Carbon fiber-reinforced polymer (CFRP) composites are widely used in many industries due to their outstanding multifunctional properties. The durability and performance of these materials depend on their mechanical properties and fiber/matrix interface. A good interface ensures not only efficient load transfer but also long-term safety. Studies demonstrate that composites are affected by moisture, ultraviolet irradiation, and cyclic temperature variations. This review focuses on the performance of CFRP at high and cryogenic temperatures. There is a critical need to characterize and predict composite interfacial performance under different temperature fluxes. This paper presents an overview of the fiber-matrix interface at different temperatures and strain rates. First, interfacial mechanisms, mechanical tests, physical and chemical characterization techniques, and numerical simulations are introduced. Then, the effect of high temperatures, low temperatures, and strain rates on the composite’s interface are discussed. Interfacial adhesion is quantified utilizing different experimental techniques, including Iosipescu, short beam shear, fiber pullout/pushout, and fragmentation tests. While these report different interfacial strength values, factors that affect this variability are studied. High temperatures greatly decrease the interface strength of polymer matrix composites (PMCs) at temperatures above the resin’s glass transition temperature (Tg). Cryogenic temperatures create micro-cracks between the fiber and polymer matrix. While mechanical tests, morphology observations, and chemical analysis help explain interfacial debonding after testing, these cannot explain the debonding process during testing. Simulation techniques add to the fundamentals of mechanics and predict the interfacial debonding process, and the methods to predict interfacial failure in extreme environments are discussed.

Similar content being viewed by others

References

H. S. Bedi, B. Billing, and P. Agnihotri, “Interfacial shear strength of carbon nanotubes based hybrid composites: effect of loading rate,” Frattura ed Integrità Strutturale, 13, 571-576 (2019).

P. D. Pastuszak and A. Muc, “Application of composite materials in modern constructions,” KEM, 542, 119-129 (2013).

S. Huang, Q. Fu, L. Yan, and B. Kasal, “Characterization of interfacial properties between fibre and polymer matrix in composite materials - A critical review,” J. Mater. Research and Technol., 13, 1441-1484 (2021).

X. Zhang, X. Fan, C. Yan, H. Li, Y. Zhu, X. Li, and L. Yu, “Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide,” ACS Appl. Mater. Interfaces, 4, 1543-1552 (2012).

F. Teklal, A. Djebbar, S. Allaoui, G. Hivet, Y. Joliff, and B. Kacimi, “A review of analytical models to describe pull-out behavior - Fiber/matrix adhesion,” Compos. Struct., 201, 791-815 (2018).

S. Zhandarov, “Characterization of fiber/matrix interface strength: applicability of different tests, approaches and parameters,” Compos. Sci. and Technol., 65, 149-160 (2005).

A. Molazemhosseini, H. Tourani, M. R. Naimi-Jamal, and A. Khavandi, “Nanoindentation and nanoscratching responses of PEEK based hybrid composites reinforced with short carbon fibers and nano-silica,” Polymer Testing, 32, 525-534 (2013).

A. Godara, D. Raabe, and S. Green, “The influence of sterilization processes on the micromechanical properties of carbon fiber-reinforced PEEK composites for bone implant applications,” Acta Biomaterialia, 3, 209-220 (2007).

S. Saiello, J. Kenny, and L. Nicolais, “Interface morphology of carbon fibre/PEEK composites,” J. Mater. Sci., 25, 3493-3496 (1990).

M. Zhang, J. Xu, Z. Zhang, H. Zeng, and X. Xiong, “Effect of transcrystallinity on tensile behaviour of discontinuous carbon fibre reinforced semicrystalline thermoplastic composites,” Polymer, 37, 5151-5158 (1996).

L. T. Drzal and M. Madhukar, “Fibre-matrix adhesion and its relationship to composite mechanical properties,” J. Mater. Sci., 28, 569-610 (1993).

S. Ghaffari, G. Seon, and A. Makeev, “In-situ SEM based method for assessing fiber-matrix interface shear strength in CFRPs,” Materials & Design, 197, 109242 (2021).

H. S. Bedi, B. K. Billing, and P. K. Agnihotri, “Interphase engineering in carbon fiber/epoxy composites: Rate sensitivity of interfacial shear strength and interfacial fracture toughness,” Polymer Compos., 41, 2803-2815 (2020).

R. Sweat, J. G. Park, and R. Liang, “A Digital Twin Approach to a Quantitative Microstructure-Property Study of Carbon Fibers through HRTEM Characterization and Multiscale FEA,” Materials, 13, 4231 (2020).

R. D. Downes, A. Hao, J. G. Park, Y.-F. Su, R. Liang, B. D. Jensen, E. J. Siochi, and K. E. Wise, “Geometrically constrained self-assembly and crystal packing of flattened and aligned carbon nanotubes,” Carbon, 93, 953-966 (2015).

Y.-S. Dessureault, C. Jolowsky, S. Bell, S. Spiric, J. Molyneux, J. G. Park, A. Hao, and Z. Liang, “Tensile performance and failure modes of continuous carbon nanotube yarns for composite applications,” Mater. Sci. and Eng. A, 792, 139824 (2020).

E. J. Garcia, B. L. Wardle, and A. John Hart, “Joining prepreg composite interfaces with aligned carbon nanotubes,” Compos., Part A, 39, 1065-1070 (2008).

F. Zhao, Y. Huang, L. Liu, Y. Bai, and L. Xu, “Formation of a carbon fiber/polyhedral oligomeric silsesquioxane/carbon nanotube hybrid reinforcement and its effect on the interfacial properties of carbon fiber/epoxy composites,” Carbon, 49, 2624-2632 (2011).

J.-K. Kim, Y.-W. Mai, and Y.-W. Mai, “Chapter 2 - Characterization of interfaces,” in: Engineered Interfaces in Fiber Reinforced Composites, J.-K. Kim, Y.-W. Mai, and Y.-W. Mai, eds. (Elsevier Science Ltd, 1998), pp. 5-41.

F. R. Jones, “A Review of interphase formation and design in fibre-reinforced composites,” J. Adhesion Sci. and Technol., 24, 171-202 (2010).

D. Cho, Y. Choi, J.-H. Chang, and L. T. Drzal, “Interphase sizing temperature effect of LaRC PETI-5 on the dynamic mechanical thermal properties of carbon fiber/BMI composites,” Composite Interfaces, 13, 215-229 (2006).

N. Dilsiz and J. P. Wightman, “Surface analysis of unsized and sized carbon fibers,” Carbon, 37, 1105-1114 (1999).

T. J. Swait, C. Soutis, and F. R. Jones, “Optimisation of interfacial properties for tensile strength by plasma polymerisation,” Compos. Sci. and Technol., 68, 2302-2309 (2008).

T. Ramanathan, A. Bismarck, E. Schulz, and K. Subramanian, “Investigation of the influence of acidic and basic surface groups on carbon fibres on the interfacial shear strength in an epoxy matrix by means of single-fibre pull-out test,” Compos. Sci. and Technol., 7 (2001).

H. B. Ezekiel, D. Sharp, M. M. Villalba, and J. Davis, “Laser-anodised carbon fibre: Coupled activation and patterning of sensor substrates,” J. Physics and Chemistry of Solids, 69, 2932-2935 (2008).

H. Guo, Y. D. Huang, L. H. Meng, L. Liu, D. P. Fan, and D. X. Liu, “Interface property of carbon fibers/epoxy resin composite improved by hydrogen peroxide in supercritical water,” Materials Letters, 63, 1531-1534 (2009).

A. Gao, Y. Gu, Q. Wu, C. Yuan, M. Li, and Z. Zhang, “Influence of processing temperature on interfacial behavior of HKT800 carbon fiber with BMI and epoxy matrices,” Chinese J. Aeronautics, 28, 1255-1262 (2015).

M. K. Almutairi, R. A. Felemban, and S. E. Pasha, “The Effect of different surface treatments of carbon fibers and their impact on composites,” Egyptian J. Hospital Medicine, 70, 1275-1281 (2018).

L.-G. Tang and J. L. Kardos, “A review of methods for improving the interfacial adhesion between carbon fiber and polymer matrix,” Polym. Compos., 18, 100-113 (1997).

G. Wu, L. Chen, and L. Liu, “Effects of silanization and silica enrichment of carbon fibers on interfacial properties of methylphenylsilicone resin composites,” Compos., Part A, 98, 159-165 (2017).

C. Wang, J. Li, J. Yu, S. Sun, X. Li, F. Xie, B. Jiang, G. Wu, F. Yu, and Y. Huang, “Grafting of size-controlled graphene oxide sheets onto carbon fiber for reinforcement of carbon fiber/epoxy composite interfacial strength,” Compos., Part A, 101, 511-520 (2017).

Y. Zhang and S.-J. Park, “Influence of the nanoscaled hybrid based on nanodiamond–graphene oxide architecture on the rheological and thermo-physical performances of carboxylated-polymeric composites,” Compos., Part A, 112, 356-364 (2018).

Y. Zhang and S.-J. Park, “Imidazolium-optimized conductive interfaces in multilayer graphene nanoplatelet/epoxy composites for thermal management applications and electroactive devices,” Polymer, 168, 53-60 (2019).

J. Huang, M. Gao, T. Pan, Y. Zhang, and Y. Lin, “Effective thermal conductivity of epoxy matrix filled with poly(ethyleneimine) functionalized carbon nanotubes,” Compos. Sci. and Technol., 95, 16-20 (2014).

Y. Zheng, X. Wang, and G. Wu, “Chemical modification of carbon fiber with diethylenetriaminepentaacetic acid/halloysite nanotube as a multifunctional interfacial reinforcement for silicone resin composites,” Polym. Adv. Technol., 31, 527-535 (2020).

J. Karger-Kocsis, H. Mahmood, and A. Pegoretti, “Recent advances in fiber/matrix interphase engineering for polymer composites,” Progress in Mater. Sci., 73, 1-43 (2015).

F. Stojcevski, T. B. Hilditch, and L. C. Henderson, “A comparison of interfacial testing methods and sensitivities to carbon fiber surface treatment conditions,” Compos., Part A, 118, 293-301 (2019).

F. Stojcevski, T. Hilditch, and L. C. Henderson, “A modern account of Iosipescu testing,” Compos., Part A, 107, 545-554 (2018).

T. Schüller, W. Beckert, B. Lauke, C. Ageorges, and K. Friedrich, “Single fibre transverse debonding: stress analysis of the Broutman test,” Compos., Part A, 31, 661-670 (2000).

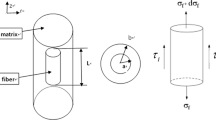

Y. Jia, W. Yan, and H.-Y. Liu, “Carbon fibre pullout under the influence of residual thermal stresses in polymer matrix composites,” Computational Mater. Sci., 62, 79-86 (2012).

Q.-S. Yang and X. Liu, “13 - Mechanical behavior of extra-strong CNT fibers and their composites,” in: Toughening Mechanisms in Composite Materials, Q. Qin and J. Ye, Eds., Woodhead Publishing Series in Composites Science and Engineering (Woodhead Publishing, 2015), pp. 339-372.

L. Teuber, H. Fischer, and N. Graupner, “Single fibre pull-out test versus short beam shear test: comparing different methods to assess the interfacial shear strength,” J. Mater. Sci., 48, 3248-3253 (2013).

B. Miller, P. Muri, and L. Rebenfeld, “A microbond method for determination of the shear strength of a fiber/resin interface,” Compos. Sci. and Technol., 28, 17-32 (1987).

J. A. Nairn, “Analytical Fracture Mechanics Analysis of the Pull-Out Test Including the Effects of Friction and Thermal Stresses,” Adv. Compos. Letters 9, 0963693500000 (2000).

L. Yang and J. L. Thomason, “Interface strength in glass fibre-polypropylene measured using the fibre pull-out and microbond methods,” Compos., Part A, 41, 1077-1083 (2010).

S. Zhandarov, C. Scheffler, E. Mäder, and U. Gohs, “Three Specimen Geometries and Three Methods of Data Evaluation in Single-Fiber Pullout Tests,” Mech. Compos. Mater., 55, 69-84 (2019).

S. Zhandarov, E. Pisanova, and E. Mäder, “Is there any contradiction between the stress and energy failure criteria in micromechanical tests? Part III. Experimental observation of crack propagation in the microbond test,” J. Adhesion Sci. and Technol., 19, 679-704 (2005).

A. Hodzic, S. Kalyanasundaram, A. Lowe, and Z. H. Stachurski, “The microdroplet test: experimental and finite element analysis of the dependance of failure mode on droplet shape,” Composite Interfaces 6, 375-389 (1998).

J. L. Thomason and L. Yang, “Temperature dependence of the interfacial shear strength in glass-fibre polypropylene composites,” Compos. Sci. and Technol., 71, 1600-1605 (2011).

J. Beter, B. Schrittesser, B. Maroh, E. Sarlin, P. F. Fuchs, and G. Pinter, “Comparison and impact of different fiber debond techniques on fiber reinforced flexible composites,” Polymers, 12, 472 (2020).

P. Krishnan, “18 - Evaluation and methods of interfacial properties in fiber-reinforced composites,” in: Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, M. Jawaid, M. Thariq, and N. Saba, eds., Woodhead Publishing Series in Composites Science and Engineering (Woodhead Publishing, 2019), pp. 343-385.

J.-K. Kim, Y.-W. Mai, and Y.-W. Mai, “Chapter 3 - Measurements of interface/interlaminar properties,” in Engineered Interfaces in Fiber Reinforced Composites, J.-K. Kim, Y.-W. Mai, and Y.-W. Mai, eds. (Elsevier Science Ltd, 1998), pp. 43-92.

C. Loumena, M. Nguyen, J. Lopez, and R. Kling, “Potentials for lasers in CFRP production,” Int. Congress on Applications of Lasers & Electro-Optics, 2012, 1026 (2018).

A. Salama, L. Li, P. Mativenga, and A. Sabli, “High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites,” Appl. Phys. A, 122, 73 (2016).

A. M. Abrão, P. E. Faria, J. C. C. Rubio, P. Reis, and J. P. Davim, “Drilling of fiber reinforced plastics: A review,” J. Mater. Processing Technol., 186, 1-7 (2007).

V. Oliveira, S. P. Sharma, M. F. S. F. de Moura, R. D. F. Moreira, and R. Vilar, “Surface treatment of CFRP composites using femtosecond laser radiation,” Optics and Lasers in Eng., 94, 37-43 (2017).

J. Stock, M. F. Zaeh, and M. Conrad, “Remote Laser Cutting of CFRP: Improvements in the Cut Surface,” Physics Procedia, 39, 161-170 (2012).

S. Ghaffari, A. Makeev, G. Seon, D. P. Cole, D. J. Magagnosc, and S. Bhowmick, “Understanding compressive strength improvement of high modulus carbon-fiber reinforced polymeric composites through fiber-matrix interface characterization,” Materials & Design, 193, 108798 (2020).

G. Holmes, R. Peterson, D. Hunston, W. McDonough, and C. Schutte, “The Effect of Nonlinear Viscoelasticity on Interfacial Shear Strength Measurements,” in Time Dependent and Nonlinear Effects in Polymers and Composites, R. Schapery and C. Sun, eds. (ASTM International, 2000), pp. 98-98-20.

G. A. Holmes, R. C. Peterson, D. L. Hunston, and W. G. McDonough, “The Influence of the matrix modulus on the interfacial shear strength parameter,” Proc. 21th Annual Meeting Adhesion Society, February 22-25, Georgia, 175-178 (1998).

T. E. Matikas, “Analysis of Load Transfer Behaviour and Determination of Interfacial Shear Strength in Single-Fibre-Reinforced Titanium Alloys,” Adv. Compos. Letters, 16, 096369350701600 (2007).

L. Broutman, “Measurement of the Fiber-Polymer Matrix Interfacial Strength,” Interfaces in Composites, 27-41 (1969).

J. Vogtmann, A. Klingler, T. Rief, and M. Gurka, “3D X-ray microscopy as a tool for in depth analysis of the interfacial interaction between a single carbon fiber and an epoxy matrix after mechanical loading,” J. Compos. Sci., 5, 121 (2021).

M. J. Pitkethly, J. P. Favre, U. Gaur, J. Jakubowski, S. F. Mudrich, D. L. Caldwell, L. T. Drzal, M. Nardin, H. D. Wagner, L. Di Landro, A. Hampe, J. P. Armistead, M. Desaeger, and I. Verpoest, “A round-robin programme on interfacial test methods,” Compos. Sci. and Technol., 48, 205-214 (1993).

S. Zhandarov, E. Mäder, C. Scheffler, G. Kalinka, C. Poitzsch, and S. Fliescher, “Investigation of interfacial strength parameters in polymer matrix composites: Compatibility and reproducibility,” Adv. Industrial and Eng. Polymer Research, 1, 82-92 (2018).

M. Lebbai, J.-K. Kim, and M. M. F. Yuen, “Effects of moisture and elevated temperature on reliability of interfacial adhesion in plastic packages,” J. of Elect. Mater. 32, 574-582 (2003).

C. A. Fuentes, K. W. Ting, C. Dupont-Gillain, M. Steensma, A. G. Talma, R. Zuijderduin, and A. W. Van Vuure, “Effect of humidity during manufacturing on the interfacial strength of non-pre-dried flax fibre/unsaturated polyester composites,” Compos., Part A, 84, 209-215 (2016).

N. R. Choudhury, A. G. Kannan, and N. K. Dutta, “CHAPTER 21 - Novel nanocomposites and hybrids for lubricating coating applications,” in Tribology and Interface Engineering Series, K. Friedrich and A. K. Schlarb, Eds., Tribology of Polymeric Nanocomposites (Elsevier, 2008), Vol. 55, pp. 501-542.

Q. Wu, M. Li, Y. Gu, S. Wang, and Z. Zhang, “Imaging the interphase of carbon fiber composites using transmission electron microscopy: Preparations by focused ion beam, ion beam etching, and ultramicrotomy,” Chinese J. Aeronautics, 28, 1529-1538 (2015).

M. C. Seghini, F. Touchard, F. Sarasini, L. Chocinski-Arnault, D. Mellier, and J. Tirillò, “Interfacial adhesion assessment in flax/epoxy and in flax/vinylester composites by single yarn fragmentation test: Correlation with micro-CT analysis,” Compos., Part A, 113, 66-75 (2018).

D. Titus, E. James Jebaseelan Samuel, and S. M. Roopan, “Chapter 12 - Nanoparticle characterization techniques,” in Green Synthesis, Characterization and Applications of Nanoparticles, A. K. Shukla and S. Iravani, Eds., Micro and Nano Technologies (Elsevier, 2019), pp. 303-319.

C. Jia, Q. Wang, P. Chen, S. Lu, and R. Ren, “Wettability assessment of plasma-treated PBO fibers based on thermogravimetric analysis,” Int. J. Adhesion and Adhesives, 74, 123-130 (2017).

H. N. Dhakal, Z. Y. Zhang, and N. Bennett, “Influence of fibre treatment and glass fibre hybridisation on thermal degradation and surface energy characteristics of hemp/unsaturated polyester composites,” Compos., Part B, 43, 2757-2761 (2012).

M. A. A. Dzul-Cervantes, O. F. Pacheco-Salazar, L. A. Can-Herrera, M. V. Moreno-Chulim, J. I. Cauich-Cupul, P. J. Herrera-Franco, and A. Valadez-González, “Effect of moisture content and carbon fiber surface treatments on the interfacial shear strength of a thermoplastic-modified epoxy resin composites,” J. Mater. Research and Technol., 9, 15739-15749 (2020).

R. K. Joki, “Cohesive zone model for mode I and mode II delamination,” DACOMAT project report, 27 (2020).

P. H. Geubelle and J. S. Baylor, “Impact-induced delamination of composites: a 2D simulation,” Compos., Part B, 29, 589-602 (1998).

M. M. Abdel Wahab, “11 - Simulating mode I fatigue crack propagation in adhesively-bonded composite joints,” in Fatigue and Fracture of Adhesively-Bonded Composite Joints, A. P. Vassilopoulos, ed. (Woodhead Publishing, 2015), pp. 323-344.

M. Heidari-Rarani and A. R. Ghasemi, “Appropriate shape of cohesive zone model for delamination propagation in ENF specimens with R-curve effects,” Theoretical and Appl. Fracture Mech., 90, 174-181 (2017).

H. Madadi, M. Naghdinasab, and A. Farrokhabadi, “Numerical investigation of matrix cracking propagation in crossply laminated composites subjected to three-point bending load using concurrent multiscale model,” Fatigue Fract. Eng. Mater. Struct., 43, 1159-1169 (2020).

K. O. Low, S. M. Teng, M. Johar, H. A. Israr, and K. J. Wong, “Mode I delamination behaviour of carbon/epoxy composite at different displacement rates,” Compos., Part B, 176, 107293 (2019).

D. Aveiga and M. L. Ribeiro, “A Delamination Propagation Model for Fiber Reinforced Laminated Composite Materials,” Math. Problems in Eng., 2018, 1-9 (2018).

M. G. Pike and C. Oskay, “XFEM modeling of short microfiber reinforced composites with cohesive interfaces,” Finite Elements in Analysis and Design, 106, 16-31 (2015).

C. T. Sun and Z.-H. Jin, “Chapter 9 - Cohesive Zone Model,” in Fracture Mechanics, C. T. Sun and Z.-H. Jin, eds. (Academic Press, 2012), pp. 227-246.

Y. Ismail, Y. Sheng, D. Yang, and J. Ye, “Discrete element modelling of unidirectional fibre-reinforced polymers under transverse tension,” Compos., Part B, 73, 118-125 (2015).

A. Lisjak and G. Grasselli, “A review of discrete modeling techniques for fracturing processes in discontinuous rock masses,” J. Rock Mech. and Geotechnical Eng., 6, 301-314 (2014).

D. Xie and A. M. Waas, “Discrete cohesive zone model for mixed-mode fracture using finite element analysis,” Eng. Fracture Mech., 73, 1783-1796 (2006).

Y. Li, Q. Wang, and S. Wang, “A review on enhancement of mechanical and tribological properties of polymer composites reinforced by carbon nanotubes and graphene sheet: Molecular dynamics simulations,” Compos., Part B, 160, 348-361 (2019).

B. Demir, L. C. Henderson, and T. R. Walsh, “Design Rules for Enhanced Interfacial Shear Response in Functionalized Carbon Fiber Epoxy Composites,” ACS Appl. Mater. Interfaces, 9, 11846-11857 (2017).

D. J. Eyckens, B. Demir, J. D. Randall, T. R. Gengenbach, L. Servinis, T. R. Walsh, and L. C. Henderson, “Using molecular entanglement as a strategy to enhance carbon fiber-epoxy composite interfaces,” Compos. Sci. and Technol., 196, 108225 (2020).

B. Demir, K. M. Beggs, B. L. Fox, L. Servinis, L. C. Henderson, and T. R. Walsh, “A predictive model of interfacial interactions between functionalised carbon fibre surfaces cross-linked with epoxy resin,” Compos. Sci. and Technol., 159, 127-134 (2018).

S. Frankland, “The stress-strain behavior of polymer-nanotube composites from molecular dynamics simulation,” Compos. Sci. and Technol., 63, 1655-1661 (2003).

B. Yang, K. Yang, F.-Z. Xuan, Y. Xiang, D. Li, and C. Luo, “Enhanced adhesion between glass, carbon, and their hybrid fiber-bundle with epoxy at room and elevated temperatures: A comparative study between graphene and MWCNT filled interface strategies,” Polym. Compos., 39, E2370-E2380 (2018).

H. Wang, X. Zhang, Y. Duan, and L. Meng, “Experimental and Numerical Study of the Interfacial Shear Strength in Carbon Fiber/Epoxy Resin Composite under Thermal Loads,” Int. J. Polymer Sci., 2018, 1-8 (2018).

B. Yang, X. Tang, K. Yang, F.-Z. Xuan, Y. Xiang, L. He, and J. Sha, “Temperature effect on graphene-filled interface between glass-carbon hybrid fibers and epoxy resin characterized by fiber-bundle pull-out test: Research Article,” J. Appl. Polym. Sci., 135, 46263 (2018).

K. Tanaka, D. Kugimoto, and T. Katayama, “Effects of temperature on the fibre matrix interfacial shear strength of carbon nanotube grafted carbon fibre reinforced heat resistant resin,” KEM, 827, 488-492 (2019).

W. Liu, Y. Gao, X. Liu, Y. Qiu, and F. Xu, “Tensile and interfacial properties of dry-jet wet-spun and wet-spun polyacrylonitrile-based carbon fibers at cryogenic condition,” J. Eng. Fibers and Fabrics, 14, 155892501983516 (2019).

R. Wang, C. Zhang, L. Hao, W. Jiao, F. Yang, and W. Liu, “Interfacial Properties of Nano-Silica Modified Cfrps under Cryogenic Condition,” Polymers and Polymer Compos., 22, 269-274 (2014).

M. Yan, W. Jiao, F. Yang, G. Ding, H. Zou, Z. Xu, and R. Wang, “Simulation and measurement of cryogenic-interfacialproperties of T700/modified epoxy for composite cryotanks,” Materials & Design, 182, 108050 (2019).

C. Ageorges, K. Friedrich, T. Schüller, and B. Lauke, “Single-fibre Broutman test: fibre-matrix interface transverse debonding,” Compos., Part A, 30, 1423-1434 (1999).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

De Leon, A., Sweat, R.D. Interfacial Engineering of CFRP Composites and Temperature Effects: A Review. Mech Compos Mater 59, 419–440 (2023). https://doi.org/10.1007/s11029-023-10106-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-023-10106-w