Abstract

Nowadays, fabrication of micro/nano-scale electronic devices with bottom-up approach is paid much research attention. Here, we provide a novel micro/nano-assembling method, which is accurate and efficient, especially suitable for the fabrication of micro/nano-scale electronic devices. Using this method, a self-powered ZnO/Sb-doped ZnO nanowire p–n homojunction ultraviolet detector (UVD) was fabricated, and the detailed photoelectric properties were tested. At a reverse bias of −0.1 V under UV light illumination, the photoresponse sensitivity of the UVD was 26.5 and the rise/decay time of the UVD was as short as 30 ms. The micro/nano-assembling method has wide potential applications in the fabrication of specific micro/nano-scale electronic devices.

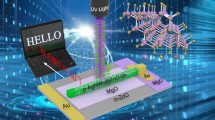

Graphical Abstract

A self-powered ZnO/Sb-doped ZnO nanowire p-n homojunction ultraviolet detector (UVD) was fabricated by using a novel micro/nano-assembling method with bottom-up approach. At reverse bias of −0.1 V under UV light illumination, the photoresponse sensitivity of the UVD was 26.5, and the rise time and decay time of the UVD were as short as 30 ms.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Due to the wide band gap of 3.37 eV, ZnO has attracted much attention for its potential applications in short-wavelength optoelectronic devices. Compared with another wide-band gap semiconductor of GaN, ZnO exhibits a lot of advantages, such as low-temperature synthesis, rich material source, low cost, and environmental friendliness. Since the first ZnO nanowire (NW) ultraviolet detector (UVD) was fabricated in 2002 [1], a lot of researches related to ZnO UVD have been reported. Generally, there are three types of ZnO UVDs from the point of view of different working principles: photoconductive UVD, Schottky junction UVD, and p–n junction UVD. Photoconductive UVD has a simple structure and a high gain [2–4], but its rise time and decay time are too long [5–10] due to the adsorption and desorption of oxygen molecules. Comparatively, Schottky junction UVD exhibits faster response speed [11, 12]. For example, Wang et al. reported a Schottky junction UVD by utilizing Schottky contact instead of Ohmic contact in device fabrication, and the reset time drastically reduced from ~417 to ~0.8 s [13].

ZnO p–n junction UVD, as a self-powered device, has attracted a great deal of research attention due to its fast response speed and high stability which are the unique advantages of p–n junction UVD [14–16]. However, the difficulties in fabrication of high-quality p-type ZnO hinder the applications of ZnO-based p–n junction UVD [17]. Most of ZnO p–n homojunctions are fabricated by two steps: growth of n-type ZnO NW section and p-type ZnO NW section [18–20]. Formation of ZnO p–n homojunction is much difficult due to the p-type doping difficulty of ZnO. Nevertheless, it is relatively easier to synthesize n-type ZnO and p-type ZnO NWs separately. Intrinsic ZnO has n-type conductivity, and group V elements are often used to form p-type doping of ZnO, such as nitrogen [21], phosphorus [20], arsenic [22], and antimony (Sb) [23–26]. Along with the development of micro/nano-assembling techniques, bottom-up fabrication of micro/nano-scale electronic devices comes true.

In this work, we demonstrate an efficient method to fabricate a self-powered ZnO p–n homojunction UVD, and high sensitivity and ultra-fast photoresponse speed were obtained. At a reverse bias of −0.1 V under UV light illumination, the ZnO p–n homojunction UVD has a sensitivity of 26.5, and the rise time τ r (10–90 %) and decay time τ d (90–10 %) of 30 ms. The size of UVD is very small and it can be integrated into a single chip to realize multifunction device. Our work presents an efficient and accurate way to build micro/nano-scale electronic devices with high performances.

2 Experimental Section

2.1 Synthesis of ZnO NWs and Sb-Doped ZnO (Sb–ZnO) NWs

Two NWs of ZnO and Sb–ZnO were synthesized via a simple chemical vapor deposition (CVD) method in a horizontal quartz tube furnace. A mixture of high-purity powders (weight ratio of ZnO:graphite = 1:1 for ZnO NWs; molar ratio of Zn:Sb2O3:graphite = 4:1:2 for Sb–ZnO NWs [24]) were used as the raw materials. For ZnO NWs, Au film with 3–5 nm thickness was firstly deposited on the Si substrate by a sputtering deposition method. In the growth process of ZnO, a mixed gas of 100 sccm Ar and 5 sccm O2 was used as the carrier gas and oxygen source, whereas 200 sccm Ar and 8 sccm O2 were used in the fabrication process of Sb–ZnO NWs. For ZnO NWs, the chamber was heated to 950 °C at a rate of 50 °C min−1 and lasted 40 min under 1 atm pressure, whereas it was heated to 930 °C and lasted 50 min for Sb–ZnO NWs. Then, the furnace was cooled down to room temperature naturally.

2.2 Device Fabrication and Characterization

The Au/Ti electrodes with 10 μm finger spacing were fabricated by optical lithography and lift-off process on oxidized Si substrate (300-nm SiO2). The thicknesses of Au and Ti layers are 50 and 10 nm, respectively. The micro/nano-assembling process was performed in a dual-beam scanning electron microscope (SEM)/focused ion beam (FIB) microscope (FEI Quanta 3D FEG) equipped with nanomanipulator (Oxford Instruments OmniProbe 100) and gas injection system (GIS), and therefore the whole operating process can be monitored in real time. Firstly, one ZnO NW with suitable width and length was selected, and the tip of the nanomanipulator was handled carefully to make the tip contact with one side of the ZnO NW lightly. Secondly, the tip of the nanomanipulator and the ZnO NW were welded together by direct-written Pt deposition. Thirdly, the other side of the ZnO NW was cut off by the FIB. Finally, the ZnO NW was extracted and transferred it to anywhere we want.

The ZnO NW and another Sb–ZnO NW were transferred to the electrodes on chip. It is necessary to make one side of Sb–ZnO NW contact with the ZnO NW transferred before. The other sides of Sb–ZnO NW and intrinsic ZnO NW were welded on the Au electrodes by direct-written Pt deposition. Care was taken to avoid any contamination on the NWs’ surface on the chip.

The morphology, crystalline structure, and element distribution of the as-synthesized samples are characterized by SEM (FEI Nova Nano-SEM 450) and high-resolution transmission electron microscope (HRTEM, FEI Titan G2 60-300). The I–V characteristics and photoresponse of the devices were measured using an Agilent B2901A with the time resolution of 20 μs, a portable UV lamp (λ = 365 nm, 0.3 mW cm−2), and a function generator. All the electrical properties and photoelectric properties were tested at room temperature under atmospheric condition.

3 Results and Discussion

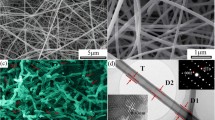

ZnO NWs and Sb–ZnO NWs were synthesized through a conventional CVD method. Sb–ZnO NWs have p-type characteristics due to the formation of SbZn–2VZn complex acceptor [23–26]. Typical SEM images of ZnO and Sb–ZnO NWs are shown in Fig. 1a, b. The ZnO and Sb–ZnO NWs are several micrometers in length, and 50 nm to 10 μm in diameter. The EDS spectrum (Fig. 1d) shows that the synthesized Sb–ZnO NWs are composed of O, Zn, and Sb elements. The content of Sb was estimated to be approximately 3 % (atom ratio). Figure 1c shows the elemental mapping images of Sb–ZnO NW, which reveals that the Sb element was doped into the ZnO NWs successfully and distributed uniformly. HRTEM images (Fig. 1e, f) of individual ZnO and Sb–ZnO NWs show clear lattice fringes, indicating that both of the NWs exhibit single-crystal structures and grow along the [0001] direction. However, the surface of Sb–ZnO NW is a rough amorphous layer (Fig. 1f). This phenomenon may be caused by the introduction of Sb3+ ion (radius 0.078 nm) that is larger than Zn2+ (0.074 nm), which leads to a large structural strain released by the rough surface [27].

The ZnO/Sb–ZnO p–n homojunctions were fabricated in a dual-beam SEM/FIB microscope. Direct-written Pt deposition by FIB was used to prepare Pt electrodes. Even though the work function of Pt (~6.1 eV) is higher than that of pure ZnO (~5.1 eV), the contact electrodes of ZnO/Pt fabricated by Ga ion surface modification process and direct-written Pt deposition could still be Ohmic [28]. Figure 2c shows the I–V characteristics of the ZnO NW and Sb–ZnO NW. One can notice that both the I–V curves are linear, indicating good Ohmic contacts between ZnO (or Sb–ZnO) and Pt electrodes. The Sb–ZnO NW exhibits better conductivity than pure ZnO NW.

a and b Schematic diagrams showing the procedure of micro/nano-assembling. c I–V characteristics of a pure ZnO NW and a Sb–ZnO NW. The linear I–V curves indicate well Ohmic contacts. d I–V characteristics of p-type Sb–ZnO/n-type ZnO homojunction in dark. The inset SEM image in d shows the device structure

The fabrication processes of ZnO/Sb–ZnO p–n homojunction are schematically shown in Fig. 2a, b. The Ohmic ZnO/Pt contact and Sb–ZnO/Pt contact were made carefully by the same processes described above. The inset of Fig. 2d shows the SEM image of the device, where the ZnO NW and Sb–ZnO NW are connected. The ZnO and Sb–ZnO NWs have the diameters of ~500 nm and the lengths of ~20 μm. The I–V curve (Fig. 2d) of ZnO/Sb–ZnO p–n homojunction displays significant rectification characteristics under dark condition. The rectification ratio of the ZnO p–n homojunction diode is about 3.3 × 102 at ±1 V, and the turn-on voltage is ~1 V.

To investigate the photoelectric properties, the I–V characteristics of the ZnO/Sb–ZnO p–n homojunction were measured both in dark and upon 365 nm UV light illumination, as shown in Fig. 3a. The distance between the UV light and the device is fixed, and the power density of the UV light is about 0.3 mW cm−2. The UVD is responsive to the UV light significantly especially at reverse bias, which agrees with the behavior of the p–n junction photodetector. Figure 3b, c shows the energy band diagram of the p–n junction in dark and under UV light illumination at reverse bias, where the width of depletion layer and the barrier height will increase and weaken the dark current. When the contact area of ZnO and Sb–ZnO NW is exposed to UV light, the reverse bias will enhance the built-in electric field of the p–n junction. The photo-induced electrons and holes in the depletion layer will be swept away to the opposite direction quickly by the strong electric field, which will cause a large increase in photocurrent.

Figure 4a, b shows the photoresponse of the UVD as a function of time when the UV illumination was switched on and off periodically, where the UV light was controlled by a function generator. At zero-voltage bias, the UVD worked as a self-powered device, and the open-circuit voltage V oc is ~9 mV under UV light illumination. At a reverse bias of −0.1 V, the dark current is 60 pA and the photocurrent is 1.65 nA under UV light illumination. The sensitivity (defined as (I light −I dark)/I dark) of the UVD is about 26.5. Both the voltage–time curve and the current–time curve show the stable and repetitive on/off cycles without significant noise. The ZnO/Sb–ZnO p–n junction UVD can work properly without external bias, which decreases the energy consumption or exhibits high sensitivity at certain reverse bias.

Fast response speed is one of the outstanding advantages of p–n junction UVD. Figure 5 shows the enlarged current–time curve of the UVD at a reverse bias of −0.1 V with 365 nm UV light illumination. The rise time τ r (10–90 %) and decay time τ d (90–10 %) are estimated to be 30 ms, which are even shorter than those of the as-grown ZnO p–n homojunction UVDs [14, 29] and Schottky junction UVDs [11, 12, 30–32]. The fast-response mechanism is attributed to the p–n junction formed between ZnO and Sb–ZnO NWs, rather than the ZnO NW or Sb–ZnO NW photoconductor. The fast photoresponse performance is very stable and reproducible even in atmosphere environment.

Photoresponse of the UVD at different reverse bias from −1.0 to 0 V was also investigated. Figure 6a shows the current–time curves of the p–n junction UVD at different reverse bias with the 365 nm UV light on and off periodically. At zero-voltage bias, the short-circuit current I sc is ~0.5 nA. The UVD works stable and reliable at different reverse bias, which implies wide potential applications. The photoresponse sensitivity of this UVD as a function of the applied reverse bias is shown in Fig. 6b. When higher extra reverse bias is applied, the dark current increases and the sensitivity decreases, which may be caused by the increasing leakage current.

The ZnO/Sb–ZnO p–n junction could be used as a UVD with fast response performance and high stability, or as a nano-scale photovoltaic cell. The micro/nano-assembling method has been proved to be an efficient and accurate way to build high-performance micro/nano-scale p–n junction UVD. The open-circuit voltage was improved using n-type ZnO and p-type ZnO with higher doping density, and it is much easier to control the doping density when the two kinds of NWs are synthesized separately. Moreover, with the help of the micro/nano-assembling method, we can freely combine semiconductor nanomaterials with different band gaps to build p–n junction photodetectors, which can be responsive to light of different wavelength ranges.

4 Conclusion

In conclusion, we fabricated a ZnO/Sb–ZnO p–n junction UVD by a micro/nano-assembling method. The self-powered UVD exhibits high sensitivity and stability, and the rise time and decay time reach 30 ms. This micro/nano-assembling method provides an efficient and accurate way to fabricate micro/nano-scale electronic devices with potential applications.

References

H. Kind, H.Q. Yan, B. Messer, M. Law, P.D. Yang, Nanowire ultraviolet photodetectors and optical switches. Adv. Mater. 14(2), 158–160 (2002). doi:10.1002/1521-4095(20020116)14:2<158:Aid-Adma158>3.0.Co;2-W

C. Soci, A. Zhang, B. Xiang, S.A. Dayeh, D.P. Aplin, J. Park, X.Y. Bao, Y.H. Lo, D. Wang, ZnO nanowire UV photodetectors with high internal gain. Nano Lett. 7(4), 1003–1009 (2007). doi:10.1021/nl070111x

Z. Zhang, Q. Liao, Y. Yu, X. Wang, Y. Zhang, Enhanced photoresponse of ZnO nanorods-based self-powered photodetector by piezotronic interface engineering. Nano Energy 9, 237–244 (2014). doi:10.1016/j.nanoen.2014.07.019

Y. Liu, X. Zhang, J. Su, H. Li, Q. Zhang, Y. Gao, Ag nanoparticles@ZnO nanowire composite arrays: an absorption enhanced UV photodetector. Opt. Express 22(24), 30148–30155 (2014). doi:10.1364/OE.22.030148

Y. Hao, J. Zhao, L. Qin, Q. Guo, X. Feng, P. Wang, Facile fabrication of UV photodetector based on spatial network of tetrapod ZnO nanostructures. Nano-Micro Lett. 7(3), 200–203 (2012). doi:10.1049/mnl.2011.0721

Y. Li, C. Cheng, X. Dong, J. Gao, H. Zhang, Facile fabrication of UV photodetectors based on ZnO nanorod networks across trenched electrodes. J. Semicond. 30(6), 38–41 (2009). doi:10.1088/1674-4926/30/6/063004

S.E. Ahn, H.J. Ji, K. Kim, G.T. Kim, C.H. Bae, S.M. Park, Y.K. Kim, J.S. Ha, Origin of the slow photoresponse in an individual sol-gel synthesized ZnO nanowire. Appl. Phys. Lett. 90(15), 153106 (2007). doi:10.1063/1.2721289

J. Cheng, Y. Zhang, R. Guo, ZnO microtube ultraviolet detectors. J. Cryst. Growth 310(1), 57–61 (2008). doi:10.1016/j.jcrysgro.2007.08.034

S.E. Ahn, J.S. Lee, H. Kim, S. Kim, B.H. Kang, K.H. Kim, G.T. Kim, Photoresponse of sol-gel-synthesized ZnO nanorods. Appl. Phys. Lett. 84(24), 5022 (2004). doi:10.1063/1.1763633

X. Zhang, X. Han, J. Su, Q. Zhang, Y. Gao, Well vertically aligned ZnO nanowire arrays with an ultra-fast recovery time for UV photodetector. Appl. Phys. A 107(2), 255–260 (2012). doi:10.1007/s00339-012-6886-6

Y. Hu, J. Zhou, P.H. Yeh, Z. Li, T.Y. Wei, Z.L. Wang, Supersensitive, fast-response nanowire sensors by using Schottky contacts. Adv. Mater. 22(30), 3327–3332 (2010). doi:10.1002/adma.201000278

Y. Yang, W. Guo, J. Qi, J. Zhao, Y. Zhang, Self-powered ultraviolet photodetector based on a single Sb-doped ZnO nanobelt. Appl. Phys. Lett. 97(22), 223113 (2010). doi:10.1063/1.3524231

J. Zhou, Y. Gu, Y. Hu, W. Mai, P.H. Yeh, G. Bao, A.K. Sood, D.L. Polla, Z.L. Wang, Gigantic enhancement in response and reset time of ZnO UV nanosensor by utilizing Schottky contact and surface functionalization. Appl. Phys. Lett. 94(19), 191103 (2009). doi:10.1063/1.3133358

H.D. Cho, A.S. Zakirov, S.U. Yuldashev, C.W. Ahn, Y.K. Yeo, T.W. Kang, Photovoltaic device on a single ZnO nanowire p-n homojunction. Nanotechnology 23(11), 115401 (2012). doi:10.1088/0957-4484/23/11/115401

Y.Q. Bie, Z.M. Liao, H.Z. Zhang, G.R. Li, Y. Ye et al., Self-powered, ultrafast, visible-blind UV detection and optical logical operation based on ZnO/GaN nanoscale p-n junctions. Adv. Mater. 23(5), 649–653 (2011). doi:10.1002/adma.201003156

Y.Q. Bie, Z.M. Liao, P.W. Wang, Y.B. Zhou, X.B. Han et al., Single ZnO nanowire/p-type GaN heterojunctions for photovoltaic devices and UV light-emitting diodes. Adv. Mater. 22(38), 4284–4287 (2010). doi:10.1002/adma.201000985

C.H. Park, S.B. Zhang, S.H. Wei, Origin of p-type doping difficulty in ZnO: the impurity perspective. Phys. Rev. B 66(7), 073202 (2002). doi:10.1103/PhysRevB.66.073202

G. Li, A. Sundararajan, A. Mouti, Y.J. Chang, A.R. Lupini, S.J. Pennycook, D.R. Strachan, B.S. Guiton, Synthesis and characterization of p-n homojunction-containing zinc oxide nanowires. Nanoscale 5(6), 2259–2263 (2013). doi:10.1039/c3nr31639d

C.L. Hsu, Y.D. Gao, Y.S. Chen, T.J. Hsueh, Vertical p-type Cu-doped ZnO/n-type ZnO homojunction nanowire-based ultraviolet photodetector by the furnace system with hotwire assistance. ACS Appl. Mater. Interfaces 6(6), 4277–4285 (2014). doi:10.1021/am406030d

M.T. Chen, M.P. Lu, Y.J. Wu, J. Song, C.Y. Lee et al., Near UV LEDs made with in situ doped p-n homojunction ZnO nanowire arrays. Nano Lett. 10(11), 4387–4393 (2010). doi:10.1021/nl101907h

B. Chavillon, L. Cario, A. Renaud, F. Tessier, F. Chevire et al., P-type nitrogen-doped ZnO nanoparticles stable under ambient conditions. J. Am. Chem. Soc. 134(1), 464–470 (2012). doi:10.1021/ja208044k

J.Y. Zhang, P.J. Li, H. Sun, X. Shen, T.S. Deng, K.T. Zhu, Q.F. Zhang, J.L. Wu, Ultraviolet electroluminescence from controlled arsenic-doped ZnO nanowire homojunctions. Appl. Phys. Lett. 93(2), 021116 (2008). doi:10.1063/1.2958230

X. Ren, X. Zhang, N. Liu, L. Wen, L. Ding et al., White light-emitting diode from Sb-doped p-ZnO nanowire Arrays/n-GaN film. Adv. Funct. Mater. 25(14), 2182–2188 (2015). doi:10.1002/adfm.201404316

Y. Yang, K.C. Pradel, Q.S. Jing, J.M. Wu, F. Zhang, Y.S. Zhou, Y. Zhang, Z.L. Wang, Thermoelectric nanogenerators based on single Sb-doped ZnO micro/nanobelts. ACS Nano 6(8), 6984–6989 (2012). doi:10.1021/Nn302481p

W. Chen, J. Wu, J. Lin, S. Lo, H. Lin, D. Hang, M. Shih, C. Liang, Y. Chang, Room temperature violet luminescence and ultraviolet photodetection of Sb-doped ZnO/Al-doped ZnO homojunction array. Nanoscale Res. Lett. 8(1), 313 (2013). doi:10.1186/1556-276X-8-313

L. Shi, F. Wang, B. Li, X. Chen, B. Yao, D. Zhao, D. Shena, A highly efficient UV photodetector based on a ZnO microwire p–n homojunction. J. Mater. Chem. C 2, 5005–5010 (2014). doi:10.1039/c3tc32547d

Y. Yang, J.J. Qi, Q.L. Liao, Y. Zhang, L.D. Tang, Z. Qin, Synthesis and characterization of Sb-Doped ZnO nanobelts with single-side Zigzag boundaries. J. Phys. Chem. C 112(46), 17916–17919 (2008). doi:10.1021/jp8064213

J.H. He, J.J. Ke, P.H. Chang, K.T. Tsai, P.C. Yang, I.M. Chan, Development of Ohmic nanocontacts via surface modification for nanowire-based electronic and optoelectronic devices: ZnO nanowires as an example. Nanoscale 4(11), 3399–3404 (2012). doi:10.1039/c2nr30688c

J. Qi, X. Hu, Z. Wang, X. Li, W. Liu, Y. Zhang, A self-powered ultraviolet detector based on a single ZnO microwire/p-Si film with double heterojunctions. Nanoscale 6(11), 6025–6029 (2014). doi:10.1039/c3nr06356a

Y. Li, A. Paulsen, I. Yamada, Y. Koide, J.J. Delaunay, Bascule nanobridges self-assembled with ZnO nanowires as double Schottky barrier UV switches. Nanotechnology 21(29), 295502 (2010). doi:10.1088/0957-4484/21/29/295502

G. Cheng, X. Wu, B. Liu, B. Li, X. Zhang, Z. Du, ZnO nanowire Schottky barrier ultraviolet photodetector with high sensitivity and fast recovery speed. Appl. Phys. Lett. 99(20), 203105 (2011). doi:10.1063/1.3660580

X. Fu, Z. Liao, Y. Zhou, H. Wu, Y. Bie, J. Xu, D. Yu, Graphene/ZnO nanowire/graphene vertical structure based fast-response ultraviolet photodetector. Appl. Phys. Lett. 100(22), 223114 (2012). doi:10.1063/1.4724208

Acknowledgments

This work was supported by the National Natural Science Foundation of China (11374110, 51371085, 11304106). Y.H.G would like to thank Prof. Zhong Lin Wang for the support of experimental facilities in WNLO of HUST.

Author information

Authors and Affiliations

Corresponding author

Additional information

Yumei Wang and Ying Chen have contributed equally to this work.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Wang, Y., Chen, Y., Zhao, W. et al. A Self-Powered Fast-Response Ultraviolet Detector of p–n Homojunction Assembled from Two ZnO-Based Nanowires. Nano-Micro Lett. 9, 11 (2017). https://doi.org/10.1007/s40820-016-0112-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40820-016-0112-6