Abstract

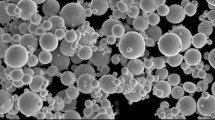

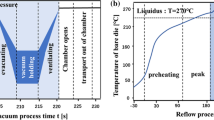

Thermal compression bonding (TCB) has been widely used in flip chip bonding processes for three-dimensional integrated packaging. Therefore, studying the TCB process and solder joint structure is significant for improving reliability. In this study, a Ni layer was deposited between the Cu/Sn-3.5Ag solder bumps of upper and lower chips, and TCB process tests were carried out at different bonding temperatures, forces and times. The solder height at the top and bottom of the copper pillar were recorded. Through the establishment of a mathematical analysis model, the relationship between the solder joint height and maximum stress was analyzed theoretically, and the trend of the shear stress and solder joint height was obtained from die shear tests. Then, the solder joint morphology, strength and microstructure composition of the microbumps were observed after aging. Our results showed that the growth rate of intermetallic compounds (IMCs) for Cu/Sn-3.5Ag microbumps with a 25 μm diameter was 2.5 times those with a 100 μm diameter and that the Ni barrier layer prevented the diffusion of Cu in Sn-3.5Ag solder. In addition, the Ni layer improved the strength of the Cu/Sn-3.5Ag joints after aging. Finally, with extended aging time, the fracture site was found to move from the solder region to the Cu6Sn5 layer for the Cu/Sn-3.5Ag samples, while it remained at the Sn-3.5Ag/IMC interface for the Cu/Ni/Sn-3.5Ag samples.

Similar content being viewed by others

References

H.-Y. You, Y. Hwang, J.-W. Pyun, Y.-G. Ryu, H.-S. Kim, IEEE, chip package interaction in micro bump and TSV structure, 2012.

X. Zhang, J.K. Lin, S. Wickramanayaka, S. Zhang, R. Weerasekera, R. Dutta, K.F. Chang, K.-J. Chui, H.Y. Li, D.S.W. Ho, L. Ding, G. Katti, S. Bhattacharya, D.-L. Kwong, Heterogeneous 2.5D integration on through silicon interposer. Appl. Phys. Rev. 2(2), 021308 (2015)

A. Sharma, D.-H. Jung, M.-H. Roh, J.P. Jung, Fabrication and shear strength analysis of Sn-3.5Ag/Cu-filled TSV for 3D microelectronic packaging. Electron. Mater. Lett. 12(6), 856–863 (2016)

S. Jin, D. Lee, W.Y. Lee, S. Lee, M.H. Lee, Seed step-coverage enhancement process for a high-aspect-ratio through-silicon via using a pyrophosphate solution. Met. Mater. Int. 21(4), 775–779 (2015)

J.-Y. Park, J.Y. Lee, H.-P. Park, S.-C. Kim, T.-Y. Lee, S. Yoo, Y.-H. Kim, Joint properties and reliability of Cu/Sn-Ag pillar bumps via low-temperature thermo-compression bonding. Microelectron. Eng. 216, 110973 (2019)

B. Lee, J. Park, S.-J. Jeon, K.-W. Kwon, H.-J. Lee, A study on the bonding process of Cu bump/Sn/Cu bump bonding structure for 3D packaging applications. J. Electrochem. Soc. 157(4), H420–H424 (2010)

M.-S. Kim, M.-S. Kang, J.-H. Bang, C.-W. Lee, M.-S. Kim, S. Yoo, Interfacial reactions of fine-pitch Cu/Sn-3.5Ag pillar joints on Cu/Zn and Cu/Ni under bump metallurgies. J. Alloy. Compd. 616, 394–400 (2014)

M.-L. Wu, S.-Y. Chiou, Y.-M. Hwang, Empirical equations for optimization conditions in thermal compression bonding of copper pillar flip chip packages. IEEE Trans. Compon. Packag. Manuf. Technol. 8(6), 1116–1120 (2018)

G.-T. Park, B.-R. Lee, K. Son, Y.-B. Park, Ni barrier symmetry effect on electromigration failure mechanism of Cu/Sn–Ag microbump. Electron. Mater. Lett. 15(2), 149–158 (2019)

K. Zeng, K.N. Tu, Six cases of reliability study of Pb-free solder joints in electronic packaging technology. Mater. Sci. Eng. R-Rep. 38(2), 55–105 (2002)

H.L.J. Pang, K.H. Tan, X.Q. Shi, Z.P. Wang, Microstructure and intermetallic growth effects on shear and fatigue strength of solder joints subjected to thermal cycling aging. Mater. Sci. Eng. A 307(1–2), 42–50 (2001)

J.-Y. Chang, R.-S. Cheng, K.-S. Kao, T.-C. Chang, T.-H. Chuang, Reliable microjoints formed by solid-liquid interdiffusion (SLID) bonding within a chip-stacking architecture. IEEE Trans. Compon. Packag. Manuf. Technol. 2(6), 979–984 (2012)

T.C. Chang, R.S. Cheng, K.S. Kao, W. Li, T.-H. Chen, in Reliable Microjoints for Chip Stacking Formed by Solid-Liquid Interdiffusion (SLID) Bonding, 6th International Microsystems, Packaging, Assembly and Circuits Technology Conference, IMPACT 2011, (IEEE, Taipei, Taiwan, 2011)

F. Guo, S. Choi, K.N. Subramanian, T.R. Bieler, J.P. Lucas, A. Achari, M. Paruchuri, Evaluation of creep behavior of near-eutectic Sn-Ag solders containing small amount of alloy additions. Mater. Sci. Eng. A 351(1–2), 190–199 (2003)

S.H. Kim, J. Yu, Fe addition to Sn-3.5Ag solder for the suppression of Kirkendall void formation. Scripta Materialia 69(3), 254–257 (2013)

H.T. Lee, M.H. Chen, H.M. Jao, C.J. Hsu, Effect of adding Sb on microstructure and adhesive strength of Sn-Ag solder joints. J. Electron. Mater. 33(9), 1048–1054 (2004)

Y.-H. Lee, H.-T. Lee, Shear strength and interfacial microstructure of Sn–Ag-xNi/Cu single shear lap solder joints. Mater. Sci. Eng. A 444(1–2), 75–83 (2007)

J.Y. Tsai, Y.C. Hu, C.M. Tsai, C.R. Kao, A study on the reaction between Cu and Sn3.5Ag solder doped with small amounts of Ni. J. Electron. Mater. 32(11), 1203–1208 (2003)

J.W. Yoon, C.B. Lee, S.B. Jung, Growth of an intermetallic compound layer with Sn-3.5Ag-5Bi on Cu and Ni-P/Cu during aging treatment. J. Electron. Mater. 32(11), 1195–1202 (2003)

M.O. Alam, Y.C. Chan, Solid-state growth kinetics of Ni(3)Sn(4) at the Sn-3.5Ag solder/Ni interface. J. Appl. Phys. 98(12), 123527 (2005)

M.O. Alam, Y.C. Chan, K.N. Tu, Effect of 0.5 wt% Cu addition in Sn-3.5%Ag solder on the dissolution rate of Cu metallization. J. Appl. Phys. 94(12), 7904–7909 (2003)

M.O. Alam, Y.C. Chan, K.N. Tu, Elimination of Au-embrittlement in solder joints on Au/Ni metallization. J. Mater. Res. 19(5), 1303–1306 (2004)

W. Zhu, L. Shi, L. Jiang, H. He, Effect of intermetallic compound thickness on mechanical fatigue properties of copper pillar micro-bumps. Microelectron. Reliab. 111, 113723 (2020)

M.S. Park, S.L. Gibbons, R. Arroyave, Phase-field simulations of intermetallic compound growth in Cu/Sn/Cu sandwich structure under transient liquid phase bonding conditions. Acta Mater. 60(18), 6278–6287 (2012)

C.K. Chung, J.-G. Duh, C.R. Kao, Direct evidence for a Cu-enriched region at the boundary between Cu6Sn5 and Cu3Sn during Cu/Sn reaction. Scripta Mater. 63(2), 258–260 (2010)

K. Chu, Y. Sohn, C. Moon, A comparative study of Cn/Sn/Cu and Ni/Sn/Ni solder joints for low temperature stable transient liquid phase bonding. Scripta Mater. 109, 113–117 (2015)

A. Kumar, M. He, Z. Chen, P.S. Teo, Effect of electromigration on interfacial reactions between electroless Ni-P and Sn-3.5% Ag solder. Thin Solid Films 462, 413–418 (2004)

B.-S. Lee, S.-K. Hyun, J.-W. Yoon, Cu-Sn and Ni-Sn transient liquid phase bonding for die-attach technology applications in high-temperature power electronics packaging. J. Mater. Sci. 28(11), 7827–7833 (2017)

D.-G. Kim, J.-W. Kim, S.-S. Ha, B.-I. Noh, J.-M. Koo, D.-W. Park, M.-W. Ko, S.-B. Jung, Effect of reflow numbers on the interfacial reaction and shear strength of flip chip solder joints. J. Alloy. Compd. 458(1–2), 253–260 (2008)

S. Ahat, M. Sheng, L. Luo, Microstructure and shear strength evolution of SnAg/Cu surface mount solder joint during aging. J. Electron. Mater. 30(10), 1317–1322 (2001)

Y.C. Chan, A.C.K. So, J.K.L. Lai, Growth kinetic studies of Cu–Sn intermetallic compound and its effect on shear strength of LCCC SMT solder joints. Mater. Sci. Eng. B 55(1), 5–13 (1998)

Author information

Authors and Affiliations

Contributions

CT: Data curation, writing—original draft. WZ: Conceptualization, methodology. ZC: Methodology, Writing—review and editing. LW: Conceptualization, methodology, writing—review and editing, supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tang, C., Zhu, W., Chen, Z. et al. Thermomechanical reliability of a Cu/Sn-3.5Ag solder joint with a Ni insertion layer in flip chip bonding for 3D interconnection. J Mater Sci: Mater Electron 32, 11893–11909 (2021). https://doi.org/10.1007/s10854-021-05819-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05819-4