Abstract

Ultrasonic thermoforming of micro structures is similar as usual thermoforming, but the heat required for softening of the polymer is at least partly generated by ultrasonic vibrations. Cycle times as short as a few seconds are achieved by ultrasonic thermoforming and not much more than a commercially available ultrasonic welding machine is required for the process. This paper describes the process window of this fabrication process for polypropylene foils, 200 µm in thickness, as a function of preheating of the tool. Best results have been obtained at room temperature. Since the process is a function of temperature, it is concluded that production should be performed with a tool preheated to 45 °C to avoid an influence by a changing room temperature. The overall size of the samples is limited by the size of the available sonotrodes. The experiments described in this paper were performed on an area of 2 × 2 cm2, but larger sonotrodes with an area of, e.g., 8 × 12 cm2 could also be employed. The size of the process window is a function of both the properties of the polymer and the inclination angle of the side walls of the structures on the tools.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Thermoforming is a process well known and applied in industry for the forming of thermoplastic polymer layers, approximately thinner than 2 mm (Illig 2008; Throne and Beine 1999). Typically, this process is employed to fabricate the packaging of sweets or tablets. A foil or thin plate from a thermoplastic polymer is softened by heating and pressed by a hot gas onto the surface of a mold. Then the polymer is cooled down and solidifies again in the shape of the mold surface.

Since 1999 several working groups have been showing to which extend thermoforming can also be applied for generating micro structures on polymer layers (Dreuth and Heiden 1999; Truckenmüller et al. 2002, 2008, 2011; Gieselbrecht et al. 2006; Focke et al. 2009, 2010; Schmidt et al. 2011; Heilig et al. 2011; Nagarajan and Yao 2011; Jungmeier 2015). The cycle times of these processes are on the order of some minutes because the entire tool needs to be heated up to the softening temperature of the thermoplastic foil and cooled down again below that temperature. Heating up of the tool is required because the polymer flow shall not be stopped before it arrives in the micro cavities.

If micro structures shall be generated on a substrate, besides injection molding and injection compression molding, hot embossing is a process often employed. A layer of thermoplastic polymer is placed onto a so-called mold insert showing micro structures on its surface. The polymer is heated up together with the mold insert and a tool in which it is mounted and the polymer softened that way is pressed onto the mold insert adapting to the micro structures on its surface. Then, the tool is cooled down, and after it got hard again, a polymer part with the desired micro structures on its surface is demolded from the mold insert. The cycle time of hot embossing micro structures is on the order of minutes because the entire tool needs to be thermally cycled.

It has been shown that the cycle time of hot embossing micro structures from thermoplastic polymers can be shortened to some seconds if the polymer is heated by ultrasonic vibrations instead of heating up the entire tool (Sackmann et al. 2015; Lee and Park 2016; Šakalys et al. 2016; Mekaru and Yano 2016; Zhu et al. 2017; Liu et al. 2018). Obviously, the polymer is held longer at an elevated temperature even when it gets into contact to a cold tool. Nevertheless, preheating of the tool to an elevated temperature during ultrasonic hot embossing results in better mold filling and the cycle time is not prolonged significantly (Sackmann et al. 2015).

Recently, it was shown that ultrasonic thermoforming of micro structures is also possible and the cycle time is also as short as some seconds (Sackmann et al. 2015; Bae et al. 2015, 2017; Lee et al. 2017; Cui et al. 2015). To investigate the process limits, the investigation of the process window of ultrasonic thermoforming of polypropylene (PP) foils is described in this paper.

2 Fabrication process

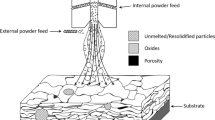

For ultrasonic thermoforming, a foil from a thermoplastic polymer is placed between an upper and a lower tool (Fig. 1a), both with micro structures on their surfaces facing the foil. The micro structures on the upper tool are mirrored to those on the lower tool.

The sonotrode of an ultrasonic welding machine is pressing the upper tool down onto the foil, and ultrasonic vibrations start when a pre-set pressing force, the so-called trigger force, is reached. The polymer foil is heated up by the friction generated by the ultrasonic vibrations and adapted to the shape of lower and upper tool (cf. Fig. 1b). The vibrations are stopped after a few seconds and the pressure is retained for some more seconds, the so-called cooling time, to allow for heat dissipation into the tools. After the polymer got cold enough and hardened again, the foil is removed from the tools in its new shape (Fig. 1c).

3 Tools

In this study, the tools were fabricated by milling into aluminum plates, 2.5 mm in thickness. One of the tools could also be made of a softer material such as silicone or even be replaced by a polymer without micro structures which cannot be welded to the foil (Sackmann et al. 2015), but for the work described in this paper, both tools had been milled into aluminum plates. The objective of this paper was to explore the process windows of ultrasonic thermoforming. Therefore, the shape of the micro structures to be thermoformed was varied on the tool. Nine prism-shaped structures were evenly placed on a square with 20 mm edge length (cf. Fig. 2).

On the lower tool, lengths and widths of the structures are 2 mm at the top and 2.2 mm at the bottom, all structures have a height of 2 mm. The edges of the prism structures S1 through S9 in Fig. 2b were rounded with varying radii from 0.15 mm to 0.95 mm with increments of 0.1 mm. The walls of the micro structures have an inclination angle of approximately 5.7° facilitating demolding the thermoformed foils from the tools. The aluminum tools used in the experiments were milled by the high precision milling machine M7 HP from Datron AG, Germany employing milling tools from hard metal, 500 µm in diameter.

The gap between the upper and lower tool is a function of the thickness d of the foil. As shown in Fig. 3, the initial length Li of the foil is stretched to the length of the side wall of the structure on the tool. As a consequence, the average thickness da of the foil after thermoforming is da = d sin(α). An inclination angle of α = 5.7° in the tool corresponds to an average wall thickness da = 10% of the initial foil thickness d. As shown in Figs. 7 and 9, the stretching of the foil can be inhomogeneous resulting in an even thinner minimum wall thickness.

4 Experiments

Ultrasonic thermoforming was performed on a commercial ultrasonic welding machine (2000IW + , Branson Ultrasonics, USA) equipped with a sonotrode, 40 and 60 mm in width and length, respectively. A heating plate equipped with an electrical heater and a sensor inside was mounted onto the anvil of the machine and its temperature was controlled by a temperature controller. The ultrasonic welding machine with heating plate, the lower tool and a roll of polymer foil are shown in Fig. 4.

The lower tool was clamped onto the heater with the upper tool positioned on its top. This way, lower and upper tool were well aligned to each other. Then, glue was applied onto the upper tool’s surface facing the sonotrode and the sonotrode was slowly moved down and pressed onto the upper tool. Thus, the upper tool was glued well aligned onto the sonotrode.

A foil from polypropylene (PP), 200 μm in thickness, was placed on the lower tool (Fig. 1a) and the experiments were started. Trigger force and peak-to-peak amplitude of the ultrasonic vibrations were kept constant for all experiments at 324 N and 16 µm, respectively. The cooling time was kept constant at 4 s for all experiments ensuring complete hardening of the polymer foil before demolding.

To investigate the process window, the pressing force was varied between 460 and 2760 N in increments of 230 N and the ultrasonic time between 0.1 and 6.0 s in increments of 0.1 s. Besides this, the process windows were determined at the following lower tool temperatures: 25, 35, 45, 55 and 65 °C. After every thermoforming, the temperature measured inside the tool was raised by about 10 °C because the ultrasonic vibrations had generated friction heat. The next part of the foil was placed onto the lower tool and the following experiment was not started before the tool was cooling down to the desired temperature again. As a consequence, the polymer foil was also heated up to the tool temperature before the experiment started.

The thermoformed structures were considered good when all nine structures were not broken and no opaque or colored areas appeared (Fig. 5a), incomplete when the total height of at least one of the structures was less than 2 mm (Fig. 5b), damaged when a decomposition of the polymer was recognized somewhere by opaque parts (Fig. 5c), and broken when one or more holes or cracks were observed on the structures (Fig. 5d).

The structure heights of tools and samples were measured with the optical microscope Eclipse LV 100 from Nikon, Japan. The surface of the upper part of the structures was focused first and the vertical position of the microscope stage was measured. Then, the lower surface of the sample was focused and the difference in the vertical position of the stage was noted as the height of the micro structure. The position of the focus can be determined with an accuracy of approximately 4 µm.

A photo of a micro structure fabricated by simply pressing the foil between the tools without ultrasound and at room temperature with 1380 N for 2 s is shown in Fig. 6. Although the foil was completely stretched between the tools, the micro structures were formed incompletely because of the viscoelastic properties of PP.

A cross-section of the thermoformed foil was observed by placing the edge of the foil over the center of the structures on the lower tool before the process. This way, after the process, the thickness of the generated structure was observed with the confocal digital microscope VHX-500FE-M-E from Keyence, Japan. An example of a micro-scope photo of two PP foils welded together during thermoforming is shown in Fig. 7.

The nine structure heights of the micro structures on the tools and on three samples were measured and are shown in Fig. 8. These samples were thermoformed with a pressing force of 1380 N and an ultrasonic time of 1.7 s. The average height of the nine structures on lower tool, upper tool, internal and external side of the samples are 2002 μm, 2020 μm, 1942 μm and 1945 μm, respectively. The differences between the heights of the nine structures on the tools are merely several micrometers and some ten micrometers on the samples. The average heights of the micro structures on the samples are approximately 96.5% of the heights on the tools indicating that there was shrinkage of a few percent.

The wall thickness of the nine structures on the samples is reducing where the tools showed a radius of curvature and got constant where the walls are not curved (cf. Fig. 7). The thicknesses were measured at these regions and they are shown in Fig. 9. These samples were thermoformed by placing their edges over the center of the structures on the lower tool and thermoformed with a pressing force of 1380 N and an ultrasonic time of 1.7 s. Both sides of each structure were measured from five different samples. The overall average thickness of all measured structures is 16.5 μm, which is close to the aforementioned theoretical calculation (20 µm). The average wall thickness of the nine structures and its standard deviation increase with the radii of curvature in the range of 0.15–0.55 mm. All larger radii of curvature correspond to wall thicknesses of approximately 15 µm.

The pressing force and duration of ultrasonic vibrations were varied to find out the limits between incomplete, good, damaged and broken thermoforming at different tool temperatures as shown in Fig. 10. The signs marking errors in the figure mean that the ultrasonic welding machine reported an error caused by an overload of the generator.

The larger the pressing force is and the longer the duration of vibrations, the more heat energy is generated in the samples. That is why the minimum time required for a complete thermoforming is increasing when the pressing force is decreasing. It also explains why the duration of vibrations at which the sample is damaged or broken in general is longer when the pressing force is smaller.

At elevated temperatures the limit at which the foil is damaged or broken is reached at shorter times than at room temperature. This may be attributed to the fact that less heat needs to be produced by ultrasonic vibrations if the polymer is already partly heated towards its softening temperature. PP is stable up to a temperature of approximately 110 °C.

5 Conclusions

It is possible to significantly reduce the process time of thermoforming by heating the polymer foil by the vibrations generated by an ultrasonic welding machine. The accuracy with which the duration of the ultrasonic vibrations of an ultrasonic welding machine can be turned on and off is well below 10 ms. Therefore, it is not important to find parameters where the process window is very wide.

According to the experiments described here and for PP foils, 200 µm in thickness, heating the tool is not necessary. However, since thermoforming is influenced by temperature, the process may become more independent of the room temperature if the tool temperature is held at a constant temperature of, e.g., 45 °C.

To achieve a short cycle time, the pressing force can be tuned to approximately 1 kN and the duration of the vibrations to 300 ms. This way, not more than enough heat is generated and the tool is not heated up too much by the vibrations. As a consequence, the cooling time can also be reduced. A comparatively long cooling time of 4 s was chosen for the experiments to ensure complete hardening of the samples before demolding. It is expected that the cooling time can be reduced significantly for real applications. Since not much more than the polymer foil is thermally cycled, besides a shorter cycle time, also the energy required for the process is significantly reduced compared to thermoforming without ultrasound.

The radii of curvature on the micro structures were varied between 0.15 and 0.95 mm and no difference in the achievable structure height, damaging or breaking was observed. However, the thickness of the polymer foil is a function of the curvature and the inclination angle of the walls of the micro structures on the tools. The smallest possible inclination angle is a function of the properties of the polymer, and the size of the process window is a function of both the properties of the polymer and the inclination angle. Obviously, the inclination angle needs to be larger than 0°, because the polymer foil would be sheared off and punched out at this inclination angle.

The overall dimensions of the samples are limited by the size of the available sonotrodes. The experiments described in this paper were performed on an area of 2 × 2 cm2, but larger sonotrodes with an area of, e.g., 8 × 12 cm2 could also be employed.

Other thermoplastic polymers than PP will show different process windows but similar trends are expected, and therefore, this paper may help finding suitable parameters for ultrasonic thermoforming of other polymers.

References

Bae H-J, Lee H-J, Park K (2015) Ultrasonic assisted thermoforming for rapid fabrication of a microspeaker diaphragm. Microsyst Technol. https://doi.org/10.1007/s00542-015-2740-z

Bae H-J, Lee H-J, Park K (2017) Effect of vibration transmission direction in ultrasonic thermoforming on the formability of micro-corrugations. Int J Precis Eng Manuf 18:697–703. https://doi.org/10.1007/s12541-017-0083-7

Cui L, Yang Z, Yang C, Tian Y, Zhang D (2015) Fabrication of polymer optical diffusers by buffer-assisted ultrasonic embossing. In: International conferences on manipulation, manufacturing and measurement on the nanoscale (3M-NANO) 5–9 October 2015, Changchun, China

Dreuth H, Heiden C (1999) Thermoplastic structuring of thin polymer films. Sens Actuators 78:198–204. https://doi.org/10.1016/S0924-4247(99)00237-X

Focke M, Faltin B, Zengerle R, von Stetten F, Müller C (2009) Blasformen von Mikrofluidikstrukturen für Lab-on-Foil Anwendungen. In: Proc. MikroSystemTechnik Kongress, 12–14 Okt., Berlin, Paper 22, VDE Verlag GmbH, Berlin, Offenbach, ISDN: 978-3-8007-3183-1

Focke M, Kosse D, Müller C, Reinecke H, Zengerle R, von Stetten F (2010) Lab-on-a-Foil: microfluidics on thin and flexible films. Lab Chip 10:1365–1386. https://doi.org/10.1039/C001195A

Gieselbrecht S, Gietzelt T, Gottwald E, Trautmann C, Truckenmüller R, Weibezahn KF, Welle A (2006) 3D tissue culture substrates produced by microthermoforming of pre-processed polymer films. Biomed Microdevice 8:191–199. https://doi.org/10.1007/s10544-006-8174-8

Heilig M, Schneider M, Dinglreiter H, Worgull M (2011) Technology of microthermoforming of complex three-dimensional parts with multiscale features. Microsyst Technol 17:593–600. https://doi.org/10.1007/s00542-010-1203-9

Illig A (ed) (2008) Thermoformen in der Praxis. Hanser Verlag, München. ISBN 3-446-40794-4

Jungmeier A (2015) The effect of pressure and temperature on microthermoforming thermoplastic films integrated in the injection moulding process. J Polym Eng. https://doi.org/10.1515/polyeng-2015-0232

Lee H-J, Park K (2016) Variable wettability control of a polymer surface by selective ultrasonic imprinting and hydrophobic coating. Coloid Polym Sci 294:1413–1423. https://doi.org/10.1007/s00396-016-3902-y

Lee H-J, Shin D-J, Park K (2017) Ultrasonic thermoforming of a large thermoplastic polyurethane film with the aid of infrared heating. J Mech Sci Technol 31:5687–5693. https://doi.org/10.1007/s12206-017-1109-x

Liu J, Chen X, Diao S (2018) Ultrasonic vibration technology for the polymer replication of high aspect ratio micro-structured surface. Microsyst Technol 24:2253–2264. https://doi.org/10.1007/s00542-017-3632-1

Mekaru H, Yano T (2016) Comparative evaluation of detachable mold fixing methods aimed at low energy loss for ultrasonic nanoimprint lithography. Microsyst Technol. https://doi.org/10.1007/s00542-016-3028-7

Nagarajan P, Yao D (2011) Uniform shell patterning using rubber-assisted hot embossing process. I. Experimental. Polym Eng Sci 51:592–600. https://doi.org/10.1002/pen.21855

Sackmann J, Burlage K, Gerhardy C, Memering B, Liao S, Schomburg WK (2015) Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 56:189–200. https://doi.org/10.1016/j.ultras.2014.08.007

Šakalys R, Janušas G, Palevičius A, Čekas E, Jūrėnas V, Sodah A (2016) Microstructures replication using high frequency excitation. Microsyst Technol 22:1831–1843. https://doi.org/10.1007/s00542-016-2858-7

Schmidt T, Müller C, Reinecke H (2011) Wirtschaftliche Fertigung dünnwandiger Mikrobautiele in technischen Polymeren mittels Tiefziehen (µ-Blistering). In: Proc. MikroSystemTechnik Kongress, 10–12 Okt., Darmstadt, pp 622–625

Throne JL, Beine J (1999) Thermoformen. Hanser Verlag, München. ISBN 3-446-21020-2

Truckenmüller R, Rummler Z, Schaller T, Schomburg WK (2002) Low-cost thermoforming of micro fluidic analysis chips. J Micromech Microeng 12:375–379. https://doi.org/10.1088/0960-1317/12/4/304

Truckenmüller R, Gieselbrecht S, van Blitterswijk C, Dambrowsky N, Gottwald E, Mappes T, Rolletschek A, Saile V, Trautwein C, Weibezahn KF, Welle A (2008) Flexible fluidic microchips based on thermoformed and locally modified thin polymer films. Lab Chip 8:1570–1579. https://doi.org/10.1039/B803619E

Truckenmüller S, Gieselbrecht N, Rivon E, Gottwald V, Saile A, van den Berg M, Wessling M, van Blitterswijk C (2011) Thermoforming of film-based biomedical microdevices. Adv Mater 23:1311–1329. https://doi.org/10.1002/adma.201003538

Zhu J, Tian Y, Yang C, Cui L, Wang F, Zhang D, Liu X (2017) Low-cost and fast fabrication of the ultrasonic embossing on polyethylene terephthalate (PET) films using laser processed molds. Microsyst Technol 23:5653–5668. https://doi.org/10.1007/s00542-017-3369-x

Acknowledgements

Open Access funding provided by Projekt DEAL. The results presented here were achieved with the support of China Scholarship Council with Award No. 201806150005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Peng, YJ., Schomburg, W.K. Process windows of ultrasonic thermoforming of micro structures. Microsyst Technol 26, 2777–2784 (2020). https://doi.org/10.1007/s00542-020-04834-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-020-04834-5