Abstract

Recently, mechanical micro-milling is one of the most promising micro-manufacturing processes for productive and accurate complex-feature generation in various materials including metals, ceramics, polymers and composites. The micro-milling technology is widely adapted already in many high-tech industrial sectors; however, its reliability and predictability require further developments. In this paper, micro-milling related recent results and developments are reviewed and discussed including micro-chip removal and micro-burr formation mechanisms, cutting forces, cutting temperature, vibrations, surface roughness, cutting fluids, workpiece materials, process monitoring, micro-tools and coatings, and process-modelling. Finally, possible future trends and research directions are highlighted in the micro-milling and micro-machining areas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Miniaturisation is a well-established recent demand of the industrial sectors, highly encouraged by the recommendations and laws of national governments and by the European Union (EU). Miniaturisation meets the recently published core missions and policy of the EU, like decreasing the negative effects of industrial processes on the climate change (product minimisation reduces the specific energy demand of the products) and increasing the number of smart systems and equipment in the cities and factories (smart systems and equipment require miniature parts like microprocessors and microcircuits) [1]. Therefore, the demand for miniature components has increased significantly in many areas of the industry, such as the aerospace, bioengineering, optics, microelectronics, automotive, medical and defence [2,3,4,5,6].

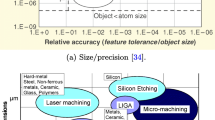

Miniaturised components can be manufactured by (i) electro-discharge machining [7,8,9,10], (ii) laser micro-manufacturing [11,12,13], (iii) lithography, electroplating and moulding (LIGA) [14, 15], (iv) deep reactive ion etching [16, 17], (v) deep UV lithography [18, 19] or (vi) mechanical micro-machining [20,21,22,23,24] technologies. Excellently precise geometrical features and small tolerances can be achieved by these micromachining technologies; however, their operation time and cost are often extremely high. Mechanical micro-machining is one of the most time-effective and most cost-effective methods for manufacturing miniaturised 3D components, mainly due to the relatively high material removal rate (MRR). Mechanical micro-machining processes can be categorized based on the analogy of the conventional-sized machining technologies: micro-milling, micro-drilling, micro-turning etc. One of the most commonly applied mechanical micro-machining technologies is the micro-milling [3, 4, 25,26,27,28]; this paper focuses therefore on its up-to-date review and discussion.

The main objective of the present paper is to review recent results and advances in micro-milling, including micro-chip removal and micro-burr formation mechanisms, cutting forces, cutting temperature, vibrations, surface roughness, cutting fluids, workpiece materials, process monitoring, micro-tools and coating, and process-modelling in order to summarise and discuss recent knowledge and outline possible future research directions and trends in micro-milling.

2 Micro-milling process

Micro-milling is a precise and flexible technology to manufacture complex 3D geometries in various types of materials (metals and its alloys, polymers, ceramics, graphite, composites etc. [3, 26,27,28,29,30,31,32,33,34,35,36,37,38]) by relatively high material removal rates. The kinematic of micro-milling is similar to the conventional-sized milling process; however, there are some unique phenomena and key issues: (i) the size of the cutting tool can be extremely small (diameter of 25 μm [39] or 50 μm [40]), the length-to-diameter ratio is therefore often high. The unfavourable size of the tool, and the vibration and/or the relatively large tool run-out often lead to a tool-breakage [41]. (ii) The uncut chip thickness is often in the same order of magnitude as the cutting edge radius or as the grain size of the workpiece material [2, 32, 42, 43]. Therefore, the material deformation mechanisms are often dominated by the ploughing-effect [20, 44], and the quality of the surface is often inadequate [42, 45]. Furthermore, the value of the theoretical chip thickness is often similar to the size of the minimum chip thickness [20, 45, 46], which may prevent chip formation in each edge step-in [47, 48]. (iii) The ratio of the burr size to the size of the machined features is higher than it is used to in the case of the conventional machining operations, the cost and time needs of the micro-deburring processes have therefore more effect on the final cost of the products [49, 50]. Furthermore, it is extremely difficult to remove burr in micro-sized features [32, 51]. (iv) The stiffness, the attenuation and the accuracy of the micro-milling machine have a significant influence on the quality of parts. In addition, milling machines require extremely high spindle speeds (up to 450,000 rpm [52]) to grant proper cutting speeds. However, current micro-milling machine tool models provide often only maximum 200,000 rpm spindle speeds [53]. (v) The importance of the monitoring and diagnostics of micro-milling processes is sufficiently high because the cutting tool can easily damage the surface of the material (inappropriate surface roughness, burr formation, micro-crack formation etc.) or break [27, 54, 55]. Therefore, the monitoring of the tool-condition is highly recommended in the case of micro-machining processes. The aforementioned issues have been investigated by many researchers in the past years; however, there are still many lacks and challenges in this area [56,57,58,59,60,61,62,63,64], as discussed in the following chapters.

2.1 Chip removal mechanism in micro sizes

Chip removal mechanisms are mostly influenced by the material type (metallic materials, polymers, ceramics, composites or sandwich structures) and its properties, followed by the tool geometry (rake angle, cutting edge radius, clearance angle, diameter etc.), scale of machining (macro, micro, or nano) and the primary process parameters (cutting speed, feed rate, depth of cut) [56,57,58,59,60,61,62,63,64,65,66]. For example, the dominant chip removal mechanism for macro machining of a Ti6Al4V is shearing in the primary shearing zone [67], while the dominant chip removal mechanisms (CRMs) for macro machining of carbon fibre reinforced polymer (CFRP) composites are bending, delamination formation, crushing and shearing, depending mainly on the fibre cutting angle and tools’ rake angle [68, 69]. However, if the above materials are machined in micro-scales, the ploughing dominates often the chip removal mechanisms [36].

In mechanical machining, the thickness of the removable material layer is limited; this limit is named as minimum chip thickness (hmin). If the undeformed chip thickness (h) is smaller than hmin, the cutting tool only compresses the top of the material instead of removing it. This phenomenon causes more often difficulties in micro-milling than in conventional-sized machining. According to Vipindas et al. [70], the cutting edge radius has the most significant influence on the size of the minimum chip thickness, as was confirmed by Wojciechowski et al. [47], Dib et al. [45], and Sahoo et al. [20] as well. The minimum chip thickness can be quasi-precisely estimated by an empiric model developed by Gao et al. [43] and Dib et al. [45].

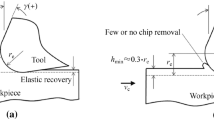

As it is already discussed in depth by the researchers, the macro-chip removal mechanisms of quasi-homogeneous (e.g. metallic) materials are mostly shearing dominated [71], but the CRMs of micro-machining are often influenced mostly by the ploughing-effect, according to Aramcharoen and Mativenga [72]. Its reason can be found in the negative kinematical rake angle of the cutting tool, caused by the relative high cutting edge radius compared to the uncut chip thickness. The negative effective rake angle of the cutting edge compresses the top of the material, and it deforms plastically. The micro-chip removal mechanisms are illustrated in Fig. 1.

If the value of h is smaller than the value of hmin (Fig. 1a), the cutting tool presses only the material below the cutting edge, and it recovers back without any chip formation. In this case, the material deforms mostly elastically and it damages the surface structure (due to the plastic deformation), which results in worse surface quality [45]. If the value of h is comparable to the value of hmin (Fig. 1b), the chip starts to form due to the shearing effect in the primary shearing zone. In addition, the specific passive cutting force is high due to the relatively significant ploughing-effect. In the case of the h is greater than hmin (Fig. 1c), chip is continuously formed due to the stable plastic deformation in the shearing zone, while the elastically deformed material springs back. Nevertheless, the ratio of elastic recovery is lower. The undeformed chip thickness (h) is often thicker than the removed material depth [73]. This mechanism is the closest to the macro-chip removal mechanism of quasi-homogeneous materials.

The undeformed chip thickness is almost constant during orthogonal machining if the vibrations and the regenerative-effect is not considered. However, it is not constant during milling: its value is changing with the tool rotation; therefore, it may happen that all of the aforementioned cases (Fig. 1 a, b and c) appears and characterize the material removal process [25]. Furthermore, a low feed and/or a relatively high tool deflection may result in that chip not forms in certain cases, and the material is deformed elastically mainly [25, 47].

In mechanical micro-machining, the effect of the microstructure of the material (material defects; density, type, position, orientation and size of grains/fibres/particles) is significant [62, 74, 75]. The influences of the microstructure of an anisotropic and an inhomogeneous material are illustrated in Fig. 2. If the micro-particle (grain, fibre etc.) of the material is positioned completely below or above the theoretical cutting depth (Fig. 2a and b), the effect of the micro-particle is negligible. Nevertheless, the micro-particles have a significant effect on the CRMs if they are located in the depth of the theoretical cutting depth, as illustrated in Fig. 2c and d. The specific cutting energy demand of the micro-particles often higher than the matrix’s [62], the pressing (Fig. 1c) or crushing (Fig. 1d) of the particles requires therefore more cutting energy, which may result in higher vibrations, faster tool wear, more burr formation and worse surface quality.

The deep technological knowledge and experience acquired in conventional-sized milling (macro-milling) cannot be directly applied to the micro-milling process, mainly, due to the size effect (the machining related phenomena and process characteristics are not correlated linearly with the tool’s size-reduction) and the relative high tool deflections [25]. Therefore, the micro-chip removal mechanisms and the micro-milling of quasi-homogeneous materials were investigated previously by theoretical [76,77,78], experimental [42, 79,80,81] and simulation [80, 82, 83] approaches by many researchers. Bissacco et al. [84] investigated the limits of the size effect in micro-milling, which border separates the micro and macro-chip removal mechanisms. Aramcharoen and Mativenga [72] conducted micro-machining experiments on a hardened, very fine-grained H13 steel, and they found that the hmin/rβ ratio of the theoretical chip thickness (h) to the cutting edge radius (rβ) is a key parameter, which influences the micro-machining process significantly. According to their studies, the size effect is significant, when the ratio is less than 1. The cutting edge radius of a micro-milling tool is approximately 1–20 μm [39], which is about in the same magnitude as it is used at the conventional sized tools. The value of the cutting edge radius depends mainly on the material of the tool, the particle size, the manufacturing precision and the state of tool wear [74]. According to Bissacco et al. [25], the aforementioned h/rβ ratio has a great influence on the relative machining accuracy, burr formation and surface quality. Furthermore, the increasing of the feed per tooth (fz) has a positive effect on the quality of machined features and also on the tool condition. Nevertheless, the optimisation process of the feed per tooth value should include the analysis of the cutting forces and the tool deflections.

Mian et al. [85] investigated the micro-machinability of an Inconel 718 alloy. They pointed out that nor only the ratio of fz/rβ, but also the cutting speed is an important parameter from the point of view the size effect and the optimisation of the micro-milling process. In addition, they concluded that the specific cutting energy, the burr root thickness and the surface quality are recommended to be analysed in order to estimate the magnitude of the size effect. Pratap et al. [86] conducted micro-machining simulations on Ti6Al4V alloy and observed that the size of stress in the primary shearing zone was relative high (2467 MPa), which was explained by the size effect.

Coatings can also be applied in the micro-machining technologies to increase tool performance and tool life, but it has to be pointed out that the thicker coating increases the value of the cutting edge radius, and thus affects minimum chip thickness [87]. Many researchers have studied the relationship between minimum chip thickness (hmin) and edge radius (rβ) using experimental [46, 88, 89], numerical [77, 90, 91], and analytical [92, 93] methods. For example, de Oliveira et al. [46] experimentally investigated the hmin/rβ ratio on an AISI 1045 steel and found that it changes between 0.22 and 0.36. Their observation was confirmed by Cuba Ramos et al. [88] and Kang et al. [89] on the same AISI 1045 material. The ratio of hmin/rβ was analysed in many materials and technologies; the calculated ratios are summarised in Table 1. As can be seen in the table, the ratio changes between 0.14 and 0.48. This ratio could indicate the goodness of technology or be a parameter which is monitored during the machining process. E.g. if the hmin/rβ gets smaller than a critical value, the cutting process parameters (or the cutting tool) has to be changed, in order not to reduce surface quality or machining efficiency.

2.2 Burr formation in micro sizes

One of the main micro-milling induced geometrical defects is the burr occurrence on the machined edges of the material. The specific size of the burr is usually smaller than it is used to observe in conventional sized milling; their removal is, therefore, more difficult and challenging task [32, 51]. The burr does not weaken the material; however, it greatly affects the quality of the part, as its size can be comparable to the diameter of the tool [98], and degrades its performance [32, 99].

Burr may be formed on the machined features of the material if the cutting tool plastically deforms the uncut material instead of removing them, which may be caused by the following main issues: (i) the uncut (theoretical) chip is not supported by any material or special supporting fixtures [100], (ii) the cutting edge radius and ploughing effect are relatively large [46, 101] (iii) the tool run-out is significant [46, 101], (iv) extensive and uncontrolled vibration (chatter) complicates the process [54, 82, 102], or (v) the type and position of the micro-particles of the part are unfavourable [62, 103]. Micro-groove-milling induced burr occurrence can be seen in Fig. 3. As it is clearly observable on the figure, the appearance of the burr on the top of the workpiece material is significant, and its size is comparable to the size of the tool diameter. However, burr can be formed not only on the top edges of the material, but it is often observable on the entry and exit edges, too [78]. Figure 4 summarises the different burr types and their locations.

Top burr on the micro-milled surface in AISI H13 (vc = 90 m/min, ap = 100 μm and (a) fz = 2 μm, (b) fz = 6 μm) [42]

Three main burr formation mechanisms can be identified, which related to micro-milling processes [106]: (i) the material is compressed, mainly due to the ploughing effect, and it gets therefore bulged plastically to the sides of the material. This mechanism is named as Poisson (Fig. 5a). (ii) The uncut chip tearing from the material, rather than gets removed clearly. This mechanism is called as tear (Fig. 5b). (iii) The uncut chip gets bent rather than removed. This mechanism is named as rollover (Fig. 5c).

Burr formation is significantly influenced by the condition of the tool, which changes continuously as the cutting progresses. In order to select the appropriate parameters, it is important to know the actual condition of the tool [98], as the burr increases as the wear progresses [94, 98]. Oliaei and Karpat [108] examined the effect of the built-up edge on burr formation, but found no strong correlation; nevertheless, they found that higher forces result in a larger burr.

In the scientific literature, two main approaches can be found to eliminate burrs. The first one is to remove the burr after machining (deburring), and the other is to reduce it during machining. The latter approach is more appropriate in terms of machining costs and operation time; the optimisation of micro-milling processes is therefore essential. According to Saptaji and Subbiah [109], the incorrect design of deburring or incorrect selection of cutting parameters may cause a significant dimensional error, micro-damage, surface error, or residual stresses.

Many researchers have examined the effect of milling strategies on burr formation: the up-milling (also known as conventional milling) was to be found ideal from the point of view burr-minimisation on OFHC [110], Inconel 718 [85], Ti6Al4V [94], AA1100 [98], AISI 1045 [4], Al6061-T6 [109], X5CrNi18-10 [111] materials. Hajiahmadi [49] observed smaller top-burr height in the case of up-milling of AISI 316L, than it was observed at the down-milled (also known as climb milling) top edges. Nevertheless, the top-burr thickness was smaller at the down-milled edges. Piquard et al. [112] found a thinner and wider burr on the down-milled side.

Wu et al. [110] proposed an extra milling process with an up-milling strategy with a small width of cut to remove the formed burr. Mian et al. [85] observed that the burr-geometry—generated by the down-milling—is more uniform than the burr-geometry generated by the up-milling strategy. Biermann and Steiner [111] showed that the quality of the micro-machined side-wall of the workpiece is better when the down-milling strategy was applied; however, the burr-size was to be found larger, as was confirmed by Saptaji and Subbiah [109]. Mian et al. [85] proposed that the burr root thickness can be effectively controlled by the optimisation of the cutting speed and the ratio of the theoretical chip thickness to the edge radius. According to Kumar et al. [99], the cutting parameters, workpiece material properties, tool geometry, coatings, and coolant lubricants also affect the burr formation significantly in micro-milling. Piquard et al. [112] analysed the micro-milling process and found that the feed per tooth and the width of cut significantly affect the burr size. They also found that higher feed per tooth and smaller cutting width values have a positive effect on the burr formation mechanisms.

Aramcharoen and Mativenga [72] experienced a decreasing burr size on hardened H13 steel, as the ratio between the undeformed chip thickness and the cutting edge radius increased. They explained it by the decreasing ploughing phenomenon. Chen et al. [113] proposed to decrease the ratio of depth of cut to tool diameter in order to minimise burr formation. Increasing the cutting speed and feed per tooth also had a positive effect on burr formation in the parameter ranges vc = 40–90 m/min and fz = 1–4 μm [4]. Kumar et al. [32] examined the lateral exit-burr and found that it is unfavourable at the up-milled sides. Nevertheless, Kiswanto et al. [98] observed significant exit-burr formation at the down-milled sides as well. Furthermore, they could not found any significant differences between the burr-shapes at the up-milled and down-milled sides. Gilbin et al. [29] conducted micro-milling experiments on 42NiCrMo16 using a diameter of 500 μm end mill. They showed that an increase in feed was found to be the most suitable for reducing the exit burr, while unlike in macro-milling, this did not have a significant effect on surface quality. In contrast, according to Biermann and Steiner [111], increasing the feed may cause a higher top burr height in X5CrNi18-10, possibly because the increased amount of material cannot be removed continuously with only a single cut. They also concluded that increasing cutting speed due to “the higher strain rate hardening of material”, and the use of sharp tools with a positive rake angle and a large spiral angle is advantageous to reduce the size of the upper burr.

Kumar et al. [32] studied the micro-machinability of Ti6Al4V and they could decrease the height of exit-burr by reducing the cutting speed from 314 m/min to 79 m/min. Aramcharoen et al. [2] micro-machined AISI H13 and observed that most of the tool coatings are suitable for reducing the size of burrs. Swain et al. [79] conducted micro-machining experiments on Nimonic 75 alloy and compared the cutting-ability of a nanostructured TiAlN coated tool and an uncoated one. They found that the tools perform almost identically at the start of the cutting, but with increasing the cutting length—due to the different wear behaviours—the burr increases more rapidly in the case of the uncoated cutting tool is applied.

According to Komatsu et al. [114], by reducing the grain size of the material, the size of the burr can be reduced. For normal grain sizes (~ 9.10 μm) the cutting force suddenly decreases at the end of the cut with the variable primary shear angle, and a large burr forms at the edges. In contrast, in the case of ultrafine grain materials, (~ 1.52 μm), the force reduction at the end of the chip separation takes place gradually. Wu et al. [110] conducted finite element and experimental investigations on an oxygen-free copper using a diamond tool and pointed out that the Poisson burr is caused by the lateral flow of stagnant material at the lower segment of the cutting edge. During their investigation, the cutting edge radii were set to 0, 1, 2 and 5 micrometres, which parameters were smaller and also higher than the uncut chip thickness. They observed that the area of the maximum stress shifted from the upper corner of the cutting edge to the lower corner, due to the dominant ploughing effect. All of these resulted in larger Poisson burr. According to the authors, the burr formation is minimal, if the uncut chip thickness is reduced to the same value than the cutting edge radius. However, the further decrease in the chip thickness induced an opposite effect. According to Aurich et al. [40], a tilted spindle results in a completely different material removal condition than the conventional one. Due to the tilted cutting tool, the effective helix angle can be minimised, which may have a positive effect on burr formation. Kou et al. [115] recommended the use of adhesive supporting material to increase the stiffness of the edge of the workpiece. In the case of their novel method, the burr is formed on the supporting material, which can be removed from the piece more easily. The procedure was experimentally verified. Saptaji et al. [109, 116] proved that tapered tools could reduce the top burr as well as the exit burr due to the sloping walls. They recommended a diamond single crystal tool with a very small cutting edge radius for ductile materials to reduce burrs, which require high accuracy and good vibration control for efficient use additionally.

2.3 Cutting force in micro-milling

The main differences between macro and micro-scaled machining from the point of view cutting force can be seen in Fig. 6. Due to the size reduction in micro-milling, the magnitude of the cutting forces is significantly smaller than in the case of macro-milling. Typically, the force amplitudes are between a few tenths and a few tens of Newtons. Nevertheless, the ratio of cutting force (Fc) to the passive force (Fp) differs significantly. In the case of micro-milling, the passive force has a more significant effect on the chip removal process, which is a consequence of the ploughing phenomenon.

It is essential to know and monitor the cutting forces because they provide information about many phenomena, such as chip formation, mechanism of material removal, vibration, and tool condition [68, 74, 118]. All of these contribute to improving the predictability of the process, reducing the speed of the tool wear and increasing the reliability of the process.

As discussed earlier, in the case of micro-milling, the cutting edge radius plays an important role in the chip removal because it affects the minimum chip thickness, as well as the material removal mechanisms. Since the value of rβ and other characteristics of the tool are constantly changing due to tool wear, the effect of wear on cutting forces is the subject of many researches [76, 94]. Afazov et al. [119] micro-milled AISI 4340 steel and proved that higher cutting edge radius causes higher cutting forces. Wu et al. [120] machined OFHC copper and found that the ratio of shear force and ploughing force to the main cutting force was 55% and 45%, respectively. As the radius increases, the difference is shown here also increases. Yang et al. [95] conducted micro-milling experiments on Al2024-T6 aluminium alloy and showed that although the cutting forces are higher, the effective stress reduces. Pratap et al. [86] analysed the cutting forces during micro-milling of Ti6Al4V alloy. They found that higher cutting forces are caused by mainly the accelerated tool wear rates (~ higher cutting edge radius), caused by the increased cutting temperatures. In this scenario, the increase in force is due to the stronger ploughing phenomenon, which occurs when the value of the chip thickness is below the value of minimum chip thickness [91, 121]. All of these phenomena often contribute to unpredictable tool life [87]. Mian et al. [85] pointed out that at small theoretical chip thickness, the ploughing effect is present for a longer time until the tool actually starts to cut. At higher feed per tooth values, the dominance of the ploughing effect is often reduced.

A significant increase in the specific cutting force is observed at small chip thicknesses due to the phenomenon of the size effect [122]. According to Gao et al. [43], a larger cutting edge radius results in a larger negative rake angle, which affects the shear and ploughing force significantly. The ploughing force increases significantly below the minimum chip thickness, which also entails a significant increase in the specific cutting force. In micro-milling, forces can also increase due to the excessive reduction in feed rate due to the ploughing phenomenon. Aslantas et al. [94] showed that a tool with a low coefficient of friction could prevent ploughing. Lu et al. [76] developed a novel cutting force model, which gives an accurate estimate of the forces taking into account the wear state of the tool. de Oliveira et al. [46] studied the effect of the feed per tooth on the specific cutting force at macro and micro-sized milling operations. In the case of micro-milling, specific cutting force by an average of 22% could be reduced by doubling the feed per tooth; and it could be reduced by 13% by doubling the depth of cut. These values were only 18% and 7% in macro sizes, respectively. Similar trends were observed in 12Cr18Ni9 by Gao et al. [43], and it was shown that increasing the cutting width (ae) also reduces the specific cutting force.

Zhou et al. [123] performed micro-milling simulations on NAK80 steel, and found that the effect of cutting speed on cutting forces is negligible in their studied parameter range (vc = 12–36 m/min, fz = 0.3–12 μm). Wang et al. [41] micro-milled Inconel 718 alloy, and showed that the cutting force increases with increasing feed per tooth and ae. They also highlighted, that the feed per tooth should be set above a critical value (hmin), and the ae should be chosen relatively small to reduce the forces. Sun et al. [36] conducted 3D finite element micro-milling simulations on Al7075-T6 alloy, and observed that higher cutting width results in higher cutting forces. According to Komatsu et al. [114], the ratio of force components (Z to X) is higher in the case of ultrafine grain steels than at normal grain sizes. The shear force decreases with ultrafine grain materials while the friction force increases. Ahmadi et al. [124] also observed higher forces for smaller grain sizes. The cutting forces depend significantly also on the milling strategies: the forces are usually lower for up-milling than for down-milling in AISI 1045 steel [38].

2.4 Cutting temperature in micro-milling

Cutting temperature plays an important role in all of metal cutting processes as it significantly affects tool wear, burr formation, chip removal mechanisms, and the surface quality [95, 125]. According to the study made by Mamedov and Lazoglu [126], cutting temperature also has a direct effect on residual stresses, 3D distortions, and dimensional accuracy of the machined micro-features. Wissmiller and Pfefferkorn [125] pointed out that thermal expansion plays a significant role in this size range, not as negligible as in the case of conventional-sized machining operations. Yang et al. [95] conducted micro-milling experiments on Al2024-T6 alloy and analysed the cutting temperature. They found that only a small part of the generated heat is concentrated on the contact between the tool and the workpiece. It was observed that the maximum temperature field extends from the rake face through the corner of the cutting edge to the flank face, as illustrated in Fig. 7.

Wissmiller and Pfefferkorn [125] investigated the geometry of cutting tools and found that shorter edges and shorter transition sections allow better thermal conduction, thus reduced the maximum tool temperature. Mamedov and Lazoglu [126] conducted micro-milling simulations and found that the temperatures increased with the chip load. Thus, increasing the feed leads to an increase in temperatures, as was confirmed by Wissmiller and Pfefferkorn [125]. In addition, higher depth of cut values results in higher cutting temperatures [126]. Nevertheless, the low feed per tooth—which mainly results in plastic deformation on the workpiece surface—can results in higher temperature and adhesive wear, according to Uhlmann et al. [128].

The measurement of cutting temperature during the micro-milling process is extremely challenging, therefore, many researchers investigated it by simulations. Yang et al. [95] simulated micro-milling process on Al2024-T6 alloy and found that increasing the radius of the cutting edge (0; 3.2; 5; 7 μm), the tool temperature decreases (57.5 °C; 51.5 °C; 45.4 °C; 40.4 °C, respectively). The temperatures obtained here were low compared to conventional sized milling. Balázs and Takács [83] observed similar results: the results of the finite element simulations of the thin chip removal process showed that the tool temperature is quite low at machining of AISI 1045 steel. According to the authors, the increase of both feed per tooth and cutting speed result in increased tool temperature.

Wissmiller and Pfefferkorn [125] simulated the micro-milling of AISI 1018 steel and resulted in a tool temperature of 91.85 °C at vc = 37.68 m/min and vf = 200 mm/min, while 49.85 °C tool temperature resulted in Al 6061-T6 alloy at vc = 37.68 m/min and vf = 700 mm/min. Despite the fact that the feed is lower in the case of steel than in the case of aluminium alloy, this is not an unexpected result, as the yield-strength of steel is much higher than that of the aluminium alloy. Pratap et al. [86] conducted finite element micro-milling simulations on Ti6Al4V material, and a maximum temperature value of 845.3 °C was determined with the parameters vc = 31.415 m/min, fz = 1 μm and ap = 30 μm. Thepsonthi and Özel [129] simulated micro-milling of Ti6Al4V and found that the cutting temperature could reach 420 °C. Based on the simulations made by Zhou et al. [123] the highest temperature occurred in the secondary shear zone (210 °C) on NAK80 mirror die steel. Biermann and Steiner [111] did not experience thermally induced softening in austenitic stainless steel even at higher cutting speeds, which may be due to the very short contact time between the workpiece and the tool.

In summary, studying the cutting temperature in micro-milling is not a very extremely investigated topic, as it is a very challenging process. The characterising temperatures of micro-machining are typically lower than in the case of conventional-sized machining. The maximum temperature of the micro-sized tool is typically below 100 °C.

2.5 Vibrations in micro-milling

Minimization of tool vibration is one of the main challenges in conventional sized milling processes because inappropriate vibration (chatter) often results in accelerated tool wear or poor surface quality [130,131,132]. In addition to these difficulties, chatter may cause tool breakage in micro-milling [82, 133]. Due to the size reduction, the micro-milling process requires small-diameter tools (slender tools), and their stiffness is therefore often one order of magnitude lower than those used in conventional sizes. This limited stiffness is a major obstacle, when machining difficult-to-cut materials, such as hardened steels and titanium alloys [134]. In addition to the low stiffness of the tools, the high specific cutting force—at small depth of cut values—also makes the optimization of the micro-milling process more difficult [135]. However, the stability of the micro-milling process can be improved by (i) the increased process damping due to the ploughing phenomenon, and by (ii) the increased contact area of the clearance surface and the workpiece [102, 136]. Cutting tool vibration can be modelled using springs and attenuations [137,138,139]. Figure 8 compares the macro and micro-cutting processes from the point of view vibration characteristics. As it can be seen in the figure, the ratio of cutting force to the passive force (Fc/Fp) is usually smaller in micro-cutting than in conventional sized cutting, the vibration in the direction of the cutting speed is therefore relatively smaller, and the vibration in the direction of the depth of cut is relatively higher in micro-cutting.

Mittal et al. [5] stated that limited stiffness is one of the main obstacles, when machining difficult-to-cut materials (such as Ti6Al4V). However, this property characteristic can be improved by using high cutting speeds because the cutting forces decrease at higher speeds, caused mainly by the reduced chip load. Although, at high cutting speeds, dynamic changes in cutting forces can make the process unstable. In this case, the heat generation may also be higher, which, combined with the poor thermal conductivity of the workpiece material (e.g. in polymers), also affects the forces and unstable behaviour. Gilbin et al. [29] stated that the low stiffness of the tools also plays a role in the development of dynamic phenomena and significant deflection. They confirmed that the stabilisation of the tool and cutting process could be achieved by increasing speeds. Singh et al. [134] also stated that the chip load should be reduced in the case of high speeds, but this may result in an intensification of the ploughing phenomenon, which can result in even an order of magnitude higher vibrations.

As it is well-known, vibrations and chatter often cause poor surface quality and tool failure due to unstable cutting conditions [37, 38, 134, 140]. Considering the special characteristics of the micro-milling process, such as the (i) small diameter of tool (< 1 mm), (ii) relatively large tool run-out and (iii) deformations; it can be concluded that the dynamic behaviour of the process is extremely complex [38]. The most common form of self-excited vibration is the regenerative chatter, which causes instability in the cutting process [5]. This is one of the main obstacles to improving productivity and component quality [141].

Takács et al. [38] demonstrated the presence of strong vibration in the AISI 1045 micromachining through a characteristic pattern left on the surface and through fast Fourier transformation (FFT) analysis. A similar case can be seen in the study of Singh et al. [134]. According to Biermann and Baschin [140], due to the small theoretical chip thickness and the effect of the cutting edge on chip formation, the regenerative effects are stronger than at macro sizes. The authors emphasise the importance of analysing the cutting forces in order to control vibrations, deformations and other errors caused by the low rigidity of the tool. Reducing the feed per tooth in micro-sizes is not advantageous, as it also changes the uncut chip thickness, which has a non-linear relationship with the cutting forces. According to Mamedov et al. [142], great emphasis should also be placed on the analysis of cutting forces in the study of the mechanics and dynamics of the micro-milling process.

Jun et al. [143] presented a dynamic micro-milling model for predicting cutting forces and vibrations, which also takes into account spindle errors and cutting tool defects. According to Moges et al. [3], the instantaneous uncut chip thickness associated with the cutting edge, which offset is the longest (compared to the other edges), is greatly influenced by the tool run-out. Furthermore, this longest-offset-edge often gets a significantly higher load and the other edge may not enter the workpiece or the edge impact’s time is shorter. The difference in chip load is greater at lower feed per tooth. According to the authors, in order to accurately predict the geometrical parameters of the process, in addition to the tool run-out, the relationship of the current path of the tool edge with the trajectory of several preceding tool edges must be taken into account. Furthermore, the elastic spring-back of the workpiece also has a significant effect on the process characteristics, when the chip thickness is below the hmin value. According to Biermann and Baschin [140], a small corner radius (~ 0.1 mm) can have a beneficial effect on the vibrational trajectories of the tool and on the reproducibility of the process. The right selection of tool radius is also important because it significantly affects the minimum chip thickness. In addition, the tool wear, the tool finishing process (which is often grinding), and the coating process also affect the condition and stability behaviour of the cutting edge.

Yilmaz et al. [37] studied the dynamics of a micro-milling tool. Their presented method is based on an inverse stability analysis, where the modal parameters are updated with the results obtained from the chatter-tests to bring even closer the dynamic behaviour of tool centre point (TCP). Stability diagrams require FRF (frequency response function) analysis of the TCP, which cannot be determined experimentally due to the small tool size, so an analytical approach has been presented by the authors [37]. Singh and Singh [82] also examined tool dynamics. Finite element modal analysis was used to determine FRF, and the results were validated experimentally. The difference between the two methods in the first mode natural frequency was 6.6%. Based on their studies, the first mode natural frequency was 4851 Hz, the second 5081 Hz, and the third 7170 Hz. In contrast to the data presented above, Takács [74] found the natural frequency value of bending no. 1 to be more than 250,000 Hz for similar l/d ratio’s tools.

The determination of stability curves also plays an important role in stable chip removal conditions and it is, therefore, the subject of much research works. Afazov et al. [119] studied stability limits on AISI 4340 steel. In the study of the effect of rake angles, lower stability limits, as well as higher forces, were observed at a rake angle of 0° than at 8°. The increase in cutting forces and the decrease in stability limits are much stronger for small cutting edge radiuses and large theoretical chip thicknesses. According to the authors’ study, the stability limits can be increased by preheating the workpiece to 600 °C, which leads to softening of the workpiece, thereby reducing the cutting forces. In another study, the same authors presented a vibration model, where they found that modal-dynamic parameters have a significant effect on stability curves, especially above 35,000 rpm (vc = ~ 55 m/min). With increasing tool run-out, as well as increasing feed per tooth, the stability area decreases linearly due to higher forces [139].

Singh et al. [134] modelled the dynamic stability of the micro-milling process in Ti6Al4V. The estimated and measured stability limits up to 70,000 rpm show a good agreement, but differ significantly above it. The differences are explained by the authors with decreasing damping at high speeds and the Coriolis-effect due to rotational and vibrational movements. Mokhtari et al. [144] presented a novel method to study the unstable vibrational behaviour of micro-milling. Their studies took into account the size effect, the gyroscopic moment, the rotary inertia, the structural nonlinearities and process damping. Sahoo et al. [145] proposed an analytical approach to study cutting forces and dynamic stability. They combined the finite element modelling with mechanical modelling, which also takes into account tool run-out, minimum chip thickness, elastic recovery, and the ploughing phenomenon. Mittal et al. [5] conducted micro-milling experiments on Ti6Al4V and found, that a transition at 47,000 rpm was clearly demonstrated from the cutting force data, where the process becomes lubrication-sensitive.

2.6 The surface roughness of micro-milled geometrical features

One of the critical quality characteristics of micro-machined components is the surface quality, so a large area of research focuses on how factors affect it. Uhlmann et al. [146] conducted micro-milling experiments on X13NiMnCuAl4-2-1-1 and found that the cutting edge radius significantly influences the surface roughness of the machined part. Aramcharoen and Mativenga [72] experienced the best surface quality on a very fine-grained AISI H13, when the uncut chip thickness and the tool radius of the cutting edge were set to the same value. Li and Chou [147] found that surface quality is closely related to the wear state of the tool in SKD 61 (38 HRC). It is well-known, that, as the cutting progresses, the edge rounding increases [95]. According to Zhu and Yu [27], the tool wear also affects surface integrity and product geometry. Oliaei and Karpat [108] analysed micro-machinability of Ti6Al4V and found that the increasing cutting speed does not improve the surface quality. Li and Chou [147] found on SKD 61 that neither the cutting speed nor the feed (vc = ~ 37.5–75.4 m/min, fz = 1–2 μm) had a significant effect on surface quality. Kiswanto et al. [98] studied the micro-milling process with statistical methods, with particular regard to productivity, and suggested that the use of higher feed rates is recommended as it does not degrade surface quality significantly (investigated parameter ranges vc = ~ 22–59.7 m/min, f = 0.05–1 mm/s).

Mian et al. [85] examined surface roughness results by means of analysis of variance (ANOVA). In contrast to the previously discussed studies, it was found that in addition to the ratio of the theoretical chip thickness to the edge radius, the cutting speed also has a significant effect on the surface roughness. It was found that the cutting speed was the most significant parameter to improve surface quality. Uhlmann et al. [128] analysed micro-milling in WCu. They observed that the surface roughness increases with decreasing cutting speed, which may be caused by the formation of a built-up edge. It was found that increasing the feed per tooth leads to (i) geometric inaccuracy and (ii) higher abrasive wear, which causes the cutting edge to round, as well as increasing the plastic deformation on the workpiece surface. An improvement in surface quality was achieved with increased cutting speed.

According to Zhang et al. [148], the low stiffness of the tool during the micro-milling process is one of the biggest obstacles in terms of surface quality. Cutting forces result in considerable tool deformations, which affect the quality of the machined surfaces, as it is proved by Mamedov et al. [142]. Ahmadi et al. [124] found slightly better surface quality in Ti6Al4V in the case of finer grain sizes of workpiece material. Oliaeia and Karpat [149] micro-milled Stavax stainless steel. It was found that each different cutting width (ae) values have a preferred feed per tooth value. Lower ae values result in lower surface roughness. With larger cutting width values, the surface quality is better at higher feed per tooth values. An optimum was found at ae = 20% and fz = 4 μm.

Bissacco et al. [84] studied micro-milled surfaces in detail. The cutter marks on the surface are related to the geometry of the tool and also includes the accumulation of plastically deformed material. In the other case, there is a smear of the material behind the tool, which generates small waves in the feed direction. Because of these effects, surface roughness can only be reduced to a limited value by reducing the tool diameter. In the study of milling strategies in Ti6Al4V by Ahmadi et al. [124], based on analyses with EBSD, up and down-milling strategies resulted in a different surface texture. It was observed that greater compressive deformation occurs in down-milling than in the up-milling. Aurich et al. [40] investigated the effect of the spindle tilting angle, and based on their experiments, tilting the tool also degrades surface quality and geometry. The significant differences between their simulated results and their experiments can be traced back to the ploughing effect, which is significant in micro-milling.

Wang et al. [150] studied the surface characteristics at different stages of tool wear on Ti6Al4V. Based on their investigations, the main forms of surface defects are: feed marks, material debris, plastic side flow and material smears. As wear progressed, mainly material debris and plastic side flow became more significant. Meanwhile, the surface quality on the up-milled side was better than on the down-milled side. According to K and Mathew’s [151] micro-milling studies in Ti6Al4V (using 3–3.5 μm cutting edge-rounding and a TiAlN coated cutting tool), as the wear progressed, the surface roughness decreased at a feed rate of fz = 5 μm per tooth, and the roughness value has a minimum at 700 mm machined length. In contrast, at fz = 0.3 μm, the roughness increased with the cutting length. The authors recommended to set the feed per tooth to a slightly higher value than the cutting edge radius in order to optimise surface roughness.

2.7 Application of cutting fluid in micro-milling

One of the main purposes of using cooling lubricants is to increase the quality of machined parts and the economy of machining. The use of coolants and lubricants in macro sizes improves the surface quality, has a positive effect on tool wear and cutting forces [71, 73]. Cutting fluids can be used to reduce thermal deformations, which also contributes to geometrical accuracy, as well as chip removal [71, 73, 127]. A significant challenge with coolants is that they are harmful to the environment and human health. Therefore, nowadays, environmentally friendly methods such as dry cutting, minimum quantity lubrication (MQL), nanofluid minimum quantity lubrication and cryogenic cooling are getting more popular [152,153,154]. There are a lot of researches going on to investigate the effect of coolants and lubricants on a micro-scale machining.

According to Li and Chou’s [147] micro-groove-milling experiments on SKD 61, even a small amount of oil (1.88 ml/h) proved to be sufficient for minimum quantity lubrication, the required air volume was found in 40 l/min. Oil is required to achieve a long tool life; just using clean air alone does not increase tool life [147]. Ziberov et al. [155] performed micro-milling experiments on Ti6Al4V material and observed that the wear behaviour of the tools differs significantly at MQL compared to dry machining. In the former, the secondary clearance surface was mainly worn, while in dry conditions, cutting edge rounding increased more. In the case of dry machining, the tool life was longer, reaching the wear criterion after more than twice the cutting length (lc = 21.0 and 50.4 mm). This may be explained by the built-up edge that protected the tool. In contrast, in the study made by Li and Chou [147], it was found that the flank wear reduced to 60%, when MQL was applied, compared to dry machining.

Kumar et al. [99] conducted micro-milling experiments and found that coolant-lubricating fluids also influence significantly burr formation not only cutting temperature or tool wear speed. Li and Chou [147] performed micro-milling experiments on SKD 61 steel and found that MQL has a beneficial effect on burr formation due to less tool wear. On the other hand, Ziberov et al. [155] measured higher top burr heights in Ti6Al4V material with MQL. In dry conditions, the burr was larger on the down-milling side, but at the minimum quantity lubrication, the milling strategies did not show a significant difference in this respect. Biermann and Steiner [111] micro-milled X5CrNi18-10, and showed an increase in the height of the top burr when using MQL, in contrast, flood lubrication and bath lubrication had a positive effect. The MQL has a favourable effect on the surface quality [147, 155].

Aslantas et al. [156] studied a newly designed hybrid cooling lubrication system and based on their experiments on Ti6Al4V, air at − 10 °C showed a favourable effect with minimum quantity lubrication. However, a colder air (− 30 °C) had a negative effect on tool wear and burr formation due to excessive chip formation. As the cutting length increased, no significant change in burr size was found, which can be a significant advantage for micro-milling. In addition, they measured the lowest Ra value at dry machining. According to Kim et al. [152], in the micro-milling of Ti6Al4V, nano-sized diamond grains (35 nm) and cold (− 25 °C, pressure 0.15 MPa) CO2 gas mixed in the minimum quantity lubrication (vegetable oil was the base lubricant) are effective solutions for reducing cutting forces, tool wear, the coefficient of friction and improve the surface quality. While the first three require a lower concentration of “nanodiamond” in the nanofluid (~ 0.1 wt.%), a higher concentration (1.0 wt.%) is required to improve surface roughness. Mittal et al. [5] investigated the effect of different lubricants on the dynamic behaviour of the micro-milling process. A significant improvement in stability limits was observed with lubrication in Ti6Al4V, showing a 20% increase at 100,000 rpm. In addition, a limit speed has been established, below which the process is insensitive, above which it is already sensitive to lubrication.

2.8 Micro-milled workpiece materials

The versatility of micro-milling is demonstrated not only by the complex geometries, but also by the wide range of machinable materials. In this chapter, the most important material characteristics, as well as the special materials and their applicability, are collected.

According to Komatsu et al. [114], smaller grain sizes are required for higher machining accuracy because the grain size is relatively large to the depth of cut in the case of micro-milling. Bissacco et al. [25] also suggested the application of workpieces with small grain sizes, and highlighted the importance of homogeneity of workpieces. According to the research work of Mian et al. [85], if the theoretical chip thickness falls below the cutting edge radius or grain size, the material of the workpiece greatly influences the chip formation, deformation mechanism and flow. Wu et al. [120] analysed micro-machinability of copper and found that forces and specific energy are also higher at smaller grain sizes. This was explained by the fact that the cutting takes place by the movement of the dislocations, which are inhibited at the micro-scale by the grain boundaries. Smaller grain sizes have longer specific grain boundaries, which means a greater inhibitory effect. Based on their results, the effect of grain size is smaller than that of the edge radius.

Micro-machining researches are carried out in a wide range of materials, with a very significant proportion of the research being steels, which is the most widely used metal in the engineering world. For the sake of example, many researchers studied micro-machinability of AISI 1045 (partly as reference material) [4, 38, 46, 77, 88], different stainless steels [43, 84, 114], and also hardened steels [29, 30, 84, 157]. Several researchers have also investigated aluminium micromachining [95, 109, 125, 142]. The Al7075-T6 is widely used in the aerospace industry because its specific material properties are excellent: it has a good volume-to-weight ratio, high strength and toughness and antioxidant [36]. Copper micromachining is also a highly researched field [40, 102, 110, 120]. Inconel 718 [41, 85, 158,159,160], a nickel-based superalloy, has been reported in several publications. It is characterised by a stable structure, high hardness, high deformation resistance, good chemical stability, as well as resistance to heat and corrosion [41]. They are often used in the aerospace industry, pressure vessels, armarioum ocean and pollution control [161]. Hard-to-cut materials can typically be machined at low cutting speeds, but this makes it difficult to reconcile their machining with efficiency and economy [41].

Researchers investigated WCu micro-milling also, which is difficult-to-machine due to its microstructural properties, for example, due to the quality of the material used as an electrode for electrical-discharge machining (EDM) [128]. Many studies are also performed on titanium and its alloys [5, 32, 35, 94], which are typically used in the aerospace industry, space research, biomedical devices, and medicine [32, 35, 40, 162, 163]. It has several favourable properties such as high strength, corrosion resistance and biocompatibility [35, 124], but they belong to the group of difficult-to-cut materials [126]. Ti alloys are poor thermal conductors, poor machinability due to hardening, strong tool wear, and burr formation characterize the micro-milling of these materials [32, 35]. According to Ahmadi et al. [124], the different grain sizes and phases located in the microstructure of Ti6Al4V in micro-milling affect the deformation behaviour of the material significantly. The smaller grain size and the smaller amount of β phase result in higher cutting forces within the alloy. In addition, it was found that the microstructure of the workpiece material also influences the size of the built-up edge: smaller grain size results in a larger built-up edge.

Table 2 summarises and categorises the workpiece materials, which were micro-machined in the reviewed key papers. We kept the standard used in the sources because in some cases, the permissible value of the alloy content differs in the different standards; thus, they cannot be perfectly matched to each other. Figure 9 shows the distribution of the reviewed scientific works from the point of view workpiece material groups.

2.9 Micro-milling process monitoring

The main purpose of process monitoring is to monitor changes of the cutting process and/or monitor the condition of the cutting tool in order to increase quality, efficiency or tool life [268]. Through its application, it is possible to prevent the changes with a negative effect. Process monitoring can be done online (in process) or offline, the former in real-time and the latter between cutting operations. Certain characteristics can be monitored in-process, such as cutting force, vibrations, power, torque, cutting temperature, and so on. Offline measurable parameters include tool wear, dimensional tolerance, surface roughness, delamination, micro-cracks etc.

As both process and quality characteristics are strongly influenced by tool wear, it is highly recommended to monitor it, which can be conducted based on the following two main measurement methods [269, 270]: (i) Direct measurement of tool wear: in this case, the wear of the tool can be measured directly (often optically). Its main disadvantage is that there is no cutting during the measurement (offline), which increases the total operation time. (ii) In the case of indirect measurement, the current state of the tool can be inferred from other process characteristics. In this case, the measurement of forces, vibrations, acoustic emissions [227] and the monitoring of their changes provide important information (indirect but online). In conventional-scale milling, tool wear has been studied in many studies, mainly using indirect measurement methods, like measuring vibration, acoustic emission, and force signals. Intelligent approaches can be used to process these data, such as neural networks and clustering [271, 272], adaptive resonance networks, and self-organising maps [227].

Zhu and Yu [27] presented a novel image processing based method for monitoring tool wear. It takes into account the wear pattern of the entire tool, through that it better reflects the condition of the tool than the traditional tool wear metrics, where only a width value is given. The current literature mainly uses the latter as a tool wear criterion. In the case of micro-milling, the wear of the cutting edges will often be different due to the different load. The effectiveness of the method presented by Zhu and Yu was also supported experimentally. Compared to other image processing methods, the presented technique reduces distortions caused by image background and noise.

According to Malekian et al. [273], accurate monitoring of machining typically requires three harmonic signals. In addition to the dynamometer’s signal, it is advisable to use accelerometers and/or acoustic emission sensors due to the significantly larger frequency range available. In conventional-sized milling, the size of flank wear is measured usually. Due to the nature and difficult-to-measure wear in the case of micro-milling, the authors measured the corner radius. Neuro-Fuzzy logic was used to analyse the signals of the process, and it was found that the combined analysis of the signals of the three sensors leads to the most accurate result. The model presented by the authors is suitable for monitoring micro-milling tools and for transmitting warnings to the machine operator, thus minimising tool breakage and exceeding the tolerance of the part.

Zhu et al. [227] used the hidden Markov model to monitor the condition of the tool. The authors used the average clearance wear on each edge to rate the wear condition. The authors recommend the use of the Noisy-robust hidden Markov model to monitor the condition of the tool. The efficiency of their method is 92.5% in copper and 90.5% in steel.

Jemielniak and Arrazola [187] chose to measure clearance wear to monitor tool condition. Due to the varying load on the tool, the cutting forces must change periodically. If the tool run-out does not take into account, the dominant frequency will be the impact frequency of the cutting edges; otherwise, it will correspond to the spindle speed. When comparing the force signals and the acoustic emission (AE) signals, a difference in the dominant frequencies was found. The latter shows 1207 Hz, and the results of the force measurement show 4828 Hz, which is the fourth harmonic of the impact frequency of the edges, and it is close to the natural frequency of the force measuring platform (5080 Hz). According to the authors, the unfiltered, raw signal can also be used for monitoring applications, as the relationship between the characteristics of the force signal and the wear is important and not their specific values. Uncertainties can be reduced and minimised by simultaneously recording and analysing the signals of multiple sensors. The use of these two sensors has led to good results. In contrast, the signal from the much cheaper, easy-to-install AE sensor produced less accurate but acceptable results.

One of the main problems of micro-milling is the premature failure of cutting tools. To predict tool life, Dai and Zhu [55] presented an automated machine vision system. In the captured images, the tool can be in any positions, and the algorithm can evaluate it correctly. This is based on the fact that the size of the tool (which perpendicular to the cutting edges of the tool) does not change. The image processing method is based on the characteristics of micro-milling, with the exception of the progressive wear phase. In order to predict the wear status of the tool, in addition to flank wear, a wear land area is recommended. When the tool arrived at the stage judged to be worn or experienced abnormal behaviour, they intervened in the process and reduced the feed. They highlighted that they did not encounter any accidental tool failure during their investigations.

Jáuregui et al. [54] dealt with tool monitoring through the analysis of force and vibration signals. Fast Fourier transformation and continuous wavelet transformation (CWT) were used for the investigations. The analysis of process-specific frequencies was based on the impact frequency of the cutting edges (IPF). For a tool in a good condition, the harmonic and non-harmonic components are displayed at the nominal frequency 1xIPF, 2xIPF, 3xIPF and 0.5xIPF, 1.5xIPF, 2.5xIPF. However, with a worn tool, those harmonic frequencies appear that are not exact fractions of the IPF. It was found that in the case of a tool in a good condition, the harmonic and non-harmonic frequencies are present at the nominal value, while in the case of a worn tool, the characteristic frequencies are different or missing. As the wear progressed, the appearance of new frequencies in the vibration signal was observed. FFTs made from force amplitudes did not provide any convincing evidence that they could be used as an indicator of tool wear. Similarly, the study of the effects at nonlinear levels by CWT analysis does not provide any evidence for a correlation of phenomena.

The main process control methods and monitored characteristics often used in micro-milling are summarised in Table 3.

3 Micro-milling tools and coatings

In this section, cutting tool geometries and coatings for micro-milling are reviewed and discussed. Micro-milling tools are geometrically similar to those used in conventional sizes, but often show different behaviour in terms of the cutting process. The key dimensions of the micro-cutting tools are often in the same order of magnitude as the key dimensions of the chip removal or burr formation processes, as it was discussed earlier. The micro-cutting tool is relatively slender, which often results in a difficult-to-estimate process, high vibrations and short tool life. Figure 10 summarises the micro-milling cutting tool types which are often used in scientific works or used by the industry.

End mills are widely used in micro sizes [4, 133, 144, 216], the geometry of which is similar to those used in macro-sizes. Commercially one- (Fig. 10a), two- (Fig. 10b) or multi-fluted versions are available. It is important to highlight that a higher number of cutting edges often drastically reduce the stiffness of the cutting tool, therefore, the lower number of cutting edges is recommended for micro-milling. Nevertheless, higher number of tool edges may increase the material removal rate (MMR) significantly. These type of the tools are suitable to produce structures with quasi-sharp corners. However, this geometry has many challenges: the corner starts to round relatively soon due to the wear, which results in significant changes in the tool geometry, in the process and in the produced microstructures. The single-fluted geometries are often made of artificial diamond [204, 255], which can result in a very sharp cutting edge; however, it often causes higher vibrations [109, 140].

Figure 10c shows a schematic of a micro flat end mill with a corner radius. Recently, this design is very common as it provides increased edge stability. The corner radius is much more resistant to wear compared to the previous designs. Furthermore, these milling tools can produce complex 3D curved surfaces. In addition, this construction can be used with increased feed rates in the case of smaller depth of cut values. In this scenario, the main cutting edge angle is smaller, which results in the chip thinning phenomena. Due to the radius, there is an increased axial force component, which causes less bending-directional deformation in the tool than the cutting force, and also could be suitable to reduce the vibration [42].

Figure 10d shows the schematic of a ball-end micro mill, which is also commonly found in the scientific literature [174, 184, 255, 276]. This type is especially suitable to produce complex 3D geometries. However, it also has difficulties, e.g. when machining flat surfaces the cutting speed is very small near the tool centre point (TCP), and the minimum chip thickness problem comes to view due to the chip thinning phenomena. However, these difficulties can be solved partly with the use of push-milling or pull-milling strategies; although, it requires a more complex (4 or 5-axis) machining centre, which is extremely cost consuming.

The tapered micro-milling tools (Fig. 10e) are also applied widely, which is suitable to reduce the burr formation [109]. In addition, there are many papers, where tailored micro-tools are used for the optimisation of the process [108, 217].

According to Aramcharoen and Mativenga [72], the geometry of the cutting edge plays a major role in terms of surface quality and burr formation in micro-milling. For better surface quality, rounded cutting edges or chamfered geometries are preferred. Afazov et al. [119] studied the effect of the rake angle on AISI 4340 steel. Higher forces and lower stability limits were observed at rake angle of γ = 0° than at γ = 8°. Based on the micro-milling studies in 42NiCrMo16, conducted by Gilbin et al. [29], it was found that the edge geometry of micro-mills has a greater role in wear resistance than in the quality of the machined part. In contrast to macro-milling, a rake angle of γ = 0° is advantageous in decreasing tool wear, while its negative effect on the cutting forces is not significant. Based on the micro-milling experiments performed by Oliaeia and Karpat [149] in a modified AISI 420 steel, the interaction between the tool wear and the cutting speed is clearly visible, which is one of the main factors followed by feed per tooth. Tool wear is one of the most significant limitations of the micro-milling process, as it is almost unpredictable and also affects dimensions, surface quality, and tool life [192]. For this reason, the subject of many scientific researches is the examination of the geometry of milling tools and the increase of their performance. Uhlmann et al. [220] attached great importance to edge preparation in the production of micro-mills. Their studies were shown that immersed tumbling can achieve better results than polishing and polish blasting methods. Immersed tumbling on grade 2 titanium reduced active forces from 7.5 N to 4 N, while average surface roughness (Ra) increased to 0.67 μm from 0.53 μm. Tools prepared with this method were also tested in micro-machining of X13NiMnCuAl4-2-1-1. According to the authors, edge preparation can stabilise the cutting edge and reduce tool wear. Larger cutting edge radius led to longer tool life. The active forces were almost the same for the prepared and un-prepared tools, their fluctuation decreased to rβ = 2.9 μm, and then started to slightly increase [146]. The authors also studied tool wear on Böhler M261 material quality. During preparation, processing time was found to be the main factor in forming the cutting edge radius. No crater-wear-tendency was found for the geometries developed with the new method. The prepared tools showed a 14% lower tendency to clearance wear compared to the unprepared ones, while the variance of the results was reduced by 92% [87].

Micro cutting tools are often coated because coating has many positive effects on the machining process characteristics, like increasing tool life or reducing cutting force and vibrations. However, the application of coating increases the edge radius of the cutting tool, which is often not allowed because it may increase the ploughing effect and the cutting force, thus decreases tool life. Aramcharoen et al. [2] analysed the influences of different coatings on tool wear in a very fine-grained AISI H13. They showed that TiN, TiCN, TiAlN, CrN, and CrTiAlN coatings help to reduce edge chipping and increase edge rounding compared to uncoated ultrafine carbide milling cutter. The TiN and CrTiAlN coatings are suitable for reducing flank wear. Based on their studies, the TiN coating showed the best performance in terms of tool wear, machined surface and burr formation. Furthermore, TiN has the lowest hardness and the best adhesion. Aslantas et al. [94] analysed the tool wear of nanocrystalline diamond, TiN, AlCrN coated tools in Ti6Al4V. In their work, abrasive wear was found to be significant, and edge chipping and built-up edge formation were also observed. Each analysed coating reduced the resulting burr sizes compared to the uncoated tools. The TiN and AlCrN coatings showed less wear, diameter changes and burrs than it was observable by using a nanocrystalline diamond or an uncoated tool. De Cristofaro et al. [192] investigated seven different novel coatings (multilayer chromium, titanium coating, single-layer nanostructured silicon, chromium, and single-layer nanostructured coating with small, medium, and large amounts of silicon) in micro-milling of 1.2842 (62 HRC). The single-layer, nanostructured and low-silicon coating was found the best: this coating seemed to suitable for reducing wear while increasing productivity and reliability, as well as creating a sharp cutting edge. Swain et al. [79] performed micro-milling experiments on Nimonic 75 (40–41 HRC). They found that the typical failure modes of tool are the flank wear, the chipping of the tool tip and then chipping the edge. In the case of the 2 μm thick nanostructured TiAlN coating, the outstanding performance was observed in terms of wear, diameter reduction and surface integrity compared to the uncoated tool. It was found that the increase of the cutting speed resulted in an increase of the flank wear, in each coated and uncoated tools.

Hao et al. [257] designed and fabricated polycrystalline diamond (PCD) micro ball-end mills in order to achieve high quality when machining micro-lens array of cemented carbide. Since the diamond is very sensitive to the vibrations, the authors calculated the excitation frequency which related to the milling kinematics and to the number of the cutting edges. Moreover, modal analysis was conducted, and the natural frequencies (up to six order) were calculated. Based on their investigations, a critical overhanging length was determined for the specified cutting circumstances. Jiao and Cheng [263] used CVD diamond coated micro ball-end mills for micro-milling of polymethyl methacrylate components with a very small surface roughness (nanometric). Four different milling strategies were studied, and it was found that those ones, which are suitable for groove-milling, are not necessarily the best choice for preparing larger areas (2 x 2 mm) because the dynamics of the process also plays a significant role. When machining larger areas, optical surfaces can be achieved by joining up-milling and down-milling strategies. However, the step-over was found as the most significant factor that is affecting the surface roughness. Hao et al. [277] studied the fabrication methods for PCD micro-milling tools with a large aspect ratio. The authors proposed a fabrication method which is combined the pulsed nanosecond and picosecond laser with precision grinding. The micro tool fabricated was compared with a cemented carbide tool through micro-milling experiments. The PCD tool produced smaller surface roughness and forces, while the wear of the tool was smaller at machining a deep-narrow-slot in an oxygen-free copper. Oliaei and Karpat [108] investigated the formation of a predictable, stable built-up edge on Ti6Al4V. As this can increase the tool life, it can be especially important, when machining micro moulding tools. Based on their tests, the built-up edge resulted in higher cutting force and improved the surface quality. Based on their studies, the small clearance angle resulted in the most stable conditions in built-up edge formation, and based on their observations, the performance of custom (tailored) tools is acceptable. Nevertheless, it has to be pointed out that a built-up edge formation is recommended to be avoided because it is extremely difficult to control its formation (to stabilise it) and influence.

Tool wear is primarily affected by tool edge geometry and coating type; however, the effect of primary technological parameters is also significant [180, 214]. Kuram and Ozcelik [35] investigated the effect of milling strategies on tool wear on TiAl4V6 material. At low feed rates (vf = 75 mm/min), increasing the rotation speed (12,000–28,000 rpm) at the down-milling and zig-zag paths reduced tool wear, but the up-milling had a negative effect on the tool wear. At high feed rates (vf = 150 mm/min), higher the spindle speed increased the tool wear for all the three strategies, resulting in better surface quality and smaller Fx and Fy forces. Up-milling is proposed in the case of low feed rates and high spindle speeds, and down-milling is more favourable in high feed and spindle speed. Oliaeia and Karpat [149] conducted pocket milling experiments on a Stavax stainless steel (25 HRC) with different cutting parameters. They found that the cutting speed has the most significant effect on tool wear, followed by the feed, depth of cut and cutting width, respectively. According to Aurich et al. [40], tilting the cutting tool may be advantageous, since in this case, the end of the tool is in a contact with only the bottom of the groove for a short length, which may result in reduced tool wear.

Chi-Hsiang et al. [185] investigated the micro-milling process using 2D finite element simulations on SKD61 material. Based on their simulation results, temperature and cutting force have the most significant effect on the condition of the cutting edge, which are important criteria for improving the performance of the tools. Based on their study, the rake angle has the largest effect on complex quality characteristics (37.80% contribution based on ANOVA), so it should be an important consideration in tool design. The optimal micro-milling design parameters were defined in γ = 20 °, α = 7 °, and the cutting parameters in vc = 11.31 m/min and ap = 0.01 mm. Under these conditions, the average cutting length of the tools was lc = 299 mm.

4 Micro-milling modelling

Sufficiently accurate modelling of the micro-milling processes is of great importance because cutting force, cutting temperature, crack propagation, surface roughness, tool wear or tool breakage etc. can be estimated without numerous experimental work, which is often time and cost consuming. The micro-milling process was modelled and simulated by the researchers using (i) analytical models [78, 148, 239], (ii) numerical models [117, 191, 249], (iii) regression analysis [42, 171] or (iv) response surface methodology [200, 201, 205]. Table 4 summarises the key scientific studies from the past five years in the topic of modelling of the micro-milling process.

According to de Oliveira et al. [46], the behaviour of the specific cutting force at micro-sizes is much more sensitive to cutting conditions than the models set up by Taylor and Kienzle, which consider only the feed per tooth. The method proposed by the authors also takes the depth of cut into account. They also proved that the constants of macro-sized models cannot be directly adapted to micro-sizes. Biró and Szalay [171] extended the empirical specific cutting force model to the region of thin chip removal, and identified a new breakpoint in the region of the micro-chip removal.

Zhang et al. [148] presented a novel analytical cutting force model and a model estimating the instantaneous tool deformation. The run-out of the tool is taken into account, which includes differences originating form axial and tilt offset, the trochoidal trajectory and the different tool entry and exit angles. In addition, the size effect was also taken into consideration as a factor, with shear and ploughing dominant parts separated. During the validation of the results in Al6061-T6, a good agreement was found in a wide range of cutting parameters. The presented model is promising for monitoring the micro-milling process and for its adaptive control. In an advanced micro-milling force model, Afazov et al. [119] proposed to consider tool run-out, edge radius, cutting speed, tool helix and rake angle, and workpiece preheating.