Abstract

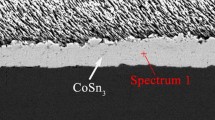

To obtain the interfacial behaviors and the joint strength of Sn–Bi solid solution solder, Sn–2.5Bi and Sn–5Bi solders were selected to be investigated in this work with pure Sn/Cu solder joints as a reference. The results showed that the growth behaviors of intermetallic compound (IMC) at Sn–Bi solder joints were different under reflow soldering and isothermal aging, which was related with the presence of Bi atoms and the diffusion rate of Cu atoms. Furthermore, the Cu6Sn5 particles in solder matrix and the Bi precipitation could change the diffusion path of Cu atoms, which caused the change on the distribution and size of Cu6Sn5 in pure Sn, Sn–2.5Bi and Sn–5Bi solder matrix after isothermal aging. The size and distribution of Cu6Sn5 in solder matrix finally affected the shear strength of solder joints. The shear strength of Sn–2.5Bi/Cu solder joints increased compared with pure Sn/Cu solder joints, and there was no obvious change with the aging times for Sn–2.5Bi/Cu solder joints due to the effect of the reinforcement of Bi atoms. However, the shear strength of Sn–5Bi/Cu solder joints increased firstly and then decreased with the prolongation of aging times. This phenomenon was attributed to the segregation of Bi and the large amounts of Cu6Sn5 particles distributed in solder matrix during the aging condition. Besides, the IMC thickness in Sn–5Bi/Cu solder joint played the important role on the shear strength due to the brittle nature of IMC. In pure Sn solder matrix, the size of Cu6Sn5 particles were larger than that in Sn–Bi solder matrix, which deteriorated the shear strength on pure Sn solder. From the observation on the fracture morphologies, Sn/Cu and Sn–2.5Bi/Cu solder joints showed the ductile fracture occurred in the solder matrix, while Sn–5Bi/Cu solder joints exhibited a mixed fracture.

Similar content being viewed by others

References

L. Zhang, K.N. Tu, Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. R 82, 1–32 (2014)

S. Cheng, C.-M. Huang, M. Pecht, A review of lead-free solders for electronics applications. Microelectron. Reliab. 75, 77–95 (2017)

D.A. Shnawah, M.F.M. Sabri, I.A. Badruddin, A review on thermal cycling and drop impact reliability of SAC solder joint in portable electronic products. Microelectron. Reliab. 52(1), 90–99 (2012)

B.L. Silva, G. Reinhart, H. Nguyen-Thi, N. Mangelinck-Noël, A. Garcia, J.E. Spinelli, Microstructural development and mechanical properties of a near-eutectic directionally solidified Sn–Bi solder alloy. Mater. Charact. 107(504), 43–53 (2015)

W. Dong, Y. Shi, Z. Xia, Y. Lei, F. Guo, Effects of trace amounts of rare earth additions on microstructure and properties of Sn–Bi-based solder alloy. J. Electron. Mater. 37(7), 982–991 (2008)

Н. П. Лякишев, The Manual of Metal Binary Phase Diagram (Chemical Industry Press, Beijing, 2008)

Z.M. Lai, D. Ye, Microstructure and fracture behavior of non eutectic Sn–Bi solder alloys. J. Mater. Sci.: Mater. Electron. 27(4), 3182–3192 (2016)

Z. Lai, D. Ye, Effect of cooling method and aging treatment on the microstructure and mechanical properties of Sn–10Bi solder alloy. J. Mater. Sci.: Mater. Electron. 27(2), 1–10 (2015)

Z. Lai, D. Ye, Microstructure and properties of Sn–10Bi–xCu solder alloy/joint. J. Electron. Mater. 45(7), 3702–3711 (2016)

Q.H. Guo, Z.J. Zhao, C.L. Shen, Comparison study on microstructure and mechanical properties of Sn–10Bi and Sn–Ag–Cu solder alloys and joints. Microelectron. Reliab. 78, 72–79 (2017)

J.-W. Yoon, S.-B. Jung, Investigation of interfacial reactions between Sn–5Bi solder and Cu substrate. J. Alloys Compd. 359, 202–208 (2003)

T.Y. Kang, Y.Y. Xiu, L. Hui, J.J. Wang, W.P. Tong, C.Z. Liu, Effect of bismuth on intermetallic compound growth in lead free solder/Cu microelectronic interconnect. J. Mater. Sci. Technol. 27(8), 741–745 (2011)

Z.M. Lai, X.D. Kong, Q.R. You, X.B. Cao, Microstructure and mechanical properties of Co/Sn–10Bi couple and Co/Sn–10Bi/Co joint. Microelectron. Reliab. 68, 69–76 (2017)

J. Wang, H.S. Liu, L.B. Liu, Z.P. Jin, Interfacial reaction between Sn–Bi alloy and Ni substrate. J. Electron. Mater. 35(10), 1842–1847 (2006)

J. Zhao, L. Qi, X.M. Wang, L. Wang, Influence of Bi on microstructures evolution and mechanical properties in Sn–Ag–Cu lead-free solder. J. Alloys Compd. 375(1–2), 196–201 (2004)

J. Zhao, C.Q. Cheng, L. Qi, C.Y. Chi, Kinetics of intermetallic compound layers and shear strength in Bi-bearing SnAgCu/Cu soldering couples. J. Alloys Compd. 473(1), 382–388 (2009)

M. He, S.N. Ekpenuma, V.L. Acoff, Microstructure and creep deformation of Sn–Ag–Cu–Bi/Cu solder joints. J. Electron. Mater. 37(3), 300–306 (2008)

A.A. El-Daly, Y. Swilem, M.H. Makled, M.G. El-Shaarawy, A.M. Abdraboh, Thermal and mechanical properties of Sn–Zn–Bi lead-free solder alloys. J. Alloys Compd. 484(1), 134–142 (2009)

J. Chen, J. Shen, D. Min, C. Peng, Influence of minor Bi additions on the interfacial morphology between Sn–Zn–xBi solders and a Cu layer. J. Mater. Sci.: Mater. Electron. 20(11), 1112–1117 (2009)

R. Zhou, X. Zhang, G. Huang, Influence of trace elements Bi and Sb on solderability of solder. Chin. J. Nonferrous Met. 8, 192–196 (1998)

Z.-M. Guan, G.-X. Liu, T. Liu, Kinetics of interface reaction in 40Sn–Bi/Cu and 40Sn–Bi–2Ag/Cu systems during aging in solid state. IEEE Trans. Adv. Packag. 23(4), 737–742 (2000)

O.M. Abdelhadi, L. Ladani, IMC growth of Sn–3.5Ag/Cu system: combined chemical reaction and diffusion mechanisms. J. Alloys Compd. 537, 87–99 (2012)

H.T. Lee, S.Y. Hu, T.F. Hong, Y.F. Chen, The shear strength and fracture behavior of Sn–Ag–xSb solder joints with Au/Ni–P/Cu UBM. J. Electron. Mater. 37(6), 867–873 (2008)

F. Wang, Y. Huang, Z. Zhang, C. Yan, Interfacial reaction and mechanical properties of Sn–Bi solder joints. Materials 10(8), 920 (2017)

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, F., Chen, H., Huang, Y. et al. Interfacial behavior and joint strength of Sn–Bi solder with solid solution compositions. J Mater Sci: Mater Electron 29, 11409–11420 (2018). https://doi.org/10.1007/s10854-018-9233-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-9233-7