Abstract

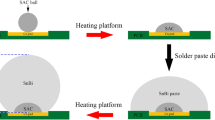

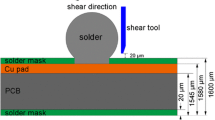

To improve the mechanical properties of SnBi solder joints, Sn–Ag–Cu–Bi–Ni (SACBN) bumps were pre-soldered on the Cu pads, and thus the SnBi/SACBN/Cu solder joints were obtained in this work. By comparing with SnBi/Cu, the effects of soldering time on the microstructure and mechanical properties of SnBi/SACBN/Cu solder joint were investigated. Experimental results show that increasing soldering time suppresses the composition segregation in SnBi bulk, but it leads to the coarsening of β-Sn and Bi-rich phases. As the soldering time increases, the interfacial IMC layers in the SnBi/Cu and the SnBi/SACBN/Cu solder joints gradually become thicker. The growth of the (Cu, Ni)6Sn5 interfacial IMC in SnBi/SACBN/Cu is mainly based on solid–solid diffusion. Its growth rate is lower than that of the IMC whose growth is dominantly due to liquid–solid diffusion in SnBi/Cu. The addition of SACBN bulk decreases the hardness of the SnBi bulk. Meanwhile, the hardness shows a decreasing trend as the soldering time increases. When the soldering time is 40 s and 160 s, SACBN bulk suppresses the propagation of fracture in SnBi bulk and improves the shear strength of the solder joint. As the soldering time reaches 280 s, the shear strength of the SnBi/SACBN/Cu solder joint decreases, and the fracture is mainly located in the SnBi bulk.

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

G. Ren, I.J. Wilding, M.N. Collins, Alloying influences on low melt temperature SnZn and SnBi solder alloys for electronic interconnections. J. Alloy. Compd. 665, 251–260 (2016)

Y. Liu, B. Ren, M. Zhou, X. Zeng, F. Sun, Microstructure, mechanical, and thermal behaviors of SnBi/Cu solder joint enhanced by porous Cu. J. Mater. Sci-Mater. El. 31, 8258–8267 (2020)

Z. Lai, D. Ye, Microstructure and properties of Sn-10Bi-xCu solder alloy/joint. J. Electron. Mater. 45, 3702–3711 (2016)

Y.A. Shen, S. Zhou, J. Li, C.H. Yang, S. Huang, S.K. Lin, H. Nishikawa, Sn-3.0 Ag-0.5Cu/Sn-58Bi composite solder joint assembled using a low-temperature reflow process for PoP technology. Mater. Des. 183, 108144 (2019)

X. Zhao, M. Muraoka, M. Saka, Length-dependent electromigration behavior of Sn58Bi solder and critical length of electromigration. J. Electron. Mater. 46, 1287–1292 (2017)

L. Zhao, Z. He, Z. Wang, L. Su, X. Lu, Simulation and experimental investigation on active thermography test of the solder balls. IEEE. T. Ind. Inform. 16, 1617–1624 (2019)

C. Wu, J. Shen, C. Peng, Effects of trace amounts of rare earth additions on the microstructures and interfacial reactions of Sn57Bi1Ag/Cu solder joints. J. Mater. Sci. Mater. El. 23, 14–21 (2012)

J. Shen, C. Wu, S. Li, Effects of rare earth additions on the microstructural evolution and microhardness of Sn30Bi0.5Cu and Sn35Bi1Ag solder alloys. J. Mater. Sci. Mater. El. 23, 156–163 (2012)

D.L. Ma, P. Wu, Effects of Zn addition on mechanical properties of eutectic Sn-58Bi solder during liquid-state aging. Trans. Nonferr. Metal. Soc. 25, 1225–1233 (2015)

W. Zhu, W. Zhang, W. Zhou, P. Wu, Improved microstructure and mechanical properties for SnBi solder alloy by addition of Cr powders. J. Alloy. Compd. 789, 805–813 (2019)

Z. Wang, Q.K. Zhang, Y.X. Chen, Z.L. Song, Influences of Ag and In alloying on Sn-Bi eutectic solder and SnBi/Cu solder joints. J. Mater. Sci. Mater. El. 30, 18524–18538 (2019)

S.Y. Zhao, Z.H. Cai, Y.P. Zhang, Y.H. Zhang, Effect of Sb doping on microstructure and mechanical properties of tin-bismuth near-eutectic solder. Welding Technology. 39, 47–50 (2010)

X. Hu, H. Qiu, X. Jiang, Effect of Ni addition into the Cu substrate on the interfacial IMC growth during the liquid-state reaction with Sn-58Bi solder. J. Mater. Sci. Mater. El. 30, 1907–1918 (2019)

L. Yang, S. Ma, G. Mu, Improvements of microstructure and hardness of lead-free solders doped with Mo nanoparticles. Mater. Lett. 304, 130654 (2021)

S.M. Lee, J.W. Yoon, S.B. Jung, Interfacial reaction and mechanical properties between low melting temperature Sn–58Bi solder and various surface finishes during reflow reactions. J. Mater. Sci. Mater. El. 26, 1649–1660 (2015)

W.R. Myung, Y. Kim, S.B. Jung, Evaluation of the bondability of the epoxy-enhanced Sn-58Bi solder with ENIG and ENEPIG surface finishes. J. Electron. Mater. 44, 4637–4645 (2015)

J. Kim, W.R. Myung, S.B. Jung, Effects of aging treatment on mechanical properties of Sn-58Bi epoxy solder on ENEPIG-surface-finished PCB. J. Electron. Mater. 45, 5895–5903 (2016)

H.F. Zou, Q.K. Zhang, Z.F. Zhang, Interfacial microstructure and mechanical properties of SnBi/Cu joints by alloying Cu substrate. Mater. Sci. Eng. A 532, 167–177 (2012)

F. Wang, D.Y. Li, Z.J. Zhang, Improvement on interfacial structure and properties of Sn-58Bi/Cu joint using Sn-30Ag-05Cu solder as barrier. J. Mater. Sci. Mater. El. 28, 19051–19060 (2017)

Y. Liu, R. Xu, H. Zhang, F. Sun, Microstructure and shear behavior of solder joint with Sn58Bi/Sn3.0Ag0.5Cu/Cu superposition structure. J. Mater. Sci. Mater. El. 30, 14077–14084 (2019)

Y. Liu, J. Chang, M. Zhou, Y. Xue, X. Zeng, F. Sun, Microstructure and shear behavior of Sn58Bi/Cu solder joint enhanced by SnAgCuBiNi bump. Mod. Phys. Lett. B 34, 2050413 (2020)

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

YL: conceptualization, methodology, investigation, and writing—review & editing. JC: investigation, writing—original draft. YX: supervision. RC: investigation. HL: review & editing. SZ: review & editing. XZ: supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Y., Chang, J., Xue, Y. et al. Effect of soldering time on the microstructure and mechanical properties of SnBi/SACBN/Cu solder joint. J Mater Sci: Mater Electron 33, 8270–8280 (2022). https://doi.org/10.1007/s10854-022-07981-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-022-07981-9