Abstract

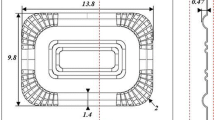

The energy of ultrasonic vibrations has been used in various polymer fabrication processes owing to its rapid and energy-efficient heating capability. This study concerns ultrasonic thermoforming of micro-speaker diaphragms, especially investigating the effect of the direction of vibration transmission to improve the forming accuracy of micro-corrugations; direct and indirect ultrasonic thermoforming processes were compared thereby. Experimental comparison reveals that indirect ultrasonic thermoforming shows better heating capability and formability than direct ultrasonic thermoforming does. This indirect thermoforming was then further investigated to find optimal forming condition, with the aid of response surface analysis. By applying the optimal forming condition, the micro-speaker diaphragm could be successfully fabricated with an excellent forming ratio (> 90%), within 10 seconds cycle time. The sound quality of the developed diaphragm was as good as that of conventional diaphragms fabricated by the conventional thermoforming process, which required more than 100 seconds cycle time.

Similar content being viewed by others

References

Sackmann, J., Burlage, K., Gerhardy, C., Memering, B., Liao, S., and Schomburg, W., “Review on Ultrasonic Fabrication of Polymer Micro Devices,” Ultrasonics, Vol. 56, pp. 189–200, 2015.

Daniels, H. P. C., “Ultrasonic Welding,” Ultrasonics, Vol. 3, No. 4, pp. 190–196, 1965.

Benatar, A., Eswaran, R. V., and Nayar, S. K., “Ultrasonic Welding of Thermoplastics in the Near-Field,” Polymer Engineering & Science, Vol. 29, No. 23, pp. 1689–1698, 1989.

Benatar, A. and Cheng, Z., “Ultrasonic Welding of Thermoplastics in the Far-Field,” Polymer Engineering & Science, Vol. 29, No. 23, pp. 1699–1704, 1989.

Liu, S. J. and Dung, Y. T., “Hot Embossing Precise Structure Onto Plastic Plates by Ultrasonic Vibration,” Polymer Engineering & Science, Vol. 45, No. 7, pp. 915–925, 2005.

Mekaru, H., Goto, H., and Takahashi, M., “Development of Ultrasonic Micro Hot Embossing Technology,” Microelectronic Engineering, Vol. 84, No. 5, pp. 1282–1287, 2007.

Mekaru, H., Goto, H., and Takahashi, M., “Development of Ultrasonic Micro Hot Embossing Technology,” Microelectronic Engineering, Vol. 84, No. 5, pp. 1282–1287, 2007.

Michaeli, W., Kamps, T., and Hopmann, C., “Manufacturing of Polymer Micro Parts by Ultrasonic Plasticization and Direct Injection,” Microsystem Technologies, Vol. 17, No. 2, pp. 243–249, 2011.

Sacristan, M., Planta, X., Morell, M., and Puiggali, J., “Effects of Ultrasonic Vibration on the Micro-Molding Processing of Polylactide,” Ultrasonics Sonochemistry, Vol. 21, No. 1, pp. 376–386, 2014.

Bae, H. and Park, K., “Design and Analysis of Ultrasonic Horn for Polymer Sheet Forming,” Int. J. Precis. Eng. Manuf.-Green Tech., Vol. 3, No. 1, pp. 49–54, 2016.

Bae, H.-J., Lee, H.-J., and Park, K., “Ultrasonic Assisted Thermoforming for Rapid Fabrication of a Microspeaker Diaphragm,” Microsystem Technologies, pp. 1–10, 2015. (DOI: 10.1007/s00542-015-2740-z)

Mekaru, H. and Takahashi, M., “Ultrasonic Nanoimprint on Poly (Ethylene Terephthalate) at Room Temperature,” Japanese Journal of Applied Physics, Vol. 47, No. 6S, pp. 5178–5184, 2008.

Seo, Y.-S. and Park, K., “Direct Patterning of Micro-Features on a Polymer Substrate Using Ultrasonic Vibration,” Microsystem Technologies, Vol. 18, No. 12, pp. 2053–2061, 2012.

Jung, W., Lee, H.-J., and Park, K., “Investigation of Localized Heating Characteristics in Selective Ultrasonic Imprinting,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 9, pp. 1999–2004, 2015.

Throne, J., “Technology of Thermoforming,” Hanser, New York, 1996.

Hosseini, H., Berdyshev, B. V., and Mehrabani-Zeinabad, A., “Modeling of Deformation Processes in Vacuum Thermoforming of a Pre-Stretched Sheet,” Polymer-Plastics Technology and Engineering, Vol. 45, No. 12, pp. 1357–1362, 2006.

Kim, D.-C. and Jeong, H.-Y., “An Optimal Design of the Internal Space in a Micro-Speaker Module,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 6, pp. 1141–1147, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bae, H., Lee, HJ. & Park, K. Effect of vibration transmission direction in ultrasonic thermoforming on the formability of micro-corrugations. Int. J. Precis. Eng. Manuf. 18, 697–703 (2017). https://doi.org/10.1007/s12541-017-0083-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0083-7