14–28

ASTM E1245 (2016) Standard practice for determining the inclusion or second-phase constituent content of metals by automatic image analysis

Liljas M (1995) The welding metallurgy of duplex stainless steels. Proc. Duplex Stainless Steels ‘94, Glasgow, Scotland, Paper KV:2:15pp.

Ogawa T, Koseki T (1989) Effect of composition profiles on metallurgy and corrosion behavior of duplex stainless steel weld metals. Weld J 68:181s–191s

Westin EM, Brolund B, Hertzman S (2008) Weldability aspects of a newly developed duplex stainless steel LDX 2101. Steel res Int 79:473–481

Westin EM, Hertzman S (2014) Element distribution in lean duplex stainless steel welds. Weld World 58:143–160

Westin EM, Olsson C-OA, Hertzman S (2008) Weld oxide formation on lean duplex stainless steel. Corros Sci 50:2620–2634

Brauser S, Kannengiesser T (2013) Hydrogen absorption and diffusion in different welded duplex steel. Weld World 55:26–36

Dabah E, Kannengiesser T, Mente T, Brauser S (2013) Quantification of hydrogen effective diffusion coefficients and effusion behavior in duplex stainless steel weld metals. Weld World 57(4):561–567

Brauser S, Kannengiesser T (2010) Hydrogen absorption of different welded duplex steels. Int J Hydrog Energy 35(9):4368–4374

ASTM G48—standard test methods for pitting and crevice corrosion resistance of stainless steels and related alloys by use of ferric chloride solution. 2011

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels. Welding metallurgy and weldability of stainless steels, 376pp. Wiley-VCH, Weinheim

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IX - Behaviour of Metals Subjected to Welding

Rights and permissions

About this article

Cite this article

Sales, A.M., Westin, E.M. & Jarvis, B.L. Effect of nitrogen in shielding gas of keyhole GTAW on properties of duplex and superduplex welds. Weld World 61, 1133–1140 (2017). https://doi.org/10.1007/s40194-017-0486-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0486-1