Abstract

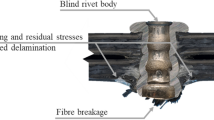

Two major areas of enquiry exist in the field of fibre-matrix adhesion in composite materials. One is the fundamental role that fibre-matrix adhesion plays on composite mechanical properties. The other is what is the “best” method used to measure fibre-matrix adhesion in composite materials. Results of an attempt to provide an experimental foundation for both areas are reported here. A well-characterized experimental system consisting of an epoxy matrix and carbon fibres was selected in which only the fibre surface chemistry was altered to produce three different degrees of adhesion. Embedded single-fibre fragmentation tests were conducted to quantify the level of fibre-matrix adhesion. Observation of the events occurring at the fibre breaks led to the documentation of three distinct failure modes coincident with the three levels of adhesion. The lowest level produced a frictional debonding, the intermediate level produced interfacial crack growth and the highest level produced radial matrix fracture. High fibre volume fraction composites made from the same material were tested for on- and off-axis, as well as fracture, properties. Results indicate that composite results can be explained if both differences in adhesion and failure mode are considered. It will be further demonstrated that fibre-matrix adhesion is an “optimum” condition which has to be selected for the stress state that the interface will experience. The embedded single-fibre fragmentation test is both a valuable measurement tool for quantifying fibre-matrix adhesion as well as the one method which provides fundamental information about the failure mode necessary for understanding the role of adhesion on composite mechanical properties.

Similar content being viewed by others

References

L. T. Drzal andP. J. Herrera-Franco, “Composite Fiber-Matrix Bond Tests”, “Engineered Materials Handbook: Adhesives and Sealants”, Vol. 3 (ASM International, Metals Park, OH, 1990).

B. Miller, P. Muri andL. Rebenfield,Compos. Sci. Technol. 28 (1987) 17.

M. Narkis, E. J. H. Chen, andR. B. Pipes,Polym. Compos. 9 (1988) 245.

A. Kelly, andW. R. Tyson,J. Mech. Phys. Solids 13 (1965) 329.

A. N. Netravali, L. T. T. Topoleski, W. H. Sachse andS. L. Phoenix,Compos. Sci. Technol. 35 (1989) 13.

D. L. Caldwell, andF. M. Cortez,Modern Plastics September (1988) 132.

“Engineered Materials Handbook: Composites”, Vol. 1 (ASM International, Metals Park, OH, 1988).

L. B. Donnet andR. C. Bansal, “Carbon Fibers” (Marcel Dekker, New York, 1984).

M. C. Waterbury andL. T. Drzal,J. Rein. Plast. Compos. 8 (1989) 627.

C. Zweben, W. S. Smith andM. W. Wardle, in “Composite Materials Testing and Design” (Fifth Conference), ASTM STP 674, edited by S. W. Tsai, (American Society for Testing and Materials, Philadelphia, PA, 1979) pp. 228–62.

D. F. Adams andD. E. Walrath, “Composite Materials Testing and Design” (Sixth Conference), ASTM STP 787, edited by I. M. Daniel (American Society for Testing and Materials, Philadelphia, PA, 1982) pp. 19–33.

L. A. Carlsson andR. B. Pipes, “Experimental Characterization of Composite Materials” (Prentice Hall, Englewood Cliffs, NJ 1987).

L. T. Drzal andM. J. Rich, “Effect of Graphite Fibre-Epoxy Adhesion on Composite Fracture Behavior”, Research Advances in Composites in the United States and Japan, ASTM STP 864 (American Society for Testing and Materials, Philadelphia, PA, 1985) pp 16–26.

L. T. Drzal,SAMPE J. 19 (1983) 7.

L. T. Drzal, M. J. Rich, M. F. Koenig, andP. F. Lloyd,J. Adhesion 16 (1983) 133.

K. Hook, R. Agrawal, andL. T. Drzal,J. Adhesion,32 (1990) 157.

J. D. H. Hughes,Carbon 24 (1986) 551.

M. S. Dresselhaus, G. Dresselhaus, K. Sugihara, I. L. Spain andH. A. Goldberg, “Graphite Fibers and Filaments”, Springer Series in Materials Science, edited by M. Cardona, (1988) Ch. 6, pp. 120–48.

R. M. Jones, “Mechanics of Composite Materials” (McGraw-Hill, New York, 1975).

H. T. Hahn andM. M. Sohi Compos. Sci. Technol. 27 (1986) 25.

P. Yeung andL. J. Broutman,Polym. Engng Sci. 18 (1978) 62.

N. Sela andO. Ishai,Composites 20 (1989) 423.

W. D. Bascom, D. J. Boll, D. L. Hunston, B. Fuller andP. J. Phillips, “Fractographic Analysis of Interlaminar Fracture”, in “Toughened Composites”, ASTM STP 937, edited by N. J. Johnston (American Society for Testing and Materials, Philadelphia, PA, 1987) pp. 131–49.

D. L. Hunston, R. J. Moulton, N. J. Johnston andW. D. Bascom, “Matrix Resin Effects in Composite Delamination Mode I Fracture Aspects”,ibid.“, pp. 74–94.

A. J. Russell andK. N. Street, “The Effect of Matrix Toughness on Delamination Static and Fatigue Fracture Under Mode II Shear Loading of Graphite Fiber Composites”,ibid.“ pp. 275–94.

W. L. Bradley andR. N. Cohen, “Matrix Deformation and Fracture in Graphite-Reinforced Epoxies”, in Delamination and Debonding of Materials, ASTM STP 876, edited by W. S. Johnson (American Society for Testing and Materials, Philadelphia, PA, 1985) pp. 389–410.

H. Chai,Engng Fract. Mech. 24 (1986) 413.

A. J. Russell andK. N. Street, “Moisture and Temperature Effects on the Mixed Mode Delamination Fracture of Graphite/Epoxy”, in Delamination and Debonding of Materials, ASTM STP 876, edited by W. S. Johnson (American Society for Testing and Materials, Philadelphia, PA, 1985) pp. 349–70.

A. J. Smiley andR. B. Pipes, in “Proceedings of the American Society for Composites, First Technical Conference”, Dayton, OH (Technomic, Lancaster, PA, 1986) pp. 439–49.

H. Chai, in “Proceedings of the American Society for Composites, Fourth Technical Conference”, Blacksburg, VA (Technomic, Lancaster, PA, 1989) pp. 815–25.

W. M. Jordan, in “Proceedings of the American Society for Composites, Third Technical Conference”, Seattle, WA (Technomic, Lancaster, PA, 1988) pp. 495–504.

L. A. Carlsson, J. W. Gillespie andR. B. Pipes,J. Compos. Mater. 20 (1986) 594.

W. M. Jordan andW. L. Bradley, “Micromechanisms of Fracture in Toughened Graphite-Epoxy Laminates”, in Toughened Composites, ASTM STP 937, edited by N. J. Johnston (American Society for Testing and Materials, Philadelphia, PA, 1987) pp. 95–114.

V. B. Gupta, L. T. Drzal, C. Y. C. Lee andM. J. Rich,J. Macromol. Sci. Phys. B23 (1985) 435.

W. S. Johnson andP. D. Mangalgiri, “Influence of the Resin on Interlaminar Mixed-Mode Fracture”, in Toughened Composites, ASTM STP 937, edited by N. J. Johnston (American Society for Testing and Materials, Philadelphia, PA, 1987) pp. 295–315.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Drzal, L.T., Madhukar, M. Fibre-matrix adhesion and its relationship to composite mechanical properties. J Mater Sci 28, 569–610 (1993). https://doi.org/10.1007/BF01151234

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01151234