Abstract

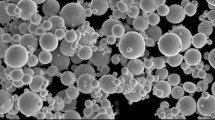

This paper investigates the influence of the welding process on the microstructure and mechanical properties of Au/Sn–3.0Ag–0.5Cu/Cu solder joints. In this study, the flip-chip LED chip and the substrate were connected by a heating platform, hot air reflow, and vacuum reflow soldering methods to form Au/Sn–Ag–Cu/Cu composite solder joints. Sn–3.0Ag–0.5Cu is selected as the solder. The microstructure of the solder joint interface and the inferred surface is studied to characterize the influence of different welding methods on the intermetallic compound (IMC) interface. The void ratio of the flip-chip solder layer was tested to characterize the effect of the effective connection area between the chip and the solder joint on the shear strength. The experimental results show that the void ratio of the solder joints welded by the heating platform is as high as 26%, the IMC interface thickness is higher, and the diffusion coefficient of the solder is the lowest. The void distribution of hot air reflow soldering joints is relatively uniform, and there is less solder residue on the fractured surface. Vacuum reflow soldering has the lowest void rate in the solder joints, and the solder joints have flat cross sections with almost no solder residues. The fracture occurs at the lower layer of solder. Considering comprehensively, when the soldering method is vacuum reflow, the IMC layer of the flip-chip solder joint is the thinnest, and the diffusion coefficient of the solder is the highest. There are almost no voids in the solder layer, and the mechanical properties of the solder joint are the best. At this time, the photo-thermoelectric parameters of the filament are the best, and the performance is the most stable and reliable.

Similar content being viewed by others

References

M. Li, J. Zou, W. Wu, N. Jiang, Y. Liu, L. Wang, M. Shi, and W. Li, Analysis of high-temperature aging and microstructure of FC LED solder joints of a silver conductive layer bonded using SAC solder. J. Phys. 1074, 1742 (2018).

M. Hamidnia, Y. Luo, and X.D. Wang, Application of micro/nano technology for thermal management of high power LED packaging: a review. Appl. Therm. Eng. 145, 637 (2018).

A. Kroupa, D. Andersson, N. Hoo, J. Pearce, A. Watson, A. Dinsdale, and S. Mucklejohn, Current problems and possible solutions in high-temperature lead-free soldering. J. Mater. Eng. Perform. 21, 629 (2012).

B. Arfaei, N. Kim, and E.J. Cotts, Dependence of Sn grain morphology of Sn–Ag–Cu solder on solidification temperature. J. Electron Mater. 41, 362 (2012).

K. Mehrabi, F. Khodabakhshi, E. Zareh, A. Shahbazkhan, and A. Simchi, Effect of alumina nanoparticles on the microstructure and mechanical durability of meltspun lead-free solders based on tin alloys. J. Alloy Compd. 688, 143 (2016).

G. Wanbing, Y. Zou, G. Chen, Y. Shi, and J. Yang, Effect of different bonding materials on flip-chip LED filament properties. Appl. Sci. 10, 47 (2019).

X. Zhai, C. Guan, Y. Li, J. Zou, M. Shi, and Y. Li, Effect of different soldering temperatures on the solder joints of flip-chip LED chips. J. Electron Mater. 12, 796 (2020).

J.W. Yoon, and S.B. Jung, Effect of immersion Ag surface finish on interfacial reaction and mechanical reliability of Sn–3.5Ag–0.7Cu solder joint. J. Alloy Compd. 458, 200 (2008).

J.F. Li, P.A. Agyakwa, and C.M.J.J.O.A. Johnson, Effect of trace Al on growth rates of intermetallic compound layers between Sn-based solders and Cu substrate. J. Alloy Compd. 545, 70 (2012).

M. Yunus, K. Srihari, J.M. Pitarresi, and A. Primavera, Effect of voids on the reliability of BGA/CSP solder joints. Microelect. Reliab. 43, 2077 (2003).

P. Wild, D. Lorenz, T. Grzinger, and A. Zimmermann, Effect of voids on thermo-mechanical reliability of chip resistor solder joints: experiment, modelling and simulation. Microelect. Reliab. 85, 163 (2018).

W. Chao-hong, S. Han-ting, and L. Wei-han, Effective suppression of electromigration-induced Cu dissolution by using Ag as a barrier layer in lead-free solder joints. J. Alloy Compd. 564, 35 (2013).

K.R. Kaushik, U. Batra, and J.D. Sharma, Aging induced structural and electrochemical corrosion behaviour of Sn-1.0Ag-0.5Cu and Sn–3.8Ag–0.7Cu solder alloys. J. Alloy Compd. 745, 446 (2018).

Y. Goh, A.S.M.A. Haseeb, H.L. Liew, and M.F.M. Sabri, Deformation and fracture behaviour of electroplated Sn–Bi/Cu solder joints. J. Mater Sci. 50, 4258 (2015).

X. Hu, Y. Li, Y. Liu, and Z. Min, Developments of high strength Bi-containing Sn0.7Cu lead-free solder alloys prepared by directional solidification. J. Alloy Compd. 625, 241 (2015).

C.E. Ho, R.Y. Tsai, Y.L. Lin, and C.R. Kao, Effect of Cu concentration on the reactions between Sn–Ag–Cu solders and Ni. J. Electron Mater. 31, 584 (2002).

M. Xiong, L. Zhang, S. Lei, P. He, and W. Long, Effect of CuZnAl particles addition on microstructure of Cu/Sn58Bi/Cu TLP bonding solder joints. Vacuum 167, 301 (2019).

C. Yu, Y. Yang, J. Chen, J. Xu, J. Chen, and L. Hao, Effect of deposit thickness during electroplating on Kirkendall voiding at Sn/Cu joints. Mater. Lett. 128, 9 (2014).

C. Ming, C. Lung, and K. Lin, Effect of microelements addition on the interfacial reaction between Sn–Ag–Cu solders and the Cu substrate. J. Electron Mater. 32, 1426 (2003).

G. Chen, X.H. Wang, J. Yang, W.L. Xu, and Q. Lin, Effect of micromorphology on corrosion and mechanical properties of SAC305 lead-free solders. Microelect. Reliab. 108, 113634 (2020).

Y. Kariya, T. Hosoi, S. Terashima, and T.M. Otsuka, Effect of silver content on the shear fatigue properties of Sn–Ag–Cu flip-chip interconnects. J. Electron Mater. 33, 321 (2004).

E. Wernicki, and Z. Gu, Effect of Sn nanoparticle additions on thermal properties of Sn–Ag–Cu lead-free solder paste. Thermochim Acta. 690, 178642 (2020).

M.I. Okereke, and L. Yuxiao, A computational investigation of the effect of three-dimensional void morphology on the thermal resistance of solder thermal interface materials. Appl. Therm. Eng. 142, 346 (2018).

M. Rauer, A. Volkert, T. Schreck, S. Harter, and M. Kaloudis, Computed-tomography-based analysis of voids in SnBi57Ag1 solder joints and their influence on the reliability. J. Fail. Anal. Pre. 14, 272 (2014).

L. Hailong, A. Rong, W. Chunqing, T. Yanhong, and J. Zhi, Effect of Cu grain size on the voiding propensity at the interface of SnAgCu/Cu solder joints. Mater. Lett. 144, 97 (2015).

J. Chengshuo, F. Jiajie, Q. Cheng, Z. Hao, F. Xuejun, G. Weiling, and Z. Guoqi, Effects of voids on mechanical and thermal properties of the die attach solder layer used in high-power LED chip-scale packages. IEEE Trans. Comp. Pack. Man. 99, 1 (2018).

T.C. Liu, C.M. Liu, Y.S. Huang, C. Chen, and K.N. Tu, Eliminate Kirkendall voids in solder reactions on nanotwinned copper. Sripta Mater. 68, 241 (2013).

D. Bušek, K. Dušek, D. Růžička, M. Plaček, P. Mach, J. Urbánek, and J. Starý, Flux effect on void quantity and size in soldered joints. Microelect. Reliab. 60, 135 (2016).

D. Kim, J.H. Chang, J. Park, and J.J. Pak, Formation and behavior of Kirkendall voids within intermetallic layers of solder joints. J. Mater. Sci. Mater. El. 22, 703 (2011).

X. Bi, X. Hu, and Q. Li, Effect of Co addition into Ni film on shear strength of solder/Ni/Cu system: Experimental and theoretical investigations. Mater. Sci. Eng. A. 788, 139589 (2020).

Y.F. Huang, X. Chen, F. Xue, T. Wu, W.S. Liu, Y.Z. Ma, and S.W. Tang, Effects of isothermal aging on interfacial microstructure evolution and shear behavior of Au-12Ge/Ni(P)/Kovar Solder Joints. Intermetallics 124, 106865 (2011).

L. Ping, Y. Pei, and J. Liu, Evolutions of the interface and shear strength between SnAgCu-xNi solder and Cu substrate during isothermal aging at 150 degrees C. J. Alloy Compd. 486, 474 (2009).

Y. Huang, Z. Xiu, G. Wu, Y. Tian, P. He, X. Gu, and W. Long, Improving shear strength of Sn–3.0Ag–0.5Cu/Cu joints and suppressing intermetallic compounds layer growth by adding graphene nanosheets. Mater. Lett. 169, 262 (2016).

S. Lei, and Z. Liang, Properties and microstructures of Sn–Ag–Cu–X lead-free solder joints in electronic packaging. Adv. Mater. Sci. Eng. 2015, 1 (2015).

X. Yu, X. Hu, Y. Li, T. Liu, R. Zhang, and Z. Min, Tensile properties of Cu/Sn–58Bi/Cu soldered joints subjected to isothermal aging. J. Mater. Sci. Mater. El. 25, 2416 (2014).

X. Zeng, Thermodynamic analysis of influence of Pb contamination on Pb-free solder joints reliability. J. Alloy Compd. 348, 1 (2003).

T. An, and F. Qin, Relationship between the intermetallic compounds growth and the microcracking behavior of lead-free solder joints. J. Electron Pack. 138, 1224 (2016).

P. Peasura, and B. Poopat, Effect of post weld heat treatment on fusion and heat affected zone microstructure and mechanical properties of inconel X-750 welds. Adv. Mater. Res. 214, 108 (2011).

C.C. Chang, Y.W. Lin, Y.W. Wang, and C.R. Kao, The effects of solder volume and Cu concentration on the consumption rate of Cu pad during reflow soldering. J. Alloy Compd. 492, 99 (2010).

L. Tsao, S.Y. Chang, C.I. Lee, W.H. Sun, and C.H. Huang, Effects of nano-Al2O3 additions on microstructure development and hardness of Sn3.5Ag0.5Cu solder. Mater Des. 31, 4831 (2010).

Y. Lei, C. Xiao, X. Wang, J. Yue, and Q. Zhu, Tensile properties and fracturing behavior of weld joints in the CLAM at high temperatures. Fusion Eng. Des. 95, 27 (2015).

L.L. Liou, B. Bayraktaroglu, and C.I. Huang, Theoretical thermal runaway analysis of heterojunction bipolar transistors: junction temperature rise threshold. Solid State Elect. 39, 165 (1996).

Acknowledgments

This research is supported by the Shanghai Alliance Plan (LM201978), the Science and Technology Planning Project of Zhejiang Province, China (2018C01046), and Enterprise-funded Latitudinal Research Projects J2016-141, J2017-171, J2017-293, and J2017-243.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhai, X., Chen, Y., Li, Y. et al. Effect of the Welding Process on the Microstructure and Mechanical Properties of Au/Sn–3.0Ag–0.5Cu/Cu Solder Joints. J. Electron. Mater. 51, 1597–1607 (2022). https://doi.org/10.1007/s11664-021-09426-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-021-09426-1