Abstract

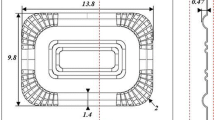

This study concerns ultrasonic thermoforming of Thermoplastic polyurethane (TPU) film for the fabrication of a television speaker diaphragm. The speaker diaphragm has a convex-protruded feature with a rounded-rectangular shape on which a number of micro-corrugations are formed for sound quality improvement. This diaphragm has generally been manufactured out of thin TPU film using a thermoforming process, which required cycle time as long as several minutes for proper heating and cooling of the polymer film and mold. In this study, an ultrasonic thermoforming process was introduced to reduce the cycle time to fabricate the diaphragm by taking advantage of the rapid and localized heating capability of ultrasonic vibration energy. To improve the forming quality of a large diaphragm for a television speaker, infrared heating was added to the process to preheat the TPU film before the forming stage. Various processing parameters including ultrasonic thermoforming and infrared heating conditions were investigated in relation to the forming quality. As a consequence, the diaphragm could be fabricated with acceptable forming ratios (> 95 % in the band region and > 70 % in the micro-corrugations) and short cycle time (12 s). This means that the proposed process is superior to conventional thermoforming processes that require long cycle time (> 200 s).

Similar content being viewed by others

References

J. L. Throne, Technology of thermoforming, Hanser Verlag GmbH & Co, Munich (1996).

H. J. Lee and D. G. Ahn, Manufacture of a large-sized Flat panel airlift Photobioreactor (FPA PBR) case, J. Mech. Sci. Technol., 29 (12) (2015) 5099–5105.

J. Sackmann, K. Burlage, C. Gerhardy, B. Memering, S. Liao and W. K. Schomburg, Review on ultrasonic fabrication of polymer micro devices, Ultrasonics, 56 (2015) 189–200.

A. Sato, H. Ito and K. Koyama, Study of application of ultrasonic wave to injection molding, Polym. Eng. Sci., 49 (4) (2009) 768–773.

W. Michaeli, T. Kamps and C. Hopmann, Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection, Microsyst. Technol., 17 (2) (2011) 243–249.

M. Sacristana, X. Plantaa, M. Morellc and J. Puiggalic, Effects of ultrasonic vibration on the micro-molding processing of polylactide, Ultrason. Sonochem., 21 (1) (2014) 376–386.

H. Mekaru, H. Goto and M. Takahashi, Development of ultrasonic micro hot embossing technology, Microelectron Engng., 84 (5–8) (2007) 1282–1287.

W. K. Schomburg, K. Burlage and C. Gerhard., Ultrasonic hot embossing, Micromachines, 2 (2) (2011) 157–166.

C. Y. Chang and C. H. Yu, A basic experimental study of ultrasonic assisted hot embossing process for rapid fabrication of microlens arrays, J. Micromech. Microeng., 25 (2) (2015) 025010.

H. Mekaru and M. Takahashi, Ultrasonic nanoimprint on poly (Ethylene terephthalate) at room temperature, Jap. J. Appl. Phys., 47 (6) (2008) 5178–5184.

W. Jung, H. J. Lee and K. Park, Investigation of localized heating characteristics in selective ultrasonic imprinting, Int. J. Precis. Engng. Manuf., 16 (9) (2015) 1999–2004.

H. J. Lee and K. Park, Variable wettability control of a polymer surface by selective ultrasonic imprinting and hydrophobic coating, Colloid Polym. Sci., 294 (9) (2016) 1413–1423.

H. Bae and K. Park, Design and analysis of ultrasonic horn for polymer sheet forming, Int. J. Precis. Eng. Manuf. Green Technol., 3 (1) (2016) 49–54.

H. Bae, H. J. Lee and K. Park, Ultrasonic assisted thermoforming for rapid fabrication of a microspeaker diaphragm, Microsyst. Technol., 23 (6) (2017) 1677–1686.

H. Bae, H. J. Lee and K. Park, Effect of vibration transmission direction in ultrasonic thermoforming on the formability of micro-corrugations, Int. J. Precis. Eng. Manuf., 18 (5) (2016) 697–703.

J. O. Sun and K. J. Kim, Isolation of vibrations due to speakers in audio-visual electronic devices without deteriorating vibration of speaker cone, J. Mech. Sci. Technol., 26 (3) (2012) 723–730.

D. C. Kim and H. Y. Jeong, An optimal design of the internal space in a micro-speaker module. Int. J. Precis. Eng. Manuf., 16 (6) (2015) 1141–1147.

K. M. Kim and K. Park, Numerical investigation on vibration characteristics of a micro-speaker diaphragm considering thermoforming effects, J. Mech. Sci. Technol., 27 (10) (2013) 2923–2928.

W. Liang, Y. Liu, B. Zhu, M. Zhou and Y. Zhang, Conduction heating of boron alloyed steel in application for hot stamping. Int. J. Precis. Eng. Manuf., 16 (9) (2015) 1983–1992.

Author information

Authors and Affiliations

Corresponding author

Additional information

Hyun-Joong Lee is a Ph.D. candidate in the Department of Mechanical Design and Robot Engineering at Seoul National University of Science and Technology, Korea. He received his B.S. and M.S. degrees from Seoul National University of Science and Technology, in 2013 and 2015, respectively. His current research includes ultrasonic fabrications of polymer parts including ultrasonic imprinting and ultrasonic thermoforming processes.

Keun Park received his B.S. and M.S. degrees in Precision Engineering and Mechatronics from KAIST, Korea, in 1992 and 1994, respectively. He then received his Ph.D. degree in Mechanical Engineering from KAIST in 1999. Dr. Park is currently a Professor of the Department of Mechanical System Design Engineering at Seoul National University of Science and Technology, Korea. His research interests include numerical analysis of material forming processes, micro-fabrication, and additive manufacturing.

Rights and permissions

About this article

Cite this article

Lee, HJ., Shin, DJ. & Park, K. Ultrasonic thermoforming of a large thermoplastic polyurethane film with the aid of infrared heating. J Mech Sci Technol 31, 5687–5693 (2017). https://doi.org/10.1007/s12206-017-1109-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-017-1109-x