Abstract

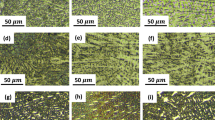

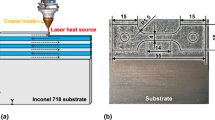

Powder-based laser-directed energy deposition (L-DED) enables rapid prototyping and production of complex geometry Inconel 718 parts for structural applications. However, the heterogeneous microstructure obtained by the L-DED could lead to non-uniform mechanical properties at room temperature. Therefore, evaluating the local heterogeneity in mechanical properties of L-DED manufactured Inconel 718 superalloy is important. The mechanical properties in terms of hardness and local tensile properties of Inconel 718 superalloy have been investigated within the sample volume manufactured by L-DED to determine the local variations in properties. The mechanical properties were compared under the as-deposition and standard solution treatment and aging (STA) conditions. The average hardness and tensile strength properties of L-DED Inconel 718 in as-deposition conditions were significantly lower, while the strain-to-failure is significantly higher than that of its wrought counterparts. STA leads the average mechanical properties of L-DED Inconel 718, which is equivalent to its wrought counterpart. The hardness varied along the deposition direction in as-deposited L-DED Inconel 718. Interestingly, the local variability in the hardness along the deposition direction in L-DED Inconel 718 was eliminated after STA. The tensile strength properties varied along the deposition direction and were found to be lowest near the surface. The local variation trend in tensile strength properties was the same even after STA. The local ductility followed a trend relative to the strength in L-DED Inconel 718. A careful assessment shows that local variation in the mechanical properties was significant along the deposition direction, while it was minimal along the scanning direction of L-DED Inconel 718 under as-deposition and STA conditions. The local heterogeneity in the mechanical properties in L-DED Inconel 718 is explained in terms of the respective microstructure and deformation characteristics.

Graphical abstract

Similar content being viewed by others

Data and code availability

Data will be made available on request.

References

Thomas A, El-Wahabi M, Cabrera JM, Prado JM (2006) High temperature deformation of Inconel 718. J Mater Process Technol 177:469–472. https://doi.org/10.1016/j.jmatprotec.2006.04.072

Slama C, Abdellaoui M (2000) Structural characterization of the aged Inconel 718. J Alloy Compd 306:277–284. https://doi.org/10.1016/S0925-8388(00)00789-1

Ezugwu EO, Wang ZM, Machado AR (1999) The machinability of nickel-based alloys: a review. J Mater Process Technol 86:1–16. https://doi.org/10.1016/S0924-0136(98)00314-8

Rahman M, Seah WKH, Teo TT (1997) The machinability of inconel 718. J Mater Process Technol 63:199–204. https://doi.org/10.1016/S0924-0136(96)02624-6

Dudzinski D, Devillez A, Moufki A, Larrouquère D, Zerrouki V, Vigneau J (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manuf 44:439–456. https://doi.org/10.1016/S0890-6955(03)00159-7

Kumar P, Farah J, Akram J, Teng C, Ginn J, Misra M (2019) Influence of laser processing parameters on porosity in Inconel 718 during additive manufacturing. Int J Adv Manuf Technol 103:1497–1507. https://doi.org/10.1007/s00170-019-03655-9

Pratheesh Kumar S, Elangovan S, Mohanraj R, Ramakrishna JR (2021) A review on properties of Inconel 625 and Inconel 718 fabricated using direct energy deposition. Mater Today Proc 46:7892–7906. https://doi.org/10.1016/j.matpr.2021.02.566

Jinoop AN, Paul CP, Mishra SK, Bindra KS (2019) Laser Additive Manufacturing using directed energy deposition of Inconel-718 wall structures with tailored characteristics. Vacuum 166:270–278. https://doi.org/10.1016/j.vacuum.2019.05.027

Zhong C, Gasser A, Backes G, Fu J, Schleifenbaum JH (2022) Laser additive manufacturing of Inconel 718 at increased deposition rates. Mater Sci Eng A 844:143196. https://doi.org/10.1016/j.msea.2022.143196

Bambach M, Sizova I, Kies F, Haase C (2021) Directed energy deposition of Inconel 718 powder, cold and hot wire using a six-beam direct diode laser set-up. Addit Manuf 47:102269. https://doi.org/10.1016/j.addma.2021.102269

Li Z, Sui S, Ma X, Tan H, Zhong C, Bi G, Clare AT, Gasser A, Chen J (2022) High deposition rate powder- and wire-based laser directed energy deposition of metallic materials: a review. Int J Mach Tools Manuf 181:103942. https://doi.org/10.1016/j.ijmachtools.2022.103942

Svetlizky D, Das M, Zheng B, Vyatskikh AL, Bose S, Bandyopadhyay A, Schoenung JM, Lavernia EJ, Eliaz N (2021) Directed energy deposition (DED) additive manufacturing: physical characteristics, defects, challenges and applications. Mater Today. https://doi.org/10.1016/j.mattod.2021.03.020

Onuike B, Bandyopadhyay A (2019) Additive manufacturing in repair: influence of processing parameters on properties of Inconel 718. Mater Lett 252:256–259. https://doi.org/10.1016/j.matlet.2019.05.114

Mueller M, Franz K, Riede M, López E, Brueckner F, Leyens C (2023) Influence of process parameter variation on the microstructure of thin walls made of Inconel 718 deposited via laser-based directed energy deposition with blown powder. J Mater Sci 58:11310–11326. https://doi.org/10.1007/s10853-023-08706-x

Corbin DJ, Nassar AR, Reutzel EW, Beese AM, Kistler NA (2017) Effect of directed energy deposition processing parameters on laser deposited Inconel® 718: external morphology. J Laser Appl 29:022001. https://doi.org/10.2351/1.4977476

Kim J-H, Oh W-J, Lee C-M, Kim D-H (2022) Achieving optimal process design for minimizing porosity in additive manufacturing of Inconel 718 using a deep learning-based pore detection approach. Int J Adv Manuf Technol 121:2115–2134. https://doi.org/10.1007/s00170-022-09372-0

Xu L, Chai Z, Chen H, Zhang X, Xie J, Chen X (2021) Tailoring Laves phase and mechanical properties of directed energy deposited Inconel 718 thin-wall via a gradient laser power method. Mater Sci Eng A 824:141822. https://doi.org/10.1016/j.msea.2021.141822

Zhao X, Chen J, Lin X, Huang W (2008) Study on microstructure and mechanical properties of laser rapid forming Inconel 718. Mater Sci Eng A 478:119–124. https://doi.org/10.1016/j.msea.2007.05.079

Chen B, Mazumder J (2017) Role of process parameters during additive manufacturing by direct metal deposition of Inconel 718. Rapid Prototyp J 23:919–929. https://doi.org/10.1108/RPJ-05-2016-0071

Hosseini E, Popovich VA (2019) A review of mechanical properties of additively manufactured Inconel 718. Addit Manuf 30:100877. https://doi.org/10.1016/j.addma.2019.100877

Li S-H, Kumar P, Chandra S, Ramamurty U (2023) Directed energy deposition of metals: processing, microstructures, and mechanical properties. Int Mater Rev 68:605–647. https://doi.org/10.1080/09506608.2022.2097411

Paul CP, Ganesh P, Mishra SK, Bhargava P, Negi J, Nath AK (2007) Investigating laser rapid manufacturing for Inconel-625 components. Opt Laser Technol 39:800–805. https://doi.org/10.1016/j.optlastec.2006.01.008

Zhong C, Gasser A, Schopphoven T, Poprawe R (2015) Experimental study of porosity reduction in high deposition-rate laser material deposition. Opt Laser Technol 75:87–92. https://doi.org/10.1016/j.optlastec.2015.06.016

Wang X, Chou K (2017) Electron backscatter diffraction analysis of Inconel 718 parts fabricated by selective laser melting additive manufacturing. JOM 69:402–408. https://doi.org/10.1007/s11837-016-2198-1

Liu F, Lin X, Huang C, Song M, Yang G, Chen J, Huang W (2011) The effect of laser scanning path on microstructures and mechanical properties of laser solid formed nickel-base superalloy Inconel 718. J Alloy Compd 509:4505–4509. https://doi.org/10.1016/j.jallcom.2010.11.176

Martin N, Hor A, Copin E, Lours P, Ratsifandrihana L (2022) Correlation between microstructure heterogeneity and multi-scale mechanical behavior of hybrid LPBF-DED Inconel 625. J Mater Process Technol 303:117542. https://doi.org/10.1016/j.jmatprotec.2022.117542

Zeng Y, Li L, Huang W, Zhao Z, Yang W, Yue Z (2022) Effect of thermal cycles on laser direct energy deposition repair performance of nickel-based superalloy: microstructure and tensile properties. Int J Mech Sci 221:107173. https://doi.org/10.1016/j.ijmecsci.2022.107173

Zhu L, Xu ZF, Liu P, Gu YF (2018) Effect of processing parameters on microstructure of laser solid forming Inconel 718 superalloy. Opt Laser Technol 98:409–415. https://doi.org/10.1016/j.optlastec.2017.08.027

Parimi LL, Ravi GA, Clark D, Attallah MM (2014) Microstructural and texture development in direct laser fabricated IN718. Mater Charact 89:102–111. https://doi.org/10.1016/j.matchar.2013.12.012

Tian Y, McAllister D, Colijn H, Mills M, Farson D, Nordin M, Babu S (2014) Rationalization of microstructure heterogeneity in Inconel 718 builds made by the direct laser additive manufacturing process. Metall Mater Trans A 45:4470–4483

Alhuzaim A, Imbrogno S, Attallah MM (2021) Controlling microstructural and mechanical properties of direct laser deposited Inconel 718 via laser power. J Alloy Compd 872:159588. https://doi.org/10.1016/j.jallcom.2021.159588

Stevens EL, Toman J, To AC, Chmielus M (2017) Variation of hardness, microstructure, and Laves phase distribution in direct laser deposited alloy 718 cuboids. Mater Des 119:188–198. https://doi.org/10.1016/j.matdes.2017.01.031

Liu F, Lin X, Leng H, Cao J, Liu Q, Huang C, Huang W (2013) Microstructural changes in a laser solid forming Inconel 718 superalloy thin wall in the deposition direction. Opt Laser Technol 45:330–335. https://doi.org/10.1016/j.optlastec.2012.06.028

Jia T, Zou B, Liu W, Lei T, Ding H (2023) Effect of process parameters on mechanical properties of Inconel718 superalloy fabricated by directional energy deposition. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-10854-y

Blackwell PL (2005) The mechanical and microstructural characteristics of laser-deposited IN718. J Mater Process Technol 170:240–246. https://doi.org/10.1016/j.jmatprotec.2005.05.005

Qi H, Azer M, Ritter A (2009) Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured Inconel 718. Metall Mater Trans A 40:2410–2422. https://doi.org/10.1007/s11661-009-9949-3

Chechik L, Christofidou KA, Markanday JFS, Goodall AD, Miller JR, West G, Stone H, Todd I (2022) Hardness variation in inconel 718 produced by laser directed energy deposition. Materialia 26:101643. https://doi.org/10.1016/j.mtla.2022.101643

Al-Lami J, Hoang P, Davies C, Pirzada T, Pham M-S (2023) Plastic inhomogeneity and crack initiation in hybrid wrought: additively manufactured Inconel 718. Mater Charact 199:112815. https://doi.org/10.1016/j.matchar.2023.112815

Kwabena Adomako N, Haghdadi N, Primig S (2022) Electron and laser-based additive manufacturing of Ni-based superalloys: a review of heterogeneities in microstructure and mechanical properties. Mater Design 223:111245. https://doi.org/10.1016/j.matdes.2022.111245

Yang H, Yang J, Huang W, Wang Z, Zeng X (2018) The printability, microstructure, crystallographic features and microhardness of selective laser melted Inconel 718 thin wall. Mater Des 156:407–418. https://doi.org/10.1016/j.matdes.2018.07.007

Tabernero I, Lamikiz A, Martínez S, Ukar E, Figueras J (2011) Evaluation of the mechanical properties of Inconel 718 components built by laser cladding. Int J Mach Tools Manuf 51:465–470. https://doi.org/10.1016/j.ijmachtools.2011.02.003

Ning J, Yan Z, Zhu L, Zhao J, Yang Z, Wang S, Xue P, Xin B (2022) Process-induced mechanical property heterogeneity along the building direction of directed energy deposited IN718 thin-walled parts. Int J Mech Sci 218:107075. https://doi.org/10.1016/j.ijmecsci.2022.107075

Li Z, Chen J, Sui S, Zhong C, Lu X, Lin X (2020) The microstructure evolution and tensile properties of Inconel 718 fabricated by high-deposition-rate laser directed energy deposition. Addit Manuf 31:100941. https://doi.org/10.1016/j.addma.2019.100941

Yeoh YC, Macchi G, Jain E, Gaskey B, Raman S, Tay G, Verdi D, Patran A, Grande AM, Seita M (2021) Multiscale microstructural heterogeneity and mechanical property scatter in Inconel 718 produced by directed energy deposition. J Alloy Compd 887:161426. https://doi.org/10.1016/j.jallcom.2021.161426

Kumara C, Balachandramurthi AR, Goel S, Hanning F, Moverare J (2020) Toward a better understanding of phase transformations in additive manufacturing of alloy 718. Materialia 13:100862. https://doi.org/10.1016/j.mtla.2020.100862

Li Z, Ma X, Zhong C, Sui S, Gasser A, Chen J (2022) Microstructure homogeneity and mechanical property improvement of Inconel 718 alloy fabricated by high-deposition-rate laser directed energy deposition. Mater Sci Eng A 832:142430. https://doi.org/10.1016/j.msea.2021.142430

Kumar P, Ravi Chandran KS, Cao F, Koopman M, Fang ZZ (2016) The nature of tensile ductility as controlled by extreme-sized pores in powder metallurgy Ti–6Al–4V Alloy. Metall Mater Trans A 47:2150–2161. https://doi.org/10.1007/s11661-016-3419-5

Shamsaei N, Yadollahi A, Bian L, Thompson SM (2015) An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit Manuf. 8:12–35. https://doi.org/10.1016/j.addma.2015.07.002

Choi J-P, Shin G-H, Yang S, Yang D-Y, Lee J-S, Brochu M, Yu J-H (2017) Densification and microstructural investigation of Inconel 718 parts fabricated by selective laser melting. Powder Technol 310:60–66. https://doi.org/10.1016/j.powtec.2017.01.030

Ding RG, Huang ZW, Li HY, Mitchell I, Baxter G, Bowen P (2015) Electron microscopy study of direct laser deposited IN718. Mater Charact 106:324–337. https://doi.org/10.1016/j.matchar.2015.06.017

Yu X, Lin X, Liu F, Wang L, Tang Y, Li J, Zhang S, Huang W (2020) Influence of post-heat-treatment on the microstructure and fracture toughness properties of Inconel 718 fabricated with laser directed energy deposition additive manufacturing. Mater Sci Eng A 798:140092

Calandri M, Yin S, Aldwell B, Calignano F, Lupoi R, Ugues D (2019) Texture and microstructural features at different length scales in Inconel 718 produced by selective laser melting. Materials 12:1293. https://doi.org/10.3390/ma12081293

Li P, Zhou J, Gong Y, Meng X, Lu J (2021) Effect of post-heat treatment on the microstructure and mechanical properties of laser metal deposition Inconel 718. J Mech Sci Technol 35:2871–2878. https://doi.org/10.1007/s12206-021-0610-4

Zhang Y, Li Z, Nie P, Wu Y (2013) Effect of heat treatment on niobium segregation of laser-cladded IN718 alloy coating. Metall Mater Trans A 44:708–716. https://doi.org/10.1007/s11661-012-1459-z

Zhang Y, Yang L, Chen T, Zhang W, Huang X, Dai J (2017) Investigation on the optimized heat treatment procedure for laser fabricated IN718 alloy. Opt Laser Technol 97:172–179. https://doi.org/10.1016/j.optlastec.2017.06.027

Sui S, Chen J, Li Z, Li H, Zhao X, Tan H (2020) Investigation of dissolution behavior of laves phase in inconel 718 fabricated by laser directed energy deposition. Addit Manuf 32:101055. https://doi.org/10.1016/j.addma.2020.101055

Huang SG, Vanmeensel K, Mohrbacher H, Woydt M, Vleugels J (2015) Microstructure and mechanical properties of NbC-matrix hardmetals with secondary carbide addition and different metal binders. Int J Refract Metal Hard Mater 48:418–426. https://doi.org/10.1016/j.ijrmhm.2014.10.014

Tucho WM, Cuvillier P, Sjolyst-Kverneland A, Hansen V (2017) Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater Sci Eng A 689:220–232. https://doi.org/10.1016/j.msea.2017.02.062

Tabaie S, Rézaï-Aria F, Jahazi M (2020) Microstructure evolution of selective laser melted Inconel 718: influence of high heating rates. Metals 10:587. https://doi.org/10.3390/met10050587

Olovsjö S, Wretland A, Sjöberg G (2010) The effect of grain size and hardness of wrought alloy 718 on the wear of cemented carbide tools. Wear 268:1045–1052. https://doi.org/10.1016/j.wear.2010.01.017

Schirra JJ (1997) Effect of heat treatment variations on the hardness and mechanical properties of wrought Inconel 718. Superalloys 718:431–438

Zhai Y, Lados DA, Brown EJ, Vigilante GN (2019) Understanding the microstructure and mechanical properties of Ti–6Al–4V and Inconel 718 alloys manufactured by laser engineered net shaping. Addit Manuf 27:334–344

Soffel F, Eisenbarth D, Hosseini E, Wegener K (2021) Interface strength and mechanical properties of Inconel 718 processed sequentially by casting, milling, and direct metal deposition. J Mater Process Technol 291:117021

Mazzucato F, Forni D, Valente A, Cadoni E (2021) Laser metal deposition of Inconel 718 alloy and as-built mechanical properties compared to casting. Materials 14:437

Zhu L, Xu Z, Gu Y (2018) Effect of laser power on the microstructure and mechanical properties of heat treated Inconel 718 superalloy by laser solid forming. J Alloy Compd 746:159–167. https://doi.org/10.1016/j.jallcom.2018.02.268

El-Bagoury N, Matsuba T, Yamamoto K, Miyahara H, Ogi K (2005) Influence of heat treatment on the distribution of Ni2Nb and microsegregation in cast Inconel 718 alloy. Mater Trans 46:2478–2483. https://doi.org/10.2320/matertrans.46.2478

Jelvani S, Shoja Razavi R, Barekat M, Dehnavi MR, Erfanmanesh M (2019) Evaluation of solidification and microstructure in laser cladding Inconel 718 superalloy. Opt Laser Technol 120:105761. https://doi.org/10.1016/j.optlastec.2019.105761

Rao GA, Kumar M, Srinivas M, Sarma DS (2003) Effect of standard heat treatment on the microstructure and mechanical properties of hot isostatically pressed superalloy inconel 718. Mater Sci Eng A 355:114–125. https://doi.org/10.1016/S0921-5093(03)00079-0

Zhang D, Niu W, Cao X, Liu Z (2015) Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater Sci Eng A 644:32–40. https://doi.org/10.1016/j.msea.2015.06.021

Sui S, Tan H, Chen J, Zhong C, Li Z, Fan W, Gasser A, Huang W (2019) The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing. Acta Mater 164:413–427. https://doi.org/10.1016/j.actamat.2018.10.032

Acknowledgements

The research is partially supported by the New Mexico Space Grant Consortium. The authors greatly acknowledge Optomec Inc. for providing the samples for the present study and Thomas J. Lienert from Optomec for the heat treatment cycle discussion. The authors also acknowledge Md Mehadi Hassan for helping with the tensile testing. PK acknowledges the startup fund for this work.

Author information

Authors and Affiliations

Contributions

LA was involved in experiments and data collection, SB helped in experiments and data collection, TK contributed to experimental design and data analysis, PK was involved in experiment design, data analysis, and manuscript writing.

Corresponding author

Ethics declarations

Conflict of interest

No conflicts of interest exist.

Ethical approval

Not Applicable.

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Alqawasmi, L., Bijjala, S.T., Khraishi, T. et al. Mechanical property heterogeneity in Inconel 718 superalloy manufactured by directed energy deposition. J Mater Sci 59, 5047–5065 (2024). https://doi.org/10.1007/s10853-023-09249-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09249-x