Abstract

This work aims to develop the herbal oil-incorporated nanostructure mats with antifungal activity for the prevention and treatment of Candida-associated denture stomatitis. The nanofiber mats loaded with betel oil or clove oil were fabricated via electrospinning process. The morphologies and physicochemical properties of the herbal oil loaded nanofiber mats were examined using scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FT-IR), differential scanning calorimetry (DSC), and mechanical testing. The release characteristic, antifungal activity, and cytotoxicity were also investigated. The SEM images confirmed the homogeneous and smooth nanoscale fibers. The addition of the herbal oil into the nanofiber mats reduced the fiber diameters. The DSC and FT-IR results confirmed the presence of the oil in the nanofiber mats. The herbal oils can be released from the mats in a very fast manner and inhibit the growth of candida cells within only few minutes after contact. These nanofiber mats may be beneficial for the prevention and treatment of denture stomatitis.

Similar content being viewed by others

INTRODUCTION

Even though there has been great medical advancement, the increment in the prevalence of the opportunistic oral fungal infection has been observed, especially in denture wearers. Poor oral hygiene and several systemic factors are the most probable initial causes of this infection (1).The oral fungal infection induced by wearing denture with inflammation and erythema of the oral mucosal areas covered by the denture can be defined as denture stomatitis (2–4). Poor denture and oral hygiene are believed to be critical risk factors for denture stomatitis. In addition to poor hygiene, unceasing denture wearing can boost opportunistic overgrowth of pathogenic yeasts, such as Candida (2). Candida albicans is a commensal of the microbial communities of the human oral cavity, and it has been shown to be the dominant strain responsible for oral candidiasis and Candida-associated denture stomatitis (2). Maintaining good oral and denture hygiene and balancing the oral microflora could help to prevent denture stomatitis.

Natural products as traditional therapeutics are in considerable demand, as they are comprehended to have minimal side effect on humans (5). Recently, a variety of herbal products are encouraged for oral and dental uses as alternative to standard commercial products. Some herbal compounds have effective antimicrobial effects, and many herbal components such as chamomile, clove oil, echinacea, eucalyptus, ginger, etc. are included in herbal oral products (6). Piper betle Linn. (betel) is a tropical plant closely related to the common pepper. It is a traditional herb that has been used as mouthwash, dental medicine, cough medicine, astringent, tonic, and others. The extract of betel leaves has been reported to demonstrate antioxidative, antiinflammatory, antibacterial, and antifungal activities (7–9). Another plant is Syzygium aromaticum (clove) which is one of the interesting plants with antifungal activity. The clove oil from S. aromaticum and eugenol are wildly used in dental medicine because they exhibit useful antiseptic, analgesic, and anaesthetic effects (10,11). Some research studies have reported antifungal activity of clove oil and eugenol against several yeasts and fungi (10–13). Clove oil and eugenol have also been evaluated as antifungal agents in animal models (14).

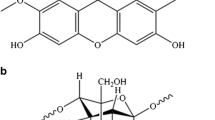

In the recent past, new tactics for drug delivery have gained much attention. The considerable advantages of fast dissolving drug delivery systems such as enhanced drug solubility, onset of action, and bioavailability make this system more fascinating (15,16) However, the selection of appropriate polymer that can dissolve rapidly and easily is required to accomplish the fast dissolution. Polyvinylpyrrolidone (PVP) is one of the desirable polymers that can provide these features; it is capable of ultrafast dissolution. Cyclodextrins (CDs) are cyclic oligosaccharides consisting of 1,4-linked glucopyranoside units having either six, seven, or eight glucose units arranged in a cyclic structure with a hydrophilic outer surface and a lipophilic central cavity which suit for a variety of lipophilic drugs (17,18). Because the physicochemical properties of incorporated compounds can be oriented by complexation with CDs, the CDs are employed in many application fields, such as pharmaceuticals, foods, cosmetics, home/personal care, textiles, and so on (18,19).

Recent advances in nanotechnology and increasing recognition of the potential of nanomaterials in many fields of application lead to a surging interest in the fabrication and development of nanofibrous scaffolds. Nanofiber materials demonstrate outstanding characteristics such as low density, high porosity, large specific surface areas, and very small pore sizes. They have been applied in many areas (tissue engineering, drug delivery systems, wound dressing, filtration, etc.) (20–22) One of the marvelous methods that can be used to generate nanofibers is electrospinning. Electrospinning is a process that uses an electric field to control the formation and generation of polymers. This process is remarkably efficient, rapid, and inexpensive (23).

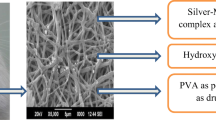

Until now, there are only a limited number of studies that investigate the incorporation of volatile oil into the nanofiber. We have successfully incorporated plain oil-CDs inclusion complex into electrospun fibers for topical application (18). In this study, the betel oil or clove oil was incorporated into the PVP nanofiber mats using electrospinning process with the assistance of CDs. The morphology and structure as well as physicochemical properties of the PVP/HPβCD nanofiber and herbal oil loaded PVP/HPβCD nanofiber were investigated. Moreover, the release of the oil from the nanofiber mats, antifungal activity against oral fungi, and cytotoxicity was also evaluated.

MATERIALS AND METHODS

Materials

Polyvinylpyrrolidone (PVP, MW. ∼1,300,000) and 2-hydroxypropyl-β-cyclodextrin (HPβCD) were purchased from Sigma-Chemical Co. (St. Louis, MO, USA). Betel oil and clove oil were obtained from the Thai China Flavours and Fragrances Industry Co., Ltd., Thailand. Sabouraud dextrose broth was purchased from Becton, Dickinson and Company (Franklin Lakes, NJ, USA). All other reagents were used without further purification. Artificial saliva was composed of 2.38 g Na2HPO4, 0.19 g KH2PO4, and 8 g of NaCl per liter of distilled water adjusted with the phosphoric acid to pH 6.8 ± 0.05. Human gingival fibroblast cells (HGF) obtained from explants of gingival tissue attached to non-carious, freshly extracted third molars from three patients. All patients provided informed consent before tissue collection. Ethical approval for the study was obtained from Naresuan University.

Fabrication of Nanostructured Mats

The polymer solutions were prepared by dissolution of PVP in 50:50 volume ratio of ethanol to water mixture at the concentration of 8% (by weight). After which, varied amounts of HPβCD (90–190 mM) were added to the polymer solutions. The polymer solutions were stirred using a magnetic stirrer for several hours until homogenous solutions were obtained. The solutions were spun into a nanofiber using electrospinning process at room temperature. In this process, the spinning solution was placed in a 5-ml glass syringe connected to a stainless steel needle with a 0.9-mm inner diameter. The needle was connected to an emitting electrode with a positive polarity of a Gamma High Voltage Research device. The electrospinning process was conducted with a fixed applied voltage of 15 kV, a distance between the tip and the collector of 15 cm, and a feeding rate of 0.4 ml/h. The electrospun nanofibers were collected on an aluminum foil covering the rotating collector.

Fabrication of Herbal Oil Loaded Nanofiber Mats

To fabricate the herbal oil loaded nanofibers, betel oil or clove oil (20–40% weight to polymers) was added to the polymer solution containing 150 mM HPβCD. The mixtures were stirred for 24 h to allow the oil incorporate into the HPβCD. After which, the mixtures underwent electrospinning process as previously mentioned to obtain the herbal oil loaded nanofiber mats. The content of the oils from the betel oil or clove oil loaded nanofiber mats was determined to select the suitable percentage to be incorporated.

Characterization of the Nanofibers

Scanning Electron Microscope

The morphological appearances and diameters of the nanofiber mats were observed (3000×) using a scanning electron microscope (SEM, Camscan M×2000, England). Samples were prepared by cutting the nanofiber and attaching them on aluminum stubs. After that, the samples were then gold sputtering coated before the SEM observations. The average diameters of the fibers were analyzed using an image analysis software (JMicroVision V.1.2.7, Switzerland).

Fourier Transform Infrared Spectrophotometry

The Fourier transform infrared spectroscopy was carried out using a Fourier transform infrared spectrophotometer (FT-IR, Nicolet 4700, USA) with a wave number range of 400–4000 cm−1 to confirm the incorporation of the herbal oil in the nanofiber mats. The fiber samples were ground and pressed into KBr dishes prior to the FT-IR analysis. The used resolution and number of scans were 4 and 32, respectively.

Differential Scanning Calorimetry

A differential scanning calorimeter (Pyris Diamond DSC, PerkinElmer instrument, USA) was used to determine the thermal behavior of the herbal oil loaded nanofiber mats. The experiments were conducted using dry samples, under nitrogen flow, weighing approximately 5 mg. The DSC traces were recorded from 50 to 250°C at 10°C/min.

Mechanical Characterizations

Tensile testing of the nanofiber was investigated using a texture analyzer (TA.XT plus, Stable Micro Systems, UK) by applying a 5-kg load cell equipped with tensile grip holder. All samples were cut into rectangle shapes with dimensions of 25 × 5 mm2.

Ex vivo Mucoadhesion Assay

The ex vivo mucoadhesive study was performed according to a previous study (24). Mucoadhesive force of nanofiber mats onto porcine buccal mucosa were performed using a texture analyzer (TA.XT plus, Stable Micro Systems, UK) equipped with a 5-kg load cell. The porcine cheek pouches were employed as the model surface for the mucoadhesion assay. After the cheek pouches were excised and trimmed in a regular way, they were rinsed with simulated saliva and then used right away. The nanofiber mats were cut into circular shapes with a diameter of 13.7 cm and then fixed to a cylindrical Perspex support (diameter 2 cm, length 4 cm, surface area 3.14 cm2) using a double-sided adhesive tape. During the experiment, 500 μL of artificial saliva was dispersed on the surface of the tissue. The probe moved down at a speed of 2 mm s−1 until it contacted the tissue at a force of 0.3 N for a contact time of 15 s.

Determination of the Oil Content

The total amounts of the oil incorporated in the nanofiber mats were quantified in triplicate using UV-visible spectrophotometer (Agilent G1103A UV-Vis Spectrophotometer, Agilent Technologies, USA) at 279 mm. Accurately weighed samples (10 mg) of the fiber mats were dissolved in 1 ml of ethanol and were continuously shaken in an incubator (Orbital Shaking Incubator Model: SI4) at 150 rpm for 24 h. The experiments were performed in triplicate. The loading capacity was calculated according to Eq. (1):

where Pt is the amount of oil (μg) embedded in the nanofiber mats and Mt is the weight of nanofiber mats (mg).

In vitro Release

The in vitro release studies were adapted from those of Singh et al. (25). Briefly, 10 mg of the herbal oil loaded nanofiber mats was placed in a 50-ml bottle containing 20 ml of artificial saliva (pH 6.8) that was incubated at 37°C and shaken at 150 rpm. To determine the amount of the oil released from the fiber mats after a given interval, an aliquot (1.0 ml) of the release medium solution was withdrawn and replaced with the same volume of fresh medium to maintain a constant volume. The amounts of oil in the sample solutions were analyzed by UV-visible spectrophotometer (Agilent G1103A UV-Vis Spectrophotometer, Agilent Technologies, USA). The experiments were conducted in triplicate.

Antifungal Activities

Candida Strains and Inoculum Preparation

The ATCC 90028 strain of oral C. albicans was used in this study. Sabouraud dextrose broth (SDB) was used to revive the culture. An active culture was prepared by inoculating fresh nutrient broth medium with a loop full of cells from stock cultures at 37°C overnight. The candida suspensions were diluted in SDB and spectrophotometrically standardized to 1 × 106 CFU/ml (Perkin Elmer Lambda 2, Germany).

Antifungal Activity of Betel Oil and Clove Oil

The antifungal activity of betel oil and clove oil were determined via assessing susceptibility of C. albicans toward the oils using broth microdilution assay in accordance with the guidelines recommended by the CLSI (Clinical and Laboratory Standards Institute, 2002). Briefly, C. albicans were incubated (104 CFU/ml) in 48-well plates for 24 h at 37°C after being exposed to serial twofold dilutions of the herbal oil in SDB culture medium (from 100 to 0.05 μL/ml). The results were expressed as the minimum inhibitory concentration (MIC) and minimum fungicidal concentration (MFC) toward Candida cells.

Time-kill Curve Studies

The time-kill analyses were performed as previously described protocol (26) using SDB. Ten microliters of the adjusted inoculum suspension (approximately 1 × 106 CFU/ml) was dispensed into a plastic Eppendorf tube containing 1 ml of SDB, providing the starting inoculum of approximately 1 × 104 CFU/ml. The samples of the herbal oil loaded nanofiber mats with varied oil were incubated with Candida suspensions under agitation at 37°C. After the predetermined contact times (5, 15, 30, 60, and 120 min), small aliquots of the samples were removed, and the microorganisms were counted by spreading each sample onto an SDA agar plate. The plates were incubated for 24 h, and the viable colonies were counted. The kill curves were constructed by plotting the CFU/ml surviving at each time point in the presence and absence of the nanofiber mats.

In vitro Cytotoxicity

The HGF cells obtained from explants of gingival tissue attached to non-carious, freshly extracted third molars from three patients were used to examine the compatibility of the blank nanofiber mats and herbal oil loaded nanofiber mats. The cytotoxicity tests were performed based on a procedure adapted from the ISO10993-5 standard testing method (indirect contact). The HGF cells were cultured in DMEM medium supplemented with 10% FBS, 2 mM l-glutamine, 1% non-essential amino acids, and 0.1% penicillin-streptomycin at 37°C in humidified 5% CO2 atmosphere. The cells were seed at a density of 10,000 cells/well in 96-well plates for 24 h before sample treatment. The nanofibers were sterilized using UV radiation for 45 min before being immersed in a serum-free medium (SFM; containing DMEM, 1% l-glutamine, 1% lactalbumin, and 1% antibiotic and antimycotic formulation) and incubated for 24 h to produce extraction media with varying concentrations. The extraction media at varying concentrations were replaced, and the cells were re-incubated for 2 and 24 h. After treatment, the tested extraction solutions were removed, and the cytotoxicity was determined by MTT assay. The relative viability (%) was calculated based on the absorbance at 550 nm determined using a microplate reader (Universal Microplate Analyzer, Model AOPUS01 and AI53601, Packard BioScience, CT, USA). The viability of non-treated control cells was defined as 100%.

Statistical Analysis

All experimental measurements were collected in triplicate. The values are expressed as the mean ± standard deviation (SD). The statistical significance of the differences in each experiment was examined using one-way analysis of variance (ANOVA), followed by a least significant difference (LSD) post hoc test. The differences were significant at p < 0.05.

RESULTS AND DISCUSSION

Fabrication of Betel Oil or Clove Oil Loaded Nanofiber Mats

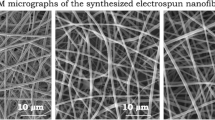

To fabricate the nanofiber, the amounts of HPβCD were varied in the range of 90–190 mM because adding the HPβCD could help in reducing the hygroscopic property of PVP. In addition, HPβCD could entrap the medicinal oil and increase the solubility of the oil (18). Figure 1 shows the SEM images of the PVP nanofiber mats containing different amount of HPβCD. The nanofiber mats had a smooth surface without bead. Increasing the amounts of HPβCD resulted in the increase in diameters of the nanofiber mats. The diameters of the nanofibers containing 90 to 190 mM HPβCD were in the range of 394.40 ± 45.17 to 496.07 ± 125.65 nm. The nanofiber mat with 150 mM was selected for further investigation because this is the highest amount of HPβCD that can be loaded into the nanofibers with good physical textures.

After known the appropriate amount of HPβCD to be used, the amount of oils was varied from 20 to 40% weight to polymer. The 8% w/v PVP/150 mM HPβCD solution containing various amounts of betel oil or clove oil (containing 20, 30 and 40 wt% to polymer) was prepared, and the betel oil or clove oil loaded nanofiber mats were successfully fabricated. The loading capacity of these betel oil or clove oil loaded nanofiber mats were determined and were presented in Fig. 2. It can be seen from the results that after increasing the amount of oil from 20 to 30%, the loading capacity values increased. The 30% betel oil loaded nanofiber mats and the 30% clove oil loaded nanofiber mats demonstrated the highest loading capacity. The increase in amount of the oil loading from 30 to 40% resulted in the decrease in the amount of betel oil or clove oil entrapped in the nanofiber mats. This may be due to the capacity of nanofiber mats that can carry the oils with the maximum amount at 30%. There were some variations in the loading capacity between both oils. The results revealed that 30% betel oil loaded mats showed higher loading capacity than 30% clove oil loaded mat (Table I). This may be due to the difference in composition and properties of these oils (27,28). Thus, 30% betel oil and 30% clove oil were selected to be incorporated into the nanofiber mats for further investigations.

The SEM images of the blank PVP/HPβCD, 30% betel oil-loaded, and 30% clove oil loaded nanofiber mats are illustrated in Fig. 3. The SEM images revealed bead-free and smooth fibers without delamination or phase separation of the oils from the nanofiber mats which confirmed the interaction of the oil with the polymer. The addition of the oils into the nanofiber reduced the fiber diameters. The HPβCD added into the polymer solution could entrap the oil into it and help protect the polymer from melting (18). The diameters of the oil loaded fibers were in the range of 396.56 ± 65.31 to 425.89 ± 82.28 nm.

FT-IR Analysis

The FT-IR spectra of PVP, HPβCD, betel oil, clove oil, PVP/HPβCD nanofiber mats, betel oil loaded nanofiber mats and clove oil loaded nanofiber mats are shown in Fig. 4. The spectrum of PVP presented peaks at 3452.2 , 2926.5, 1663.4, 1415.7, and 1290.1 cm−1 that were attributed to N–H, CH2, C=O, C–N stretching vibration, and C–H bending, respectively (29). The peaks at 3423.7, 2915.4, 1167.8, and 1083.7 of the HPβCD spectrum corresponded to O–H, C–H, C–H, and C–O stretching vibrations, respectively (30). The pure PVP/HPβCD nanofiber mats exhibited absorption peaks as observed in the spectra of PVP and HPβCD. The spectrum of betel oil and clove oil exhibited absorption peaks at 3514.0, 3077.1, and 2932.3 cm−1 that were attributed to O–H, =C–H, and C–H stretching, respectively (31). The bands at 1602.4 and 1510.8 corresponded to aromatic C=C stretching (32). The spectrum of betel oil and clove oil loaded nanofiber mats displayed all features of the peaks that were observed in the spectrum of PVP/HPβCD, betel oil, and clove oil. It seems to be the evidence for the present of the herbal oil in the nanofiber mats. Especially, the bands of aromatic C=C stretching of the betel oil and clove oil spectra that were generally not observed in the spectrum of PVP/HPβCD were found in the spectrum of betel oil and clove oil loaded nanofiber mats.

Differential Scanning Calorimetry

Differential scanning calorimetry (DSC) studies were carried out to investigate the thermal behavior of the betel oil and clove oil in the electrospun nanofiber mats, and the thermograms are displayed in Fig. 5. Pure betel oil and pure clove oil exhibited endothermic peaks related to the process of evaporation at 216.1 and 233.4°C, respectively. The thermograms of the blank nanofiber mats and the betel oil or clove oil loaded nanofiber mats were quite similar. This indicated that the incorporation of betel oil and clove oil into the nanofiber mats did not affect the thermal properties of the nanofiber mats.

Mechanical Properties

The mechanical properties in terms of Young’s modulus of the PVP/HPβCD nanofiber mats with and without the herbal oils loading were determined using a texture analyzer, and the results are displayed in Table I. The Young’s modulus values of all tested nanofiber mats were in the range of 0.69–3.58 MPa. Adding the oil into the nanofiber did not have negative effect on the tensile strength of the nanofiber mats, but it improved the mechanical properties of the mats. The 30% betel oil loaded nanofiber mats demonstrated the highest value of Young’s modulus.

Ex vivo Mucoadhesion Assay

The ex vivo mucoadhesion studies were carried out to evaluate the ability of the mats to adhere to the mucous within the mouth. The results of the mucoadhesion assay are listed in Table I. The mucoadhesive strengths of all nanofiber mats were in the range of 26–34 mg. The loading of the herbal oils into the nanofiber did not diminish the mild mucoadhesion property of PVP polymer. On the other hand, the mucoadhesion values rose a little after the herbal oils were incorporated. Thus, these herbal oils can be incorporated in the nanofiber mats without any negative effects on the mucoadhesion property of PVP.

In vitro Release

The release characteristics of the herbal oil loaded nanofiber mats are presented in Fig. 6. It is clearly observed from the release profiles that both betel oil and clove oil displayed very fast release from the nanofiber mats followed by gradual release. Almost 50% of the betel and clove oil that was incorporated in the nanofiber mats released to the release medium within 1 min. This is due to the very fast dissolving property of PVP polymer (26). The betel oil loaded nanofiber mats and the clove oil loaded nanofiber mats exhibited quite similar release patterns except that the betel oil loaded nanofiber mats had faster release rate in the initial period. This might be due to the high loading amount of betel oil in the nanofiber mats.

Antifungal Studies

The susceptibility testing of betel oil and clove oil was performed using a broth dilution assay to determine MIC and MFC values against C. albicans ATCC 90028. Betel oil and clove oil were strongly active against C. albicans with MIC values of 0.781 and 0.049 μg/ml and the MFC values of 0.781 and 0.092 μg/ml, respectively.

Time-kill analyses were performed to evaluate the antifungal activity of the herbal oil loaded nanofiber mats by determining the exposure time required to kill standardized microbial inoculums. The time-kill plots of nanofiber mats containing betel oil or clove oil and the control sample are displayed in Fig. 7. As compared to the control sample, the nanofiber mats loaded with betel oil or clove oil can inhibit the growth of candida cell after contact with only few minutes. The betel oil loaded nanofibers started inhibiting the Candida cells since 5 min after contact. The very fast dissolving property of PVP polymer resulted in very fast release of the oils from the nanofiber mats and inhibited the Candida cells. Previous study reported that the rapid wetting/disintegration of the PVP/HPβCD nanofibers leading to free CZ rapidly released from the mats caused faster antifungal activity (26). In addition, the betel oil loaded nanofiber mats exhibited rapid antifungal activity and displayed significantly faster antifungal activity at 30 to 120 min after contact compared to the clove oil loaded nanofiber mats. These results might be due to the greater amount of the betel oil contained in the nanofiber mats with approximately 3 times higher than that of clove oil.

Time-kill plots of C. albicans ATCC 90028 versus the treatment time: (diamond) control, (square) 30% betel oil loaded nanofiber mats and (square) 30% clove oil loaded nanofiber mats.The data are expressed as mean ± standard deviation from three independent experiments. *Statistically significant (P < 0.05) from control. **Statistically significant (P < 0.05) from clove oil loaded nanofiber mats

Cytotoxicity Studies

The in vitro cytotoxicity of the blank nanofiber mats and herbal oil loaded nanofiber mats were determined using MTT assay. This investigation was performed to evaluate the biocompatibility of the prepared systems and their potential application for oral candidiasis. The cytotoxicity of the prepared systems was assessed at various concentrations (0.0001 to 10 mg/ml). The results from the test are illustrated in Fig. 8. Figure 8a, b shows the cell viabilities of the extraction medium from blank nanofiber mats and herbal oil loaded nanofiber mats at the mats concentrations from 0.0001 to 10 mg/ml after incubation at pH 7.4 for 2 and 24 h, respectively, against the HGF cells. There was a significant decrease in the cell viability when the HGF cells were incubated with high concentration of the herbal oil loaded mats (1–10 mg/ml) compared to the control (p < 0.05). This finding might be because the amount of herbal oil was too high and toxic to fibroblast cells. However, the clove oil loaded nanofiber mats were safe for use at the concentration of 0.0001 to 1 mg/ml for 2 h and at 0.0001 to 0.1 mg/ml for 24 h. On the other hand, the betel oil loaded nanofiber mats exhibit higher toxicity due to the higher oil loading. They were safe for use at the concentration of 0.001 to 0.1 mg/ml for 2 and 24 h. In fact, the nanofiber mats are fast dissolving and would be contacted with the mouth for only few minutes. This could help reduce the toxicity of the herbal oils against the oral cells.

Conclusion

In this study, the nanofiber mats containing herbal oils with antifungal activity were successfully fabricated via electrospinning process. The HPβCD was employed to entrap the oil and reduce hygroscopic property of PVP. The oil incorporated in nanofiber mats exhibited very fast release and rapidly reduce the candida cell in vitro. These nanofiber mats may have potential to be used as a material for oral hygiene maintenance in denture stomatitis for oral candidiasis prevention. Further in vivo investigation should be done to confirm the clinical efficacy of these materials.

References

Pereira-Cenci T, Del BelCury AA, Crielaard W, Ten Cate JM. Development of Candida-associated denture stomatitis: new insights. J Appl Oral Sci. 2008;16(2):86–94.

Gendreau L, Loewy ZG. Epidemiology and etiology of denture stomatitis. J Prosthodont. 2011;20(4):251–60.

Figueiral MH, Fonseca P, Lopes MM, Pinto E, Pereira-Leite T, Sampaio-Maia B. Effect of denture-related stomatitis fluconazole treatment on oral Candida albicans susceptibility profile and genotypic variability. Open Dent J. 2015;9:46–51.

Johnson CC, Yu A, Lee H, Fidel PL, Noverr MC. Development of a contemporary animal model of Candida albicans-associated denture stomatitis using a novel intraoral denture system. Infect Immun. 2012;80(5):1736–43.

Maghrani M, Zeggwagh NA, Haloui M, Eddouks M. Acute diuretic effect of aqueous extract of Retamaraetam in normal rats. J Ethnopharmacol. 2005;99(1):31–5.

Sabzghabaee AM, Shirdare Z, Ebadian B, Aslani A, Ghannadi A. Clinical evaluation of the essential oil of Pelargonium graveolens for the treatment of denture stomatitis. Dent Res J. 2011;8(Suppl1):S105–8.

Toprani R, Patel D. Betel leaf: revisiting the benefits of an ancient Indian herb. South Asian J Cancer. 2013;2(3):140–1.

Fazal F, Mane PP, Rai MP, Thilakchand KR, Bhat HP, Kamble PS, et al. The phytochemistry, traditional uses and pharmacology of Piper Betel. linn (Betel Leaf): A pan-asiatic medicinal plant. Chin J Integr Med. 2014.

Himratul-Aznita WH, Mohd-Al-Faisal N, Fathilah AR. Determination of the percentage inhibition of diameter growth (PIDG) of Piper betle crude aqueous extract against oral Candida species. J Med Plant Res. 2011;5(6):878–84.

Nuñez L, Aquino MD. Microbicide activity of clove essential oil (Eugenia caryophyllata). Braz J Microbiol. 2012;43(4):1255–60.

Pramod K, Ansari SH, Ali J. Eugenol: a natural compound with versatile pharmacological actions. Nat Prod Commun. 2010;5(12):1999–2006.

Dagli N, Dagli R, Mahmoud RS, Baroudi K. Essential oils, their therapeutic properties, and implication in dentistry: a review. J Int Soc Prev Community Dent. 2015;5(5):335–40.

Mith H, Duré R, Delcenserie V, Zhiri A, Daube G, Clinquart A. Antimicrobial activities of commercial essential oils and their components against food-borne pathogens and food spoilage bacteria. Food Sci Nutr. 2014;2(4):403–16.

Ahmad N, Alam MK, Shehbaz A, Khan A, Mannan A, Hakim SR, et al. Antimicrobial activity of clove oil and its potential in the treatment of vaginal candidiasis. J Drug Target. 2005;13(10):555–61.

Parkash V, Maan S, Deepika, Yadav SK, Hemlata, Jogpal V. Fast disintegrating tablets: opportunity in drug delivery system. J Adv Pharm Tech Res. 2011;2(4):223–35.

Li X, Kanjwa MA, Lin L, Chronakis IS. Electrospun polyvinyl-alcohol nanofibers as oral fast-dissolving delivery system of caffeine and riboflavin. Colloids Surf B. 2013;103:182–8.

Tiwari G, Tiwari R, Rai AK. Cyclodextrins in delivery systems. J Pharm Bioallied Sci. 2010;2(2):72–9.

Tonglairoum P, Chuchote T, Ngawhirunpat T, Rojanarata T, Opanasopit P. Encapsulation of plai oil/2-hydroxypropyl-beta-cyclodextrin inclusion complexes in polyvinylpyrrolidone (PVP) electrospunnanofibers for topical application. Pharm Dev Technol. 2014;19(4):430–7.

Valle D, Martin EM. Cyclodextrins and their uses: a review. Process Biochem. 2004;39:1033–46.

Tonglairoum P, Ngawhirunpat T, Rojanarata T, Opanasopit P. Lysozyme-immobilized electrospun PAMA/PVA and PSSA-MA/PVA ion-exchange nanofiber for wound healing. Pharmaceutical development and technology. 2014:1-8.

Homaeigohar S, Buhr K, Ebert K. Polyethersulfoneelectrospunnanofibrous composite membrane for liquid filtration. J Membr Sci. 2010;365:68–77.

Tonglairoum P, Ngawhirunpat T, Rojanarata T, Kaomongkolgit R, Opanasopit P. Fabrication of a novel scaffold of clotrimazole-microemulsion-containing nanofibers using an electrospinning process for oral candidiasis applications. Colloids Surf B. 2015;126:18–25.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28(3):325–47.

Samprasit W, Rojanarata T, Akkaramongkolporn P, Ngawhirunpat T, Kaomongkolgit R, Opanasopit P. Fabrication and in vitro/in vivo performance of mucoadhesive electrospun nanofiber mats containing α-mangostin. AAPS PharmSciTech. 2015;16(5):1140–52.

Singh S, Jain S, Muthu MS, Tiwari S, Tilak R. Preparation and evaluation of buccalbioadhesive films containing clotrimazole. AAPS PharmSciTech. 2008;9(2):660–7.

Tonglairoum P, Ngawhirunpat T, Rojanarata T, Kaomongkolgit R, Opanasopit P. Fast-acting clotrimazole composited PVP/HPbetaCD nanofibers for oral candidiasis application. Pharm Res. 2014;31(8):1893–906.

Ferreres F, Oliveira AP, Gil-Izquierdo A, Valentão P, Andrade PB. Piper betle leaves: profiling phenolic compounds by HPLC/DAD-ESI/MS(n) and anti-cholinesterase activity. Phytochem Anal. 2014;25(5):453–60.

Rana IS, Rana AS, Rajak RC. Evaluation of antifungal activity in essential oil of the Syzygium aromaticum (L.) by extraction, purification and analysis of its main component eugenol. Braz J Microbiol. 2011;42(4):1269–77.

Basha MA-F. Magnetic and optical studies on polyvinylpyrrolidone thin films doped with rare earth metal salts. Polym J. 2010;42(9):728–34.

Al-Zein H, Sakeer K, Alanazi FK. Designing an extended release waxy matrix tablet containing nicardipine–hydroxy propyl β cyclodextrin complex. Saudi Pharm J. 2011;19(4):245–53.

Kadam SS, Waghmare JS. Identification of major volatile (essential oil) constituents of Carrom seeds and clove buds. IJSRR. 2014;3(2):85–94.

Rahimi AA, Ashnagar A, Nikoei H. Isolation and characterization of 4-allyl-2methoxyphenol (eugenol) from clove buds marketed in Tehran city of Iran. Int J Chem Tech Res. 2012;4(1):105–8.

Acknowledgments

The authors would like to thank the Commission of Higher Education (Thailand), the Thailand Research Funds through the Royal Golden Jubilee Ph.D. Program (Grant No.PHD/0092/2554), the Thailand Research Funds and Faculty of Pharmacy, the Silpakorn University, and the Silpakorn University Research and development institute for their financial support.

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 128 kb)

Rights and permissions

About this article

Cite this article

Tonglairoum, P., Ngawhirunpat, T., Rojanarata, T. et al. Fabrication and Evaluation of Nanostructured Herbal Oil/Hydroxypropyl-β-Cyclodextrin/Polyvinylpyrrolidone Mats for Denture Stomatitis Prevention and Treatment. AAPS PharmSciTech 17, 1441–1449 (2016). https://doi.org/10.1208/s12249-016-0478-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1208/s12249-016-0478-2

) betel oil loaded nanofiber mats and (

) betel oil loaded nanofiber mats and ( ) clove oil loaded nanofiber mats containing 20, 30, and 40% of the oils loaded

) clove oil loaded nanofiber mats containing 20, 30, and 40% of the oils loaded

) blank nanofiber mats, (

) blank nanofiber mats, ( ) clove oil loaded nanofiber mats, and (

) clove oil loaded nanofiber mats, and ( ) betel oil loaded nanofiber mats against HGF cells after incubation for a 2 h and b 24 h. *Statistically significant (P < 0.05) from control

) betel oil loaded nanofiber mats against HGF cells after incubation for a 2 h and b 24 h. *Statistically significant (P < 0.05) from control