Abstract

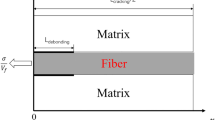

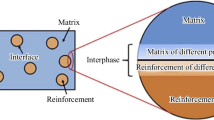

This work investigates the effects of high-temperature curing processes on the stress–strain and failure responses of additively manufactured aligned discontinuous fiber-reinforced composites (DFRCs). A micromechanical framework is used for finite element simulation of damage and failure in the three-dimensional (3-D) representation of DFRCs under mechanical and thermal loadings. Accurate constitutive equations are utilized to explicitly consider the fibers, matrix, and fiber/matrix interfaces within the composite’s microstructure. The coupled thermo-mechanical analysis available on the commercial nonlinear finite element software ABAQUS is used to accurately simulate the response of the studied DFRC when exposed to different curing temperatures and mechanical loading. All material and geometrical parameters of the microstructural representation are defined based on a recently developed 3-D printed aligned discontinuous fiber-reinforced thermosetting polymer. The curing-induced thermal residual stresses and damage are then simulated and validated against the experimental data. The effects of different curing processes on the initiation and propagation of different damage types and on the stress–strain response up to and including final failure are predicted. Also, the impact of the perfect versus cohesive interfacial bonding on the DFRC’s performance is examined. This work reveals that the DFRCs’ responses are significantly affected when residual thermal stresses due to curing are considered, providing guidance for better design, manufacturing, and analysis of such composites.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available on reasonable request.

References

Tekinalp, H., Kunc, V., Velez-Garcia, G., Duty, C., Love, L., Naskar, A., Blue, C., Ozcan, S.: Highly oriented carbon fiber-polymer composites via additive manufacturing. Compos. Sci. Technol. 105, 144–150 (2014)

Compton, B., Lewis, J.: 3D-printing of lightweight cellular composites. Adv. Mater. 26, 5930–5935 (2014)

Lewicki, J., Rodriguez, J., Zhu, C., Worsley, M., Wu, A., Kanarska, Y., Horn, J., Duoss, E., Ortega, J., Elmer, W.: Others 3D-printing of meso-structurally ordered carbon fiber/polymer composites with unprecedented orthotropic physical properties. Sci. Rep. 7, 1–14 (2017)

Pierson, H., Celik, E., Abbott, A., De Jarnette, H., Sierra Gutierrez, L., Johnson, K., Koerner, H., Baur, J.: Mechanical properties of printed epoxy-carbon fiber composites. Exp. Mech. 59, 843–857 (2019)

Yang, L., Yan, Y., Ma, J., Liu, B.: Effects of inter-fiber spacing and thermal residual stress on transverse failure of fiber-reinforced polymer-matrix composites. Comput. Mater. Sci. 68, 255–262 (2013)

Danzi, F., Fanteria, D., Panettieri, E., Mancino, M.: A numerical micro-mechanical study on damage induced by the curing process in carbon/epoxy unidirectional material. Compos. Struct. 210, 755–766 (2019)

Hui, X., Xu, Y., Zhang, W.: An integrated modeling of the curing process and transverse tensile damage of unidirectional CFRP composites. Compos. Struct. 263, 113681 (2021)

Nairn, J., Zoller, P.: Matrix solidification and the resulting residual thermal stresses in composites. J. Mater. Sci. 20, 355–367 (1985)

Parlevliet, P., Bersee, H., Beukers, A.: Residual stresses in thermoplastic composites-A study of the literature-Part I: Formation of residual stresses. Compos. A Appl. Sci. Manuf. 37, 1847–1857 (2006)

Parlevliet, P., Bersee, H., Beukers, A.: Residual stresses in thermoplastic composites-A study of the literature-Part II: Experimental techniques. Compos. A Appl. Sci. Manuf. 38, 651–665 (2007)

Bogetti, T., Gillespie, J., Jr.: Process-induced stress and deformation in thick-section thermoset composite laminates. J. Compos. Mater. 26, 626–660 (1992)

Cowley, K., Beaumont, P.: The measurement and prediction of residual stresses in carbon-fibre/polymer composites. Compos. Sci. Technol. 57, 1445–1455 (1997)

Olivier, P., Cottu, J.: Optimisation of the co-curing of two different composites with the aim of minimising residual curing stress levels. Compos. Sci. Technol. 58, 645–651 (1998)

Gopal, A., Adali, S., Verijenko, V.: Optimal temperature profiles for minimum residual stress in the cure process of polymer composites. Compos. Struct. 48, 99–106 (2000)

Chen, W., Zhang, D.: A micromechanics-based processing model for predicting residual stress in fiber-reinforced polymer matrix composites. Compos. Struct. 204, 153–166 (2018)

Sweeting, R., Thomson, R.: The effect of thermal mismatch on Z-pinned laminated composite structures. Compos. Struct. 66, 189–195 (2004)

Zhang, Y., Xia, Z., Ellyin, F.: Evolution and influence of residual stresses/strains of fiber reinforced laminates. Compos. Sci. Technol. 64, 1613–1621 (2004)

Zhao, L., Warrior, N., Long, A.: A micromechanical study of residual stress and its effect on transverse failure in polymer-matrix composites. Int. J. Solids Struct. 43, 5449–5467 (2006)

Zhao, L., Warrior, N., Long, A.: A thermo-viscoelastic analysis of process-induced residual stress in fibre-reinforced polymer-matrix composites. Mater. Sci. Eng., A 452–453, 483–498 (2007)

Jia, Y., Yan, W., Liu, H.: Carbon fibre pullout under the influence of residual thermal stresses in polymer matrix composites. Comput. Mater. Sci. 62, 79–86 (2012)

D’Mello, R., Maiarú, M., Waas, A.: Effect of the curing process on the transverse tensile strength of fiber-reinforced polymer matrix lamina using micromechanics computations. Integr. Mater. Manuf. I(4), 119–136 (2015)

Yuan, Z., Wang, Y., Yang, G., Tang, A., Yang, Z., Li, S., Li, Y., Song, D.: Evolution of curing residual stresses in composite using multi-scale method. Compos. B Eng. 155, 49–61 (2018)

Shah, S., Maiarú, M.: Effect of manufacturing on the transverse response of polymer matrix composites. Polymers 13, 2491 (2021)

Shah, S., Patil, S., Hansen, C., Odegard, G., Maiarú, M.: Process modeling and characterization of thermoset composites for residual stress prediction. Mech. Adv. Mater. Struct. pp. 1-12 (2021)

Hernandez, L., Sepasdar, R., Shakiba, M.: Sensitivity of crack formation in fiberreinforced composites to microstructural geometry and interfacial properties. In: Proceeding of The American Society for Composites, Thirty-Fifth Technical Conference. pp. 1576-1591 (2020)

Shakiba, M.: Detecting transverse cracks initiation in composite laminates via statistical analysis of sensitivity data. Mech. Res. Commun. 103701 (2021)

Sepasdar, R., Niazi, S., Case, S., Shakiba, M.: A 3-D micro-mechanical framework to study damage propagation and failure of printed discontinuous fiber-reinforced composites. J. Compos. Mater. 00219983231153236 (2023)

Systémes, D. ABAQUS 6.10: Analysis user’s manual. Providence, RI: Dassault Systémes Simulia Corp. (2010)

Li, C., Potter, K., Wisnom, M., Stringer, G.: In-situ measurement of chemical shrinkage of MY750 epoxy resin by a novel gravimetric method. Compos. Sci. Technol. 64, 55–64 (2004)

Yu, H., Mhaisalkar, S., Wong, E.: Cure shrinkage measurement of nonconductive adhesives by means of a thermomechanical analyzer. J. Electron. Mater. 34, 1177–1182 (2005)

Khoun, L., Centea, T., Hubert, P.: Characterization methodology of thermoset resins for the processing of composite materials-case study: CYCOM 890RTM epoxy resin. J. Compos. Mater. 44, 1397–1415 (2010)

Tu, W., Chen, Q.: Evolution of interfacial debonding of a unidirectional graphite/polyimide composite under off-axis loading. Eng. Fract. Mech. 230, 106947 (2020)

Sepasdar, R., Karpatne, A., Shakiba, M.: A data-driven approach to full-field damage and failure pattern prediction in microstructure-dependent composites using deep learning. Comput. Methods Appl. Mech. Eng. 397, 115126 (2022)

Sepasdar, R., Shakiba, M.: Micromechanical study of multiple transverse cracking in cross-ply fiber-reinforced composite laminates. Compos. Struct. 281, 114986 (2022)

Lubliner, J., Oliver, J., Oller, S., Oñate, E.: A plastic-damage model for concrete. Int. J. Solids Struct. 25, 299–326 (1989)

Lee, J., Fenves, G.: Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 124, 892–900 (1998)

Vaughan, T., McCarthy, C.: Micromechanical modelling of the transverse damage behaviour in fibre reinforced composites. Compos. Sci. Technol. 71, 388–396 (2011)

Microscopic mechanisms and modeling: Canal, L., González, C., Segurado, J. & LLorca, J. Intraply fracture of fiber-reinforced composites. Compos. Sci. Technol. 72, 1223–1232 (2012)

Herráez, M., Mora, D., Naya, F., Lopes, C., González, C., LLorca, J.: Transverse cracking of cross-ply laminates: A computational micromechanics perspective. Combust. Sci. Technol. 110, 196-204 (2015)

Herráez, M., González, C., Lopes, C.: A numerical framework to analyze fracture in composite materials: From R-curves to homogenized softening laws. Int. J. Solids Struct. 134, 216–228 (2018)

Sepasdar, R., Shakiba, M.: Overcoming the convergence difficulty of cohesive zone models through a Newton-Raphson modification technique. Eng. Fract. Mech. 233, 107046 (2020)

Gao, Y., Bower, A.: A simple technique for avoiding convergence problems in finite element simulations of crack nucleation and growth on cohesive interfaces. Modell. Simul. Mater. Sci. Eng. 12, 453–463 (2004)

Cheng, H., Gao, J., Kafka, O., Zhang, K., Luo, B., Liu, W.: A micro-scale cutting model for UD CFRP composites with thermo-mechanical coupling. Compos. Sci. Technol. 153, 18–31 (2017)

Hyer, M., White, S.: Stress Analysis of Fiber-reinforced Composite Materials. DEStech Publications, Inc (2009)

Hernandez, D., Soufen, C., Orlandi, M.: Carbon fiber reinforced polymer and epoxy adhesive tensile test failure analysis using scanning electron microscopy. Mater. Res. 20, 951–961 (2017)

Niazi, S., Najmeddine, A., Shakiba, M.: A 3D thermo-mechanical analysis of additively manufactured aligned discontinuous fiber-reinforced composites. In: Proceeding of The American Society for Composites, Thirty-Seventh Technical Conference. pp. 1292-1311 (2022)

Gentz, M., Armentrout, D., Rupnowski, P., Kumosa, L., Shin, E., Sutter, J., Kumosa, M.: In-plane shear testing of medium and high modulus woven graphite fiber reinforced/polyimide composites. Compos. Sci. Technol. 64, 203–220 (2004)

Gentz, M., Benedikt, B., Sutter, J., Kumosa, M.: Residual stresses in unidirectional graphite fiber/polyimide composites as a function of aging. Compos. Sci. Technol. 64, 1671–1677 (2004)

Chen, Q., Chen, X., Zhai, Z., Zhu, X., Yang, Z.: Micromechanical modeling of viscoplastic behavior of laminated polymer composites with thermal residual stress effect. J. Eng. Mater. Technol. 138, 031005 (2016)

Livingston, R., Koohbor, B.: Characterizing fiber-matrix debond and fiber interaction mechanisms by full-field measurements. Composites Part C. 7, 100229 (2022)

Shokrieh, M., Safarabadi, M.: Effects of imperfect adhesion on thermal micro-residual stresses in polymer matrix composites. Int. J. Adhes. Adhes. 31, 490–497 (2011)

Niazi, S., Chen, Z., Bobaru, F.: Crack nucleation in brittle and quasi-brittle materials: A peridynamic analysis. Theoret. Appl. Fract. Mech. 112, 102855 (2021)

Niazi, S. Peridynamic models for crack nucleation in brittle and quasi-brittle materials. Doctoral dissertation, The University of Nebraska-Lincoln (Dec. 2020)

Hillerborg, A., Modéer, M., Petersson, P.: Analysis of crack formation and crack growth in concrete by means of fracture mechanics and finite elements. Cem. Concr. Res. 6, 773–781 (1976)

Acknowledgements

The authors gratefully acknowledge the support from the Air-Force Office of Scientific Research (AFOSR) Young Investigator Program (YIP) award (Award No. FA9550-20-1-0281). The authors also acknowledge Advanced Research Computing at Virginia Tech for providing computational resources and technical support that have contributed to the results reported within this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix. On Alleviating Mesh-Dependency in the Damage Constitutive Framework

Appendix. On Alleviating Mesh-Dependency in the Damage Constitutive Framework

It is well-known that after the initiation of damage/microcracks within materials, they usually exhibits a softening behavior in their macroscopic stress–strain response, leading to strain localization [52, 53]. Within a traditional finite element framework, this issue would introduce a strong mesh dependency into the results. However, recently in ABAQUS, the damage evolution law in the utilized plasticity damage constitutive framework uses a formulation intended to greatly alleviate the mesh dependency [28]. This is accomplished by implementing Hillerborg’s (1976) fracture energy proposal that introduces a characteristic length, L, into the formulation and expresses the softening part of the constitutive law as a stress-displacement, rather than stress–strain, relation (see [54]). For example, for 2-D elements, the characteristic length is described as the square root of the average area of the mesh elements [28].

Utilizing the characteristic length, the evolution of damage variable, \(\dot{d}\), is calculated in terms of displacement to alleviate the mesh dependency of results (see Eq. (3)). For more information on the damage constitutive framework, readers are referred to [28, 35, 37].

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niazi, S., Najmeddine, A. & Shakiba, M. The Effects of Curing Process on the Damage Behavior of Additively Manufactured Fiber-Reinforced Thermosetting Composites. Appl Compos Mater 30, 1305–1331 (2023). https://doi.org/10.1007/s10443-023-10135-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-023-10135-7