Abstract

The excessive reliance on fossil fuels has resulted in an energy crisis, environmental pollution, and health problems, calling for alternative fuels such as biodiesel. Here, we review computational chemistry and machine learning for optimizing biodiesel production from waste. This article presents computational and machine learning techniques, biodiesel characteristics, transesterification, waste materials, and policies encouraging biodiesel production from waste. Computational techniques are applied to catalyst design and deactivation, reaction and reactor optimization, stability assessment, waste feedstock analysis, process scale-up, reaction mechanims, and molecular dynamics simulation. Waste feedstock comprise cooking oil, animal fat, vegetable oil, algae, fish waste, municipal solid waste and sewage sludge. Waste cooking oil represents about 10% of global biodiesel production, and restaurants alone produce over 1,000,000 m3 of waste vegetable oil annual. Microalgae produces 250 times more oil per acre than soybeans and 7–31 times more oil than palm oil. Transesterification of food waste lipids can produce biodiesel with a 100% yield. Sewage sludge represents a significant biomass waste that can contribute to renewable energy production.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

In recent decades, extensive reliance on oil-based products has led to a profound energy crisis, widespread environmental pollution, and a surge in health problems, including heart disease and cancer. Fossil fuels like natural gas, oil, and coal have dominated the global energy landscape, constituting over 80% of the world's energy production, primarily driven by carbon emissions from these sources (Alalaiwat and Khan 2023; Esmaeili 2022). Despite technological improvements and energy efficiency laws, the increase in global population and economic growth has led to a rise in energy consumption, which has not been offset by the gains made in energy efficiency. Additionally, the ongoing conflict between Russia and Ukraine has triggered an energy crisis, significantly impacting households' energy costs for heating, cooling, and transportation. In 2021, the European Union relied on imports for over 45% of its gas supply, representing nearly 40% of its total gas consumption (Farghali et al. 2023b). The extensive use of non-renewable energy sources and increasing industrialization have resulted in the release of large amounts of greenhouse gases, leading to environmental degradation and a rise in global temperatures (Wang et al. 2022a). The global average atmospheric carbon dioxide concentration has seen a significant increase, surging from 285 ppm in 1850 to 419 ppm in 2022 (Chen et al. 2022). According to estimations by the United Kingdom Meteorological Office, the global average surface temperatures have been projected to rise by approximately 0.97–1.21 °C between 1850 and 2022, with an average estimate of 1.09 °C. Additionally, the year 2022 is anticipated to be one of the warmest years on record (Sangomla 2022). Moreover, greenhouse gas emissions are predicted to increase by 50% by 2050, primarily due to carbon dioxide emissions from non-renewable energy sources (Chen et al. 2022; Draper et al. 2022; Mukhtar et al. 2022). As a result of ongoing increases in atmospheric carbon dioxide, global warming has brought the globe to the brink of an environmental disaster (Bahman et al. 2023; Halawy et al. 2022).

Energy is a fundamental necessity for our survival, and as the demand for energy sources surges, optimizing resource utilization becomes imperative (Farghali et al. 2023a). The limited availability of traditional energy sources, coupled with escalating global demand, underscores the importance of alternative fuels (Maheshwari et al. 2022). While renewable and green energy resources are in use, none can completely replace conventional fossil fuels (Brahma et al. 2022). Biofuels, particularly biodiesel, have garnered significant attention as a renewable, biodegradable, and non-toxic fuel with lower emissions compared to regular diesel (Arslan et al. 2022; Brahma et al. 2022; Yaashikaa et al. 2022). Biodiesel boasts superior chemical and physical properties when compared to petrol-diesel (Osman et al. 2023a). The direct use of biodiesel or biodiesel blends leads to substantial reductions in combustion gases and carbon monoxide emissions (Sarwer et al. 2022). Indonesia and the United States are the world's largest biodiesel producers, generating 7.9 and 6.5 billion liters in 2019, respectively, and by 2025, the United States is expected to produce over 1 billion gallons of biodiesel. Estimates suggest that biodiesel could replace up to 7 volume% of the world's fossil fuels by 2030 (Babadi et al. 2022). It presents a feasible solution to the dual challenges of fossil fuel depletion and environmental degradation (Borah et al. 2019). However, alternative fuels face significant challenges, including special handling requirements, high costs, low energy density compared to petroleum-based fuels, and inadequate supply to meet nationwide requirements (Maheshwari et al. 2022).

The production of biodiesel can utilize waste materials such as waste cooking oils, animal fats, various non-edible vegetable oils, and municipal waste as raw materials (Du et al. 2016). Waste-based biodiesel has its origins in World War II and the energy crises of the 1970s when alternative oil resources were sought due to fuel shortages. In the 1980s, the trans-esterification method enabled biodiesel production from waste materials (Ayadi et al. 2016). Therefore, waste-based biodiesel is regarded as the second generation of biodiesel production (Heidari and Wood 2021). The benefits of converting waste to biodiesel are multifaceted, encompassing waste management, reduced greenhouse emissions, economic stability, energy resource diversification, and climate change mitigation (van Eijck et al. 2014). However, the high viscosity of biodiesel compared to petroleum-based fuel posed challenges.

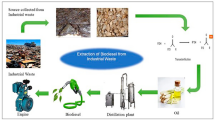

Thus, optimizing waste-based biodiesel production represents a critical step towards sustainable energy solutions. Computational chemistry and machine learning techniques have emerged as invaluable tools in this endeavor. Computational chemistry aids in deciphering the complex chemical reactions involved in biodiesel production, offering insights into reaction mechanisms, kinetics, and catalyst design. Machine learning, on the other hand, empowers precise predictions and optimization of various biodiesel production parameters, enhancing process efficiency and yield. Together, these cutting-edge approaches enable a more comprehensive understanding of waste-based biodiesel production, facilitating the development of efficient and eco-friendly processes to meet the growing demand for renewable energy sources while reducing the environmental footprint (Abdelbasset et al. 2022; Ibrahim 2021). Figure 1 illustrates the utilization of various waste resources for biodiesel production, incorporating pretreatment and transesterification processes. These processes are further enhanced through the integration of machine learning and computational chemistry techniques.

Utilization of different waste resources for biodiesel production through pretreatment and transesterification processes enhanced by machine learning and computational chemistry. The figure illustrates the diverse range of waste resources utilized for biodiesel production, including animal fats, waste cooking oil, algae, municipal sewage sludge, and food waste. These waste materials undergo pretreatment processes to remove impurities and enhance their suitability for biodiesel production. Computational chemistry techniques play a significant role in understanding the complex chemical reactions involved in the pretreatment and transesterification processes. By leveraging computational chemistry, researchers can optimize reaction conditions, catalyst selection, and process parameters, leading to improved biodiesel yield and quality. Machine learning algorithms are employed to develop predictive models that aid in process optimization and parameter selection. The integration of machine learning and computational chemistry enables precise predictions and efficient utilization of waste resources for sustainable biodiesel production, contributing to waste management, renewable energy generation, and environmental sustainability

This article review delves into the world of biodiesel production, exploring the potential of waste materials as sustainable feedstocks. With a specific focus on computational chemistry and machine learning techniques, it highlights innovative approaches to optimize the biodiesel production process. The discussion covers the various waste materials that can be used to produce biodiesel, their availability and suitability for the process, and the chemical reactions involved in the conversion process. Additionally, the review addresses policy recommendations for fostering the integration of waste-based biodiesel into existing energy systems, thereby promoting environmental sustainability and economic stability.

Computational chemistry in the production of biodiesel from waste

Computational chemistry is crucial in various fields, such as chemistry, biochemistry, chemical physics, and material science. It is a discipline that utilizes fundamental principles from physics to examine a wide range of molecular properties and phenomena. Advanced computational techniques enable researchers to investigate molecular structures, thermodynamics, spectroscopic data, reaction rates, and dynamics with exceptional precision and accuracy. Computational chemistry can simulate different phases, including gases, liquids, solids, solutions, and interfaces (Osman et al. 2023b). One of the key advantages of computational chemistry is its ability to simulate adsorption and desorption processes, considering factors such as surface composition, spatial configuration, solution environment, ionic strength, and solution pH. Additionally, it can calculate and interpret spectroscopic data from techniques such as infrared, ultraviolet, nuclear magnetic resonance, and X-ray spectroscopy. The chosen level of theory greatly influences the accuracy and efficiency of these calculations and simulations (Ahmed et al. 2023; Osman et al. 2023b).

Predictive trends may be found using computational approaches that effectively map important chemical features, such as various catalytic materials' carbon and oxygen binding energies. Model surfaces with realistic compositions and structures based on experimental characterizations must be used in computer investigations to yield the most insightful understanding of reaction processes. Now, density functional theory-based ab initio calculations are expensive and frequently limited by computer resources to somewhat idealized model systems. But even when used to interpret experimental kinetic data or create general catalyst design parameters, consistent computational results from realistic, well-built, simplified models may still offer insightful information (Murphy and Xu 2018).

Quantum solutions based on the fundamental axioms of quantum mechanics can help with sustainable energy research. By employing orbitals, their occupations, electron interactions, and excitations as crucial variables, correlated wavefunction theories provide maximum accuracy. Correlated wavefunction approaches, on the other hand, are computationally costly, restricting their use to tiny or medium-sized molecules. Local correlation techniques make use of electron correlation's nearsightedness to ignore or approximate spatially separated excitations. Quantum solutions, which are based on the theory that regulates electron behavior, play critical roles in tackling many challenges connected to sustainable energy research. Theoretical quantum solutions are based on fundamental physical principles and provide prediction assessments of molecule and material characteristics that are frequently completely independent of an experiment. Atomic-scale simulation, investigation of materials and systems at the atomic scale, and analysis of their electrical characteristics can cover knowledge gaps that experiments cannot address. However, using quantum mechanics should be done cautiously because sample characteristics can all impact the results (Dieterich and Carter 2017).

Computational chemistry plays a significant role in the production of biodiesel from waste. By employing advanced computational techniques, researchers can model and simulate the chemical reactions in the biodiesel production process, providing valuable insights and guidance for optimizing production efficiency. One of the key aspects where computational chemistry is crucial is in the design and development of catalysts. Catalysts are essential in the transesterification reaction, which converts waste oils and fats into biodiesel. Computational chemistry allows researchers to study and analyze the interactions between catalysts and reactants at the molecular level. This enables the identification and design of highly effective catalysts that can accelerate the reaction rate and improve the overall yield of biodiesel (Aghbashlo et al. 2021). Furthermore, computational chemistry can assist in optimizing reaction conditions such as temperature, pressure, and solvent composition (Dharmegowda et al. 2022). Through molecular simulations, researchers can investigate the impact of different parameters on the reaction kinetics and select the optimal conditions that maximize the conversion of waste oils into biodiesel. Another area where computational chemistry proves valuable is in understanding the properties of biodiesel molecules. Researchers can use computational methods to study the physicochemical properties of biodiesel, including its viscosity, density, and combustion characteristics. This knowledge is essential for assessing the performance and compatibility of biodiesel as a fuel and ensuring its efficient utilization in engines and vehicles. Moreover, computational chemistry can provide insights into biodiesel's stability and degradation mechanisms. By studying the molecular structures and analyzing reaction pathways, researchers can identify potential degradation pathways and develop strategies to enhance biodiesel products' stability and shelf life. Figure 2 illustrates the various methods of computational chemistry and their application in the production of biodiesel.

Computational chemistry techniques and their application in biodiesel production. The figure depicts computational chemistry techniques vital for biodiesel production from waste. It covers catalyst design for tailored catalyst development, reaction optimization for improved yields, and reactor design to enhance production conditions. Waste feedstock analysis selects suitable materials, process scale-up transitions to commercial scale, reaction mechanism elucidation dissects pathways, and molecular dynamics simulations aid in catalyst design and reaction understanding. These computational tools revolutionize biodiesel production, offering insights and optimizations to develop sustainable and efficient processes from various waste sources

Computational techniques used for biodiesel production from waste

Computational chemistry plays a significant role in biodiesel production by providing insights into reaction mechanisms, catalyst design, and optimization. Here are some examples of computational chemistry models and techniques employed in biodiesel production:

Molecular dynamics simulations (MD): Many scientific areas, including chemical physics, materials science, and biophysics, have benefited greatly from molecular dynamics simulations. This computational methodology has proven extremely useful in the detailed characterization of biomolecular systems, including complementarity with experimental data, experimental design optimization, and prediction of relevant properties for chemical systems that are expensive or difficult to handle experimentally (Filipe and Loura 2022). Molecular dynamics simulations are used to study the behavior and interactions of molecules in biodiesel production (Hwang et al. 2014). They provide insights into the structure, dynamics, and properties of biodiesel molecules, catalysts, and other components. Molecular dynamics simulations can help in understanding reaction mechanisms (Ibrahim 2021), optimize catalysts, and analyze biodiesel's stability and properties (Bravo-Suárez et al. 2013). However, there is little research on the crucial characteristics of fatty acids, which are biodiesel precursors. Experimenting to determine key qualities for fatty acids is difficult owing to their ability to self-associate due to the presence of carboxylic groups via hydrogen bonds. These parameters can be determined using molecular simulation approaches (González et al. 2022). The thermal behavior of biodiesel (Yan et al. 2023), kinematic viscosity, and fuel density are investigated using molecular dynamics simulations (Yang et al. 2023a).

Density functional theory (DFT): Density functional theory is a quantum mechanical method used to calculate molecules' electronic structure and properties. It can be applied to study the energetics and reactivity of biodiesel production reactions, as well as the properties of catalysts and reactants. Density functional theory calculations provide valuable information about reaction pathways, energetics, and activation barriers (Ju et al. 2019; Moses et al. 2007; Ning et al. 2020; Osman et al. 2023b). Although experimental studies can help us understand the reactions catalyzed by heterogeneous acids, some more detailed mechanisms, such as elementary reactions and reaction paths, must still be defined using molecular simulation based on density functional theory (Ning et al. 2020). The acid-catalyzed transesterification mechanism for biodiesel production from waste cooking oils can be investigated using the density functional theory model (Li et al. 2018).

The density functional theory module was used by Li et al. (2018) to analyze the acid (H+)-catalyzed transesterification process of methanol and oleic acid monoacylglycerol. Path 1, Path 2, and Path 3 were created to represent the one-step transesterification without a catalyst and possible pathways of substitution nucleophilic bimolecular (SN2) and substitution nucleophilic unimolecular (SN1) reaction processes with H+-based catalysts. According to the computed structural, thermodynamic, and kinetic data, H+-based catalysts could efficiently minimize the activation energy for the transesterification reaction, and Path 2, based on the substitution nucleophilic bimolecular reaction mechanism, was the best reaction path. The molecular simulation based on density functional theory can deeply reveal its catalytic reaction mechanism (Li et al. 2022). Ning et al. (2020) synthesized various heterogeneous acid catalysts by incorporating phosphotungstic acid onto bamboo-activated carbon and utilized them for catalyzing esterification in biodiesel production. The catalyst demonstrated excellent performance in catalyzing the esterification of oleic acid, achieving a maximum efficiency of 96%. The catalyst also exhibited satisfactory renewability, with a regenerated catalyst achieving an efficiency of 93%. The density functional theory results provided insights into the esterification process, revealing an activation barrier of 19.73 kcal/mol and a reaction energy of 15.83 kcal/mol. This study highlights the promising catalytic capabilities of phosphotungstic acid supported on bamboo-activated carbon for esterification in biodiesel production. The findings from density functional theory analysis provide valuable information regarding the activation barrier and reaction energy involved in the esterification process. Kim et al. (2022) used density functional theory calculations to examine the electronic and catalytic activity of the single sodium-doped graphitic carbon nitrides catalyst for efficient biodiesel production via triglyceride transesterification.

Quantum mechanics/molecular mechanics (QM/MM): QM/MM methods combine quantum mechanical calculations (often density functional theory) with molecular mechanics simulations. They are useful for studying complex systems where both the active site, like the catalyst and the surrounding environment, like the solvent, play significant roles (Quesne et al. 2019; Rungrotmongkol et al. 2007; Senn and Thiel 2009). QM/MM simulations can provide insights into reaction mechanisms, catalyst-substrate interactions, and the influence of the surrounding environment on the biodiesel production process. The molecular mechanism of sonication-induced improvement in the kinetics of lipase-catalyzed processes for biodiesel synthesis is thoroughly investigated (Kumar et al. 2023a). Novel insights are gained into the precise nature of interactions between substrates/products and lipase enzymes on a molecular level by determining the structure of binding pockets of lipases, visualizing binding pockets in various secondary structure motifs, and docking analysis of ligands with lipases using hybrid QM/MM concepts.

Kinetic modeling: Computational kinetic modeling involves developing mathematical models based on experimental data and theoretical calculations to describe the reaction kinetics of biodiesel production. These models can be used to predict reaction rates, optimize reaction conditions, and assess the impact of various parameters on the process efficiency (Hough et al. 2016; Jagaba et al. 2022; Manion and McGivern 2016; Norinaga and Deutschmann 2007). To produce biodiesel, waste cotton-seed cooking oil is microwave-assisted transesterified (Sharma et al. 2019a). The research focuses on optimizing the kinetic modeling of this process. A response surface approach based on a complete factorial design method was used to improve process parameters such as catalyst loading, reaction time, and methanol-to-oil ratio. Kostic et al. (2016) studied kinetic modeling and optimization of the esterification of the oil derived from wasted plum stones as a pretreatment step in biodiesel manufacturing. In addition, Gaurav et al. (2019) presented a kinetic model for converting model yellow grease, a mixture of waste cooking oil and animal fats, into biodiesel using a heteropolyacid catalyst supported on alumina (HSiW/Al2O3) in a batch autoclave. They prepared three model yellow grease feeds by incorporating palmitic, oleic, and linoleic acids into canola oil to simulate real-world conditions. The study developed a pseudo-homogeneous kinetic model that accounted for both esterification and transesterification reactions. By determining rate constants and activation parameters, the research validated the model's accuracy by comparing it with experimental biodiesel data obtained from commercial yellow grease feed processing. Notably, the calculated biodiesel production closely matched experimental results for feeds containing 12.26 wt.% palmitic and linoleic acid, whereas the feed with oleic acid exhibited a higher conversion rate due to its faster esterification kinetics. This kinetic model has the potential to be applied to various catalyst systems, offering valuable insights for process design and cost-effective production of sustainable biodiesel from non-food grade oils with high free fatty acids content.

Moreover, Hazrat et al. (2022) conducted a study on process optimization and reaction kinetics modeling for the two-stage esterification-transesterification reactions of waste cooking oil biodiesel. Optimal conditions were determined for both the esterification and transesterification processes. For the esterification process, the optimal conditions were as follows: a methanol-to-oil molar ratio of 8.12:1, 1.9 wt.% sulfuric acid content of the waste cooking oil, a reaction temperature of 60 °C, and a reaction time of 90 min. On the other hand, the optimal conditions for the transesterification process were found to be a methanol-to-esterified oil molar ratio of 6.1:1, 1.2 wt.% potassium hydroxide catalyst content of the esterified oil, a reaction temperature of 60 °C, and a reaction time of 110 min in a batch reactor system. After determining the optimized process parameters, the researchers developed reaction kinetic models for both the esterification and transesterification processes. Two types of kinetics modeling were employed. The overall process conversion efficiency was calculated to be 97.4%, based on the yield efficiency of both processes. The fatty acid composition of the produced biodiesel was analyzed, revealing the highest amount of methyl oleate at 44.1 wt.%, followed by methyl linoleate and methyl palmitate at 23.5 wt.% and 16.5 wt.%, respectively. Serrano et al. (2015) studied the kinetic modeling of biodiesel production from waste salmon oil, specifically salmon oil obtained from salmon silage in a tricanter centrifuge. The kinetic parameters were varied to obtain the most satisfactory data. A reaction mechanism with four consecutive reactions was considered, and the attack of the nucleophile alcohol on the protonated carbonyl substrate was corroborated as the rate-determining step. A kinetic model with eight independent parameters described with high accuracy the experimental data of 27 reactions with a regression coefficient of 90.9%.

Computational fluid dynamics (CFD): The field of computational fluid dynamics deals with numerical simulations of fluid flows with significant scientific and industrial engineering applications. Fluid flows are governed by the Navier–Stokes equations, which are partial differential equations that describe the conservation of mass and momentum in a Newtonian fluid. These partial differential equations are nonlinear because of the convective acceleration, which captures the change in velocity concerning position. Turbulence, a time-dependent chaotic behavior, is commonly observed in these flows. However, solving the Navier–Stokes equations for turbulent flows can be computationally expensive or even intractable at high Reynolds numbers due to the wide range of spatial and temporal scales involved. Various numerical methods can be employed to solve the Navier–Stokes equations to address this challenge. These methods include finite-difference, finite-volume, finite-element, and spectral methods. Each method discretizes the equations using different orders of approximation. Additionally, turbulence can be simulated at different levels of accuracy and computational cost, depending on the desired fidelity of the results (Vinuesa and Brunton 2022).

Computational fluid dynamics simulations are used to model fluid flow, heat transfer, and mass transfer in biodiesel production reactors. They provide insights into reactor design, mixing efficiency, and heat distribution. Computational fluid dynamics simulations can help optimize reactor configurations, improve mass transfer rates, and ensure efficient heat transfer, enhancing biodiesel production performance. In this context, Huang et al. (2022) presented the design and development of a novel static mixing bioreactor for enzymatic bioprocess, specifically in biodiesel production. To achieve this, the structure of the bioreactor, including unit configuration, aspect ratio, and rotation angle, was designed and optimized using computational fluid dynamics. The researchers used the realizable k-epsilon model, which was proven to be grid-independent with 833,678 hexahedral unstructured grids to improve material mixing. The optimized structure of the bioreactor was determined to be an R-R configuration with an aspect ratio of 1.5 and a rotation angle of 150°. Under these conditions, the researchers optimized the enzymatic production of biodiesel. The optimized process conditions included a static mixer length of 30 cm, a material flow rate of 1.77 m/s, a reaction temperature of 40 °C, the addition of methanol three times, and a molar ratio of 3.4 alcohol to oil with a 10% lipase dose. The results showed that under optimal conditions, the yield of biodiesel reached 81.3% in 1.5 h. Furthermore, even after 12 repeated uses of lipase, the yield remained above 70%. Comparing the static mixer bioreactor with a stirred reactor under the same reaction conditions, the static mixer achieved the same conversion rate (81.3%) in only one-third of the time, demonstrating its excellent mass transfer performance.

Additionally, the study of the specific flow behavior within the microchannel, such as the mixing pattern and the optimization of a microchannel design for biodiesel synthesis, has been extensively conducted using computational fluid dynamics simulations (Mohd Laziz et al. 2020). For better hydrocyclone separation of biodiesel contaminants made from used cooking oil, computational fluid dynamics modeling is used to understand the flow behavior and optimize the hydrocyclone design (Salmanizade et al. 2021). The suitability of the Eulerian and Lagrangian modeling methodologies for various particle concentrations is covered in the above study. The study focuses on the hydrocyclone's structural design and operating factors, such as the diameter of the vortex finder, apex, and cylindrical part length.

Monte Carlo methods (MCM): Monte Carlo is an extremely useful technique for simulating and comprehending random systems and data. It is critical for real-world random system modeling and deterministic numerical computing because it permits stochastic algorithms to escape local optima, allowing for greater search space exploration. The Monte Carlo method also gives insight into randomness by allowing random experiments to be seen on a computer. To evaluate huge and/or high-dimensional data sets, modern statistics increasingly utilize computational methods such as resampling and Monte Carlo methods. Monte Carlo approaches have a theoretical foundation, allowing exact claims on estimator accuracy and algorithm performance. They are utilized in various applications, including industrial engineering and operations research, mathematical programming, autonomous machines and robotics, physical processes and structures, and chemical kinetics (Kroese et al. 2014). Monte Carlo methods involve stochastic simulations to study biodiesel production processes. They can be used to explore the conformational space of molecules, assess the impact of uncertainties in reaction parameters, and simulate the behavior of complex systems. Monte Carlo methods provide statistical information and help understand biodiesel production processes' variability and robustness. To guarantee plant safety and cost-efficiency, prospective investors, governments, engineers, and other stakeholders need additional performance measures, which the Monte Carlo simulation can provide (Abubakar et al. 2015).

Schade and Wiesenthal (2011) applied a risk assessment to the Bio PÓL biofuel model, which predicts the volume of biofuel production in the EU-27 until 2030, using the Monte Carlo simulation approach. The BioPOL model, which simulates the effects of various biofuel support policies on both the production and consumption sides, is a recursive dynamic model. Two simplified policy instances representing a "no tax exemption policy" and a policy introducing a 30% decrease of fossil fuel taxes on biofuels throughout all time stages have been selected as examples. In order to assess the energy use and greenhouse gas emissions from the trap grease-to-biodiesel manufacturing process, Tu and McDonnell (2016) examined the implications of employing a Monte Carlo simulation. Their research emphasized the critical role of incorporating solids in trap grease for anaerobic digestion to achieve significant reductions in both energy consumption and greenhouse gas emissions. The Monte Carlo simulation revealed substantial variations in both life cycle energy consumption and greenhouse gas emissions, primarily due to uncertainties associated with key variables. In comparison to currently popular feedstocks like soybean and algae, trap grease has the potential to be a more energy-efficient and low greenhouse gas emission feedstock under specific circumstances, according to the sensitivity analysis. In restaurants and food processing plants, trap grease builds up in the grease traps as a mixture of water, solids, fats, oils, and greases. Mendecka et al. (2020) considered the energy, economic, environmental, and social effects of the biodiesel production process from used cooking oil using a probabilistic multi-criteria approach that combines Monte Carlo simulation and data reconciliation techniques. The stochastic formulation offers a potent tool to boost the plant's resistance to changes in feed quality. Monte Carlo simulation is used to demonstrate the effect of stochastic optimization in the distribution function of the constraints (Janbarari and Ahmadian Behrooz 2020).

Table 1 presents an insightful comparison of computational techniques extensively used in biodiesel production, outlining their distinctive advantages and limitations. In addition, computational chemistry techniques contribute to the understanding, optimization, and sustainability of biodiesel production processes, facilitating the development of efficient and environmentally friendly methods for renewable fuel production.

Applications of computational chemistry

Catalyst design

Catalyst design may be defined as the systematic application of the knowledge currently available for selecting a catalyst in a specific reaction. It is a difficult undertaking since there aren't many precise and specific techniques for developing and designing catalysts for certain reaction systems; instead, trial and error are used most of the time. A range of catalysts can often be expected to work well for a certain process and can only be verified by tests. By correctly implementing the catalyst design technique, the number of catalysts that must be tested can be decreased. It is frequently advised in catalyst design to modify the currently available catalyst for a specific process based on the user's demands rather than creating a new catalyst material. Designing a completely new catalyst and modifying an existing catalyst for a particular purpose involves significantly different techniques. Technical, economic, and environmental assessments are required before constructing a wholly unique catalyst. The designed catalysts should be economically viable, environmentally safe, and technically possible. But if a catalyst must be created for an already-existing mechanism, the creation might be based on some chemical principles (Arun et al. 2015).

Computational design of catalysts necessitates mechanistic insights into reaction chemistry, catalyst structure and evolution under reaction conditions, and methods for quick screening of prospective catalysts (Varghese 2019). Designing and improving catalysts for the transesterification reaction required to produce biodiesel from waste can be done using computational chemistry. Researchers can find extremely effective catalysts that speed up the reaction and increase biodiesel yield by modeling and simulating the interactions between catalysts and reactants at the molecular level. Computational chemistry allows researchers to study and analyze the interactions between catalysts and reactants at the molecular level. This enables the identification and designing of highly effective catalysts that can accelerate the reaction rate and improve the overall yield of biodiesel.

An effective approach for forecasting and creating catalysts, understanding their roles, and anticipating the outcomes of the chemical reactions they facilitate, including activity, selectivity, and potential applications, involves combining computational chemistry and catalysis. Transition metal, organo-, photo redox, and surface catalysis have all been used to explain the activity and selectivity of the catalyst function as well as the related reaction mechanisms in recent decades. This has been made possible by advancements made in the applied theoretical framework involving density functional theory and solvation models (Stiriba 2023). Today, computational chemistry is frequently used to support the interpretation of spectroscopic catalytic characterization, the prediction of the relative stability of various adsorbed species on catalytic surfaces, and the simulation of reaction pathways, useful for cross-validating proposed catalytic mechanisms based on kinetic and spectroscopic measurements. It is expected that computational approaches and theory will continue to make it easier to comprehend the links between catalyst composition, reactivity, and structure, which is essential for directing the design of engineered catalytic materials.

The design of catalytic processes affects the content and characteristics of biofuels, and engine operating conditions affect fuel needs. An inefficient design cycle of catalyst design, manufacture of biofuel candidates, fuel property testing, potentially low fuel quality, restart, and repeat is involved in developing approved "drop-in" biofuels (Kim et al. 2020). This study applied a fuel-property-first paradigm, which uses computational screening techniques to link desired fuel attributes to chemical structures. By linking fuel qualities to catalyst design and process development at the beginning of the design cycle, this strategy intends to reduce failures in creating biofuels with desirable attributes.

Overall, computational chemistry offers a powerful toolset for understanding and optimizing biodiesel production from waste. It enables the design of efficient catalysts, optimization of reaction conditions, characterization of biodiesel properties, and investigation of degradation mechanisms. By leveraging computational methods, researchers can accelerate the development and commercialization of sustainable biodiesel production processes, contributing to the advancement of renewable energy and waste.

The following areas have been chosen for future development in computational catalysis to accomplish this goal (Bravo-Suárez et al. 2013):

Better and more accurate techniques for cluster analysis at length and time scales play a crucial role in catalysis. For example, current density functional theory exhibits energetic associated errors in the range of 10 kJ/mol, highlighting the need for improvement. Enhancing these techniques is essential to enhance the prediction powers of computational methods, specifically in the context of catalyst selectivity. Another important aspect is incorporating solvent effects into simulations, enabling the modeling of spectra and the forecast of the stability of surface/cluster complexes. Computational detection of non-equilibrium structures poses a challenge, while surface phase composition can undergo changes during reactions under various gas and/or liquid phase compositions. Additionally, the impact of solvents on reactivity cannot be disregarded.

In the case of complicated systems with extended surfaces like transition metal oxides, carbides, nitrides, and sulfides, the existing methods or correlations between reactivity and kinetic characteristics, such as theoretical reactivity descriptors, are currently absent. This knowledge gap hampers the understanding of these systems and impedes the optimization of catalysts based on such materials. However, advancements have been made in developing more effective techniques and related computer programs for researching complicated industrial multicomponent catalysts. These catalysts encompass various components, including flaws, promoters, and two- or three-phase systems. The development of these techniques and software tools has facilitated deeper insights into the behavior and performance of such catalysts, ultimately aiding in their design and optimization for industrial applications. Strategies for predicting the synthesis of catalysts include incorporating weak forces like van der Waals interactions and examining the changes in catalyst precursors and reaction intermediates. These strategies allow researchers to consider subtle intermolecular interactions and provide a comprehensive understanding of catalyst synthesis. By accounting for these factors, researchers can improve their ability to predict and optimize the synthesis of catalysts.

Catalyst deactivation analysis

Understanding catalyst deactivation mechanisms and devising ways to build stable catalysts are just as essential as catalytic selectivity and activity studies, yet deactivation processes are frequently disregarded in academic studies. Poisoning, fouling, sintering, crushing, catalyst surfaces interacting with a gas to generate volatile chemical, and inactive phase development on catalyst surfaces following interaction with vapor, support, or promoter are the six types of deactivation mechanisms identified by Bartholomew (2001). Modeling is important in understanding catalyst deactivation processes, aiding process improvement, and thereby improving biofuel commercialization (Adkins et al. 2021; Chen et al. 2021b; Lattanzi et al. 2020; Pecha et al. 2021). Computational chemistry can assist in the analysis of catalyst deactivation mechanisms during biodiesel production. By studying the interactions between catalysts and contaminants present in waste feedstocks, researchers can identify factors contributing to catalyst deactivation and develop strategies to mitigate or prevent it, thereby extending catalyst lifespan and improving process economics.

Reaction optimization

Computational chemistry makes the optimization of reaction conditions, including temperature, pressure, and solvent composition, possible (Basdogan et al. 2020; Mendis et al. 2022). Researchers may examine the influence of various factors on the reaction kinetics and find the ideal conditions that optimize waste conversion into biodiesel using molecular simulations. Gong et al. (2020) focused on the optimization of the static mixer structure for enzymatic synthesis of biodiesel from waste cooking oil using computational fluid dynamics modeling. The optimal static mixer consists of six mixer units with a length-diameter ratio of 1.5. The enzymatic synthesis of biodiesel was conducted between waste cooking oil and methanol by transesterification and esterification. The reaction conditions were also optimized in this designed static-mixed reactor. Under optimal conditions, the reaction time can save half-time when compared with the traditional stirred reactor, indicating that the static mixer has higher production efficiency.

Reactor design and optimization

Computational chemistry can assist in the design and optimization of biodiesel production reactors. Through computational fluid dynamics simulations, researchers can model the fluid flow, heat transfer, and mass transfer within the reactor. This information helps optimize reactor geometry, configuration, and operating conditions to achieve efficient mixing, heat distribution, and mass transfer, resulting in improved biodiesel production. In addition, computational chemistry can provide insights into reactor scale-up for biodiesel production. By simulating reactions at different scales, researchers can evaluate the impact of reactor size on reaction kinetics, heat transfer, and mass transfer. This knowledge guides the scaling-up process and helps design larger-scale reactors that maintain optimal performance and productivity.

In recent years, the development of microreactors as a type of reactor used to synthesize biodiesel has attracted attention (Tiwari et al. 2018). Researchers and industry experts use modeling and simulation to optimize machinery and procedures in traditional-size operations. In contrast to typical scale processes, modeling and simulation in microfluidics are still relatively new, making the literature on biodiesel production even rarer. From the perspective of modeling and microreactor simulations, the study by Santana et al. (2019) explores biodiesel synthesis in microreactors.

Stability assessment

Biodiesel offers advantages but faces storage stability issues, poor oxidation stability, and limited energy availability, affecting its widespread commercialization in various countries (Moreira et al. 2022). Several factors can influence the stability of biodiesel, including auto-oxidation, thermal decomposition or thermal fluctuations, water absorption, biodegradation with microbial growth, storage conditions, metal contamination, and the presence and absence of additives (Jakeria et al. 2014). Computational chemistry plays a role in understanding biodiesel's stability and degradation mechanisms. By studying molecular structures and analyzing reaction pathways, researchers can identify potential degradation pathways and develop strategies to enhance biodiesel products' stability and shelf life.

Waste feedstock analysis

Computational chemistry can aid in the analysis and characterization of waste feedstocks for biodiesel production. By studying the chemical composition and properties of different waste oils and fats, researchers can determine their suitability for biodiesel production and optimize the selection of feedstock sources. Computational chemistry can play a crucial role in optimizing the selection of waste feedstock sources for biodiesel production by providing insights into their chemical composition and properties. Here's how computational chemistry can assist in this process:

Chemical analysis: Computational chemistry can be employed to analyze the chemical composition of different waste feedstocks. By simulating the molecular structures and properties of the components present in the feedstocks, researchers can identify the types and quantities of fatty acids, triglycerides, and other relevant compounds. This analysis helps in assessing the potential of a particular waste feedstock for biodiesel production (Achinas and Euverink 2016; Li et al. 2021; Long et al. 2022).

Property prediction: Computational chemistry enables the prediction of important properties of waste feedstocks. Researchers can use computational methods to estimate viscosity, density, molecular weight, and oxidative stability properties. These predictions aid in evaluating the suitability of a waste feedstock for biodiesel production and comparing it with other potential sources (Ahmad et al. 2023b; Canakci et al. 2009; García et al. 2010).

Reaction modeling: Computational chemistry can simulate and model the transesterification reaction of different waste feedstocks with alcohol to produce biodiesel. Researchers can assess the feasibility and efficiency of using specific feedstocks by studying the reaction kinetics, conversion rates, and yield predictions. This information helps identify the most promising waste feedstock sources for biodiesel production (Anitescu and Bruno 2012; Baioni e Silva et al. 2023; Silitonga et al. 2020).

Contaminant analysis: Waste feedstocks for biodiesel production often contain contaminants, such as water, free fatty acids, and impurities. Computational chemistry can assist in analyzing the impact of these contaminants on the reaction kinetics and efficiency. By modeling the interactions between contaminants and catalysts or reactants, researchers can determine the potential challenges and develop strategies to mitigate their negative effects (Yadav et al. 2021).

Environmental impact assessment: Computational chemistry can also be used to assess the environmental impact of different waste feedstock sources. Researchers can estimate factors such as energy consumption, greenhouse gas emissions, and waste generation by modeling and simulating the production processes associated with each feedstock. This information aids in selecting feedstock sources that have lower environmental footprints and align with sustainability goals (Azadi et al. 2014; Caldeira et al. 2019; Pasha et al. 2021a).

Process scale-up

On a laboratory scale, biodiesel has been produced via acid transesterification, alkali transesterification, acid–alkali transesterification, enzymatic transesterification, and supercritical alcohol transesterification (Tabernero et al. 2012). Zhang et al. (2003) demonstrated a large-scale simulation of several of the previously described acquiring processes. The number of industrial bioprocesses is continuously increasing because of increased market demand for bulk production of chemicals, biofuels, materials, nutrition components, and healthcare goods. This need is accompanied by the pressing need to shift from a fossil-based to a bio-based economy. Scaling up from laboratory to large-scale requires verification of process and product quality comparability, which generally follows a time-consuming, lab-intensive, sequential scale-up strategy. This is based on expert empiricism and does not account for possible strain changes (Wang et al. 2020a).

Olkiewicz et al. (2016) evaluated the economic feasibility of biodiesel production from municipal primary sewage sludge, a promising lipid feedstock for biodiesel production. The study focuses on eliminating high water content before lipid extraction, which is the main limitation of scaling up. The study uses computational tools to model the process scale-up and different configurations of lipid extraction to optimize this step, which is the most expensive. The operational variables with a major influence on the cost were extraction time and the amount of solvent. The optimized extraction process had a break-even price of biodiesel of 1232 USD per ton, being economically competitive with the current cost of fossil diesel. Understanding how to scale up biodiesel manufacturing systems may be gained through computational chemistry. The behavior of reaction systems at greater sizes may be simulated and modeled, which allows researchers to foresee problems and improve process parameters for efficient and economical production.

Reaction mechanism elucidation and molecular dynamics simulations:

Computational chemistry can be used to better understand the complex chemical pathways involved in producing biodiesel from waste materials. Researchers can better understand the underlying chemistry and suggest methods for increasing reaction efficiency by looking at the step-by-step routes and identifying the rate-determining phases. In this context, the computational chemistry study showed that the interaction mechanism between the optimized catalyst and stearic acid was preferable between tin(IV) oxide (SnO2) active sites and the carbonic group of stearic acid (Ibrahim 2021). In addition, computational chemistry techniques, such as molecular dynamics simulations, can provide insights into the behavior and interactions of biodiesel molecules with other components, such as enzymes or additives. This understanding can aid in developing more efficient and selective processes for biodiesel production (Hwang et al. 2014).

In conclusion, the use of computational chemistry is crucial in the progress of biodiesel production from waste, as it provides valuable tools for catalyst development, reaction improvement, and process enhancement. It allows for a detailed understanding at the molecular level, aiding in the selection and design of effective catalysts and optimized reaction conditions. Computational simulations are useful in exploring complex reaction mechanisms, contributing to a better understanding of the intricate pathways involved in biodiesel synthesis. Furthermore, these techniques support reactor design, analysis of waste feedstocks, and the scaling up of processes, which are essential for the successful application of laboratory findings in large-scale industrial settings. As computational methodologies continue to advance, they offer promising opportunities for the sustainable and efficient production of biodiesel from diverse waste sources.

Machine learning and data mining

In the past 10 years, machine learning has experienced tremendous growth as a crucial data processing tool. This has substantially expanded artificial intelligence's problem-solving capabilities. Machine learning is a group of advanced data analysis techniques that find patterns between characteristics in a data set and make predictions when faced with new inputs. These techniques are founded on the concepts of probability and, statistics, and mathematics (Wang et al. 2022b). Data mining is a discipline closely related to machine learning and knowledge areas such as statistics. The development of data mining as an autonomous discipline has been allowed by the increase in size and structuring of the data to which these techniques are applied (Taranto-Vera et al. 2021).

Machine learning surpasses conventional mathematical and statistical models in the manufacturing sector in effectiveness. This is due to the limitations of traditional models in comprehending intricate relationships between data characteristics and predicting feature values for new samples. Consequently, the manufacturing industry has increasingly embraced machine learning techniques that are widely utilized in various scientific domains. Leveraging intelligent data analysis is of great value as it allows companies to gain fresh insights and attain a crucial competitive edge. Thus, the application of machine learning and data mining methods in manufacturing has become well-established (Dogan and Birant 2021).

The main machine-learning approaches may be broken down into two basic categories: supervised learning and unsupervised learning (Taranto-Vera et al. 2021). Although clustering problems are more frequent in unsupervised learning, classification problems are a common problem in supervised learning. While k-means is the most used clustering technique, classification algorithms like artificial neural networks (ANNs), support vector machines (SVMs), and decision trees are also extensively utilized (Ahmadinia et al. 2013; Dogan and Birant 2021; Parvin et al. 2015). Artificial intelligence and machine learning have recently been used to successfully implement statistical modeling in various applications. To optimize the production of biodiesel, these models have shown themselves to be trustworthy and dependable. Machine learning techniques for finding useful findings from experimental outputs are the most important advancements that have impacted many scientific domains (Almohana et al. 2022; Wang et al. 2021; Xing et al. 2021a). Table 2 summarizes the advantages and disadvantages of artificial intelligence and machine learning-based models typically employed in the prediction of biodiesel process and fuel properties.

Methodology for machine learning-based biodiesel production prediction from waste

The methodology for machine learning-based biodiesel production prediction from waste encompasses several key steps, which can be summarized as follows:

Dataset collection: Compile a complete dataset of waste feedstocks, biodiesel production parameters, and associated biodiesel attributes. Include a variety of waste sources and a wide range of operational circumstances (Cheng et al. 2016; Gupta et al. 2021).

Data preprocessing: Clean the dataset by removing any missing or erroneous values and perform necessary transformations or normalization to ensure consistency and quality (Ahmad et al. 2023b).

Feature selection: Determine the key characteristics or factors that substantially influence waste-to-biodiesel production. To choose the most informative characteristics, statistical analysis, domain expertise, or feature ranking algorithms may be used (Ahmad et al. 2023a; Balabin and Smirnov 2011).

Model selection: Choose appropriate machine learning algorithms for biodiesel production prediction from waste. Consider regression models, such as linear regression, support vector regression, or decision tree regression, as well as more advanced techniques like random forests, gradient boosting, or neural networks (Bobadilla et al. 2018).

Model training: Split the dataset into training and validation sets. Train the selected machine learning models using the training data, adjusting hyperparameters and optimizing model performance through techniques like cross-validation and grid search (Fangfang et al. 2021; Sharon et al. 2012).

Model evaluation: Assess the performance of the trained models using appropriate evaluation metrics, such as mean squared error (MSE), root mean squared error (RMSE), or coefficient of determination (R-squared). Compare the performance of different models to select the most accurate and reliable one (Fangfang et al. 2021; Freitas et al. 2011; Kumar et al. 2023b).

Model optimization: Improve the prediction performance of the chosen model by modifying hyperparameters or using techniques such as regularization. Consider ensemble learning or model stacking to integrate many models and improve overall accuracy (Almohana et al. 2022; Bobadilla et al. 2018).

Predictive modeling: Use the learned machine learning model to forecast biodiesel production from waste for unseen data points. Apply the algorithm to new waste feedstocks to determine their potential for biodiesel generation (Chuck et al. 2009; Freitas et al. 2011; Oke et al. 2021a).

Model deployment: Integrate the trained model into a user-friendly software or web application that allows users to input waste feedstock characteristics and obtain predictions of biodiesel production. Ensure the application is scalable and can handle large volumes of data (Sharma et al. 2023; Tozzi and Jo 2017).

Continuous improvement: Regularly update the model with new data and retrain it to capture evolving trends and improve prediction accuracy. Monitor the model's performance and gather user feedback to identify areas for further refinement or enhancement (Bachinger et al. 2021).

Ethical considerations: Consider the ethical implications of using machine learning for biodiesel production from waste. Ensure data privacy and security, address potential biases in the data or models, and adhere to relevant regulatory and ethical guidelines in the development and deployment of the system (Hagendorff and Meding 2023; Samuel et al. 2020).

Machine learning techniques can be employed to analyze large datasets generated from experimental or computational studies. Machine learning algorithms can identify patterns, correlations, and trends in the data, aiding in process optimization, catalyst design, and property prediction, as illustrated in Fig. 3. Data mining techniques can also assist in extracting useful information from existing databases and literature. Machine learning and data mining techniques can play a crucial role in the production of biodiesel from waste materials by optimizing processes, improving feedstock selection, enhancing quality control, and supporting sustainability efforts (Aghbashlo et al. 2021; Sharma et al. 2023). Table 3 illustrates the different artificial intelligence-based models used for the production of biodiesel from different waste feedstock.

Machine learning methods and their application in biodiesel production. The figure offers an extensive portrayal of machine learning's vital involvement in various crucial aspects of biodiesel production. Across feedstock characterization and selection, machine learning demonstrates proficiency in identifying and assessing the most suitable feedstock for biodiesel production. In process optimization and reaction kinetics modeling, this technology showcases its capability to enhance production efficiency and accurately predict reaction rates. Moreover, the figure delineates quality prediction, catalyst selection, and sustainability assessment, emphasizing the pivotal role of machine learning in ensuring top-notch product quality, efficient catalyst selection, and evaluating environmental impact. Additionally, it addresses predictive maintenance, highlighting how machine learning facilitates proactive equipment upkeep and process scale-up and optimization, elucidating its contribution to refining and scaling production processes for maximum efficiency

Applications of machine learning and data mining

Here are some specific applications of machine learning and data mining in biodiesel production from waste:

Feedstock characterization and selection: Machine learning algorithms can analyze large volumes of data on waste feedstocks, including their composition, properties, and availability. By training models on this data, machine learning can identify the most suitable feedstocks for biodiesel production based on their lipid content, moisture levels, impurities, and other factors. This helps optimize feedstock selection and ensures efficient resource utilization. Making mathematical correlations between feedstock composition and quality parameters with reasonable accuracy could have several benefits on scientific plans. It could help estimate the ability of a feedstock to produce a good quality of biodiesel before undergoing time and money-consuming characterization. It could also help determine appropriate treatment strategies for feedstock to improve biodiesel properties (Mairizal et al. 2020). In the case of feedstock characterization, Multiple non-linear regression and artificial neural networks were used by Tchameni et al. (2019) to forecast the rheological characteristics of used vegetable oil for the generation of biodiesel.

Process optimization and reaction kinetics modeling: Machine learning algorithms can be applied to optimize process parameters such as temperature, pressure, catalyst concentration, and reaction time. Machine learning models can identify optimal operating conditions that maximize yield and minimize energy consumption by analyzing historical process data and biodiesel yield. In addition, machine learning techniques can be employed to model the kinetics of the biodiesel production process. Machine learning models can predict reaction rates and conversion levels by analyzing reaction time, temperature, and other variables, aiding in process optimization and control. In order to enhance the production of biodiesel from a feedstock, several machine-learning regression models were developed (Abdelbasset et al. 2022). Several operational factors, including reaction time, reaction temperature, the molar ratio of oil to alcohol, catalyst yield percentage, and others, may strongly impact the transesterification process's ability to produce biodiesel. Numerous tests must be conducted to optimize the numerous transesterification reaction variables, as well as the use of an appropriate statistical technique that can forecast the influence of every factor on the reaction and its interactions. For the optimization of the process variables to achieve the desired output with fewer tests, the response surface methodology technique has been widely employed. The number of tests is carried out using a variety of experimental designs, including the Taguchi experimental design, factorial design, central composite design, and box-banging design (Gupta et al. 2021). Waste cooking oil was considered the reaction's feedstock, and a heterogenous catalyst was considered. The model considered four distinct input variables: reaction temperature, time, catalyst loading, and methanol to oil molar ratio, with the predicted output being the production yield (%). The maximum production yield was sought by determining the input parameters' ideal values.

Almohana et al. (2022) used three ensemble models: Huber regression, decision trees, and gaussian process regression to optimize biodiesel production using cooking oil as a feedstock. Batch reaction experiments with four input parameters, reaction temperature, reaction duration, catalyst loading, and methanol to oil ratio, were used in the optimization process. These models, which have been used in various applications, have shown encouraging results in estimating the output of biodiesel production. Sultana et al. (2020) focused on applying data mining techniques to optimize the synthesis of non-edible papaya seed waste oil for biodiesel production. Thus, several soft computing or data mining techniques, including support vector regression, artificial neural network, and response surface methodology, may be utilized for predicting oil yields from used papaya seeds after solvent extraction. According to the results, the support vector regression model outperformed the artificial neural network and response surface methodology models in terms of several performance-measuring factors when it came to estimating oil yields. Oil yields increase as extraction time increases but decrease as particle size increases. A support vector regression and crow search algorithm-based interface were implemented to discover the global optimum set. Moradi et al. (2013) investigated the best conditions for producing biodiesel from soybean oil, as well as the use of artificial neural networks to predict the yield of the biodiesel. The methanol-to-oil molar ratio, the amount of catalyst, and the reaction temperature were the variables that were examined. It was determined that a 9:1 methanol-to-oil molar ratio, a catalyst quantity of 1 wt.%, and a reaction temperature of 60 °C were the best conditions. It took one hour to produce 93.2% of the biodiesel production under these conditions.

Quality prediction: Machine learning models can be used to predict the quality attributes of biodiesel produced from different waste feedstocks. These models can estimate parameters such as cetane number, viscosity, density, and oxidation stability, enabling producers to ensure compliance with biodiesel standards and regulations. The most popular machine learning technique for predicting quality is an artificial neural network developed by a regression model, which uses input variables such as reaction temperature, reaction time, calcination temperature, pressure, and flow rate and output variables such as fatty acid methyl ester content, viscosity, composition, quantity, cetane number, and density (Xing et al. 2021a). As a function of iodine value and molecular weight, Ramírez-Verduzco et al. (2012) developed a correlation to predict cetane number, viscosity, density, and higher heating value. With the independent variables of iodine value and carbon chain length, Pinzi et al. (2011) provided a mathematical model for low calorific value, kinematic viscosity, flash point, cetane number, and cold filter plugging point. The viscosity, flash point, density, higher heating value, and oxidative stability of biodiesel made from sunflower oil, peanut oil, hydrogenated coconut oil, hydrogenated copra oil, beef tallow, rapeseed oil, and walnut oil were predicted by Mairizal et al. (2020) using multiple linear regressions. The findings suggested that using polyunsaturated/monounsaturated fatty acids balance (PU/MU) as an independent parameter might improve prediction accuracy.

Catalyst selection: Machine learning algorithms can be utilized to identify the most effective catalysts for biodiesel production from specific waste feedstocks. Machine learning models can recommend the best catalysts to achieve high conversion efficiency by analyzing catalyst properties, reaction conditions, and biodiesel yield data. Sukpancharoen et al. (2023) used machine learning techniques to forecast the amount of biodiesel that would be produced from transesterification processes that used three distinct types of catalysts: homogeneous, heterogeneous, and enzyme. The most accurate prediction methods were extreme gradient boosting algorithms, with a coefficient of determination accuracy of over 0.98. The findings showed that, for homogeneous, heterogeneous, and enzyme catalysts, respectively, linoleic acid, behenic acid, and reaction time were the most significant parameters impacting biodiesel yield predictions.

Sustainability assessment: Machine learning techniques can be used to evaluate the environmental impact and sustainability of biodiesel production from waste. Machine learning models can analyze energy consumption, greenhouse gas emissions, and resource utilization data to identify improvement areas and guide sustainable decision-making. In this context, Fangfang et al. (2021) emphasize the potential of waste cooking oil as a valuable feedstock for biodiesel production, highlighting its environmental benefits, economic feasibility, and contribution to waste management using machine learning. The use of artificial neural network modeling provides a reliable tool for simulating and predicting biodiesel production and engine characteristics. The results showed that biodiesel production with 1% catalyst concentration, a 9:1 methanol to waste cooking oil molar ratio, 60 min reaction time, and 500 rpm mixing intensity resulted in reduced waste generation and positive environmental impacts. The artificial neural network model accurately predicted biodiesel yield and engine performance, with overall regression coefficients of 0.98 and 0.99, respectively. This research provides valuable insights into the sustainable production of biodiesel from waste cooking oil, emphasizing the use of artificial neural network modeling for prediction purposes.

Predictive maintenance: Machine learning algorithms can be applied to monitor equipment health and predict maintenance needs in biodiesel production plants. Machine learning models can anticipate equipment failures, optimize maintenance schedules, and reduce downtime by analyzing sensor data and historical maintenance records. Kanawaday and Sane (2017) emphasized the significance of machine learning in the industrial internet of things (IIoT), particularly in quality management, quality control, cost-effective maintenance, and enhancing productivity to predict possible failures and quality defects in order to improve the overall manufacturing process. The paper also discusses the data collection process from the slitting machine, including the machine details and the system setup using a programmable logic controller (PLC), supervisory control and data acquisition (SCADA), industrial personal computer (IPC), and cloud platforms. In addition, the research concludes that internet of things-based machine learning, coupled with predictive maintenance techniques, can effectively address productivity and maintenance cost limitations. It emphasizes the significance of supervised models for extracting insights from data and using prognostics and forecasting to ensure efficient production processes and minimize maintenance costs and product quality degradation. The paper contributes to the literature on predictive maintenance using internet of things sensor data in industrial settings. The findings highlight the potential of machine learning techniques, specifically auto-regressive integrated moving averages (ARIMA), in improving the overall manufacturing process by predicting failures and enhancing productivity. The research mentioned above discusses the advancement from predictive maintenance to intelligent maintenance using artificial intelligence and the industrial internet of things.

Zheng et al. (2020) evaluated the state of predictive maintenance approaches and proposed an innovative framework called intelligent maintenance. The study reviews the evolution of reliability modeling technology and introduces key framework components, including machine learning algorithms, real-time data collection through wireless smart sensors, big data technologies, and mobile device applications. The paper highlights the importance of addressing challenges such as implementing artificial intelligence and machine learning algorithms for manufacturing time series data, collecting data from remote sources, processing and storing high-frequency data, keeping models up to date, and enabling fast decision-making in the field. The authors also propose a novel probabilistic deep learning reliability modeling approach and demonstrate its application using the turbofan engine degradation dataset. The evolution of reliability technologies is outlined, and the potential of artificial intelligence and the industrial Internet of Things (IoT) for enhancing maintenance practices across different industries is highlighted.

Process scale-up and optimization: Utilize machine learning models to predict the performance of biodiesel production processes at different scales. By extrapolating data from lab-scale experiments and pilot plants, these models can provide insights into process scalability and guide decision-making for large-scale production. Ajala et al. (2023) discussed the development of artificial intelligence techno-economic models for predicting the overall cost–benefit value of large-scale biodiesel production from palm kernel oil. The study aims to provide fundamental investment decisions for potential investors. The article emphasizes the economic viability of large-scale biodiesel production from palm kernel oil and highlights investors' challenges in making informed decisions. By utilizing artificial intelligence models, the study provides a means to predict the cost–benefit value and assists in optimizing the scale-up process for biodiesel production. In the context of scale-up in biodiesel production, this research demonstrates the effectiveness of artificial intelligence techniques in predicting techno-economic parameters. It emphasizes the significance of considering input parameters, particularly catalyst calcination temperature, in the scale-up process. The findings of this study can be valuable for researchers and investors seeking to optimize large-scale biodiesel production and make informed investment decisions.

Challenges

Machine learning and artificial intelligence-based models used for biodiesel predictions from waste face several challenges that need to be addressed:

Ensuring data quality and availability: Obtaining high-quality and comprehensive datasets for training machine learning models can be difficult. The data may contain missing values, outliers, or inaccuracies, which must be addressed through data preprocessing techniques. Additionally, collecting diverse waste sources and covering a wide range of operating conditions may necessitate extensive data collection efforts (Ascher et al. 2022; Mowbray et al. 2021; Wang et al. 2022b).

Handling feature selection and dimensionality: Identifying the most relevant features or variables that influence biodiesel production from waste can be intricate. Waste feedstocks and production parameters may possess numerous dimensions, resulting in high-dimensional feature spaces. It is crucial to select an optimal set of features that significantly contribute to prediction accuracy while reducing dimensionality to enhance model performance (Abdulwahab et al. 2022; Balabin and Smirnov 2011; Cai et al. 2018; Rong et al. 2019).

Dealing with model complexity and interpretability: Advanced machine learning and artificial intelligence techniques like neural networks and ensemble models can offer high prediction accuracy but often lack interpretability (Wang et al. 2022b). Understanding the underlying mechanisms and decision-making processes of complex models can be challenging, especially in the context of biodiesel production from waste. In certain cases, interpretable models may be preferred, emphasizing transparency and explainability (Ascher et al. 2022; Lim et al. 2023; Yang et al. 2023b).

Ensuring generalization and transferability: One of the main challenges for generative models is ensuring the transferability of computationally predicted lead candidates to synthesis and experiment (Hase et al. 2020; Osman et al. 2023b). Thus, it is vital to ensure that machine learning models can generalize well to unseen data and be transferable to different waste feedstocks and operating conditions. Models trained on specific datasets or waste sources may not perform effectively when applied to new, unseen data. Therefore, developing robust models capable of handling variations in waste composition and operating parameters is necessary for practical applications.

Conducting model validation and evaluation: Assessing the performance of machine learning models for biodiesel production prediction requires appropriate validation and evaluation techniques (Mondal et al. 2023). Selecting suitable evaluation metrics and establishing robust validation procedures are essential for reliable and accurate performance assessment. Additionally, model evaluation should account for prediction uncertainties and quantify confidence in the results.

Ensuring scalability and computational efficiency: Implementing machine learning and artificial intelligence models that can handle large volumes of data and provide real-time predictions is crucial for their practical deployment in biodiesel production processes. Ensuring the scalability and computational efficiency of the models is vital to enable efficient prediction and decision-making in real-world scenarios (Cui et al. 2021b).

Addressing ethical considerations: Machine learning and artificial intelligence-based models used in biodiesel production prediction from waste must address ethical considerations (Ahmad et al. 2021; Okolie et al. 2022). This includes addressing privacy concerns related to data collection, storage, and usage. Biases in the data or models need to be identified and mitigated to ensure fair and unbiased predictions. Compliance with regulatory guidelines and ethical standards should be maintained throughout the development and deployment of machine learning-based systems.